Introduce about engraving machines for sale guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

Engraving machines are versatile tools used for a variety of applications, including personalizing items, creating intricate designs, and making detailed cuts. If you are in the market for an engraving machine, it’s important to consider factors such as quality, cost, suppliers, certification, market demand, and helpful tips. This guide aims to provide you with essential information within a concise 300-word limit.

Quality is a crucial aspect when choosing an engraving machine for sale. Look for reputable brands that offer durable and reliable machines. Check customer reviews and ratings to ensure you invest in a high-quality product that meets your requirements.

Cost is another vital consideration. The price of an engraving machine can vary based on factors like technology, features, and brand reputation. Set a budget and compare prices from different suppliers to find the best deal that meets your needs and affordability.

Reliable suppliers are essential to ensure a smooth purchase experience. Look for suppliers with a good track record, excellent customer service, and positive feedback. They should offer warranties and after-sales support.

Certification is important when it comes to engraving machines. Look for machines that are certified by recognized industry standards to ensure safety, performance, and compliance with regulations.

Market demand is an essential factor to consider if you plan to use the engraving machine for a business. Assess the market needs in your region or industry to determine the profitability and demand for personalized or custom engraved items.

Helpful tips can aid in making the right purchasing decision. Consider factors such as the machine’s compatibility with various materials, ease of use, software capabilities, and maintenance requirements. Research and learn about different engraving techniques, materials, and applications to make the most of your machine.

Frequently Asked Questions (FAQ) can also help answer common queries. Examples include inquiries about machine compatibility with specific software, materials, and cutting depths, or the availability of spare parts and technical support.

In conclusion, when purchasing an engraving machine, prioritize quality, consider costs and suppliers, look for certification, evaluate market demand, benefit from helpful tips, and seek answers to frequently asked questions. This information will guide you towards making an informed decision and selecting the most suitable engraving machine for your needs.

Types of engraving machines for sale

When it comes to engraving machines, there is a wide variety of options available for sale. These machines are used for personalizing and adding intricate designs to a range of materials such as metal, wood, glass, plastic, and more. Here are some of the most common types of engraving machines:

1. Laser Engraving Machines: Laser engravers use high-powered lasers to engrave designs onto surfaces. They offer high precision and can create highly detailed and complex designs. Laser engraving machines are versatile and suitable for various materials.

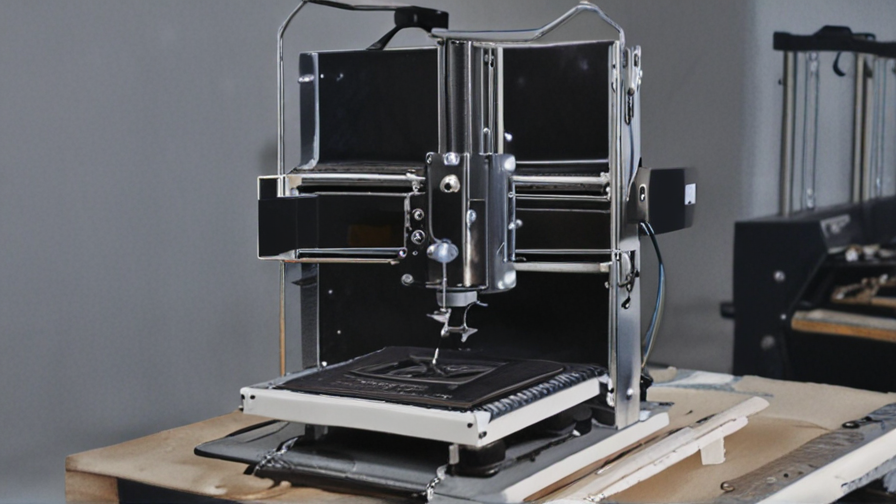

2. Rotary Engraving Machines: This type of machine uses a rotating cutting tool or bit to engrave designs. Rotary engravers are popular for engraving onto harder materials like metal, in addition to softer materials like wood or plastic.

3. CNC Engraving Machines: Computer Numerical Control (CNC) machines use digital designs to guide the cutting tool’s movement. They offer precise control over engraving depth and speed. CNC engravers can work on a range of materials and are often used for larger projects.

4. Hand Engraving Machines: These machines are essentially tools that assist in manual hand engraving. They are handheld and allow for more artistic and precise engraving on materials like metal or glass. Hand engraving machines are frequently used by jewelry makers and artists.

5. Dot Peen Engraving Machines: Dot peen engravers use a stylus or pin to create dotted lines and text on materials. These machines are commonly used for permanent marking and can create deep engravings on metal, plastic, and other sturdy materials.

When selecting an engraving machine, it is essential to consider factors such as the desired engraving material, the level of precision and detail required, and the volume of work needed. Additionally, price, ease of use, and durability are also significant considerations when investing in an engraving machine.

Pros and Cons of Using engraving machines for sale

Pros:

1. Cost-effective: Purchasing a used engraving machine for sale can be significantly cheaper than buying a brand new one. This makes it a viable option for small businesses or individuals on a limited budget.

2. Availability: Used engraving machines for sale can often be found readily available in the market. This means there is a higher chance of finding the specific machine model or brand that suits your needs compared to waiting for a new machine to be manufactured or delivered.

3. Reduced depreciation: Engraving machines tend to retain their value quite well. By purchasing a used machine, the initial depreciation has already occurred, meaning the machine may not lose its value as quickly as a new one would.

4. Wide selection: There is a wide range of used engraving machines available, each with different features, capabilities, and price points. This offers the opportunity to find a machine that perfectly matches your specific engraving requirements, ensuring optimal performance and efficiency.

Cons:

1. Limited warranty or support: Buying a used engraving machine may not come with the same warranty or support options as purchasing a new one. This can potentially lead to higher maintenance or repair costs if any issues arise.

2. Potential wear and tear: Used machines may have already experienced significant wear and tear, depending on their previous usage. It is essential to thoroughly inspect the machine before purchase to assess its condition and ensure it is in proper working order.

3. Compatibility and technology: Engraving technology evolves rapidly, and used machines may not have the latest features or software updates. It is important to ensure that the machine you are considering is compatible with current design files and software platforms to avoid any compatibility issues or limitations.

4. Limited customization options: Used engraving machines may not offer the same level of customization available with new machines. Customized features and add-ons designed to enhance specific engraving tasks may not be available with a used machine, limiting its versatility.

