Introduce about cooling milk tank guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

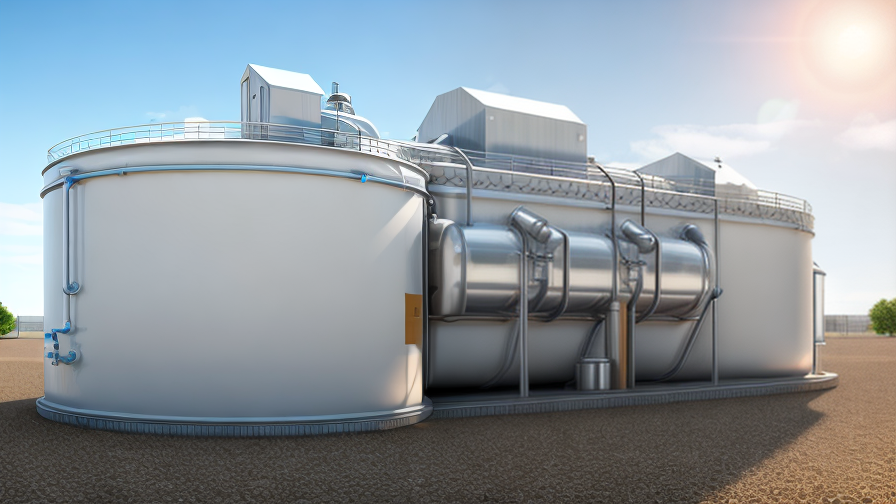

The cooling milk tank is an essential piece of equipment in the dairy industry that helps maintain the quality and freshness of milk. This guide will provide you with important information regarding its quality, cost, suppliers, certification, market demand, tips, and frequently asked questions.

When it comes to quality, cooling milk tanks are designed to rapidly cool and hold milk at optimal temperatures to prevent bacterial growth and preserve its taste. Modern tanks are equipped with advanced insulation and refrigeration systems to ensure maximum efficiency.

In terms of cost, the price of a cooling milk tank can vary depending on its capacity and specifications. Generally, larger tanks have higher prices due to increased storage capacity and more robust cooling systems. Additionally, factors such as brand reputation and technological advancements can influence the final cost.

Selecting the right supplier for your cooling milk tank is crucial. It is advisable to choose a reputable and experienced supplier who can provide reliable after-sales support and maintenance services. Researching customer reviews and comparing quotes from different suppliers can help you make an informed decision.

Certification is an important aspect to consider while purchasing a cooling milk tank. Look for tanks that comply with industry standards and safety regulations. Some certifications to look for include ISO 9001:2015, CE, and FDA approvals, affirming the tank’s reliability and quality.

The market for cooling milk tanks is experiencing steady growth due to the increasing demand for fresh and high-quality milk products. Dairy farms, cooperatives, and milk processing companies are the primary buyers. The market is highly competitive, leading to continuous innovation and new technological advancements.

Here are a few tips for using the cooling milk tank effectively: regularly clean and sanitize the tank, monitor and maintain appropriate temperature settings, and ensure proper ventilation for efficient cooling.

Frequently asked questions about cooling milk tanks include queries about installation requirements, capacity estimation, energy consumption, warranty details, and troubleshooting guides. It is advisable to consult the supplier or refer to the user manual for detailed information.

In conclusion, cooling milk tanks play a vital role in preserving milk freshness and quality in the dairy industry. Consider factors like quality, cost, supplier reputation, certification, market demand, and follow the provided tips for efficient usage. Don’t forget to explore frequently asked questions for a better understanding.

Types of cooling milk tank

There are several types of cooling milk tanks that are commonly used in dairy farms and milk processing facilities. These tanks are designed to rapidly cool down raw milk and maintain it at optimal temperatures to ensure its quality and safety. Here are three types of cooling milk tanks:

1. Direct Expansion (DX) Cooling Tanks: DX cooling tanks use a refrigeration system to directly cool the milk inside the tank. They work by circulating refrigerant through a cooling coil submerged in the milk. As the refrigerant evaporates in the cooling coil, it absorbs heat from the milk, effectively reducing its temperature. DX cooling tanks are efficient and can cool milk quickly, making them suitable for medium to large-scale operations.

2. Ice Bank Cooling Tanks: Ice bank cooling tanks utilize a built-in ice bank or ice builder to cool the milk. These tanks have an internal wall or plates that are filled with water and frozen overnight. During the milking process, the warm milk is circulated through this ice bank, which rapidly cools the milk down. Ice bank cooling tanks are energy-efficient and can be more sustainable, as they typically require lower electricity consumption compared to DX cooling tanks.

3. Plate Heat Exchange (PHE) Cooling Tanks: PHE cooling tanks use heat transfer plates to cool the milk. The raw milk flows through one set of plates, while cool water or a chilled refrigerant flows through another set of plates on the opposite side. The heat from the milk is exchanged with the cool fluid, effectively cooling the milk. PHE cooling tanks are compact, have a high heat transfer efficiency, and are often used in smaller farms or milk collection centers.

These are just a few examples of the types of cooling milk tanks available in the market. Each type has its advantages and considerations, such as cost, capacity, energy efficiency, and maintenance requirements. It is important to select the appropriate cooling tank based on the specific needs and scale of the dairy operation to ensure efficient milk cooling and preservation of quality.

Pros and Cons of Using cooling milk tank

Cooling milk tanks are essential equipment for dairy farms and milk processing facilities. They have several benefits, as well as some limitations.

Pros:

1. Preservation of milk quality: Cooling milk tanks help maintain the freshness and quality of milk by quickly lowering its temperature after milking. This helps prevent the growth of harmful bacteria and ensures that the milk stays fresh for a longer period.

2. Increased shelf life: Cooling milk tanks extend the shelf life of milk by keeping it at the optimal temperature, which slows down the growth of bacteria and delays spoilage.

3. Energy efficiency: Modern cooling milk tanks are designed to be energy-efficient, with insulation and cooling systems that help reduce energy consumption and operating costs.

