Introduce about diy overhead crane guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

DIY Overhead Crane Guide:

DIY overhead cranes have become increasingly popular among individuals and small businesses looking for cost-effective lifting solutions. This guide aims to provide essential information about DIY overhead cranes, including quality, cost, suppliers, certifications, the market, tips, and frequently asked questions.

Quality:

The quality of a DIY overhead crane is crucial for the safety and efficiency of its operation. It is essential to invest in high-quality materials, such as sturdy steel beams, reliable hoists, and durable trolleys. Ensuring proper installation and maintenance will further enhance the crane’s quality and longevity.

Cost:

Compared to professionally installed overhead cranes, DIY options can offer significant cost savings. By eliminating installation expenses and having the ability to source affordable materials, building a DIY overhead crane can be a budget-friendly alternative.

Suppliers:

Various suppliers offer components and kits specifically designed for DIY overhead crane assembly. These suppliers specialize in providing the necessary parts, from beam sections to hoists, allowing you to create a tailored crane system that meets your lifting needs.

Certification:

Certification is not typically required for DIY overhead cranes, as they are not considered commercial-grade machinery. However, adhering to local safety regulations and guidelines is imperative to maintain a safe working environment.

Market:

The market for DIY overhead cranes has been growing steadily, catering to individuals, hobbyists, and small businesses seeking affordable lifting solutions. This trend has led to an increase in the availability and variety of DIY overhead crane components and kits.

Tips:

– Before starting your DIY overhead crane project, carefully assess your lifting requirements and workspace limitations.

– Take accurate measurements and consult with suppliers to ensure you purchase the appropriate components for your crane system.

– Follow assembly instructions meticulously, and if in doubt, seek professional advice to ensure the crane’s structural integrity and safety.

– Regularly inspect and maintain your DIY overhead crane to identify any potential issues and address them promptly.

FAQ:

Q: Can I modify an existing structure to accommodate a DIY overhead crane?

A: It is possible to retrofit an existing structure if it possesses sufficient load-bearing capacity and meets safety criteria. Consult a structural engineer or professional installer for guidance.

Q: Are DIY overhead cranes suitable for heavy-duty applications?

A: While DIY overhead cranes can handle moderate loads, heavy-duty applications typically require professionally designed and installed overhead cranes.

In conclusion, DIY overhead cranes offer a cost-effective solution for individuals and small businesses seeking lifting capabilities. By focusing on quality, sourcing from reliable suppliers, adhering to safety regulations, and following the provided tips, one can successfully build and operate a DIY overhead crane.

Types of diy overhead crane

There are various types of DIY overhead cranes that you can build depending on your specific needs and budget. Here are some common types:

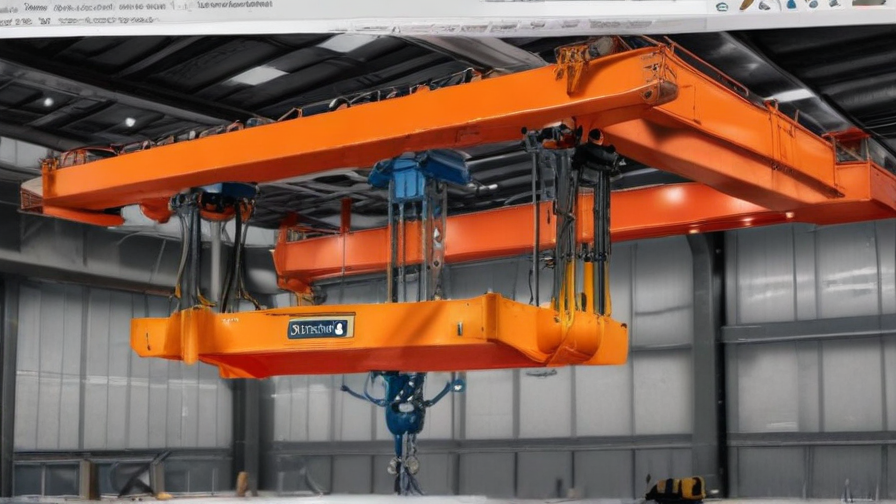

1. Single Girder Overhead Crane: This is the most common and cost-effective type of overhead crane. It consists of a single bridge beam supported by two end trucks, which are responsible for moving the crane along the runway. A hoist is attached under the bridge beam to lift and lower the load.

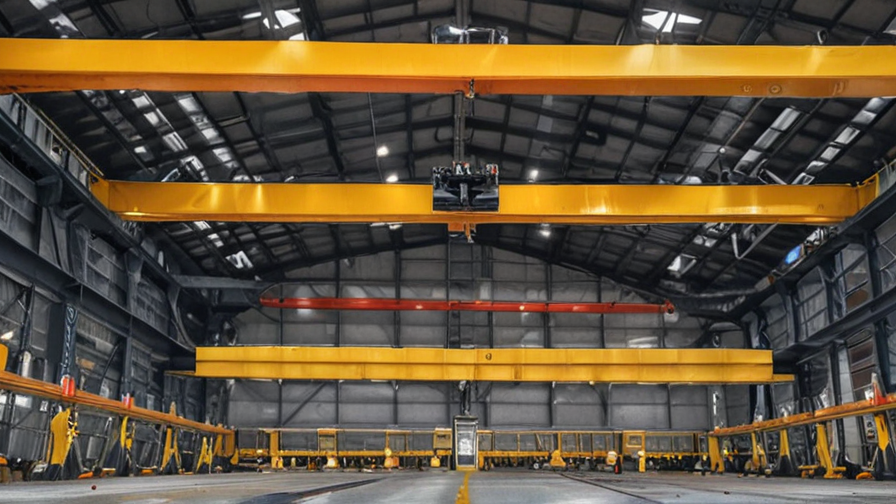

2. Double Girder Overhead Crane: This type of crane has two bridge beams supported by end trucks. Double girder cranes offer higher lifting capacities and greater stability compared to single girder cranes. They are suitable for heavy-duty applications where precision and efficiency are required.

3. Gantry Crane: Gantry cranes are similar to overhead cranes, but they are supported by legs or wheels instead of being installed on a runway. These cranes are typically used in outdoor settings or in areas where a permanent installation is not possible. Gantry cranes are versatile and can be used for various applications.

4. Jib Crane: A jib crane is a type of DIY overhead crane that consists of a horizontal jib or boom that supports a hoist or other lifting device. It is typically mounted on a wall or pillar to provide 180 or 360-degree rotation. Jib cranes are used for lifting and moving objects in a specific area, making them ideal for smaller workspaces.

5. Mobile Gantry Crane: This type of crane is equipped with wheels, allowing it to be easily moved around a workshop or job site. Mobile gantry cranes provide flexibility and convenience when working on different projects or areas within a facility. They are commonly used for maintenance, repair, and assembly tasks.