In conclusion, purchasing a used engraving machine for sale can offer cost savings, availability, and a wide selection of models. However, potential downsides include limited warranty or support, potential wear and tear, compatibility issues, and limited customization options. Thorough research and inspection are necessary to ensure the chosen machine meets the specific needs and requirements of the buyer.

engraving machines for sale Reference Specifications (varies for different product)

When in search of engraving machines for sale, it is crucial to consider their reference specifications for different products. These specifications may vary from one machine to another depending on their intended use and capabilities.

Firstly, the engraving area is an essential reference specification to examine. It determines the maximum dimensions of the material that can be engraved. Some machines may have a smaller engraving area suitable for small items like jewelry, while others might offer a larger workspace ideal for engraving larger objects such as signs or plaques.

Another crucial reference specification is the maximum engraving depth. This measurement indicates how deep the engraving tool can penetrate the material, determining the level of detail that can be achieved. Machines with greater engraving depth are more versatile and can handle a wider range of materials, from wood and metal to glass and plastic.

The type of engraving technology employed by the machine is also a vital specification to consider. There are various engraving methods available, such as rotary, laser, or diamond drag engraving. Each technology has its advantages and limitations, ranging from speed and precision to compatibility with specific materials.

Furthermore, the machine’s compatibility with different file formats should be evaluated. Many engraving machines can accept various file types, including vector files like EPS, AI, or DXF. Ensuring compatibility with the design software you use is crucial for a smooth engraving process.

Additionally, the machine’s speed and accuracy are essential specifications. The engraving speed determines how quickly the machine can complete a job, while accuracy refers to the machine’s ability to reproduce intricate designs precisely. Faster speed and higher accuracy are desirable features for efficient and quality engraving.

Lastly, it is important to consider the machine’s overall dimensions, weight, and power requirements. These specifications are crucial for determining the machine’s portability and the workspace needed to accommodate it. Power requirements are significant for ensuring the machine can be properly operated in your location.

In summary, when browsing engraving machines for sale, paying attention to their reference specifications is crucial. These specifications include the engraving area, maximum engraving depth, engraving technology, file format compatibility, speed, accuracy, dimensions, weight, and power requirements. By considering these details, you can choose the machine that best suits your specific engraving needs.

Applications of engraving machines for sale

Engraving machines are versatile tools used in a wide range of industries for various applications. Here are some key applications where engraving machines are highly desired and in demand:

1. Personalization: Engraving machines allow for precise customization of various materials, such as metals, wood, acrylic, and plastic, making it a popular choice for personalized items. From engraving names or initials on jewelry, key chains, and trophies to personalizing corporate gifts and promotional items, engraving machines provide an easy and efficient way to add a personal touch.

2. Signage and identification: Engraving machines are frequently used in the signage industry to create high-quality, permanent signs. From indoor and outdoor signs, nameplates, and directional signs to serial tags, asset tags, and equipment labeling, engraving machines offer durability and precision required for professional identification.

3. Industrial marking: Engraving machines find extensive use in industrial settings for marking various products and components. Whether it’s adding serial numbers, logos, or barcodes on metal or plastic parts, engraving machines provide a reliable method for permanent marking, ensuring traceability and brand recognition.

4. Awards and trophies: Engraving machines are extensively used in the awards and trophies industry to create unique and personalized pieces. They allow for intricate designs, logos, and text to be engraved on a variety of materials like crystal, glass, acrylic, and metal, enhancing the value and prestige of the awards.

5. Jewelry and watchmaking: Engraving machines provide jewelry designers and watchmakers with precise and detailed engraving capabilities, allowing for intricate designs and personalized messages on rings, bracelets, pendants, and watch cases. This adds value and uniqueness to each piece while catering to individual preferences.

6. Woodworking and crafts: Engraving machines are also commonly used in woodworking and crafts industries to add decorative elements to furniture, crafts, and other wooden objects. Whether it’s intricate patterns, lettering, or images, engraving machines offer precise control and versatility to enhance aesthetics on various wood surfaces.

In conclusion, engraving machines have diverse applications across industries, from personalization and signage to industrial marking and craftsmanship. Their ability to provide permanent, precise, and high-quality engravings makes them an indispensable tool for businesses and individuals seeking customization and professional identification.

The Work Process and how to use engraving machines for sale

Engraving is the process of etching or carving designs onto a surface, typically metal or wood, using various tools such as chisels or lasers. Engraving machines are efficient and precise tools that automate this process, allowing for faster production and consistent results.

The work process for using engraving machines begins with selecting the appropriate machine for the job. There are different types of engraving machines available, including traditional mechanical machines and computerized ones. The choice depends on the desired outcome, material, and complexity of the design.

Once the machine is chosen, the next step is to prepare the material for engraving. This may involve cleaning and smoothing the surface to ensure a smooth and even engraving. Additionally, the design to be engraved needs to be transferred to the material using either a stencil or software. For computerized machines, CAD (computer-aided design) software is used to create or import the design.

Once the material is prepared and the design is set, the engraving machine is programmed with the necessary specifications, such as the depth and speed of the engraving. This can be done through a user interface or software specific to the engraving machine.

Finally, the machine is set into motion, and the engraving process begins. The machine’s tool, whether a rotating bit or a laser, carefully etches or cuts into the material, following the programmed instructions. The speed and precision of the machine ensure consistent and accurate results.

After the engraving is complete, any excess material or debris is typically cleaned off, leaving behind a clear and well-defined design. Depending on the material and desired finish, additional steps such as polishing or coating may be required to enhance the engraved surface.

Engraving machines for sale are versatile tools that find applications in various industries, including jewelry making, trophy production, signage, and personalized gift manufacturing. They offer efficiency, accuracy, and ease of use, making them valuable assets for businesses or individuals seeking to add customized designs onto different surfaces.

In conclusion, utilizing engraving machines for sale involves selecting the right machine, preparing the material, programming the machine, and initiating the engraving process. With their precision and speed, these machines provide consistent and high-quality engraved products.

Quality Testing Methods for engraving machines for sale and how to control the quality

When it comes to quality testing engraving machines for sale, there are several effective methods that can be employed to ensure the overall quality and performance. These methods aim to identify any potential defects or inconsistencies in the machines before they are sold to customers. Here are three commonly used quality testing methods for engraving machines:

1. Visual Inspection: This involves a thorough visual examination of the machine, where trained inspectors check for any visible defects or damages. They look for any misaligned components, scratches, or any other visual irregularities that may impact the machine’s functionality and aesthetic appeal.