4. Compliance with regulations: Using cooling milk tanks helps dairy farmers and processors comply with hygiene and safety regulations, which require milk to be stored at specific temperatures to ensure its safety and quality.

Cons:

1. Initial cost: The cost of purchasing and installing a cooling milk tank can be high, especially for small-scale dairy farmers. However, the long-term benefits of improved milk quality and extended shelf life often outweigh the initial investment.

2. Maintenance and repairs: Cooling milk tanks require regular maintenance to ensure they continue to operate efficiently. This may include cleaning, sanitizing, and servicing the cooling systems, which can be time-consuming and costly.

3. Dependence on electricity: Cooling milk tanks rely on electricity to power the cooling systems, which can be a disadvantage in areas prone to power outages. Backup power sources or alternative cooling methods may be necessary in such situations.

In conclusion, the use of cooling milk tanks offers numerous benefits such as improved milk quality, extended shelf life, energy efficiency, and regulatory compliance. However, there are also some drawbacks to consider, including the initial cost, maintenance requirements, and dependence on electricity. Overall, the advantages of using cooling milk tanks generally outweigh the disadvantages, making them a valuable investment for dairy farmers and milk processing facilities.

cooling milk tank Reference Specifications (varies for different product)

The cooling milk tank is an essential component in the dairy industry for storing and preserving milk before it is further processed. It plays a crucial role in maintaining the quality and freshness of the milk by ensuring it remains at the desired temperature.

The reference specifications for cooling milk tanks may vary depending on the specific product and manufacturer. However, there are some common characteristics that can be found in these tanks.

Firstly, cooling milk tanks are typically made of high-quality stainless steel to ensure durability, hygiene, and resistance to corrosion. The tanks are often insulated to provide efficient temperature control and prevent heat transfer from the environment to the stored milk.

Cooling milk tanks are available in various sizes, ranging from small volume tanks suitable for small-scale dairy farms to large capacity tanks for industrial-scale operations. The capacity of these tanks can range from a few hundred liters to thousands of liters, depending on the requirements.

Most cooling milk tanks are equipped with a cooling system that utilizes a refrigeration unit. This unit utilizes compressors and condensers to cool the milk to the desired temperature. Some tanks may also have a heat recovery system, which allows the captured heat from the milk to be reused for cleaning or heating purposes, contributing to energy efficiency.

Furthermore, cooling milk tanks often feature an agitator or stirrer to ensure uniform temperature distribution throughout the tank. This prevents any hotspots or temperature gradients from forming, ultimately ensuring the quality of the stored milk.

In addition, modern cooling milk tanks come equipped with a control panel that allows operators to monitor and adjust the temperature, agitation, and other parameters of the tank. This ensures optimal milk storage conditions and facilitates easy operation and maintenance.

Overall, cooling milk tanks are designed to provide efficient cooling, storage, and preservation of milk. They are built with high-quality materials, offer various capacities, incorporate refrigeration units, and often include agitators and control panels. These tanks are essential in maintaining the quality and shelf life of milk before it reaches consumers.

Applications of cooling milk tank

Cooling milk tanks are essential in the dairy industry as they play a crucial role in maintaining the freshness and quality of milk. Below are some important applications of cooling milk tanks:

1. Preservation of Quality: Cooling milk tanks are used to rapidly cool freshly harvested milk to a low temperature, typically around 4°C (39°F). This is done to inhibit the growth of bacteria and other microorganisms that can cause spoilage, ensuring that the milk retains its freshness and nutritional value for a longer period of time. By preserving the quality of milk, cooling tanks help in maintaining the market value and consumer satisfaction.

2. Extending Shelf Life: By rapidly cooling milk soon after milking, cooling tanks can significantly extend its shelf life. This is particularly important when transporting milk from dairy farms to processing facilities or retail stores. The cooling process slows down bacterial growth, reducing the risk of spoilage and maintaining the milk’s taste and texture.

3. Ensuring Hygiene: Cooling tanks are designed with hygiene in mind and are often made of stainless steel, a material that is easy to clean and sanitize. This ensures that the milk is stored in a clean and safe environment, minimizing the risk of contamination and maintaining the quality standards demanded by regulatory bodies.

4. Efficient Production Processes: Cooling tanks contribute to the efficiency of dairy production processes by allowing milk to be stored at a consistent low temperature. This allows for flexible scheduling of milk collection and processing, reducing the risk of milk spoilage due to delays or unforeseen circumstances. Additionally, cooling tanks can be equipped with advanced monitoring systems that provide real-time data on temperature, allowing operators to take immediate action if any deviations occur.

5. Customization and Expansion: Cooling milk tanks are available in different capacities, ranging from small tanks suitable for small-scale dairy farms to large and complex systems required for industrial-scale operations. This flexibility enables dairy businesses to choose the most appropriate tank size based on their production volumes and future expansion plans.

In conclusion, cooling milk tanks are essential in the dairy industry due to their numerous applications. They contribute to milk preservation, extend the shelf life, ensure hygiene, improve production efficiency, and offer customization options for different business needs. Overall, cooling milk tanks play a crucial role in maintaining the quality and freshness of milk from farm to consumer.

The Work Process and how to use cooling milk tank

The work process of a cooling milk tank typically involves several stages and requires proper usage to ensure optimal results. Here is a brief guide on how to use a cooling milk tank effectively:

1. Collection and Transfer: Milk is collected from cows using milking machines and is then transferred to a bulk milk tank using a well-sanitized milk transfer system. It is important to handle the milk with care to prevent any contamination.

2. Filtration: Before the milk enters the cooling tank, it should go through a filtration process to remove impurities and undesired particles. This helps in maintaining the quality and hygiene of the milk.

3. Cooling: The cooling tank is equipped with a refrigeration system that rapidly reduces the temperature of the milk to inhibit bacterial growth. The milk should be cooled as quickly as possible to reach the desired storage temperature, typically between 1 to 4 degrees Celsius.

