Benefits of DIY CNC Laser

A DIY CNC laser may seem like an overwhelming project, but the benefits far outweigh any challenges you may face while building it. Here are some reasons why building your own CNC laser may be worth the effort:

1. Affordability

One of the most significant benefits of building a DIY CNC laser is that it can be far more affordable than purchasing a pre-made machine. This is especially true if you have some of the necessary parts lying around your workshop.

2. Precise Cuts

A DIY CNC laser cutter is a precise tool that is capable of cutting through a wide variety of materials with great accuracy. This means you can achieve precision cuts that are not always possible with other tools.

3. Customization

Building your own CNC laser puts you in control of the machine’s features and design. You can customize it to fit your needs and preferences, ensuring that the machine is as efficient and effective as possible.

4. Versatility

A DIY CNC laser cutter is a versatile tool that can work with a range of materials. This means you can use it for woodworking, metalworking, and even engraving intricate designs and patterns into your projects.

5. Learning Experience

Building a DIY CNC laser gives you an opportunity to learn about the technology and the various components that make up the machine. This knowledge can open up new opportunities for future projects and endeavors.

In conclusion, building a DIY CNC laser is a cost-effective way to obtain a highly-accurate and versatile tool. It offers a customizable and unique experience that can be very rewarding, and give users the chance to learn new skills. Whether for small scale or larger applications, a DIY CNC laser can be a valuable addition to any workshop.

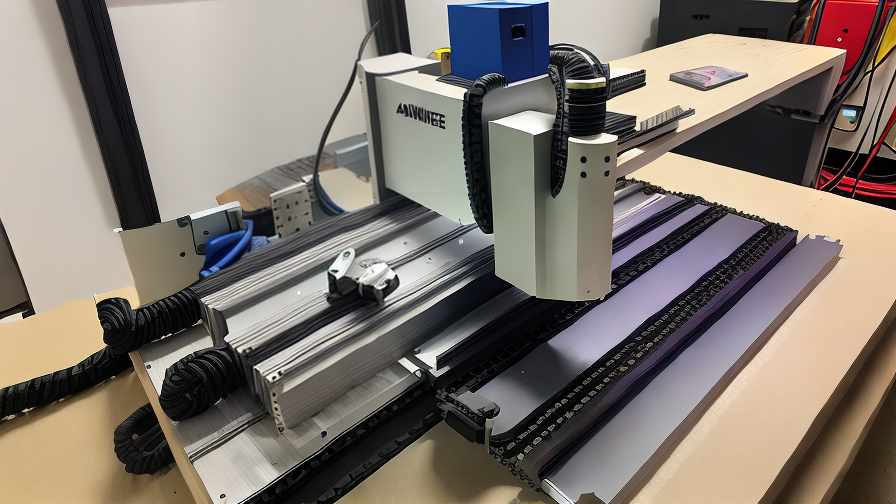

Features of DIY CNC Laser

DIY CNC lasers are becoming increasingly popular among hobbyists and makers. These machines are highly versatile and offer a wide range of features that allow users to create custom designs with ease.