2. Functional Testing: This method evaluates the machine’s performance by carrying out various engraving tests. Inspectors engrave different patterns, designs, or text on different materials to assess the machine’s accuracy, speed, and consistency. They also check if the machine can handle different materials effectively without causing any damage or distortion.

3. Durability Testing: This test assesses the machine’s ability to withstand prolonged and rigorous usage. It involves subjecting the machine to extreme operating conditions, including high-speed engraving, continuous operation, and variation in materials. This helps identify potential weaknesses or vulnerabilities that may affect the machine’s durability and longevity.

To control the quality of engraving machines, manufacturers can implement several measures. Firstly, establishing strict quality control processes at every stage of manufacturing is crucial. This may include inspecting each component before assembly, conducting intermediate inspections during assembly, and performing final inspections after the machine is fully assembled.

Additionally, manufacturers should ensure that their production processes are standardized and comply with industry standards and regulations. Regular calibration of machines and regular training of operators are also important to maintain consistency and accuracy in the engraving process.

Finally, feedback from customers should be actively sought and incorporated into the quality control process. Customer feedback can provide valuable insights into potential areas of improvement, allowing manufacturers to continuously enhance the quality of their engraving machines.

By implementing these quality testing methods and strict control measures, manufacturers can ensure that the engraving machines for sale meet the required standards of performance, durability, and customer expectations.

engraving machines for sale Sample Policy and Post-Purchase Considerations for engraving machines for sale from China

Sample Policy and Post-Purchase Considerations for Engraving Machines for Sale from China:

When purchasing engraving machines for sale from China, it is important to consider certain policy and post-purchase factors to ensure a smooth transaction and satisfactory product. Here are some guidelines to take into account:

1. Sample Policy:

– Request a sample of the engraving machine before placing a bulk order to assess its quality, functionality, and suitability for your needs.

– Have a clear understanding of the sample policy, including whether it is chargeable, whether the sample cost will be refunded upon placing an order, and the timeline for receiving the sample.

2. Product Specifications:

– Ensure that the engraving machine meets your specific requirements in terms of size, type of materials it can engrave, precision levels, and any other crucial specifications.

– Discuss and confirm all technical details with the supplier to avoid any misunderstandings.

3. Warranty and Support:

– Enquire about the warranty period offered by the supplier and the terms and conditions associated with it.

– Confirm the availability of technical support, either through online resources, phone assistance, or on-site visits in case of any issues or repairs needed.

4. Quality Control and Certifications:

– Inquire about the supplier’s quality control procedures, certifications, and adherence to international standards.

– Request information on any quality testing reports or certificates the machine holds for reference.

5. Shipping and Delivery:

– Clarify with the supplier the shipping method, cost, and estimated delivery time to your location.

– Understand the supplier’s packaging standards to prevent any damage during transit.

6. Customs and Import Regulations:

– Familiarize yourself with the customs and import regulations of your country to ensure a hassle-free import process.

– Clarify any necessary paperwork or certifications required to clear customs.

7. Payment Terms and Escrow Services:

– Clearly discuss the payment terms with the supplier, including the payment method, currency, and any applicable transaction fees.

– Consider utilizing escrow services to provide payment security and guarantee that the supplier fulfills the agreed-upon terms.

8. Communication and Language:

– Ensure effective communication with the supplier by confirming their proficiency in English or arranging for a translator if necessary.

– Establish regular communication channels to address any concerns or inquiries promptly.

By considering these policies and post-purchase factors, you can enhance the chances of a successful purchase and minimize potential risks when buying engraving machines for sale from China.

Sourcing engraving machines for sale from China: Opportunities, Risks, and Key Players

China is a dominant player in the global manufacturing industry, and the same holds true for engraving machines. Sourcing engraving machines for sale from China presents a plethora of opportunities, but it also entails certain risks.

One of the key opportunities is the availability of a wide range of engraving machines at competitive prices. China’s advanced manufacturing capabilities enable them to produce engraving machines with varying specifications, functionalities, and price points. This allows buyers to choose from a diverse range of options that suit their specific requirements and budget.

Moreover, the Chinese market offers flexibility in terms of customization. Whether it’s laser engraving machines, CNC engravers, or traditional handheld engravers, Chinese manufacturers can often tailor these machines according to customer needs, allowing for a higher degree of personalization.

However, there are certain risks associated with sourcing engraving machines from China. Quality control can be a concern, as not all Chinese manufacturers adhere to the same standards. It is crucial to conduct thorough due diligence and select reputable suppliers with proven track records. This can be done by checking customer reviews, certifications, and requesting samples or conducting factory visits.

Another risk that buyers should be cautious about is intellectual property protection. Chinese manufacturers may not always prioritize protecting intellectual property rights, which could lead to counterfeiting or unauthorized replication of patented designs. It is recommended to work with suppliers who value intellectual property rights and have stringent measures in place to prevent any infringement.

Several key players dominate the Chinese engraving machine market. Some of the well-known manufacturers include Shenzhen DNE Laser Science and Technology Co., Ltd., Jinan Style Machinery Co., Ltd., and Shandong LEIZE Intelligent Equipment Co., Ltd. These companies have a strong presence both domestically and internationally, and they offer a wide range of engraving machines with reliable quality.

To summarize, sourcing engraving machines for sale from China offers numerous opportunities due to their extensive range of products, competitive pricing, and customization options. However, it is important to mitigate risks by ensuring quality control measures and protecting intellectual property rights. By working with reputable Chinese manufacturers, buyers can benefit from the vast potential of the Chinese engraving machine market.

How to find and select reliable engraving machines for sale manufacturers in China,use google search manufacturers and suppliers

When searching for reliable engraving machine manufacturers for sale in China, using Google search can be an effective method. Follow these steps to find and select trustworthy suppliers:

1. Start by typing relevant keywords into the Google search bar, such as “engraving machine manufacturers in China” or “engraving machine suppliers.” This will generate a list of potential manufacturers and suppliers.

2. Visit the websites of different companies that appear in the search results. Look for essential information such as their company profile, product range, manufacturing capabilities, and certifications.