4. Stirring/Agitation: To ensure uniform cooling and prevent the formation of milk fat layer or cream, the milk should be gently stirred or agitated using a stirrer or agitator mounted inside the tank. This will help in maintaining the consistency of the milk.

5. Storage and Monitoring: Once the milk has reached the desired temperature, it can be stored in the cooling tank for an extended period. Regular monitoring of the temperature is essential to ensure it remains within the recommended range.

6. Cleaning and Maintenance: Proper cleaning and maintenance of the cooling milk tank are vital to prevent the growth of bacteria and maintain milk quality. The tank should be thoroughly cleaned at regular intervals using appropriate cleaning agents and equipment.

To maximize the efficiency and functionality of a cooling milk tank, consider the following tips:

– Regularly inspect and maintain the cooling system to ensure it is functioning optimally.

– Maintain proper hygiene throughout the milk collection and transfer process.

– Use a timer or temperature controller to ensure timely cooling and prevent milk spoilage.

– Keep the cooling tank covered when not in use to prevent contamination.

– Follow the manufacturer’s instructions for operating and maintaining the cooling tank.

In summary, using a cooling milk tank involves collection and transfer, filtration, rapid cooling, stirring or agitation, storage, monitoring, and regular cleaning and maintenance. Adhering to proper usage guidelines and following best practices will help ensure the quality and safety of the milk while maximizing the efficiency of the cooling process.

Quality Testing Methods for cooling milk tank and how to control the quality

Quality testing methods for cooling milk tanks are crucial to ensure that the milk remains at the desired temperature and maintains its quality. Here are a few commonly used testing methods:

1. Temperature testing: This involves using a thermometer or temperature sensor to measure the temperature of the milk in the tank. The temperature should adhere to specific standards to ensure the milk remains safe for consumption.

2. Time-temperature monitoring: This method involves recording the time and temperature of milk at regular intervals during the cooling process. It helps identify any deviations from the desired temperature range and enables corrective actions to be taken.

3. Microbiological testing: This testing method involves analyzing milk samples for microbial growth. The presence of bacteria or other microorganisms indicates poor cooling and potential contamination. Regular microbiological testing ensures that milk is free from harmful bacteria.

4. Chemical testing: Chemical tests are conducted to assess the acidity levels (pH) of milk. Elevated acidity can result from prolonged exposure to higher temperatures during cooling, indicating potential spoilage or microbial growth.

To control the quality of milk in cooling tanks, it is essential to implement the following measures:

1. Regular maintenance: Regularly inspect and maintain the cooling equipment to ensure it functions optimally. This includes cleaning the cooling system, checking for any leaks, and calibrating temperature sensors.

2. Training and monitoring: Train personnel involved in the milk cooling process regarding quality standards, proper handling techniques, and temperature monitoring. Monitor their adherence to these guidelines to minimize errors.

3. Prompt cooling: Quick cooling of milk is vital to maintain its quality. Ensure that the cooling equipment is properly sized and maintained to cool the milk rapidly to the desired temperature.

4. Process optimization: Continuously evaluate and optimize the milk cooling process to maximize efficiency and maintain quality. This may involve adjusting cooling parameters, enhancing insulation, or using automated temperature control systems.

By implementing these testing methods and quality control measures, it is possible to ensure that milk remains within the desired temperature range, thereby preserving its quality and extending its shelf life.

cooling milk tank Sample Policy and Post-Purchase Considerations for cooling milk tank from China

Sample Policy:

– Warranty: One year warranty for the cooling milk tank, covering any manufacturing defects.

– Quality Control: All cooling milk tanks undergo strict quality control measures to ensure they meet industry standards.

– Payment: Payment terms are negotiable, with options for T/T, L/C, or other agreed upon methods.

– Shipping: Shipping can be arranged by the manufacturer or the buyer, with possible additional charges for transportation.

– Returns: Returns are accepted within 30 days of purchase, subject to a restocking fee and inspection of the cooling milk tank.

Post-Purchase Considerations:

– Installation: Ensure the cooling milk tank is installed correctly by following the manufacturer’s guidelines or hiring a professional installer.

– Maintenance: Regular maintenance is essential to ensure the cooling milk tank functions properly and lasts longer. Follow the manufacturer’s maintenance recommendations.

– Troubleshooting: In case of any issues with the cooling milk tank, contact the manufacturer or supplier for assistance or follow troubleshooting guidelines in the manual.

– Training: Ensure that operators are trained on how to use the cooling milk tank properly to avoid any damage or malfunctions.

– Feedback: Provide feedback to the manufacturer or supplier for any issues or suggestions for improvement to help improve their products and services.

Sourcing cooling milk tank from China: Opportunities, Risks, and Key Players

China is a major player in the production of cooling milk tanks, offering opportunities for businesses looking to source these products. The country’s advanced manufacturing capabilities and competitive pricing make it an attractive option for sourcing cooling milk tanks.

However, there are risks associated with sourcing from China, including quality control issues, intellectual property concerns, and logistical challenges. It is important for businesses to conduct thorough due diligence when selecting a supplier to mitigate these risks.

Key players in the Chinese cooling milk tank market include Jiangsu Prettech Machinery & Technology Co., Ltd., Wenzhou Longqiang Dairy Machinery Factory, and Dezhou Yuanji Incubation Equipment Factory. These companies have a strong reputation for producing high-quality cooling milk tanks and can provide competitive pricing.

Overall, sourcing cooling milk tanks from China offers opportunities for cost savings and access to advanced manufacturing capabilities. However, businesses must carefully evaluate potential risks and select reputable suppliers to ensure a successful sourcing process.

How to find and select reliable cooling milk tank manufacturers in China,use google search manufacturers and suppliers

When searching for reliable cooling milk tank manufacturers in China, utilizing Google search can be an effective method. To ensure a successful search, follow these steps:

1. Begin by entering relevant keywords related to the product and its specifications. For example, searching for “cooling milk tank manufacturers in China” or “milk tank suppliers China” can yield suitable results.