When building a DIY overhead crane, it is essential to consider your specific requirements, such as lifting capacity, span, and height. Additionally, keep in mind safety regulations and guidelines to ensure that your crane is constructed properly to prevent accidents or damage. It is recommended to consult professional engineers or crane manufacturers to ensure a well-designed and safe DIY overhead crane.

Pros and Cons of Using diy overhead crane

Using a DIY overhead crane can have both pros and cons, and it is important to consider these before deciding to use one. Here are some of the main advantages and disadvantages:

Pros:

1. Cost-effective: Building a DIY overhead crane can be more affordable compared to buying a pre-made crane. This can be especially beneficial for individuals or businesses operating on a tight budget.

2. Customization: By building your own overhead crane, you have the opportunity to customize it according to your specific needs and requirements. This can include adjusting the lifting capacity, size, and even features such as remote control operation.

3. Learning experience: Building a DIY overhead crane can be a valuable learning experience, allowing you to develop skills in engineering, fabrication, and assembly. This can be particularly useful for individuals interested in a career in mechanical or structural engineering.

4. Accessibility: Pre-made overhead cranes may not always be readily available in all locations. By building your own crane, you can have access to a lifting solution without needing to wait for delivery or rely on a supplier.

Cons:

1. Safety risks: Building and operating a DIY overhead crane can pose significant safety risks if not done correctly. Lifting heavy loads requires proper engineering, knowledge of load capacity, and adherence to safety protocols. Without proper training, accidents can occur, leading to property damage, injuries, or even fatalities.

2. Lack of warranty: Unlike pre-made cranes that come with warranties, DIY overhead cranes do not offer the same level of assurance. If something goes wrong or if the crane malfunctions, you don’t have the same level of customer support or protection.

3. Time-consuming: Building a DIY overhead crane can be time-consuming, especially if you lack experience or the necessary tools. It may require a significant investment in time and effort, which may not be feasible for everyone.

4. Expertise and knowledge required: Building a safe and functional DIY overhead crane requires a certain level of expertise and knowledge in engineering and fabrication. Without adequate skills or access to expert guidance, you may encounter difficulties or produce a subpar crane.

In conclusion, using a DIY overhead crane can offer advantages such as cost-effectiveness, customization, and a valuable learning experience. However, it also comes with risks and challenges, including safety concerns, warranty limitations, time consumption, and the need for expertise. Therefore, it is crucial to weigh the pros and cons carefully before deciding whether to use a DIY overhead crane.

diy overhead crane Reference Specifications (varies for different product)

When it comes to DIY overhead cranes, there are certain reference specifications that vary depending on the specific product being used.

One important aspect is the lifting capacity of the crane. Different DIY overhead cranes have different weight capacities, which determine the maximum load they can lift. The lifting capacity can range from a few hundred pounds to several tons, depending on the specific product. It is crucial to select a crane with a lifting capacity that meets the requirements of the intended application.

Another specification to consider is the span of the crane. This refers to the horizontal distance between the runway rails or supporting structures. DIY overhead cranes come in various span lengths, and it is essential to choose a crane that fits within the available space.

The hoisting height is another reference specification to consider. This refers to the vertical distance that the crane can lift the load. DIY overhead cranes come with different hoisting heights, which must be chosen according to the application requirements and the available vertical space.

The travel length is also an important factor to consider. This refers to the distance the crane can travel along the rails or supporting structure. DIY overhead cranes can have various travel lengths, and selecting the appropriate one is important to ensure sufficient coverage within the workspace.

Furthermore, the lifting speed is another specification to take into account. This determines how quickly the crane can lift or lower the load and is typically measured in feet per minute or meters per minute. The lifting speed should match the requirements of the application to ensure efficient operations.

Additionally, safety features such as limit switches, overload protection, and emergency stop buttons should be considered when selecting a DIY overhead crane.

It is crucial to consult the product-specific documentation and guidelines to ensure safe and proper installation, maintenance, and operation of the DIY overhead crane. Always follow the manufacturer’s recommendations and guidelines to ensure optimum performance and safety.

Applications of diy overhead crane

DIY overhead cranes are versatile tools that can be used in a variety of applications. They are commonly used in workshops, garages, warehouses, and other industrial settings to lift and move heavy objects.

One of the main applications of a DIY overhead crane is in automotive workshops. These cranes are ideal for lifting engines, transmissions, and other heavy car parts. Mechanics can easily position the crane over the car and use it to lift and remove the engine for repair or replacement. It eliminates the need for multiple workers and increases efficiency in the workspace.

In addition to automotive workshops, DIY overhead cranes are also commonly used in construction sites. They can transport construction materials such as steel beams, concrete blocks, and scaffolding with ease. The versatility of these cranes allows workers to maneuver heavy materials to different areas of the construction site quickly and safely.

Another application of DIY overhead cranes is in warehouses and distribution centers. These cranes are used to lift and transport heavy items such as pallets, crates, and machinery. They can be equipped with hooks, forks, or grabbers to securely hold the load during transportation. This reduces the risk of injuries caused by manual lifting and increases the efficiency of the warehouse operations.

DIY overhead cranes also find applications in manufacturing industries. They can be used to move heavy machinery and equipment within the production line. By using an overhead crane, workers can easily lift and position heavy components, ensuring accurate and efficient assembly. This reduces the strain on workers and minimizes the risk of damage to the equipment.

Moreover, DIY overhead cranes are beneficial in shipyards and ports. They are used to load and unload heavy cargo from ships onto trucks or vice versa. These cranes can lift containers, machinery, and other heavy items, making the loading and unloading process more efficient and time-saving.

In conclusion, DIY overhead cranes have a wide range of applications in different industries. They are versatile tools that can lift and transport heavy objects effectively. From automotive workshops to construction sites, warehouses to manufacturing industries, and shipyards to ports, these cranes provide numerous benefits, including increased efficiency, improved safety, and reduced manpower requirements.

The Work Process and how to use diy overhead crane

The work process of using a DIY overhead crane is relatively simple, especially when following the appropriate safety measures. Here is a step-by-step guide on using a DIY overhead crane:

1. Preparation: Before operating the crane, ensure that it is set up on a level and stable surface. Inspect all components, including the hoist, trolley, and cables, for any signs of damage or wear. Make sure the area is clear of any obstructions, and establish a safe working zone.

2. Load assessment: Determine the weight and dimensions of the load to be lifted. Ensure that the crane’s capacity is sufficient for the intended lift. Always avoid lifting loads that exceed the crane’s rated capacity.

3. Attach the load: Use appropriate slings, chains, or hooks to securely attach the load to the crane’s lifting hook. Ensure that the load is evenly balanced and centered beneath the hook to prevent any potential issues during the lift.

4. Lifting procedure: Stand at a safe distance from the crane, ensuring that you have a clear line of sight. Use the controls to slowly and smoothly lift the load off the ground. Maintain a controlled speed throughout the lift to prevent swinging or sudden movements.