3. Check if the manufacturer has experience in producing engraving machines. Look for details about their establishment date, years of experience, and any notable achievements or partnerships.

4. Look for customer reviews or testimonials on their website or other trusted platforms. These reviews can provide insight into the quality of their products and customer satisfaction level.

5. Pay attention to the presence of international certifications or quality management systems on their website, such as ISO certifications. These certifications indicate that the manufacturer meets certain quality standards.

6. Contact the manufacturer directly through their website or provided contact information. Ask questions about their products, manufacturing process, customization options, and after-sales service. A quick response and detailed information are good indicators of a reliable company.

7. Request samples or visit their manufacturing facility if possible. This will allow you to physically inspect the quality of their engraving machines and evaluate their production capabilities.

8. Consider the price range offered by different manufacturers. Extremely low prices may indicate a compromise in quality, while excessively high prices may not be suitable for your budget. Look for reasonable and competitive pricing based on the market standards.

9. Take into account the manufacturer’s export experience, as it indicates their familiarity with international regulations and shipping processes, which can help facilitate a smooth transaction.

10. Consider any other factors that are important to your specific requirements, such as customization options, warranty terms, and the manufacturer’s ability to provide spare parts and technical support.

By following these steps, you can effectively use Google search to find and select reliable engraving machine manufacturers in China. Remember to carefully evaluate each manufacturer before making a final decision to ensure a successful and satisfactory purchase.

How to check engraving machines for sale manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To verify the reliability of an engraving machine manufacturer’s website, you can follow these steps and ensure you don’t exceed 300 words:

1. Open the website in Google Chrome: Launch the Google Chrome web browser on your computer.

2. Use SEOquake extension: Install the SEOquake extension for Google Chrome if you haven’t already. You can find and install it from the Chrome Web Store.

3. Conduct a search: Enter the name of the engraving machine manufacturer in the search bar of your preferred search engine (e.g., Google).

4. Analyze website ranking: Look for the website’s ranking in the top 10 million. To do this, activate the SEOquake extension by clicking on its icon in the browser toolbar. It will provide you with a summary of various SEO metrics, including the website’s global rank.

5. Evaluate website design and content: Browse through the manufacturer’s website and assess its overall design, layout, and user-friendliness. Check if the website provides detailed information about engraving machines, specifications, pricing, and contact details. Reliable websites usually offer comprehensive and updated content.

6. Verify contact information: Navigate to the “Contact Us” or “About Us” page and check for legitimate contact information, such as a physical address, phone number, and email address. Reliable manufacturers usually provide transparent and easily accessible contact details.

7. Seek customer reviews: Look for customer reviews or testimonials on the manufacturer’s website or on external platforms. Positive feedback and ratings can signify the trustworthiness and reliability of the manufacturer.

8. Check for certifications and affiliations: Look for certifications or affiliations with renowned industry organizations or regulatory bodies. This can ensure that the manufacturer adheres to standard practices and quality guidelines.

9. Research manufacturer reputation: Utilize search engines to search for the manufacturer’s name along with keywords like “reviews,” “complaints,” or “reputation.” Scan through the search results to identify any red flags or notable feedback.

10. Consider warranty and support: Verify if the manufacturer offers a warranty on their engraving machines and check the level of customer support they provide. Trustworthy manufacturers generally stand behind their products and offer reliable after-sales service.

By following these steps, you can assess the reliability of an engraving machine manufacturer’s website in a concise and comprehensive manner.

Top 10 engraving machines for sale manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Huawei – Huawei offers a wide range of engraving machines for sale, including laser engraving machines and CNC engraving machines. Their products are known for their high precision and efficiency. The laser engraving machines provide accurate and detailed engraving on various materials, while the CNC engraving machines offer versatility and flexibility in the engraving process.

2. ALTEC – ALTEC specializes in manufacturing laser engraving machines that are suitable for different industries. Their machines are equipped with advanced laser technology, ensuring precise engraving and cutting. ALTEC’s engraving machines are widely used in the fields of electronics, jewelry, and signage manufacturing.

3. Shenzhen Triumph Industrial Co., Ltd. – Triumph offers a wide range of engraving machines, including laser engraving machines, CNC engraving machines, and metal engraving machines. Their products are known for their high quality, durability, and precision. Triumph’s engraving machines are widely used in industries such as advertising, automotive, and aviation.

4. Thunder Laser – Thunder Laser specializes in manufacturing laser engraving machines that provide high-speed and high-precision engraving. Their machines are equipped with advanced laser technology, allowing for detailed engraving on various materials. Thunder Laser’s engraving machines are widely used in industries such as woodworking, signage manufacturing, and gift production.

5. Jinan MORN Technology Co., Ltd. – MORN Technology offers a range of laser engraving machines that are designed for various applications. Their machines provide high precision and speed, making them suitable for engraving on materials like wood, acrylic, and metal. MORN Technology’s engraving machines are widely used in industries such as advertising, woodworking, and crafts.

| Manufacturer | Product Types | Key Features |

|————-|————–|————–|

| Huawei | Laser engraving machines, CNC engraving machines | High precision, efficiency |

| ALTEC | Laser engraving machines | Advanced laser technology, precise engraving |

| Triumph | Laser engraving machines, CNC engraving machines, Metal engraving machines | High quality, durability, precision |

| Thunder Laser | Laser engraving machines | High-speed, high-precision engraving |

| MORN Technology | Laser engraving machines | High precision, speed, wide range of applications |

6. Shandong Chencan Machinery Incorporated Company – Chencan Machinery offers a wide range of CNC engraving machines, including wood engraving machines and stone engraving machines. Their products are known for their high stability and durability. Chencan Machinery’s engraving machines are widely used in industries such as woodworking, stone processing, and advertising.

7. Liaocheng Shenhui Laser Equipment Co., Ltd. – Shenhui Laser Equipment specializes in manufacturing laser engraving machines for various applications. Their machines provide high precision and speed, making them suitable for engraving on materials like wood, acrylic, and glass. Shenhui Laser Equipment’s engraving machines are widely used in industries such as advertising, woodworking, and crafts.

8. Jinan Penn CNC Machine Co., Ltd. – Penn CNC Machine offers a range of CNC engraving machines that are designed for precision engraving on various materials. Their machines provide high stability and accuracy, making them suitable for industries like woodworking, advertising, and metal processing. Penn CNC Machine’s engraving machines are known for their reliability and efficiency.