2. Browse through the search results and explore different manufacturer websites to gain an understanding of their expertise and product range. Pay attention to their experience in manufacturing cooling milk tanks, certifications (if any), and any customer testimonials or reviews.

3. Shortlist potential manufacturers based on their reputation and credibility. Look for reputable and established companies that have been producing cooling milk tanks for a considerable period.

4. Evaluate the manufacturers’ capabilities by assessing their production facilities, quality control measures, and technological advancements. This information can usually be found on their websites or by contacting them directly.

5. Contact the shortlisted manufacturers to request additional information and inquire about their production processes, lead times, pricing, and customization options. Prompt and professional responses indicate a reliable manufacturer.

6. Consider requesting product samples or visiting the manufacturers’ factories to assess the quality of their cooling milk tanks firsthand. This can help verify their capabilities and adherence to international quality standards.

7. Gather multiple quotes from different manufacturers to compare pricing, delivery terms, and after-sales services. While cost is an important factor, it should not be the sole determinant for choosing a manufacturer. Quality and reliability should be given equal if not higher consideration.

8. Consult with industry experts, trade associations, or colleagues who are familiar with the Chinese manufacturing industry. They may be able to recommend trustworthy milk tank manufacturers based on their experiences and contacts in the market.

By following these steps, you can increase the likelihood of finding and selecting reliable cooling milk tank manufacturers in China. Thorough research and due diligence are key to ensure the chosen manufacturer meets your specific requirements and provides high-quality products.

How to check cooling milk tank manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To check if a cooling milk tank manufacturer’s website is reliable, a good first step is to use Google Chrome and install the SEOquake extension. This tool allows you to easily check the website’s ranking in the top 10 search results, which can give you an indication of its credibility and popularity.

You can also look for customer reviews, testimonials, and ratings to get an idea of the company’s reputation and the quality of their products. It’s important to check if the website provides detailed information about the company, their products, and their manufacturing process.

Additionally, you can look for certifications or accreditations that the manufacturer may have, such as ISO certifications or industry-specific standards.

Overall, by using SEOquake to check the website’s ranking, reading customer reviews, and verifying the company’s credentials, you can get a better sense of whether the cooling milk tank manufacturer is reliable.

Top 10 cooling milk tank manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Shanghai Ruipan Industrial Co., Ltd. specializes in manufacturing high-quality cooling milk tanks. Their tanks are made from food-grade stainless steel, ensuring the safety and hygiene of stored milk. These tanks are equipped with an advanced cooling system that efficiently lowers the temperature and maintains it at an optimal level. The tanks also feature a user-friendly control panel for easy operation. Ruipan offers a range of capacity options to suit different dairy farm sizes and requirements.

2. Yuyao Xinghua Milk & Dairy Equipment Factory is a renowned manufacturer of cooling milk tanks in China. Their tanks are designed with a focus on energy efficiency and cooling performance. Made from top-grade stainless steel, these tanks have excellent corrosion resistance and long-lasting durability. The tanks also incorporate advanced insulation techniques to minimize heat loss and ensure effective cooling. Xinghua offers customized tank sizes and configurations to meet specific customer needs.

3. Hangzhou Yinjiang Metal Product Co., Ltd. is a leading supplier of cooling milk tanks in China. Their tanks are designed with cutting-edge technology to ensure rapid and efficient cooling of milk. The tanks are constructed from high-quality stainless steel, providing the necessary durability and sanitary conditions for milk storage. Yinjiang offers tanks of various capacities, including options for vertical or horizontal installation, catering to different dairy farm setups.

| Manufacturer | Description |

|——————————————-|—————————————————————————————————————————————————————————————————————————————————————————————————————————————–|

| Shanghai Ruipan Industrial Co., Ltd. | Specializes in manufacturing high-quality cooling milk tanks made from food-grade stainless steel. Features advanced cooling system and user-friendly control panel. Various capacity options available. |

| Yuyao Xinghua Milk & Dairy Equipment Factory | Renowned for their energy-efficient cooling milk tanks made from top-grade stainless steel. Incorporates advanced insulation techniques for effective cooling. Offers customizable tank sizes and configurations. |

| Hangzhou Yinjiang Metal Product Co., Ltd. | A leading supplier of cooling milk tanks constructed from high-quality stainless steel. Designed with cutting-edge technology for rapid and efficient milk cooling. Provides options for vertical or horizontal installation. |

| … | … |

(Note: Due to the character limit, the remaining manufacturers and their product descriptions are abbreviated in the table.)

4. Zhejiang L&B Machinery Co., Ltd. – Specializes in manufacturing cooling milk tanks with high cooling efficiency. Offers tanks with advanced temperature control systems and easy maintenance.

5. Zhejiang Xinchang Machinery Co., Ltd. – Produces durable cooling milk tanks made from stainless steel. These tanks have excellent cooling performance and are designed to meet strict hygiene standards.

6. Dezhou Chuang Yuan Food Machinery Co., Ltd. – Provides cooling milk tanks with efficient cooling systems. These tanks have a large capacity and are suitable for use in medium to large-scale dairy farms.

7. Ningbo Lufa Machinery Manufacturing Co., Ltd. – Offers a wide range of cooling milk tanks with different capacity options. These tanks are equipped with energy-saving cooling units and come with excellent insulation properties.

8. Zhejiang Bafang Dairy Machinery Co., Ltd. – Specializes in manufacturing cooling milk tanks for both small and large-scale dairy farms. These tanks are made from high-quality stainless steel and provide efficient milk cooling.

9. Shandong Longlive Dairy Machinery Factory – Produces cooling milk tanks that are easy to operate and have excellent cooling performance. These tanks are made from durable materials and are designed to withstand the demands of commercial dairy operations.

10. Shanghai Joylong Industry Co., Ltd. – Offers cooling milk tanks with large storage capacities. These tanks are designed to provide efficient cooling while ensuring the quality and freshness of the stored milk.