5. Traveling with the load: Once the load is airborne, use the crane controls to maneuver it to the desired location. Ensure that there are no obstacles in the path and maintain a slow and steady pace.

6. Lowering the load: Carefully and gradually lower the load to the designated spot using the crane controls. Make sure to maintain control and prevent any sudden movements that could cause damage or injury.

7. Post-operation: After completing the lift, carefully return the crane to its original position, ensuring that all control buttons are released and power is switched off. Inspect the crane and its components again for any signs of damage or wear.

It is crucial to prioritize safety at all times when operating a DIY overhead crane. Make sure you are familiar with the crane’s user manual and follow the manufacturer’s guidelines precisely. If in doubt, seek guidance from professionals or consult an experienced operator.

Quality Testing Methods for diy overhead crane and how to control the quality

When it comes to the quality testing of a DIY overhead crane, there are several methods that can be employed to ensure its reliability and safety. These methods focus on testing various aspects of the crane’s construction and functionality.

One common method is visual inspection, where the crane is thoroughly examined to identify any visible defects or anomalies. This includes checking for structural integrity, proper alignment of components, and absence of any damages or signs of wear.

Load testing is another important quality testing method. It involves applying heavy loads to the crane to ensure its capacity meets the intended requirements and specifications. This test helps determine if the crane can safely lift and move loads of a certain weight without any failures, such as structural deformation or component breakage.

Functional testing is also crucial. It involves testing the crane’s various functions, such as hoisting, lowering, trolley movement, and crane travel, to ensure they operate smoothly and efficiently. This can be done by simulating different scenarios that the crane might encounter during its operation.

Furthermore, non-destructive testing methods can be used to assess the integrity of the crane’s structural components without causing damage. These methods include ultrasonic testing, magnetic particle inspection, and dye penetrant testing, which can detect any internal defects or material flaws that may affect the crane’s performance.

To control the quality of the DIY overhead crane, it is important to follow relevant industry standards and specifications during the construction process. Strict adherence to design plans and manufacturer guidelines is crucial. Quality control can be enhanced by conducting regular inspections during the assembly, installation, and commissioning stages. Any identified deviations or discrepancies should be promptly addressed and corrected.

Additionally, ensuring proper training and qualification of the personnel involved in the DIY overhead crane construction is crucial. This includes their knowledge of safety procedures, regulations, and proper use of tools and equipment. Ongoing maintenance and periodic inspections are essential to detect any potential issues early on and prevent them from escalating into major problems.

In conclusion, quality testing methods for a DIY overhead crane include visual inspection, load testing, functional testing, and non-destructive testing. Following industry standards, conducting regular inspections, and ensuring proper training of personnel are key factors in controlling the quality of the crane. These measures help ensure that the DIY overhead crane operates safely and efficiently.

diy overhead crane Sample Policy and Post-Purchase Considerations for diy overhead crane from China

Sample Policy:

1. Quality Assurance: Ensure that the diy overhead crane from China meets national and international quality standards, such as ISO and CE certifications. Request detailed technical specifications and documentation to confirm the product’s quality.

2. Warranty: Check for warranty coverage and duration, including provisions for after-sales service and support. Ensure that spare parts availability and maintenance services are provided by the manufacturer or supplier.

3. Customization: Discuss the possibility of customization based on specific requirements, such as lifting capacity, span, and lifting height. Ensure that any customization does not compromise safety or quality.

4. Delivery and Shipment: Discuss the delivery timeframe and shipping arrangements, including packaging and insurance coverage. Clarify any additional costs involved in the shipping process.

5. Payment Terms: Establish clear payment terms, such as deposit, progress payments, and final payment upon product acceptance. Consider using methods like letters of credit to ensure secure transactions.

6. Documentation: Request all necessary documentation, including invoice, packing list, bill of lading, and import/export compliance documents for customs clearance.

7. Dispute Resolution: Establish procedures for resolving disputes, such as arbitration or mediation, should any issues arise during the purchasing process.

Post-Purchase Considerations:

1. Inspect the Crane: Upon receiving the diy overhead crane, thoroughly inspect it for any damages or missing parts. Test its functionality and ensure it meets the specifications and requirements agreed upon.

2. Installation and Commissioning: Follow the manufacturer’s instructions for proper installation and commissioning of the crane. Consider hiring professional technicians if required.

3. Operator Training: Provide adequate training to the crane operators to ensure safe and efficient operation. This training may include understanding the controls, load capacity, and safety protocols.

4. Regular Maintenance: Adhere to the manufacturer’s recommended maintenance schedule to keep the crane in optimal working condition. This will prevent breakdowns and ensure prolonged lifespan.

5. Supplier Relationship: Establish a good working relationship with the supplier or manufacturer. Regular communication and feedback can help address any issues that may arise and facilitate future purchase or support.

6. Stay Informed: Keep up-to-date with industry standards, regulations, and safety guidelines. This will allow for continuous improvement in crane operations and safety.

7. Share Feedback: Provide feedback to the supplier or manufacturer, both positive and negative, to help improve their products and services. This also helps future buyers make informed decisions.

Remember, conducting due diligence, communication, and following proper procedures are crucial when purchasing a diy overhead crane from China to ensure a smooth buying process and a quality product.

Sourcing diy overhead crane from China: Opportunities, Risks, and Key Players

Sourcing a DIY overhead crane from China can offer several opportunities for businesses and individuals. China is known for its manufacturing capabilities and cost-effective production, making it an attractive option for those looking to purchase cranes at a lower price point. The abundance of suppliers and competition in the Chinese market also opens up possibilities for customization and negotiation, allowing buyers to tailor the crane to their specific needs.

However, there are also risks associated with sourcing from China. One major concern is the quality of the product. While there are reputable manufacturers in China, there are also instances of subpar or counterfeit products being sold. It is essential to conduct thorough research and due diligence to ensure the reliability and authenticity of the supplier and the product. Another risk is the potential language and communication barriers, which can cause misunderstandings or delays in the procurement process.

Several key players in the Chinese market offer DIY overhead crane options. One prominent company is Henan Dongqi Machinery Co., Ltd, known for its expertise in manufacturing and supplying various types of cranes. They offer customization options and prioritize customer satisfaction. Another notable player is Nucleon Crane Group, specializing in the production and supply of overhead cranes and providing comprehensive after-sales services. China’s Sinoko Cranes is also a reputable manufacturer that offers a wide range of cranes, including DIY overhead crane solutions, with an emphasis on product quality and reliability.

In conclusion, while sourcing a DIY overhead crane from China presents opportunities for cost-effective customization and negotiation, it is important to exercise caution and thoroughly research potential suppliers. The risks associated with product quality and communication barriers must be mitigated to ensure a successful procurement process. Key players in the Chinese market, such as Henan Dongqi Machinery Co., Ltd, Nucleon Crane Group, and Sinoko Cranes, offer reliable options for sourcing DIY overhead cranes.