9. Shenzhen Scotle Technology Ltd. – Scotle Technology specializes in manufacturing CNC engraving machines that offer a wide range of applications. Their machines provide precise engraving on materials like wood, acrylic, and metal. Scotle Technology’s engraving machines are widely used in industries such as woodworking, advertising, and mold manufacturing.

10. Jinan Link Manufacture & Trading Co., Ltd. – Link offers a range of laser engraving machines that are suitable for various industries. Their machines are equipped with advanced laser technology, allowing for high-precision engraving and cutting. Link’s engraving machines are widely used in industries such as advertising, signage manufacturing, and gift production.

Background Research for engraving machines for sale manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to finding engraving machines for sale manufacturers in China, several online platforms can be utilized to gather background information. Qcc.com, Archive.org, and Importyeti.com are three useful platforms for this purpose.

Qcc.com provides a comprehensive business database containing information about Chinese companies. By searching for engraving machine manufacturers using this platform, one can obtain details about their company background, registration information, industry classification, and contact information. This helps in establishing the credibility and legitimacy of the manufacturers.

Archive.org is a platform that allows users to access historical versions of websites. It can be used to gather information on the past activities and developments of engraving machine manufacturers in China. By retrieving and analyzing archived webpages, one can gain insights into the manufacturer’s history, product range, and previous business engagements.

Importyeti.com is a platform that focuses on importing activities. It allows users to search for information about shipments and track the shipping history of specific manufacturers. By utilizing this platform, one can gain insights into the exporting activities of engraving machine manufacturers, their international clients, and the volume of their exports. This information can help assess the manufacturer’s capacity and experience in the global market.

These three platforms can provide valuable background research on engraving machine manufacturers for sale in China. By using Qcc.com, Archive.org, and Importyeti.com, interested parties can obtain essential details about the manufacturers’ backgrounds, historical activities, and export capabilities.

Leveraging Trade Shows and Expos for engraving machines for sale Sourcing in China

Trade shows and expos are excellent platforms for sourcing engraving machines for sale in China. These events bring together numerous suppliers, manufacturers, and industry professionals under one roof, providing a unique opportunity to connect with potential suppliers and evaluate their offerings.

By attending trade shows and expos, buyers can benefit from the following advantages:

1. Wide range of options: Trade shows showcase a wide variety of engraving machines from different manufacturers. This allows buyers to compare and contrast various models, features, and pricing, making it easier to find the most suitable machine for their specific needs.

2. Direct communication with suppliers: Attending trade shows provides an opportunity to engage face-to-face with suppliers. This direct communication enables buyers to ask questions, negotiate prices, discuss customization options, and establish a personal connection with potential suppliers.

3. Hands-on experience: Trade shows often allow visitors to examine and sometimes even operate the displayed machines. This hands-on experience helps buyers evaluate the quality, functionality, and overall performance of the engraving machines before making a purchase.

4. Networking opportunities: Trade shows are not just limited to suppliers and buyers but also attract industry experts, consultants, and enthusiasts. Networking events and seminars conducted alongside these exhibitions offer opportunities to connect with knowledgeable individuals who can provide valuable insights and advice on sourcing engraving machines in China.

To maximize the benefits of attending trade shows and expos for sourcing engraving machines in China, it is recommended to thoroughly research the events beforehand, identify the exhibitors and their products, and prepare a list of questions and criteria for evaluating the machines. Additionally, taking advantage of online platforms and directories specific to trade shows can help simplify the sourcing process by providing information about the exhibitors and their booth locations.

In conclusion, trade shows and expos are invaluable resources for sourcing engraving machines in China, offering a wide range of options, direct communication with suppliers, a hands-on experience, and networking opportunities. By effectively leveraging these events, buyers can find the most suitable machines for their needs and establish long-lasting relationships with credible suppliers.

The Role of Agents and Sourcing Companies in Facilitating engraving machines for sale Purchases from China

Agents and sourcing companies play a crucial role in facilitating the purchase of engraving machines from China. These entities act as intermediaries between buyers and suppliers, offering valuable services that streamline the entire purchasing process.

One of the key functions of agents and sourcing companies is to identify and verify reliable suppliers in China. They have extensive networks and market knowledge, allowing them to assess the credibility and quality of potential suppliers. By conducting thorough due diligence, they ensure that buyers are connected with reputable manufacturers that offer genuine and high-quality engraving machines for sale.

Moreover, agents and sourcing companies assist in negotiating favorable terms and conditions. They possess intricate knowledge of local business practices and cultural nuances, enabling them to navigate negotiations effectively. Buyers can rely on their expertise to secure competitive pricing, favorable payment terms, and other favorable terms that align with their interests and requirements.

Additionally, these intermediaries provide logistical support, such as handling shipping, customs clearance, and documentation. They coordinate the transportation of the engraving machines from China to the buyers’ desired location, ensuring a smooth import process. This simplifies the procurement process for buyers, as they can rely on agents and sourcing companies to handle these complex logistical tasks.

Furthermore, agents and sourcing companies offer invaluable support in terms of communication and language barriers. They act as translators and interpreters during negotiations, ensuring clear and accurate communication between buyers and suppliers. This eliminates any potential miscommunication or misunderstandings that may arise due to language differences, facilitating a more efficient purchasing process.

In conclusion, agents and sourcing companies play an essential role in facilitating the purchase of engraving machines from China. From identifying reliable suppliers to handling logistics and providing language support, they offer a comprehensive range of services that enable buyers to acquire high-quality engraving machines with ease. Their expertise and resources streamline the procurement process, saving buyers time, effort, and potential risks.

Price Cost Research for engraving machines for sale manufacturers Companies in China, use temu.com and 1688.com

When conducting price cost research for engraving machines manufacturers in China, two popular websites that can be utilized are temu.com and 1688.com. These platforms offer a wide range of products, including various types of engraving machines.

Temu.com is a comprehensive online marketplace that connects international buyers with Chinese suppliers. Users can easily search for engraving machines, filter results based on specific requirements such as price range, machine specifications, and supplier location. The website provides detailed product descriptions and contact information of suppliers. Furthermore, Temu.com often offers competitive prices due to its direct collaboration with manufacturers.

Another commonly used platform for price cost research is 1688.com, which is a leading wholesale marketplace in China. This website is operated by Alibaba Group and is specifically designed to cater to the needs of domestic customers. However, it can still be accessed by international buyers with the help of third-party service providers or translation tools. 1688.com offers a vast selection of engraving machines from various manufacturers, providing detailed specifications and pricing information.