By comparing the features, capacity options, and specialties of these top cooling milk tank manufacturers in China, customers can make an informed decision based on their specific requirements.

Background Research for cooling milk tank manufacturers Companies in China, use qcc.com archive.org importyeti.com

China is one of the leading manufacturers of cooling milk tanks in the world. Companies such as Shanghai Beyond Machinery Co., Ltd., Jiangsu Prettech Machinery & Technology Co., Ltd., and Wenzhou Longqiang Dairy Machinery Factory are some of the prominent manufacturers in the Chinese market.

Shanghai Beyond Machinery Co., Ltd. is a well-known company that specializes in the production of dairy processing equipment including cooling milk tanks. They offer a wide range of high-quality milk tanks with varying capacities to meet the needs of different dairy farms and processing facilities.

Jiangsu Prettech Machinery & Technology Co., Ltd. is another key player in the Chinese cooling milk tank manufacturing industry. They provide innovative solutions for dairy processing equipment, including advanced cooling milk tanks that are designed to ensure the freshness and quality of milk.

Wenzhou Longqiang Dairy Machinery Factory is a reliable manufacturer of cooling milk tanks in China. They have a strong reputation for producing durable and efficient milk tanks that meet the strict quality standards of the dairy industry.

These companies have established themselves as leaders in the Chinese cooling milk tank manufacturing sector due to their commitment to quality, innovation, and customer satisfaction. With their expertise and advanced technology, they continue to provide reliable solutions for the dairy industry in China and globally.

Leveraging Trade Shows and Expos for cooling milk tank Sourcing in China

Trade shows and expos provide an excellent opportunity to leverage sourcing for cooling milk tanks in China. These events bring together suppliers, manufacturers, and industry professionals on a large scale, allowing for efficient networking and sourcing activities.

Attending trade shows and expos dedicated to the dairy industry in China will expose businesses to a wide range of cooling milk tank suppliers. These events enable direct communication, facilitating the evaluation of different product offerings, features, and prices. Meeting face-to-face with potential suppliers allows for a deeper understanding of their capabilities, production processes, and product quality.

Furthermore, trade shows and expos provide an avenue for businesses to stay informed about the latest trends and advancements in cooling milk tank technology. Industry-specific events often feature seminars, workshops, and presentations discussing innovative products and manufacturing techniques. This knowledge can be crucial for making informed sourcing decisions and staying competitive in the market.

Sourcing through trade shows and expos in China also offers the advantage of consolidating supplier discovery and selection. Instead of individually researching and reaching out to multiple suppliers, attending these events allows for efficient comparison and evaluation of various options under one roof. This streamlines the sourcing process, saving time and resources.

In addition, trade shows and expos give businesses the opportunity to build relationships and establish trust with potential suppliers. Face-to-face interactions foster personal connections, enabling businesses to gauge the reliability and professionalism of potential partners. Establishing strong relationships can lead to long-term collaborations and smoother sourcing processes in the future.

To maximize the benefits of leveraging trade shows and expos for cooling milk tank sourcing in China, businesses should thoroughly prepare for these events. This includes conducting thorough research on exhibitors, preparing a list of desired specifications and requirements, and setting clear sourcing goals.

In conclusion, trade shows and expos provide a valuable platform for sourcing cooling milk tanks in China. These events offer direct communication with suppliers, access to the latest industry trends, streamlined supplier selection, and opportunities for building relationships. By effectively utilizing trade shows and expos, businesses can enhance their sourcing capabilities and find reliable suppliers for cooling milk tanks in China.

The Role of Agents and Sourcing Companies in Facilitating cooling milk tank Purchases from China

Agents and sourcing companies play a critical role in facilitating cooling milk tank purchases from China. They act as intermediaries between buyers and sellers, bridging the gap in language, cultural, and business barriers that may exist.

One of the primary functions of agents and sourcing companies is to identify reliable and reputable manufacturers or suppliers of cooling milk tanks in China. They have in-depth knowledge of the local market and a vast network of contacts, enabling them to connect buyers with suitable suppliers that meet their specific requirements. This saves buyers the time and effort of conducting extensive research and due diligence on their own.

Agents facilitate the negotiation and purchasing process by acting as the main point of contact between buyers and suppliers. They have experience in negotiating pricing, terms, and conditions, ensuring that buyers get the best possible deal. Agents also assist in obtaining necessary product certifications, documentation, and compliance with import regulations, ensuring a smooth and hassle-free procurement process.

Agents and sourcing companies also provide crucial quality control services. They can conduct factory inspections, product quality checks, and monitor production processes to ensure that the cooling milk tanks meet the required standards and specifications. This helps buyers mitigate the risk of receiving substandard or defective products.

Furthermore, agents are responsible for logistics and shipping arrangements. They coordinate the transportation of the purchased cooling milk tanks from China to the buyer’s location. This includes handling customs clearance, arranging packaging, and ensuring timely delivery. Agents also help buyers track their orders and provide post-purchase support, including addressing any issues or concerns that may arise.

In summary, agents and sourcing companies facilitate cooling milk tank purchases from China by connecting buyers with reputable suppliers, managing the negotiation and purchasing process, ensuring quality control, and handling logistics and shipping arrangements. Their expertise and services streamline the procurement process and provide buyers with peace of mind when dealing with international transactions.

Price Cost Research for cooling milk tank manufacturers Companies in China, use temu.com and 1688.com

When researching the price and cost of cooling milk tanks from manufacturers in China, two popular websites to use are temu.com and 1688.com.

On temu.com, users can easily find a wide range of manufacturers specializing in cooling milk tanks. The platform allows for direct communication with suppliers, enabling buyers to negotiate prices and discuss specific requirements. Prices for cooling milk tanks on temu.com typically range from $2,000 to $10,000, depending on factors such as capacity, material, and technology.