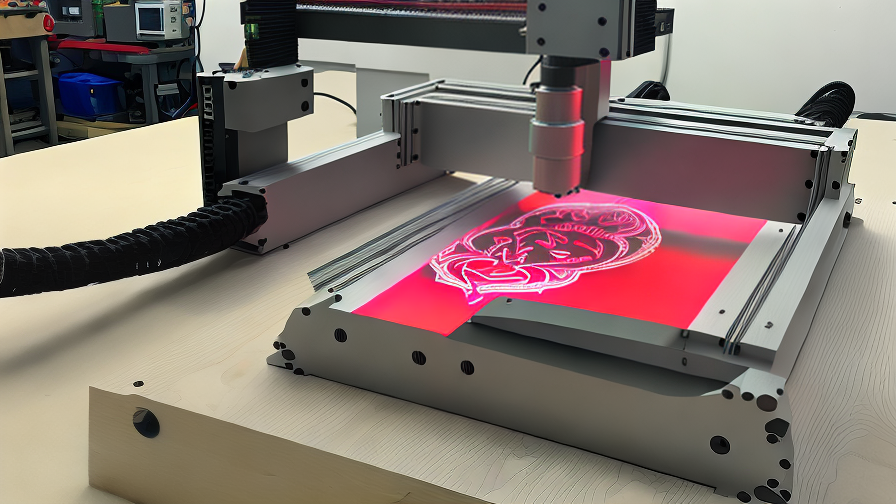

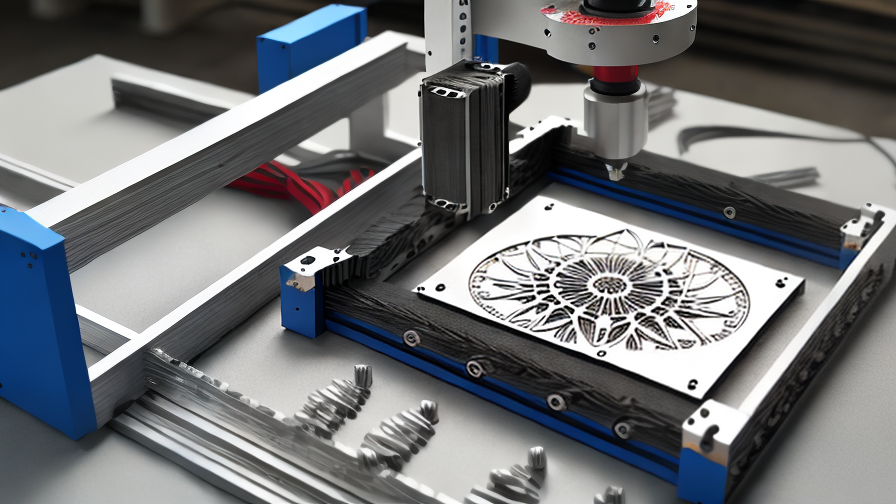

One of the key features of DIY CNC lasers is their ability to cut and engrave a variety of materials. From wood and acrylic to metal and leather, these machines can handle a range of different materials. They are also incredibly precise, meaning that users can create intricate and detailed designs with ease.

Another great feature of DIY CNC lasers is their affordability. While industrial-grade laser cutting machines can cost tens of thousands of dollars, DIY machines can be built for a fraction of the cost. This makes them accessible to a wider range of people, including hobbyists and small businesses.

DIY CNC lasers also offer a high degree of customization. Users can build their machines to meet their specific needs, incorporating features like automatic material detection, adjustable laser power, and more. This allows for greater control over the cutting and engraving process and can help to achieve more accurate results.

Perhaps one of the most compelling features of DIY CNC lasers is their compatibility with a wide range of design software. This means that users can create designs in software like Adobe Illustrator or Inkscape and then easily transfer them to their laser machine for cutting or engraving. This makes the process of creating custom designs incredibly smooth and efficient.

Overall, DIY CNC lasers offer an impressive range of features that make them a versatile and cost-effective option for hobbyists and makers. Their ability to cut and engrave a range of materials with high precision, coupled with their customizability and compatibility with design software, make them a must-have tool for any workshop.

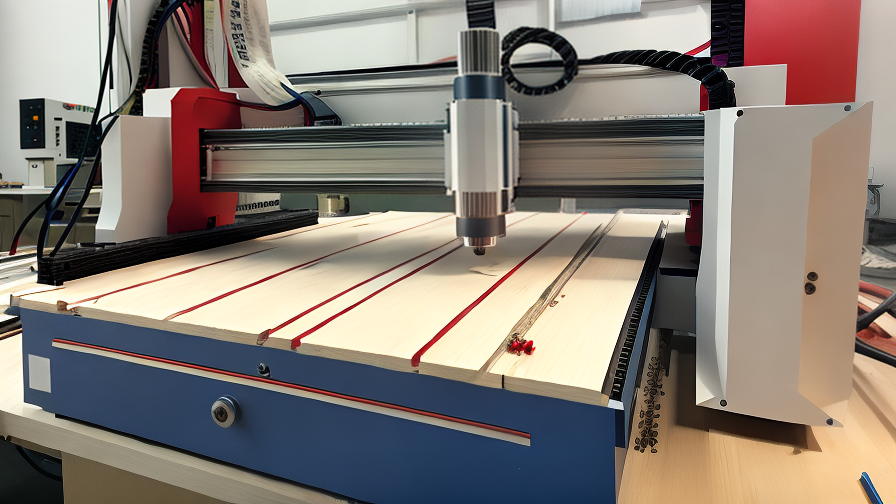

Various Types of DIY CNC Laser

CNC laser machines are now becoming more popular among DIY enthusiasts who are looking for an efficient way to achieve precision cutting or engraving on different materials. However, there are various types of DIY CNC laser machines that are available in the market, and knowing the ideal one for your project is crucial.