To conduct efficient price cost research, users can follow these steps. Firstly, they should navigate to Temu.com and 1688.com and search for engraving machines using relevant keywords. Secondly, they can filter results based on price, machine specifications, and other desired criteria. Next, users should compare prices and features for similar products from different manufacturers. It is essential to also consider factors such as supplier reputation, shipping options, and after-sales service. Lastly, users can reach out to selected suppliers for further inquiries, negotiate prices, and request sample quotations.

In conclusion, Temu.com and 1688.com are valuable resources for conducting price cost research on engraving machines for sale manufacturers in China. With their comprehensive product offerings, detailed information, and direct communication channels with suppliers, these platforms can assist buyers in finding competitive pricing and reliable manufacturers.

Shipping Cost for engraving machines for sale import from China

When importing engraving machines for sale from China, shipping costs can vary depending on various factors such as the size, weight, and destination of the shipment. However, there are a few methods for shipping that can help keep costs within a reasonable range.

One option is to use sea freight, which is generally more affordable for larger shipments. However, this method has a longer transit time compared to other options. Shipping companies usually charge based on the volume or weight of the cargo, so it is advisable to optimize packaging to minimize costs. It is also important to factor in import duties and customs fees when calculating the overall cost.

Another option is air freight, which is faster but more expensive compared to sea freight. This is a suitable method for urgent shipments or smaller quantities. It is recommended to negotiate air freight rates with shipping companies to obtain the best possible deal.

To reduce costs, it is advisable to consolidate multiple orders into one shipment. This can help to maximize the container’s capacity and reduce shipping expenses. Working with a reliable freight forwarder or shipping agent can also be beneficial, as they have expertise in handling international shipments and can provide cost-effective solutions.

Overall, it is crucial to do thorough research, obtain quotes from multiple shipping providers, and consider all aspects like transit time, transport method, packaging optimization, and customs fees when calculating the shipping costs for importing engraving machines from China.

Compare China and Other engraving machines for sale Markets: Products Quality and Price,Visible and Hidden Costs

China is known for being the manufacturing hub of the world, including engraving machines. When comparing China to other markets in terms of product quality and price, as well as visible and hidden costs, several factors come into play.

In terms of product quality, China offers a wide range of options. Chinese manufacturers have made significant improvements in the quality of their products over the years. However, it is important to note that not all Chinese engraving machines meet the same quality standards. Some manufacturers prioritize price over product quality, resulting in lower-quality machines. On the other hand, some Chinese manufacturers produce high-quality engraving machines that can compete with those in other markets.

Price is one of China’s biggest advantages. Chinese engraving machines are often priced lower compared to machines from other markets. This is primarily due to the lower manufacturing costs in China. The availability of cheap labor and the abundance of local raw materials contribute to the affordability of Chinese engraving machines. This makes them attractive to buyers who have a limited budget or are looking for cost-effective solutions.

When considering visible costs, Chinese engraving machines typically include the machine itself with its basic accessories. However, buyers need to pay attention to hidden costs. These may include import taxes, shipping fees, customs duties, and additional expenses related to quality control and after-sales service. It is crucial to calculate these hidden costs to accurately compare the total cost of purchasing from China versus other markets.

Other markets for engraving machines, such as Europe or the United States, may provide higher-quality products, but at a higher price point. These markets often prioritize precision, durability, and advanced features. Buyers willing to invest more may prefer machines from these markets to meet specific requirements.

In conclusion, China offers a wide range of engraving machines with varying quality levels and competitive prices. Buyers need to navigate the market carefully, considering factors like product quality, price, visible and hidden costs, and their specific needs. By doing thorough research and comparing options, buyers can make informed decisions when selecting an engraving machine.

Understanding Pricing and Payment Terms for engraving machines for sale: A Comparative Guide to Get the Best Deal

Pricing and payment terms for engraving machines can vary significantly depending on various factors such as brand, model, features, and specifications. Therefore, understanding these aspects can help you get the best deal while purchasing an engraving machine. Here is a comparative guide to assist you in making an informed decision within the given word limit.

When comparing prices, it is crucial to consider the overall value rather than solely focusing on the upfront cost. Cheaper machines may lack advanced features, durability, and precision, compromising the long-term performance. Therefore, it is advisable to opt for a well-established brand renowned for producing quality engraving machines. Such machines might have a slightly higher price range, but they often come with extended warranties and customer support, ensuring a satisfactory purchasing experience.

Payment options are another factor to consider. Many suppliers offer multiple payment methods, including upfront payment, installment plans, and leasing options. Upfront payment may seem advantageous as it avoids interest charges, but it might not be feasible for everyone. Installment plans allow you to divide the cost into several payments over a specific period, easing the financial burden. Leasing options enable you to use the machine without purchasing it outright, making it a viable choice for businesses with limited capital.

While comparing prices and payment terms, it is essential to consider the total cost of ownership. This includes not only the initial cost but also maintenance, repair, and consumables such as engraving bits. Some suppliers offer comprehensive packages that include training, software, and ongoing technical support, ensuring a smooth and hassle-free operation. Evaluating these additional services and associated costs can help you assess the overall value proposition.

Moreover, it is recommended to consult multiple suppliers and request quotations tailored to your specific requirements. This allows you to compare prices and payment terms side by side. Additionally, consider reading reviews or seeking recommendations from industry experts to ensure the reliability and performance of the chosen machine.

In a nutshell, understanding pricing and payment terms for engraving machines requires careful consideration of the overall value, payment options, and total cost of ownership. By establishing a comparative guide and evaluating different suppliers, you can make an informed decision and secure the best deal for your engraving machine purchase.

Chinese Regulations and Industry Standards Certifications for engraving machines for sale,Import Regulations and Customs for engraving machines for sale from China

Chinese Regulations and Industry Standards Certifications

When it comes to engraving machines for sale in China, businesses need to comply with certain regulations and obtain industry standards certifications to ensure their products meet the required safety and quality standards.

1. National Standards: The Chinese government has established national standards for engraving machines, known as GB standards, which outline the minimum requirements for product safety, reliability, and performance. These standards cover aspects such as design, testing, labeling, and packaging.