How to find and select reliable diy overhead crane manufacturers in China,use google search manufacturers and suppliers

When searching for reliable DIY overhead crane manufacturers in China, using Google search can be an effective strategy. Here are some steps to follow:

1. Keyword search: Begin by using relevant keywords such as “DIY overhead crane manufacturers in China” or “reliable DIY crane suppliers in China” on Google. This will help you identify a list of potential manufacturers and suppliers in China.

2. Narrow down the options: Go through the search results and visit the websites of different manufacturers. Look for information regarding the company’s experience, certifications, product range, and customer reviews. Focus on manufacturers that have a good reputation and positive customer feedback.

3. Check their manufacturing capabilities: Look for information on the manufacturer’s website about their production facilities, equipment, and quality control measures. A manufacturer with advanced manufacturing capabilities and strict quality control processes would be more reliable.

4. Product certification: Check if the manufacturer has relevant certifications such as ISO 9001, CE, or other international standards. These certifications indicate that the manufacturer meets specific quality standards and regulations.

5. Contact the manufacturer: Reach out to the shortlisted manufacturers and suppliers to inquire about their products, lead time, pricing, and customization options. Pay attention to their response time and professionalism. A reliable manufacturer will provide clear and detailed information.

6. Request samples or visit the factory: If possible, request samples or visit the manufacturer’s factory to assess the quality of their products and get a better understanding of their production processes. This will help you make an informed decision.

7. Consider customer reviews and recommendations: Look for customer reviews on the manufacturer’s website, social media platforms, and other online forums. Positive reviews and recommendations from other customers can help validate the manufacturer’s reliability.

By following these steps, you can find and select reliable DIY overhead crane manufacturers in China. Remember to conduct thorough research, compare multiple manufacturers, and make a well-informed decision based on their credibility, manufacturing capabilities, and customer reviews.

How to check diy overhead crane manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

When it comes to checking the reliability of a DIY overhead crane manufacturer’s website, there are a few steps you can take. One method is to use Google Chrome’s SEOquake extension to evaluate the website’s ranking. Here is a step-by-step guide to using this tool and ensuring that you stay within the specified word limit:

1. Install SEOquake: Open Google Chrome and go to the Chrome Web Store. Search for “SEOquake” and click on the “Add to Chrome” button to install the extension.

2. Enable SEOquake: Once installed, you should see the SEOquake icon in the top-right corner of your browser. Click on it to activate the extension.

3. Visit the manufacturer’s website: Go to the DIY overhead crane manufacturer’s website that you want to evaluate.

4. Check the website’s ranking: On the website’s homepage, click on the SEOquake icon. A sidebar will appear on the left side of your browser window, displaying various metrics.

5. Look at the ranking: In the SEOquake sidebar, locate the “Alexa Rank” section. This will provide you with the website’s global ranking. If the website is within the top 10 million, it indicates a relatively popular and established site.

Additionally, to ensure you don’t exceed the 300-word limit, make sure to keep the explanation of each step concise and to the point. Remove any unnecessary words or phrases and focus on delivering the necessary information clearly and efficiently.

Top 10 diy overhead crane manufacturers in China with each 160 words introduce products,then use html create table compare these companies

Here are the top 10 DIY overhead crane manufacturers in China, with a brief introduction to their products:

1. Henan Dafang Heavy Machinery Co., Ltd.: Specializes in producing various types of overhead cranes, such as single girder, double girder, and electric hoists. They have a wide range of lifting capacities and customizable options to meet specific requirements.

2. Henan Weihua Heavy Machinery Co., Ltd.: Offers a comprehensive range of overhead cranes, including bridge cranes, gantry cranes, and explosion-proof cranes. Their products are widely used in factories, warehouses, and construction sites.

3. Nucleon (Xinxiang) Crane Co., Ltd.: Produces crane equipment for various industries, such as steel mills, power plants, and shipyards. They provide high-quality overhead cranes with advanced technology and efficient performance.

4. Shandong Mingdao Heavy Industry Machinery Co., Ltd.: Specializes in manufacturing European-style overhead cranes that conform to international standards. Their products are known for their reliability, safety, and durability.

5. Zhejiang Kaidao Hoisting Machinery Co., Ltd.: Provides a wide range of overhead cranes, including double girder, single girder, and explosion-proof cranes. They offer advanced technology and reliable performance at competitive prices.

6. Liaoning Kino Heavy Machinery Co., Ltd.: Produces various types of overhead cranes, such as bridge, gantry, and jib cranes. Their products are widely used in industries like metallurgy, ports, and logistics.

7. Chongqing Shanyan Crane Machinery Co., Ltd.: Specializes in the manufacturing of European-style overhead cranes. They offer customized solutions for different lifting requirements, ensuring efficiency and safety.

8. Xinxiang Yuntian Crane Co., Ltd.: Provides a wide range of overhead cranes, including double girder, single girder, and underslung cranes. Their products are known for their high performance, low maintenance, and long service life.

9. Jiangsu Jiali Hoisting Machinery Manufacturing Co., Ltd.: Offers various types of overhead cranes, including single girder, double girder, and explosion-proof cranes. They focus on providing reliable and efficient lifting solutions.

10. Shanxi Qiulin Machinery Co., Ltd.: Specializes in the manufacturing of heavy-duty overhead cranes for industries like power plants, steel mills, and warehouses. They offer customized designs and excellent after-sales service.

Using HTML, here’s a comparative table of these crane manufacturers:

| Company | Specialization | Product Range | Notable Features |

|---|---|---|---|

| Henan Dafang Heavy Machinery Co., Ltd. | Various types of overhead cranes | Single girder, double girder, electric hoists | Wide range of lifting capacities, customization options |

| Henan Weihua Heavy Machinery Co., Ltd. | Comprehensive range of overhead cranes | Bridge cranes, gantry cranes, explosion-proof cranes | Wide usage in factories, warehouses, and construction sites |

| Nucleon (Xinxiang) Crane Co., Ltd. | Cranes for various industries | Bridge cranes, gantry cranes | High-quality, advanced technology |

| Shandong Mingdao Heavy Industry Machinery Co., Ltd. | European-style overhead cranes | Customizable options, reliable performance | Reliability, safety, and durability assurance |

| Zhejiang Kaidao Hoisting Machinery Co., Ltd. | Wide range of overhead cranes | Double girder, single girder, explosion-proof cranes | Advanced technology, competitive prices |

| Liaoning Kino Heavy Machinery Co., Ltd. | Cranes for various industries | Bridge cranes, gantry cranes, jib cranes | Widely used in metallurgy, ports, logistics |

| Chongqing Shanyan Crane Machinery Co., Ltd. | European-style overhead cranes | Customized solutions | Efficiency and safety focus |

| Xinxiang Yuntian Crane Co., Ltd. | Wide range of overhead cranes | Double girder, single girder, underslung cranes | High performance, low maintenance |

| Jiangsu Jiali Hoisting Machinery Manufacturing Co., Ltd. | Various types of overhead cranes | Single girder, double girder, explosion-proof cranes | Reliable and efficient lifting solutions |

| Shanxi Qiulin Machinery Co., Ltd. | Heavy-duty overhead cranes | Customized designs | Excellent after-sales service |

In a concise manner, the table provides an overview of these top 10 Chinese DIY overhead crane manufacturers, highlighting their specializations, product ranges, and notable features.