One of the most popular types of DIY CNC lasers is the CO2 laser. This type of laser is perfect for precise cutting and engraving on a range of materials, including wood, acrylic, leather, and paper. A CO2 laser is affordable and easy to build and has a superior performance when compared to other types of lasers, making it an excellent choice for most DIY projects.

Another type of DIY CNC laser is the fiber laser. This type of laser is ideal for engraving metals, including steel, aluminum, and copper. A fiber laser is more expensive than a CO2 laser, but it provides higher precision and speed, making it a perfect choice for those who want to work on complex projects.

Besides, there is also the diode laser that is primarily used for small-scale projects that require precise cutting and engraving. This type of CNC laser is easy to operate and is ideal for materials such as plastic, leather, and cardboard.

Lastly, the Galvo laser is a popular CNC laser among DIY enthusiasts who want to work on intricate designs such as logos and lettering. The Galvo laser is equipped with a high-speed scanning system that produces stunning results, and it is suitable for materials such as acrylic, wood, and leather.

In summary, when planning a DIY CNC laser project, it’s vital to consider the type of laser that suits your needs. While the CO2 laser is ideal for a wide range of materials, the fiber laser is perfect for metal engraving, while the diode laser is designed for small-scale projects. On the other hand, the Galvo laser is perfect for intricate designs. Choose the best DIY CNC laser that suits your preference and project needs.

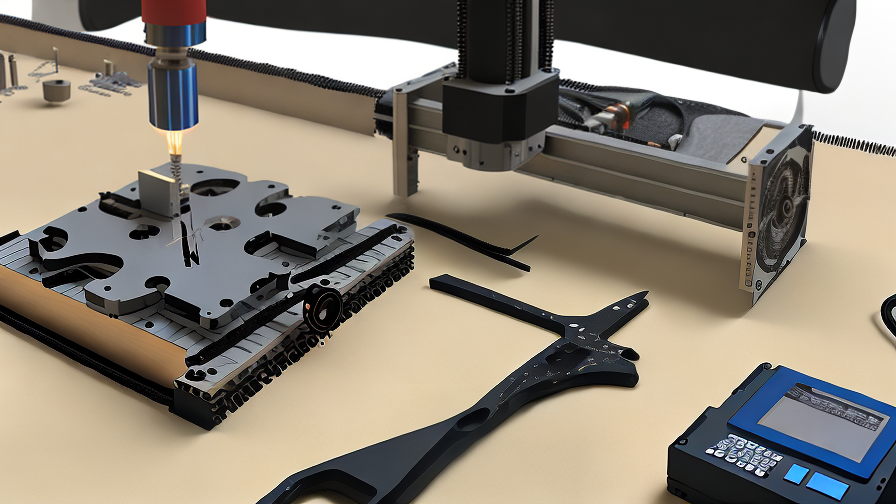

Applications of DIY CNC Laser

DIY CNC lasers are becoming increasingly popular among hobbyists and small business owners. With the advancements in technology, these affordable and easy-to-use machines have revolutionized the way people approach various tasks. Here are a few applications of DIY CNC lasers:

Engraving and Etching:

One of the most popular applications of CNC lasers is engraving and etching. These machines can quickly and accurately etch designs, logos, and texts on various materials like wood, acrylic, and metal. This makes them a favorite among enthusiasts who want to add personal touches to their creations.

Cutting and Carving:

DIY CNC lasers can cut and carve through a variety of materials, including wood, acrylic, and metal. With these machines, you can easily create intricate patterns and designs in just a few minutes. They are particularly useful for cutting precise shapes for woodworking and model making.

Jewelry Making:

CNC lasers are also being used in the jewelry-making industry. Jewelry designers can use these machines to create intricate designs and patterns on various materials like gold, silver, and acrylic. With a CNC laser, they can quickly cut, engrave, and etch designs with high precision and accuracy.