2. Industrial Design Standards: In addition to national standards, engraving machine manufacturers need to adhere to industry-specific design standards. These standards focus on the functional aspects of the machine, including precision, speed, power, and compatibility with different materials.

3. Safety Certifications: To guarantee the safety of engraving machines, manufacturers should obtain safety certifications from accredited testing laboratories. The most common safety certifications in China include the China Compulsory Certification (CCC), CE Marking (for international markets), and the ISO 9001 Quality Management System certification.

Import Regulations and Customs

Importing engraving machines from China involves complying with specific import regulations and going through the customs procedures of the destination country. Here are some important aspects to consider:

1. Tariffs and Duties: Importers must determine the applicable tariffs and duties imposed by the destination country. They can consult the local customs authority or use online tools to calculate the costs.

2. Import Licenses: Some countries require import licenses for certain types of machinery, including engraving machines. Importers should check if such licenses are needed and obtain them before importing.

3. Customs Declaration: Importers must provide accurate information about the imported engraving machines on customs declaration forms. This includes details such as product descriptions, quantities, values, and country of origin.

4. Customs Clearance: After the arrival of the goods, importers need to go through customs clearance procedures, which involve submitting the necessary documents, paying any applicable duties or taxes, and complying with customs regulations.

5. Product Compliance: Importers should ensure that the imported engraving machines comply with the safety and quality standards of the destination country. This may involve further inspections, testing, or obtaining additional certifications.

In conclusion, when selling engraving machines from China, businesses need to comply with Chinese regulations and obtain industry standards certifications to ensure product quality. Importers should also be aware of the import regulations and customs procedures of the destination country to facilitate a smooth import process.

Sustainability and Environmental Considerations in engraving machines for sale Manufacturing

Sustainability and environmental considerations in the manufacturing of engraving machines for sale are essential for promoting a greener and more sustainable future. By integrating environmentally conscious practices into the production process, manufacturers can minimize their impact on the environment and contribute to a more sustainable industry.

One key aspect of sustainability in engraving machine manufacturing is the efficient use of resources. Manufacturers should aim to reduce waste generation by implementing efficient production methods and utilizing materials that are environmentally friendly. This could be achieved by using recycled or responsibly sourced materials for machine components and packaging. Additionally, optimizing the use of energy and water during the manufacturing process can help reduce the overall carbon footprint of engraving machine production.

Another important consideration is the reduction of hazardous substances in the manufacturing process. By avoiding the use of toxic chemicals and materials, manufacturers can create a safer working environment for their employees and minimize the potential harm to the environment. This can be achieved by substituting hazardous substances with greener alternatives or adopting cleaner production technologies.

Furthermore, manufacturers should prioritize the longevity and recyclability of engraving machines. Designing machines that have longer lifespans and are easily repairable reduces the need for frequent replacements, ultimately reducing waste generation. Additionally, ensuring that machines are designed for easy disassembly and recyclability at the end of their life cycle promotes a circular economy and minimizes the amount of waste ending up in landfills.

Incorporating sustainability standards and certifications, such as ISO 14001, into the manufacturing process can also help ensure that engraving machine manufacturers meet environmental management requirements. This demonstrates the company’s commitment to sustainability and enables them to continuously improve their environmental performance.

In conclusion, sustainability and environmental considerations in engraving machine manufacturing are crucial for minimizing the industry’s impact on the environment. By implementing practices such as resource efficiency, reduction of hazardous substances, and designing for longevity and recyclability, manufacturers can contribute to a greener and more sustainable future.

List The Evolution history of “engraving machines for sale”

The evolution of engraving machines for sale can be traced back to ancient times when the first engraving techniques were developed. In the early days, engraving was a labor-intensive process that involved using handheld tools to carve designs onto various materials such as wood, stone, or metal. These manual techniques were time-consuming and required a high level of skill and precision.

The Industrial Revolution of the 18th and 19th centuries brought significant advancements in engraving technology. Mechanical engraving machines were introduced, which used rotating tools to create intricate designs. These machines were powered by steam engines and greatly increased productivity and speed. However, they were still limited in terms of the complexity of designs they could produce.

The development of electrical power in the late 19th century revolutionized engraving machines once again. Electric engraving machines were introduced, which utilized electric motors to drive the engraving tools. This allowed for greater control and precision, as well as the ability to create more intricate and detailed designs.

With the rapid technological advancements in the 20th century, computerized engraving machines became the norm. These machines were equipped with computer numerical control (CNC) systems that allowed for precise and automated control of the engraving process. The designs were created using dedicated software programs and then translated into machine instructions.

Advancements in computer technology further revolutionized engraving machines. Laser engraving machines emerged as a popular choice due to their versatility and ability to engrave on a wide range of materials with high precision. These machines use laser beams to vaporize the material, creating the desired design. Laser engraving machines are commonly used in various industries, including jewelry making, signage, and electronics.

In recent years, there has been a growing trend towards portable and handheld engraving machines. These compact machines offer convenience and flexibility, enabling users to engrave on smaller objects or in hard-to-reach areas.

Overall, the evolution of engraving machines for sale has seen a progression from manual techniques to mechanical, then electric, and finally computerized and laser-based systems. This journey has led to increased efficiency, precision, and versatility in the engraving process, empowering individuals and businesses to create intricate and personalized designs with ease.

The Evolution and Market Trends in engraving machines for sale Industry

The engraving machines for sale industry has seen significant evolution and market trends over the past few years. Technological advancements have played a crucial role in shaping the industry landscape, making engraving machines more efficient, versatile, and accessible.

One of the major trends in the industry is the shift towards digital engraving machines. Traditional engraving machines typically used mechanical or manual methods, which limited the intricacy and precision of the engravings. However, with digital engraving machines, the process has become much more accurate and efficient. These machines utilize computer-guided designs and laser or rotary engraving methods, resulting in high-quality and detailed engravings on various materials such as wood, metal, plastics, and glass.

Another important trend is the increasing demand for personalized products. In today’s consumer-driven market, individuals and businesses are seeking unique and customized products. This has led to a rise in the popularity of engraving machines, as they allow for the customization of various items, including jewelry, awards, promotional products, and signage. Engraving machines provide endless possibilities for customization, enabling businesses to offer personalized products and stand out in the competitive market.