Background Research for diy overhead crane manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to DIY overhead crane manufacturers in China, companies can explore different resources such as QCC.com, Archive.org, and Importyeti.com for background research. These platforms provide valuable information about manufacturers, their products, and their services.

QCC.com is a business information search engine that allows users to search for specific companies and provides details about their background, legal status, business scope, and contact information. Companies looking for DIY overhead crane manufacturers in China can utilize this platform to obtain important details about potential manufacturers, such as their establishment date, company size, and relevant certifications.

Archive.org, on the other hand, is a digital library that offers access to a wide range of archived websites. By using this platform, companies can explore the historical information of DIY overhead crane manufacturers in China, including their website content, product catalogs, and company profiles. This enables them to assess the manufacturers’ growth over time and evaluate their capability to meet quality standards.

Another valuable resource for background research is Importyeti.com. This platform provides import and export data, allowing companies to analyze trade activities of DIY overhead crane manufacturers in China. Companies can obtain information about the manufacturers’ export destinations, shipment quantities, and shipment frequency on this platform. This data helps assess the manufacturers’ experience, reliability, and global reach.

Through these resources, companies can gather detailed information about DIY overhead crane manufacturers in China, including their general business information, historical performance, and trade activities. This information plays a crucial role in identifying potential manufacturers, evaluating their capabilities, and making informed decisions when selecting a suitable supplier.

Leveraging Trade Shows and Expos for diy overhead crane Sourcing in China

Trade shows and expos serve as valuable platforms for businesses seeking to source DIY overhead cranes from China. These events provide an opportunity to explore a wide range of suppliers, compare product offerings, and establish partnerships with reliable manufacturers.

China is known for its strong manufacturing capabilities and cost-effective solutions, making it an attractive destination for sourcing DIY overhead cranes. By attending trade shows and expos in China, businesses gain access to a diverse pool of suppliers and can discover new and innovative products in the market.

One of the key advantages of trade shows is the ability to see and evaluate products firsthand. Exhibitors showcase their DIY overhead cranes, allowing businesses to assess their quality, functionality, and design. It also provides an opportunity to ask specific questions, get detailed information, and request product demonstrations. This firsthand experience helps in making informed decisions about potential suppliers and their offerings.

Furthermore, trade shows offer a valuable networking platform. Businesses can interact with multiple suppliers, exchange contact information, and establish relationships for future collaborations. These interactions not only facilitate the sourcing process but also enable businesses to negotiate better terms, discuss customization options, and explore potential cost-saving opportunities.

In addition to sourcing options, trade shows and expos often feature seminars, workshops, and industry-specific conferences. These events provide insights into the latest trends, technologies, and regulatory developments in the DIY overhead crane market. Attendees can gain valuable knowledge, connect with industry experts, and stay ahead of the competition.

To make the most of these opportunities, businesses planning to source DIY overhead cranes in China should thoroughly research and select relevant trade shows and expos. Preparing a list of targeted suppliers, setting meeting appointments in advance, and being equipped with specific requirements and queries will maximize the benefits of attending these events.

In conclusion, trade shows and expos in China offer an ideal platform for businesses looking to source DIY overhead cranes. These events provide firsthand product evaluation, networking opportunities, access to industry insights, and the chance to establish long-term partnerships. By leveraging these platforms effectively, businesses can find reliable suppliers and cost-effective solutions for their DIY overhead crane needs.

The Role of Agents and Sourcing Companies in Facilitating diy overhead crane Purchases from China

Agents and sourcing companies play a significant role in facilitating DIY overhead crane purchases from China. China has long been regarded as a global manufacturing hub, providing a wide range of products at competitive prices. However, navigating the Chinese market can be complex and challenging, especially for individuals or small businesses looking to purchase overhead cranes on their own.

Agents and sourcing companies act as intermediaries between buyers and Chinese manufacturers, streamlining the purchasing process and ensuring a smooth transaction. These professionals possess extensive knowledge of the Chinese market, including a deep understanding of local manufacturers, their capabilities, and product offerings.

One of the primary roles of agents and sourcing companies is to help buyers identify reputable manufacturers in China. They have established networks and connections with trusted suppliers, enabling them to select reliable and experienced manufacturers that meet the buyer’s specific requirements. This eliminates the risk of dealing with fraudulent or inexperienced manufacturers, ensuring the procurement of high-quality overhead cranes.

Additionally, agents and sourcing companies assist buyers in negotiating the best prices and payment terms with manufacturers. They possess strong bargaining skills and market knowledge, allowing them to obtain favorable terms and competitive pricing on behalf of the buyer. This enables buyers to secure the best possible deal for their DIY overhead crane purchase.

Agents and sourcing companies also handle the logistics and export process, ensuring that the purchased crane is shipped safely and efficiently to the buyer’s desired location. They handle all necessary documentation, customs clearance, and transportation arrangements, simplifying an otherwise complicated process for the buyer.

Overall, agents and sourcing companies serve as valuable intermediaries, bridging the gap between buyers and manufacturers in China. Their expertise, connections, and guidance enable individuals and small businesses to navigate the Chinese market confidently, facilitating the successful purchase of DIY overhead cranes at competitive prices.

Price Cost Research for diy overhead crane manufacturers Companies in China, use temu.com and 1688.com

When it comes to purchasing a DIY overhead crane from manufacturers in China, conducting price cost research becomes crucial to ensure a cost-effective and reliable purchase. Two websites, temu.com and 1688.com, can be valuable resources for finding suitable manufacturers and assessing the pricing.

Temu.com is a prominent online marketplace that connects buyers with verified suppliers in China. By utilizing this platform, one can explore several manufacturers specializing in overhead cranes. Moreover, temu.com provides comprehensive product information, supplier ratings, customer reviews, and even allows direct communication with the sellers. This facilitates a transparent and efficient procurement process, as buyers can inquire about pricing, customization options, and negotiate directly with the manufacturers.

Another valuable online marketplace to consider is 1688.com. Launched by Alibaba Group, this platform primarily serves the Chinese domestic market. It features a vast selection of products, including DIY overhead cranes, directly from Chinese manufacturers. This website offers product listings in Chinese, making it necessary to use translation tools such as Google Translate or seek assistance from a Chinese-speaking colleague. Despite the language barrier, 1688.com offers competitive prices due to the direct access to local manufacturers and eliminates the intermediary costs.