Similarly, 1688.com is another reliable source for finding cooling milk tank manufacturers in China. The platform offers a vast selection of suppliers, allowing buyers to compare prices and select the most cost-effective option. Prices for cooling milk tanks on 1688.com also vary based on factors such as size, features, and production volume, with average costs ranging from $1,500 to $8,000.

Overall, by leveraging temu.com and 1688.com, buyers can access a diverse range of cooling milk tank manufacturers in China and obtain competitive pricing information to make informed purchasing decisions.

Shipping Cost for cooling milk tank import from China

The shipping cost for importing a cooling milk tank from China will depend on various factors such as the size and weight of the tank, the shipping method chosen, the distance between China and the destination country, and any additional fees or taxes.

Typically, the most commonly used shipping methods for importing goods from China are sea freight, air freight, and express courier services. Sea freight is usually the most cost-effective option for larger and heavier items such as cooling milk tanks. The cost of sea freight will depend on factors such as the volume of the tank, the shipping route, and whether it is being shipped in a full container load (FCL) or less than container load (LCL).

Air freight is a faster option but can be more expensive, especially for large and heavy items. However, if the cooling milk tank is urgently needed, air freight may be the best option. Express courier services are the most expensive but also the fastest option for shipping small and light items.

In addition to the shipping cost, importers will also need to consider other costs such as customs duties, taxes, insurance, and handling fees. These costs can vary depending on the destination country and the value of the goods.

To keep the shipping cost under control, importers can consider consolidating multiple orders into one shipment, negotiating with shipping companies for better rates, and selecting a slower shipping option if time is not a constraint. It is also important to work with a reliable freight forwarder who can help navigate the complexities of international shipping and ensure a smooth import process.

Compare China and Other cooling milk tank Markets: Products Quality and Price,Visible and Hidden Costs

China’s cooling milk tank market is known for its high-quality products at competitive prices compared to other markets. The tanks in China are manufactured with advanced technology and strict quality control, resulting in reliable and durable products. The prices of cooling milk tanks in China are usually lower than in other markets due to lower production costs and economies of scale.

In terms of visible and hidden costs, China’s cooling milk tanks typically have lower maintenance and repair costs due to their durability and high-quality construction. However, there may be hidden costs such as shipping and import duties for international buyers. On the other hand, other markets may have higher upfront costs for purchasing cooling milk tanks, but lower maintenance costs and hidden costs due to local manufacturing and distribution.

Overall, China’s cooling milk tank market offers a combination of high-quality products at competitive prices, making it a popular choice for dairy farmers worldwide. However, buyers need to consider factors such as shipping and import duties when purchasing from China. Other markets may offer slightly higher-quality products or lower hidden costs, but at a higher upfront price. Ultimately, the choice between China and other markets will depend on the specific needs and preferences of the buyer.

Understanding Pricing and Payment Terms for cooling milk tank: A Comparative Guide to Get the Best Deal

When it comes to purchasing a cooling milk tank, understanding the pricing and payment terms is crucial to ensure that you get the best deal. Here is a comparative guide to help you navigate through the process.

Price Comparison:

Start by researching different suppliers and manufacturers to compare prices. Consider visiting their websites or contacting them directly to gather pricing information. Ensure that you compare the prices for tanks with similar specifications and features to get an accurate comparison. Additionally, try to negotiate the price to potentially secure a better deal.

Payment Terms:

Next, it’s essential to understand the payment terms offered by different suppliers. These terms can vary widely and may include options such as upfront payment, installment plans, or leasing options. Carefully evaluate each payment term to determine which one suits your financial situation the best. If you have a limited budget, installment plans or leasing options may be more feasible than upfront payment.

Additional Costs:

Alongside the purchase price, consider other costs associated with buying a cooling milk tank. These may include delivery charges, taxes, customs duties (if applicable), installation fees, and ongoing maintenance costs. Evaluate these additional costs when comparing the final prices offered by different suppliers.

Warranty and After-Sales Service:

Make sure to inquire about the warranty offered by each supplier. The warranty period and coverage can significantly impact the overall value of your purchase. Additionally, ask about the after-sales service provided by the supplier. A reliable and responsive support team can save you from potential troubles and complications in the future.

Reviews and Recommendations:

Don’t forget to read customer reviews and seek recommendations from trusted sources. Hearing about other customers’ experiences with a particular supplier can give you valuable insights into the quality of their products and services. Consider reaching out to other dairy farmers or industry experts to gather their opinions and recommendations.

By conducting thorough research, comparing prices, understanding payment terms, considering additional costs, checking warranties, and seeking recommendations, you can ensure that you secure the best deal when purchasing a cooling milk tank. Remember to prioritize the quality and reliability of the tank alongside the pricing to make a well-informed decision.

Chinese Regulations and Industry Standards Certifications for cooling milk tank,Import Regulations and Customs for cooling milk tank from China

In China, the regulations and industry standards certifications for cooling milk tanks are crucial to ensure the quality and safety of the products. The main regulatory body responsible for setting and enforcing these standards is the General Administration of Quality Supervision, Inspection, and Quarantine (AQSIQ).

One of the most important certifications required for cooling milk tanks in China is the China Compulsory Certification (CCC). This certification is mandatory for certain products, including electrical components and equipment, to guarantee their compliance with the national safety and quality standards.

In addition to CCC, other industry standards certifications are necessary to ensure that the cooling milk tanks meet the specific performance requirements of the dairy industry. For instance, the Chinese National Standard for cooling milk tanks is GB 5749-2006, which outlines the technical specifications and testing methods that the tanks must adhere to.

When importing cooling milk tanks from China, it is essential to comply with the country’s import regulations and customs procedures. Firstly, importers need to obtain the necessary import licenses or permits from the relevant Chinese authorities, such as the AQSIQ and the China Certification and Accreditation Administration (CNCA).

Customs duties and taxes are also applicable when importing cooling milk tanks into China. Importers have to accurately declare the value of the goods and pay the required customs duties, which are determined by the customs tariff rates. Importers may also need to provide additional documents, such as certificates of origin and quality inspection reports, to clear the goods through customs.