Medical Applications:

CNC lasers are also being used in the medical field. They can be used to cut and carve delicate materials like bone and tissue. These machines are particularly useful in orthopedic and dental surgeries, where precision is critical.

DIY CNC lasers are versatile machines that offer a wide range of applications. They provide high precision, accuracy, and speed, making them valuable tools for hobbyists, small business owners, and professionals. As technology continues to advance, it is expected that the applications of these machines will only expand.

The Process of DIY CNC Laser

DIY CNC lasers have been around for a while now, and they are becoming increasingly popular among engineers, hobbyists, and even artists. With the DIY CNC laser, you can create intricate designs on different materials, including wood, plastic, and metal. The process of making a DIY CNC laser is not as hard as it may sound, and it is an excellent opportunity to learn more about machine design and fabrication.

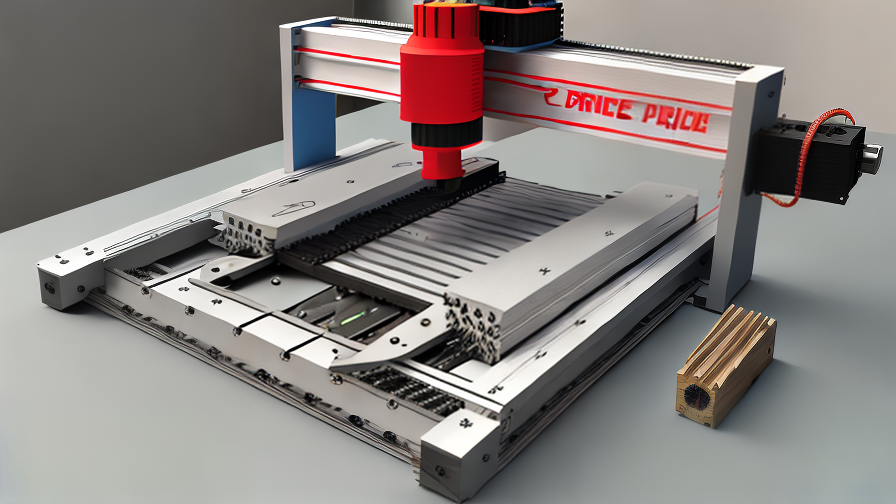

First, you need to get your hands on a CNC kit. A CNC kit contains the hardware and software that you need to build a laser cutter. A budget kit may cost a few hundred dollars, while a high-end one can run you into thousands of dollars. Once you have your kit, you’ll need to assemble it. The kit typically includes mechanical parts like stepper motors, a laser diode, a controller board, and power supplies.

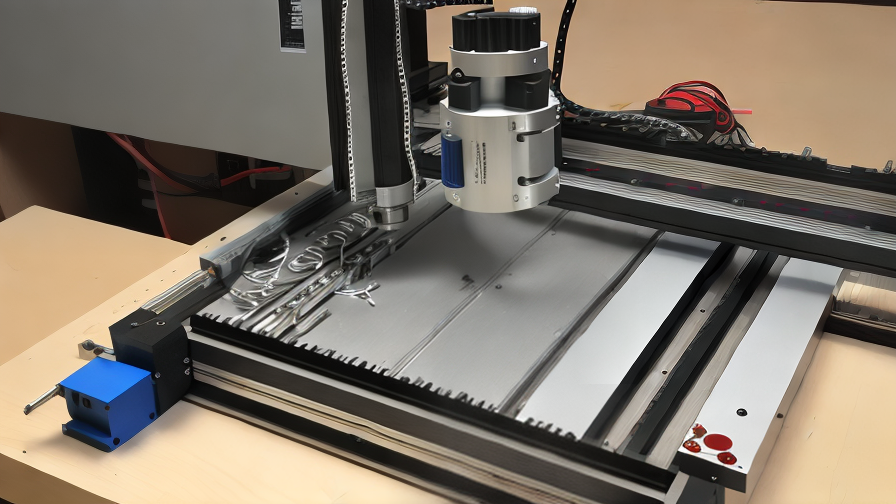

Next, you need to decide on the frame of your laser cutter. The frame is the base that supports the motors, laser, and other parts. You can build the frame from scratch using aluminum extrusions, or you can use a pre-made frame. A pre-made frame will be easier to assemble, and it will save you time.