While exploring these platforms, buyers should focus on evaluating the price-cost ratio to ensure they are obtaining the best value for their investment. Factors to consider include the quality of materials used, crane load capacity, lifting height, and the overall durability of the product. Additionally, scrutinizing the after-sales support, warranty policies, and any additional services provided by the manufacturers are also crucial considerations to evaluate the true cost of the crane.

Finally, it is important to note that while researching the pricing on these platforms, buyers can also explore other means of sourcing overhead crane manufacturers in China. Trade shows and exhibitions, online forums, and referrals from industry professionals can provide additional options for finding reliable and cost-effective suppliers.

Overall, conducting price cost research using platforms like temu.com and 1688.com can help buyers make informed decisions when purchasing DIY overhead cranes from Chinese manufacturers. Attention to detail, thorough evaluation, and effective communication with suppliers will ensure a successful procurement process.

Shipping Cost for diy overhead crane import from China

The shipping costs for importing a DIY overhead crane from China can vary depending on several factors such as the size and weight of the crane, the shipping method chosen, and the destination country. Generally, there are two main shipping methods for transporting goods from China: air freight and sea freight.

Air freight is the faster option, but it is also more expensive. For a DIY overhead crane, the cost will largely depend on its dimensions and weight. Typically, air freight charges are calculated based on either the actual weight (whichever is higher) or the volumetric weight, whichever is greater. The volumetric weight is determined by the size of the package and is calculated by multiplying the length, width, and height.

On the other hand, sea freight is a more economical option for larger, heavier shipments. The cost of sea freight is primarily determined by the volume or cubic meter (CBM) of the cargo. The shipping cost usually includes various charges such as origin charges, freight charges, destination charges, and customs clearance fees.

To estimate the shipping cost, it is important to provide the shipping company with detailed information about the overhead crane, including its weight, dimensions, and destination. Additionally, factors such as packaging, insurance, and any other additional services required should be taken into account.

In conclusion, determining the exact shipping cost for a DIY overhead crane import from China would require specific details and calculations based on the chosen shipping method, size, weight, and destination. It is recommended to contact shipping companies or freight forwarders for accurate cost estimates and to inquire about any additional fees that may apply.

Compare China and Other diy overhead crane Markets: Products Quality and Price,Visible and Hidden Costs

China is one of the largest markets for diy overhead cranes, alongside other countries such as the United States, Germany, and Japan. When comparing China with these markets, several factors can be considered, including product quality and price, visible and hidden costs.

In terms of product quality, China has made significant progress over the years. Chinese manufacturers have focused on improving their production processes and the overall quality of their diy overhead cranes. However, it is important to note that there are variations in quality among different manufacturers in China. Some Chinese companies offer high-quality cranes that meet international standards, while others may produce lower-quality products. On the other hand, countries like Germany and Japan are known for their high precision engineering and reliable cranes, which often come with a higher price tag.

Price is another important aspect to consider when comparing different markets. China is known for its competitive pricing, which has allowed it to become a major player in the diy overhead crane market. Chinese manufacturers can offer cranes at a lower price due to factors such as cost-efficient production processes and lower labor costs. In contrast, countries like Germany and Japan are associated with higher-priced cranes due to their focus on precision engineering and higher labor costs.

Visible costs, such as the upfront price of diy overhead cranes, are often transparent and easily comparable. However, hidden costs can vary between markets. These costs include factors such as maintenance, spare parts availability, and after-sales service. China’s market may have lower upfront prices, but hidden costs such as maintenance and service can vary among different manufacturers. Countries like Germany and Japan usually have well-established after-sales service and readily available spare parts, but these advantages often come at a higher cost.

In conclusion, when comparing China with other markets in terms of diy overhead cranes, product quality, and price are important factors to consider. China has made significant progress in improving product quality, although variations exist between manufacturers. China’s competitive pricing has allowed it to become a major player in the market. However, hidden costs such as maintenance and after-sales service can vary among manufacturers. Comparatively, countries like Germany and Japan are known for their higher precision engineering and reliable cranes, although they often come with a higher price tag and may have well-established after-sales service.

Understanding Pricing and Payment Terms for diy overhead crane: A Comparative Guide to Get the Best Deal

When looking to purchase a DIY overhead crane, it is important to understand the pricing and payment terms to ensure getting the best deal. Here is a comparative guide to help navigate through this process.

Pricing for DIY overhead cranes can vary based on several factors, including the size, capacity, and features of the crane. It is essential to compare prices from multiple suppliers to get an idea of the market average. Online research and contacting different vendors can provide valuable insights into the prevailing rates.

Besides the upfront cost, it is crucial to consider the long-term expenses associated with the crane, such as maintenance and spare parts. Some suppliers may offer package deals including installation, training, and warranty, while others may charge additional fees for these services. It is advisable to evaluate these offerings and determine their value for the overall cost.

Payment terms also play a significant role in securing the best deal. Some suppliers may require full payment upfront, while others may offer flexible payment options, such as installment plans or financing options. It is essential to assess one’s financial capabilities and opt for a payment plan that suits their budget and cash flow.

Comparing warranties is crucial to understanding the after-sales support provided by different suppliers. A comprehensive warranty can provide peace of mind by covering repairs and replacements for specific periods. It is important to review the terms and conditions of the warranty to identify any potential limitations or exclusions.

Lastly, it is recommended to seek feedback from previous customers or industry experts to gauge the reputation and reliability of the supplier. Online reviews and testimonials can provide insights into the supplier’s responsiveness, product quality, and overall customer satisfaction.

In conclusion, understanding the pricing and payment terms for a DIY overhead crane is essential to get the best deal. Comparing prices and evaluating long-term costs and services offered by suppliers can help make an informed decision. Flexibility in payment options, comprehensive warranties, and a reputable supplier can all contribute to a successful purchase.

Chinese Regulations and Industry Standards Certifications for diy overhead crane,Import Regulations and Customs for diy overhead crane from China

When it comes to sourcing a DIY overhead crane from China, it is important to understand the Chinese regulations and industry standards certifications, as well as the import regulations and customs. Adhering to these guidelines ensures a smooth and compliant process.

Chinese Regulations and Industry Standards Certifications:

1. GB/T 14405: This standard outlines the general specifications for overhead cranes, including design, manufacturing, installation, and safety requirements.

2. GB/T 3811: This standard specifies the design rules and requirements for overhead traveling cranes.

3. GB6067: This standard covers safety rules for the construction and installation of electric equipment of cranes.

4. CE Certification: Depending on the specific requirements of the destination country, it may be necessary for the DIY overhead crane to meet CE certification standards.

Import Regulations and Customs:

1. Documentation: Importers need to provide the necessary documentation, including a commercial invoice, bill of lading, packing list, and any specific certificates or licenses required by the importing country.

2. Customs Duties: Importers must be aware of the customs duties applicable to the DIY overhead crane. These duties vary depending on the country of import and the classification of the product.