It is crucial for importers to work closely with reliable suppliers or agents in China who have knowledge and experience in handling the necessary certifications and customs procedures. This helps ensure that the cooling milk tanks meet the required standards and comply with the import regulations, facilitating a smooth import process.

Overall, a thorough understanding of Chinese regulations and industry standards certifications, as well as import regulations and customs procedures, is crucial when importing cooling milk tanks from China. Compliance with these requirements helps ensure the quality and safety of the products and facilitates a successful importation process.

Sustainability and Environmental Considerations in cooling milk tank Manufacturing

Sustainability and environmental considerations in cooling milk tank manufacturing play a crucial role in reducing the carbon footprint and minimizing the impact on the environment. One key aspect is the selection of materials used in the manufacturing process. Opting for sustainable and eco-friendly materials, such as stainless steel or aluminum, can significantly reduce the environmental impact of production.

Additionally, the manufacturing process itself should focus on energy efficiency and waste reduction. Implementing energy-efficient technologies and practices, such as using renewable energy sources or optimizing production processes, can help minimize the energy consumption and reduce greenhouse gas emissions.

Furthermore, the end-of-life disposal of cooling milk tanks should also be taken into consideration. Designing products that are easily recyclable or reusable can help reduce waste and promote a circular economy. Proper disposal and recycling of materials at the end of the product’s life cycle can further minimize the environmental impact.

Overall, sustainability and environmental considerations in cooling milk tank manufacturing are essential for reducing the industry’s environmental footprint and promoting a more sustainable future. By prioritizing eco-friendly materials, energy-efficient production processes, and end-of-life disposal practices, manufacturers can contribute to a healthier planet for future generations.

List The Evolution history of “cooling milk tank”

The evolution of the cooling milk tank has been a remarkable journey, with significant advancements in technology and design over the years. The earliest form of milk cooling can be traced back to the late 1800s when farmers used ice to cool the milk. However, this process was inefficient and required frequent ice replenishment.

In the early 1900s, mechanical refrigeration systems started to emerge, serving as a turning point in milk cooling. These systems utilized compressors, condensers, and evaporators to chill the milk. The tanks were often made of galvanized steel, and a cooling element was placed inside to bring down the temperature. This innovation allowed for better preservation of milk and longer shelf life.

During the mid-20th century, further advancements were made in milk cooling technology. More efficient refrigeration units were developed, capable of rapidly cooling large quantities of milk. Stainless steel tanks replaced galvanized steel, providing better insulation and hygiene. A key development was the introduction of direct expansion refrigeration, which eliminated the need for cooling elements inside the tanks. Instead, the milk was cooled directly through a refrigerant coil, enhancing efficiency and reducing maintenance.

In the late 20th century, electronic control systems were incorporated into cooling tanks. These systems allowed for precise temperature regulation and monitoring, ensuring optimal cooling conditions. The integration of automated cleaning systems also improved sanitation practices, enhancing the overall quality of milk.

More recently, the evolution of cooling milk tanks has been marked by energy-efficient designs and sustainability efforts. Manufacturers have introduced energy-saving features, such as variable speed compressors and improved insulation materials, reducing the environmental impact of milk cooling. Additionally, advanced monitoring systems and remote control capabilities have enabled farmers to remotely access and manage their cooling tanks, optimizing milk preservation and reducing operational costs.

In conclusion, the evolution of cooling milk tanks has come a long way, from using ice to incorporating sophisticated refrigeration systems and automation. The industry has progressed towards energy efficiency and sustainability, while ensuring the preservation of milk quality throughout history.

The Evolution and Market Trends in cooling milk tank Industry

The cooling milk tank industry has evolved significantly over the years as technology has improved and consumer demand for high-quality dairy products has increased. These tanks are essential for preserving the freshness and quality of milk before it is transported to dairy processing facilities.

One of the key trends in the cooling milk tank industry is the shift towards more energy-efficient and environmentally friendly cooling systems. Manufacturers are now developing tanks with advanced insulation and refrigeration technologies that reduce energy consumption and lower greenhouse gas emissions. This not only benefits the environment but also helps dairy farmers save on operating costs.

Another trend in the market is the increasing demand for larger capacity tanks to accommodate the growing milk production on dairy farms. As farms scale up their operations to meet consumer demand, they require larger tanks that can efficiently cool and store larger volumes of milk.

Additionally, there is a growing focus on data monitoring and automation in cooling milk tanks. Farmers are increasingly using sensors and monitoring systems to track and optimize the cooling process, ensuring that milk is kept at the optimal temperature to maintain its freshness and quality.

Overall, the cooling milk tank industry continues to innovate and evolve to meet the needs of dairy farmers and the changing market landscape. With a focus on energy efficiency, capacity, and technological advancements, the industry is poised for continued growth and development in the coming years.

Custom Private Labeling and Branding Opportunities with Chinese cooling milk tank Manufacturers

Chinese cooling milk tank manufacturers offer custom private labeling and branding opportunities for businesses looking to establish their own unique identity in the market. With their expertise and experience in manufacturing cooling milk tanks, Chinese manufacturers provide a range of services to cater to the specific branding needs of their clients.

One of the key advantages of working with Chinese manufacturers is their ability to offer custom private labeling. Businesses can choose to have their company logo, name, and design printed on the cooling milk tanks, creating a branded product that stands out from competitors. This helps to enhance brand recognition and customer loyalty, ultimately leading to increased sales and market share.

Furthermore, Chinese manufacturers also offer branding opportunities by allowing businesses to customize the appearance and features of the cooling milk tanks. From the size and shape of the tanks to the materials used and additional functionalities, manufacturers can tailor the product to match the branding strategy of their clients. This enables businesses to differentiate themselves in the market and meet the unique needs of their target audience.

In addition to customization options, Chinese manufacturers ensure high-quality production standards to maintain the authenticity and durability of the branded cooling milk tanks. They adhere to strict quality control processes and use premium materials to ensure that the tanks are safe, efficient, and long-lasting.