After making the frame, you need to install the motors and the laser. The motors control the movement of the cutter, while the laser cuts the material. Next, connect the controller board to the motors and the laser. The controller board will receive instructions from your computer and control the movement of the motors.

Finally, you need to install the software that controls the cutter. Most CNC kit providers offer free software that you can download and use to control the laser cutter. You need to connect your computer to the controller board using a USB cable. Once you have everything set up, you can start using your DIY CNC laser cutter.

In summary, building a DIY CNC laser is a fun and exciting project that anyone can undertake. With the right CNC kit and some basic tools, you can build your laser cutter over a weekend. By doing so, you’ll learn a lot about machine design and fabrication, and you’ll be able to create unique and intricate designs on different materials.

How to use DIY CNC Laser

When it comes to working with technology, nothing is more thrilling than using a DIY CNC laser. This device is a handy addition to any workshop or office. It provides endless possibilities for cutting and engraving tasks, making it the go-to tool for those who love creating art, crafting, and designing.

To use a DIY CNC laser, you need to make a design on the computer using software like Adobe Illustrator or CorelDRAW that can handle vector graphics. Then, you upload the design to the software for the machine, which will send the instructions to the laser.

Before you start the actual cutting, you need to adjust the settings of the laser. This includes setting the power of the laser, the speed of the cutting process, and the distance between the beam and the material you are cutting or engraving. Make sure you follow the instructions of the manufacturer carefully, to avoid accidents.

After you’ve set the correct settings, put the material on the bed of the laser machine and secure it tightly to ensure that it won’t move while the laser is working. Start the laser and let it do its work. Make sure that you watch the entire process and don’t leave the laser unattended.

Once the laser has completed the design, you can remove the cut-out piece from the bed, clean it up, and enjoy the final product. Be sure to clean the machine after each use to maintain its effectiveness.

Finally, take note of some precautions when using the DIY CNC laser. Wear the necessary safety gear like gloves and goggles to protect yourself from the laser beam. Keep potentially flammable materials away from the laser area, and always work in a well-ventilated area.

In conclusion, the DIY CNC laser is an innovative tool for cutting, engraving, and designing. Always follow the instructions and take proper precautions to ensure safe usage. With its ease of use, this machine can turn your creative designs into realities.

Selecting the Ideal Manufacturer DIY CNC Laser

When it comes to selecting the ideal manufacturer for your DIY CNC laser, there are a few key factors to keep in mind.

First and foremost, you’ll want to consider the manufacturer’s reputation. Look for reviews and ratings from previous customers, and ask for referrals from fellow DIY enthusiasts. A reputable manufacturer will have a track record of high-quality products and excellent customer service.

Next, consider the features and capabilities of the laser. Look for a manufacturer that offers customization options to fit your specific needs. Consider the laser’s power, bed size, and cutting speed, as well as any additional features like autofocus or rotary attachments.

It’s also important to consider the manufacturer’s support and warranty. A good manufacturer will offer comprehensive support for their products, including technical assistance and troubleshooting. Look for a warranty that covers parts and labor for at least one year.

Finally, consider the price and value of the laser. While it’s important to stay within your budget, don’t sacrifice quality for a lower price. Look for a laser that offers the features and capabilities you need at a fair price.

By taking these factors into account, you can select the ideal manufacturer for your DIY CNC laser and enjoy the benefits of a high-quality and versatile tool for your projects.

list FAQ with answer about DIY CNC Laser

DIY CNC Laser is a trending topic among do-it-yourselfers, makers, and hobbyists. However, it is natural to have some questions and doubts when it comes to building such a complex and sophisticated machine. In this article, we will list frequently asked questions and answers about DIY CNC Lasers.

1. What is a DIY CNC Laser?

A DIY CNC Laser is a computer-numerically-controlled machine that uses a laser beam to etch, cut, or engrave a wide range of materials like wood, plastic, metal, and more.

2. What are the advantages of building a DIY CNC Laser?

There are several advantages to building a DIY CNC Laser, such as customizing the machine according to your needs, saving money, gaining knowledge and experience, and having fun while making something.