3. Customs Clearance: Importers need to submit the required documentation to customs authorities and pay any applicable customs duties and taxes to clear the goods for importation.

4. Import Restrictions: It is essential to check if there are any import restrictions or prohibitions in the destination country for DIY overhead cranes. This can include restrictions on certain materials or safety certifications.

In conclusion, when importing a DIY overhead crane from China, one must ensure compliance with Chinese regulations and industry standards certifications, as well as understanding the import regulations and customs of the destination country. Being knowledgeable about these guidelines will help streamline the import process and avoid any potential issues or delays.

Sustainability and Environmental Considerations in diy overhead crane Manufacturing

In the manufacturing of DIY overhead cranes, sustainability and environmental considerations play a crucial role in ensuring a responsible and eco-friendly production process. By incorporating sustainable practices, manufacturers can minimize the negative environmental impact while also contributing to the overall well-being of the planet.

One key area of focus is the selection of materials. Manufacturers should strive to use sustainable and recyclable materials, such as steel sourced from responsible suppliers. This reduces the carbon footprint associated with the production process and prevents the depletion of natural resources.

Energy efficiency is another vital aspect to consider. Manufacturers can adopt energy-saving technologies and practices throughout the production process. This can include the use of energy-efficient machinery, optimizing production schedules to minimize energy consumption, and installing energy-saving lighting systems in the manufacturing facility.

Additionally, waste reduction and proper waste management are essential for sustainable manufacturing. By implementing recycling programs and ensuring proper disposal of hazardous materials, manufacturers can significantly reduce the amount of waste going to landfills and minimize pollution.

Transportation is often a significant contributor to carbon emissions in manufacturing. To minimize the environmental impact, manufacturers can consider local sourcing options and optimize transportation routes to reduce fuel consumption and emissions. This can be achieved by partnering with nearby suppliers or locating production facilities close to raw material sources.

Furthermore, manufacturers should consider the entire life cycle of their products. Designing overhead cranes that are durable, long-lasting, and easily repairable can reduce the need for frequent replacements. Additionally, offering product recycling or take-back programs can ensure responsible disposal at the end of their life.

In conclusion, the manufacturing of DIY overhead cranes should prioritize sustainability and environmental considerations. By incorporating sustainable materials, energy-efficient practices, waste reduction, and responsible transportation, manufacturers can reduce their environmental impact and contribute to a greener and healthier planet.

List The Evolution history of “diy overhead crane”

DIY overhead cranes have evolved significantly over the years, with advancements in technology and materials leading to safer and more efficient designs. Here is a brief overview of the evolution history of DIY overhead cranes:

1. Early Designs: The concept of overhead cranes can be traced back several centuries, but the earliest DIY versions were simple and rudimentary. These cranes consisted of wooden beams or logs used as a bridge with ropes or chains for lifting heavy objects. They were operated manually, requiring considerable physical effort.

2. Industrial Revolution: With the onset of the Industrial Revolution in the 18th century, overhead cranes underwent significant improvements. The use of iron and steel allowed for stronger structures and increased lifting capacity. Cranes were powered by steam engines, which made lifting heavy loads easier and more efficient.

3. Electric Power: In the late 19th century, the development of electric power brought about a major evolution in DIY overhead cranes. Electric motors replaced steam engines, making the cranes quieter, more reliable, and easier to operate. Electric powered cranes also eliminated the need for manual operation, improving worker safety.

4. Modern Materials and Components: In the 20th century, advancements in materials and components further enhanced DIY overhead crane designs. Steel became the preferred material for construction due to its strength and durability. The introduction of wire ropes and chains with higher breaking strengths increased the lifting capacity of cranes.

5. Automation and Controls: In recent decades, automation and advanced control systems have revolutionized the operation of DIY overhead cranes. Computerized controls, variable frequency drives, and remote monitoring systems have made cranes more efficient and safer to operate. These developments have also led to the integration of cranes with other industrial processes, enabling seamless material handling.

6. Safety Enhancements: Overhead cranes have seen continuous improvements in safety features. These include overload protection systems, emergency stop buttons, limit switches, and anti-collision systems, among others. These safety enhancements have been crucial in reducing accidents and ensuring the well-being of workers.

In conclusion, DIY overhead cranes have evolved significantly throughout history. From simple wooden structures to modern automated systems, extensive advancements in materials, power sources, components, and safety features have led to safer, more efficient, and higher capacity cranes. As technology continues to progress, it is likely that DIY overhead cranes will continue to evolve, further improving workplace productivity and safety.

The Evolution and Market Trends in diy overhead crane Industry

The DIY overhead crane industry has witnessed significant evolution and market trends in recent years. This niche sector primarily caters to individuals and small businesses seeking cost-effective solutions for their lifting and moving needs. The evolution of this industry can be traced through advancements in technology, changing customer preferences, and emerging market trends.

One of the most noticeable developments in the DIY overhead crane industry is the advent of user-friendly and affordable crane kits. These kits typically include all the necessary components and instructions for assembling the crane, making it accessible to a wider consumer base. This evolution has expanded the market and attracted more customers who are willing to undertake the assembly process themselves.

Another key aspect driving the evolution of this industry is the integration of advanced technologies. With the rise of automation and the Internet of Things (IoT), DIY overhead cranes now incorporate features such as remote control operation, real-time monitoring, and safety sensors. These technological advancements enhance the efficiency, safety, and overall performance of the cranes, making them more appealing to customers.

Furthermore, market trends indicate a growing demand for customization and flexibility in DIY overhead cranes. Customers are increasingly inclined to choose cranes that can be tailored to their specific requirements, such as adjustable heights, different load capacities, or specific lifting mechanisms. This trend has urged manufacturers to offer a wide range of options and configurations to cater to diverse customer needs.

Moreover, sustainability and environmental concerns are becoming important factors influencing market trends in the DIY overhead crane industry. Customers now seek eco-friendly solutions that reduce energy consumption and minimize carbon footprint. Manufacturers are responding to this demand by developing energy-efficient cranes, incorporating renewable energy sources, and embracing sustainable practices in the production process.

In conclusion, the DIY overhead crane industry has undergone significant evolution and market trends, driven by advancements in technology, changing customer preferences, and emerging market demands. The availability of affordable crane kits, the integration of advanced technologies, customization options, and sustainability considerations are all contributing to the growth and diversification of this niche sector.

Custom Private Labeling and Branding Opportunities with Chinese diy overhead crane Manufacturers

Chinese diy overhead crane manufacturers offer custom private labeling and branding opportunities for businesses looking to establish their own unique identity in the market. With their wide range of expertise and experience in manufacturing cranes, these manufacturers can cater to specific branding requirements and deliver high-quality products.