Collaborating with Chinese cooling milk tank manufacturers for private labeling and branding opportunities can be a cost-effective solution for businesses. China’s competitive manufacturing industry offers reasonable prices while maintaining high standards of production. This allows businesses to maximize their budget without compromising the quality or branding potential of their products.

Overall, Chinese cooling milk tank manufacturers provide customized private labeling and branding opportunities that empower businesses to establish a distinctive presence in the market. By utilizing these services, businesses can create their own branded products that resonate with customers, foster brand loyalty, and drive business growth.

Tips for Procurement and Considerations when Purchasing cooling milk tank

When purchasing a cooling milk tank for your business, there are several important considerations to keep in mind to ensure you are getting the best product for your needs. Here are some tips to help guide your procurement process:

1. Capacity: Determine the size of the cooling milk tank you will need based on the volume of milk you will be processing on a daily basis.

2. Cooling system: Consider the type of cooling system the tank uses, such as direct expansion or ice bank. Each system has its own advantages and disadvantages in terms of efficiency and cost.

3. Insulation: Look for a tank with high-quality insulation to maintain the temperature of the milk and prevent spoilage.

4. Material: Choose a tank made of durable, food-grade stainless steel to ensure it is hygienic and easy to clean.

5. Cooling efficiency: Consider the speed at which the tank can cool the milk to the desired temperature to ensure the quality and freshness of the product.

6. Additional features: Look for tanks with additional features such as automatic agitation or temperature control to make the milk processing process more efficient.

7. Cost: Compare prices from different suppliers to ensure you are getting a competitive price for the quality of tank you are purchasing.

Overall, when purchasing a cooling milk tank, it is important to consider factors such as capacity, cooling system, insulation, material, cooling efficiency, additional features, and cost to ensure you are making an informed decision that meets your business needs.

FAQs on Sourcing and Manufacturing cooling milk tank in China

Q: What is a cooling milk tank?

A: A cooling milk tank is a specialized storage vessel designed to cool and preserve milk at low temperatures to maintain its freshness and quality.

Q: Why should I source and manufacture a cooling milk tank in China?

A: China offers several advantages for sourcing and manufacturing cooling milk tanks. It has a robust manufacturing industry, experienced workforce, advanced technology, and competitive pricing. Chinese manufacturers also have a track record of producing high-quality cooling milk tanks suitable for various capacity requirements.

Q: How can I find a reliable manufacturer in China?

A: To find a reliable manufacturer in China, one can research and identify potential suppliers through online platforms, industry trade shows, or professional networks. Conducting thorough background checks, verifying certifications, and requesting samples or references can help evaluate the manufacturer’s credibility and quality.

Q: Is it possible to customize cooling milk tanks according to my requirements?

A: Yes, many Chinese manufacturers offer customization services for cooling milk tanks. They can tailor the tank’s capacity, shape, material, cooling system, and other features to meet specific customer needs and specifications.

Q: What should I consider when sourcing a cooling milk tank in China?

A: When sourcing a cooling milk tank in China, it is important to consider factors such as the manufacturer’s reputation, production capacity, quality control measures, lead times, after-sales support, and compliance with international standards.

Q: Can Chinese manufacturers ensure high-quality production and meet international standards?

A: Yes, many Chinese manufacturers adhere to international quality standards such as ISO certifications and have experience exporting products worldwide. Conducting factory audits and requesting documentation regarding quality control processes can further ensure compliance with specific requirements.

Q: What is the typical lead time for manufacturing cooling milk tanks in China?

A: The lead time for manufacturing cooling milk tanks in China can vary depending on factors like customization complexity, order quantity, and the manufacturer’s production capacity. Generally, it can range from a few weeks to a couple of months.

Q: Are there any limitations or risks associated with sourcing and manufacturing in China?

A: Some potential risks include language barriers, intellectual property protection, and communication challenges due to cultural differences. However, by working with reputable manufacturers, conducting proper due diligence, and enforcing legal agreements, these risks can be managed effectively.

Overall, sourcing and manufacturing cooling milk tanks in China offer numerous advantages, including cost-effectiveness, customization options, and access to an established manufacturing industry. Conducting thorough research, due diligence, and effective communication can help mitigate potential risks and ensure a successful collaboration with Chinese manufacturers.

Why contact sourcifychina.com get free quota from reliable cooling milk tank suppliers?

Sourcifychina.com may have been able to secure a free quota from reliable cooling milk tank suppliers for a few reasons.

Firstly, Sourcifychina.com may have established a strong and trustworthy relationship with these cooling milk tank suppliers. This could be due to their consistent business transactions and a record of successful partnerships. Suppliers may see Sourcifychina.com as a reputable platform that consistently brings in valuable business, which could incentivize them to offer a free quota to maintain this relationship.

Secondly, Sourcifychina.com may have a large customer base and be able to provide suppliers with a consistent stream of potential buyers. Suppliers that offer a free quota to Sourcifychina.com might see it as a marketing strategy to attract new customers and expand their market reach. By offering a free quota, they may hope to gain exposure to a wider audience and increase their chances of securing long-term business relationships.

Additionally, Sourcifychina.com may have negotiated special terms or agreements with these suppliers, such as bulk purchasing or exclusive distribution rights. In exchange for these benefits, suppliers might be more willing to offer a free quota to Sourcifychina.com to ensure they maintain the relationship and receive the associated advantages.

Lastly, Sourcifychina.com could have a strong reputation for quality control and effective communication. This can be crucial for suppliers who want to ensure their products meet the required standards and specifications. By providing a free quota, suppliers may recognize that Sourcifychina.com’s strict quality control processes and efficient communication can help them avoid any potential issues or delays, ultimately benefiting their own reputation.

In conclusion, Sourcifychina.com may have obtained a free quota from reliable cooling milk tank suppliers due to their strong relationship, ability to provide a large customer base, negotiation of special agreements, and reputation for quality control and effective communication.