3. How much does it cost to build a DIY CNC Laser?

The cost of building a DIY CNC Laser can vary based on several factors like the size of the machine, the type of laser, and the components used. Generally, it can cost anywhere from a few hundred to a couple of thousand dollars.

4. What skills do I need to build a DIY CNC Laser?

Building a DIY CNC Laser requires a good understanding of electronics, programming, mechanics, and safety protocols. However, you can learn these skills through online resources, tutorials, and by joining maker communities.

5. What safety measures should I take when building and using a DIY CNC Laser?

Laser beams can cause serious damage to eyes and skin. Therefore, it is essential to follow safety guidelines like wearing protective goggles, avoiding direct exposure to the laser beam, and keeping the workspace clean and organized.

In conclusion, building a DIY CNC Laser can be a rewarding and exciting experience for anyone interested in making things. By answering these commonly asked questions, we hope to have provided some useful insights for beginners and enthusiasts alike.

Things to Consider When Purchasing DIY CNC Laser

If you’re thinking about getting into the world of CNC laser cutting and engraving, investing in a DIY CNC laser is a great choice. Not only can you create amazing projects, but you can also save money by doing it yourself. However, before you jump in and make a purchase, there are a few things to consider.

First and foremost, you need to make sure you’re getting the right size machine for your needs. If you’re only looking to do small projects, a smaller machine will do just fine, but if you’re planning on tackling bigger projects, you’ll want to invest in a larger machine.

Next, you’ll want to consider the type of laser cutter you want. There are two main types: CO2 lasers and fiber lasers. CO2 lasers are typically used for engraving and cutting through thicker materials, while fiber lasers are better suited for cutting thinner materials.

Another important factor is the software the machine runs on. You’ll want to make sure the software is user-friendly and has all the features you need to create your designs. Additionally, consider the level of support that comes with the machine and the availability of tutorials and online resources.

Another thing to consider is the level of assembly required. Some machines require a lot of assembly, while others come mostly pre-assembled. Think about how much time you are willing to dedicate to assembly, and make sure the machine you choose is realistic for your level of skill and patience.

Lastly, don’t forget to consider the cost. While you can save money by going with a DIY machine, they can still be expensive. Make sure you have a budget in mind and that the machine you choose is within your price range.

In conclusion, when purchasing a DIY CNC laser, consider the machine’s size and power, the type of laser cutter, the software, assembly level, and cost. With these factors in mind, you can make an informed decision and start creating amazing projects with your new machine.

Properties of DIY CNC Laser

A CNC laser machine can be a costly investment for many people. However, it is now possible to build one yourself with some basic tools and electronic components. In this article, we will discuss the properties of a DIY CNC laser and how it compares to a commercially available machine.

The first property of a DIY CNC laser is its cost-effectiveness. As mentioned earlier, commercial CNC laser machines can be expensive, and not everyone can afford them. Building a CNC laser machine yourself can save you a lot of money. Although the cost of building a DIY CNC laser machine can vary depending on the quality of components you use, it will still be much cheaper than buying a commercial machine.

The second property is its versatility. DIY CNC laser machines can be designed and customized based on the user’s specific needs. You can build a CNC laser for cutting and engraving different materials such as wood, acrylic, leather, and more. You can also choose the bed size, laser power, and other components that suit your needs.

The third property is the level of control offered by a DIY CNC laser. A CNC laser machine allows you to control the laser’s movement, speed, and depth of cut through a programmed set of instructions. A DIY CNC laser machine gives you complete control over these parameters so that you can create accurate and precise cuts and engravings.

Finally, a DIY CNC laser machine is an excellent learning tool. Building a CNC laser machine from scratch is a great project for people looking to learn about electronics and mechanics. It also provides an opportunity to experiment and troubleshoot different problems.

In conclusion, a DIY CNC laser machine is cost-effective, versatile, offers complete control, and can serve as an excellent learning tool. While it may not be as powerful or efficient as a commercial CNC laser machine, it still provides many benefits to hobbyists and those on a budget.