One of the significant advantages of partnering with Chinese diy overhead crane manufacturers is their ability to provide private labeling services. Businesses can customize the packaging, labels, and instructions of the crane products with their logo, design, and brand information. This ensures that the products not only meet industry standards but also reflect the brand identity and resonate with customers.

Moreover, Chinese manufacturers understand the importance of branding and can offer comprehensive branding opportunities. They can work closely with businesses to create custom-designed cranes that align with their brand image and strategy. From the color scheme and aesthetics to the inclusion of unique features or specifications, manufacturers can tailor the cranes to meet the specific branding requirements.

These manufacturers also have in-depth knowledge of international standards and regulations, ensuring that the custom-designed cranes comply with safety guidelines in different markets. This allows businesses to confidently expand their reach and market their branded cranes globally.

In addition to custom private labeling and branding, Chinese diy overhead crane manufacturers offer competitive advantages such as cost-effectiveness, high-quality production capabilities, and efficient production timelines. Their expertise in the field allows businesses to access a wide range of options in terms of crane types, sizes, and capacities, further enhancing the customizability and branding potential.

In conclusion, collaborating with Chinese diy overhead crane manufacturers presents businesses with opportunities to establish their own private labeled and branded products. Through custom packaging, labeling, and design, companies can create a unique identity for their crane products. By leveraging the expertise and cost-effective manufacturing capabilities of Chinese manufacturers, businesses can confidently market their branded cranes globally.

Tips for Procurement and Considerations when Purchasing diy overhead crane

When purchasing a DIY overhead crane for your procurement needs, there are several important considerations to keep in mind. Here are some tips to help you make an informed decision:

1. Load capacity: Determine the maximum weight you need the overhead crane to handle. It is crucial to choose a crane with a load capacity that exceeds your requirements to ensure safe and efficient operations.

2. Span and height: Consider the length of the area you will be covering with the overhead crane. Measure the distance between the runways to determine the required span. Additionally, determine the height needed for the crane to lift objects safely and comfortably.

3. Material and construction: Evaluate the quality of materials used in constructing the overhead crane. High strength steel is typically recommended for durability and longevity. Ensure that the craftsmanship and construction standards meet safety requirements.

4. Safety features: Prioritize the safety features incorporated into the DIY overhead crane design. Consider features like overload protection, emergency stop buttons, and limit switches to enhance safety during operation.

5. Installation and maintenance: Consider the ease of installation and maintenance requirements. Look for detailed installation instructions and user manuals provided by the manufacturer. Additionally, check the availability of spare parts to ensure long-term support.

6. Budget: Determine your budget and search for overhead cranes that align with it. Remember that while cost is a significant factor, compromising on quality and safety features may lead to long-term costs and operational challenges.

7. Reputation and reviews: Research the manufacturer’s reputation and customer reviews. Look for a company with a track record of reliable products and good customer support.

8. Warranty and after-sales support: Check the warranty offered by the manufacturer. Look for warranties that cover both equipment and parts. Moreover, consider the availability of technical support and customer service after the sale.

By considering these factors and conducting thorough research, you can make an informed decision when purchasing a DIY overhead crane that meets your requirements, budget, and safety needs.

FAQs on Sourcing and Manufacturing diy overhead crane in China

1. Why should I consider sourcing and manufacturing a DIY overhead crane in China?

China is known for its strong manufacturing capabilities and competitive pricing. Sourcing and manufacturing a DIY overhead crane in China can be cost-effective, allowing you to save money compared to purchasing from local suppliers. Moreover, Chinese manufacturers offer a wide range of customization options, allowing you to design a crane that meets your specific requirements. China also has a well-established supply chain, ensuring efficient sourcing of raw materials and components.

2. How can I find reliable manufacturers in China for DIY overhead cranes?

To find reliable manufacturers in China, you can start by researching online directories and trade platforms that provide verified supplier information. Attend industry exhibitions and trade shows in China to connect with potential suppliers directly. It’s crucial to thoroughly evaluate the manufacturer’s credentials, such as their certifications, experience, and customer reviews. It is also advisable to request product samples or visit the factory to assess their manufacturing capabilities and quality control processes.

3. What factors should I consider when selecting a manufacturer for DIY overhead cranes?

When selecting a manufacturer, consider factors such as their experience in producing overhead cranes, their technical capabilities, production capacity, and adherence to quality control standards. Evaluate their communication skills and responsiveness, as effective communication is imperative for successful collaboration. Additionally, verify their ability to provide post-sales services, such as product warranty and technical support.

4. Are there any potential challenges or risks in sourcing and manufacturing DIY overhead cranes in China?

There can be potential challenges and risks when sourcing and manufacturing DIY overhead cranes in China. These include language barriers, differences in business culture, intellectual property protection, and the potential for low-quality products from some unscrupulous manufacturers. It is essential to conduct due diligence and have robust contracts in place to mitigate these risks. In addition, closely monitoring the production process and conducting regular quality inspections can help ensure the final product meets your requirements.

5. How can I ensure the quality of DIY overhead cranes manufactured in China?

To ensure quality, it is crucial to have clear product specifications and quality standards communicated to the manufacturer. Conducting regular inspections during different production stages or hiring third-party quality inspection agencies can help verify compliance with your requirements. Requesting product samples and prototypes before placing a larger order can also help ensure the manufacturer’s capabilities. Developing a strong relationship with the manufacturer based on trust and open communication can further contribute to the overall quality assurance process.

Overall, sourcing and manufacturing a DIY overhead crane in China can offer cost-effective solutions and customization options. However, it requires diligent research, careful evaluation of manufacturers, and proactive quality control measures to ensure a successful outcome.

Why contact sourcifychina.com get free quota from reliable diy overhead crane suppliers?

Sourcifychina.com is able to get free quota from reliable DIY overhead crane suppliers due to several reasons. Firstly, Sourcifychina.com has established strong and long-lasting relationships with these suppliers. This means that they have built trust and credibility over time, which allows them to negotiate beneficial deals such as free quotas.

Secondly, Sourcifychina.com acts as a sourcing platform that brings together buyers and suppliers. They have a wide network of suppliers, including reliable DIY overhead crane suppliers, which enables them to access competitive pricing and additional benefits.

Thirdly, by providing regular business to these suppliers, Sourcifychina.com becomes a valuable customer. Suppliers are more likely to offer perks and incentives to customers who consistently order from them, and Sourcifychina.com can leverage this to secure free quotas.

Furthermore, Sourcifychina.com has a solid reputation for providing high-quality service to its customers. They thoroughly vet suppliers, ensuring that only reliable and trustworthy suppliers are listed on their platform. This reassures suppliers that the buyers facilitated by Sourcifychina.com are genuine and serious, which can lead to additional benefits such as free quotas.

In conclusion, Sourcifychina.com obtains free quotas from reliable DIY overhead crane suppliers due to their strong relationships, wide supplier network, consistent business, and reputation for quality service. These factors enable them to negotiate advantageous deals that benefit both them and their customers.