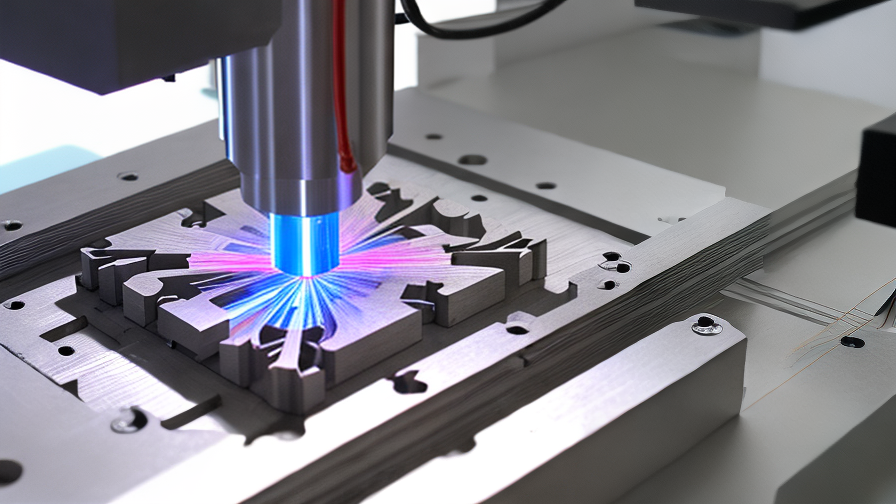

Technical Parameters Terms for DIY CNC Laser

When it comes to building and running your own CNC laser machine, understanding the technical parameters is crucial. There are several key terms that you need to be familiar with in order to properly set up and operate your DIY CNC laser.

First and foremost, you’ll need to understand laser power. This refers to the amount of energy output by the laser, measured in watts. The power of your laser will determine the thickness and type of materials that you can cut or engrave.

Another important technical parameter is the wavelength of the laser, which is measured in nanometers. This refers to the color of the laser and will affect its ability to penetrate different materials.

Next, you should familiarize yourself with the pulse duration or pulse width, which is the amount of time that the laser is turned on during each pulse. This parameter is important for controlling the depth of engraving and the precision of cutting.

The repetition rate is another crucial technical parameter. This refers to the number of laser pulses per second. A higher repetition rate will result in faster cutting speeds but may sacrifice precision.

Finally, you’ll need to understand the spot size, which is the size of the laser beam on the material being cut or engraved. This is determined by the focal length of the laser lens and will affect the level of detail and precision in your work.

By understanding these technical parameters, you’ll be better equipped to build and operate your own DIY CNC laser machine. Keep in mind that there are many other factors to consider as well, such as cooling systems and safety features, but these parameters are a good place to start.

In conclusion, building your own DIY CNC laser can be a rewarding and enjoyable project. However, it is important to take the time to understand the technical parameters in order to make the most of your machine and achieve the results you desire.

DIY CNC Laser Price

When it comes to CNC (Computer Numerical Control) machines, laser cutters have been garnering more and more interest in the DIY community. While CNC laser machines may seem expensive, DIY enthusiasts and small business owners can build one at a lower price than expected.

The cost of building a DIY CNC laser machine depends on the quality of parts used, which can cost anywhere from $500 to $2,000. Key components for a basic build include a laser diode module, stepper motors, a motor controller board, a power supply, and a CNC controller.

The laser diode is the most important component, responsible for cutting the material. Prices for laser diodes vary depending on wattage, and higher wattage diodes will give more power for cutting. However, higher wattage diodes can be more costly. Some laser hobbyists opt for low-power diodes that can be more affordable while some opt for high-power diodes that cost more but deliver better cutting capacity.

Motor controllers and power supplies are also essential in the creation of a CNC laser machine.

Depending on the type of motor, stepper motors can range between $20 and $100 per motor, while motor controller boards can vary from $20 to $200. The power supply for the motor and the laser may cost between $30 and $200.

Finally, CNC controllers, used to control the movements of the machine, can be purchased or made from scratch. Building this from scratch will take more time but will save on costs. Prices vary, but a DIY Mill Controller Board can cost between $20 and $60.

It’s important to note that while the cost of building a DIY CNC laser machine can be lower than buying a pre-made one, it may take more time to build and require a lot of patience in the process. However, making one’s own CNC laser machine can be a very satisfying experience, especially when seeing it come to fruition.

In summary, building a DIY CNC laser machine is possible for those willing to put in the effort and research. Prices may vary depending on the quality of parts used, but it sure can be a great way to save some money while still having access to a powerful tool.