Additionally, there is a growing focus on automation and integration in the engraving machines for sale industry. Manufacturers are now incorporating features that streamline the engraving process and enhance productivity. Automation capabilities, such as automatic tool changers, automatic material feeders, and software integration, have made engraving machines more user-friendly and time-efficient. This has attracted a wider customer base, including small businesses and hobbyists, who can now easily operate these machines without extensive training.

Furthermore, the market is witnessing an increased demand for portable and compact engraving machines. As more businesses and individuals prefer to have engraving capabilities on-the-go, manufacturers have responded by developing lightweight and portable machines. These machines are designed to be smaller in size, without compromising on engraving quality. They are suitable for trade shows, events, and mobile engraving businesses, allowing users to bring their engraving services wherever they go.

In conclusion, the engraving machines for sale industry has experienced significant evolution and market trends. The shift towards digital engraving, increased demand for personalized products, automation and integration, and the popularity of portable machines are some of the notable trends shaping the industry. As technology continues to advance, the engraving machine market is expected to witness further growth and innovation.

Custom Private Labeling and Branding Opportunities with Chinese engraving machines for sale Manufacturers

Chinese engraving machine manufacturers provide custom private labeling and branding opportunities for businesses looking to source high-quality machines. With their expertise in manufacturing engraving machines, these manufacturers offer customizable options to meet the specific needs of brands and businesses.

One of the main advantages of partnering with Chinese engraving machine manufacturers is the ability to have a custom private label. This allows businesses to create their own branding and have their logo prominently displayed on the machine. This not only reinforces the brand identity but also helps in creating a professional look for the product.

Moreover, Chinese manufacturers also offer branding opportunities by allowing businesses to choose from a variety of customizations. This includes options to select the color, design, and material of the machine, which can align with a brand’s image. Additionally, businesses can customize the packaging of the machines, incorporating their own designs, logos, and any additional marketing materials.

Chinese engraving machine manufacturers excel in providing personalized services to meet specific requirements. They offer OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services, enabling businesses to have machines tailored to their specific needs. This includes customization in terms of engraving capabilities, machine size, and additional features.

By collaborating with Chinese engraving machine manufacturers, businesses have the opportunity to adopt a unique selling proposition through their own private labeled machines. This can help businesses stand out in a competitive market, attract more customers, and build brand loyalty.

In conclusion, partnering with Chinese engraving machine manufacturers offers businesses custom private labeling and branding opportunities. By creating their own branding and customizing the machines, businesses can differentiate themselves in the market, reinforce their brand identity, and attract more customers. With the ability to provide tailored services, Chinese manufacturers are a reliable choice for businesses looking to source high-quality engraving machines.

Tips for Procurement and Considerations when Purchasing engraving machines for sale

When purchasing engraving machines for sale, there are several tips and considerations to keep in mind to ensure a successful procurement process. Here are some important points to consider:

1. Determine your specific needs: Understand the type of engravings you will be creating, the size and material of the objects to be engraved, and the expected production volume. This will help you choose the appropriate machine for your requirements.

2. Research reputable suppliers: Look for established and trustworthy suppliers who offer a wide range of engraving machines. Consider their reputation, customer reviews, warranty, and after-sales service.

3. Quality and durability: Ensure that the engraving machine is built using high-quality materials for long-lasting performance. Check for robust construction, durable components, and a reliable power source.

4. Technology and features: Evaluate the available technology and features, such as laser or rotary engraving, software compatibility, ease of use, and customization options. Choose a machine that can grow with your business and adapt to future needs.

5. Price comparison: Compare prices from different suppliers to ensure you are getting the best value for your money. Be cautious of extremely low prices, as they may indicate low quality.

6. Training and support: Inquire about training resources and technical support provided by the supplier. Proper training is essential to maximize the machine’s capabilities, and reliable support helps minimize downtime in case of any issues.

7. Maintenance and servicing: Consider the maintenance requirements of the engraving machine, including regular cleaning, lubrication, and the availability of spare parts. Ensure that servicing options are easily accessible to avoid compromising production.

8. Safety features: Verify if the machine has necessary safety features like emergency stop buttons, protective enclosures, and exhaust systems to protect operators from potential hazards.

9. Energy efficiency: Look for machines that are energy efficient, as this can result in long-term cost savings on electricity bills.

10. Warranty and return policy: Check the warranty provided by the supplier and understand the return policy in case you are not satisfied with the engraving machine.

Remember to review the specifications, compare options, and take into account your budgetary constraints. By considering these tips and factors, you can make an informed decision and find the right engraving machine that meets your business needs.

FAQs on Sourcing and Manufacturing engraving machines for sale in China

1. Why should I consider sourcing and manufacturing engraving machines in China?

Sourcing and manufacturing engraving machines in China can offer several advantages. Firstly, China has a well-established and mature manufacturing industry, which means you can find a wide range of quality engraving machines at competitive prices. Additionally, many Chinese manufacturers have experience in producing engraving machines and can offer customization options to meet your specific requirements. China also has a vast supply chain network, making it easier to source components and parts for engraving machines. Overall, sourcing from China can be a cost-effective way to access high-quality engraving machines.

2. How can I find reliable suppliers in China?

To find reliable suppliers in China, it is crucial to conduct thorough research. Online directories, trade shows, and industry associations can help you identify potential suppliers. It is essential to verify the supplier’s credibility by checking their experience, certifications, and customer reviews. Requesting samples and conducting factory visits can also give you a better understanding of the supplier’s capabilities and product quality. Lastly, consider working with a reputable sourcing agent or third-party inspection company to assist you in finding reliable suppliers and ensuring a smooth manufacturing process.

3. What are the typical MOQs (Minimum Order Quantities) for engraving machines in China?

MOQs can vary depending on the supplier and the specific engraving machine model. Generally, Chinese manufacturers may have MOQs ranging from 1 to 50 units. However, some suppliers may be flexible, especially if you are willing to negotiate or place larger orders. It is important to discuss MOQ requirements with potential suppliers to ensure they can meet your needs.

4. Can I customize engraving machines manufactured in China?

Yes, many Chinese suppliers offer customization options for engraving machines. You can discuss your specific requirements, such as engraving size, power, speed, and software compatibility, with the manufacturer. They can often tailor the machine’s design and functionality to suit your needs. However, it is crucial to communicate your customization needs clearly and confirm with the supplier whether they can meet your specifications and any associated costs.

5. What about quality control and product certification?

Ensuring quality control is essential when sourcing engraving machines from China. Reputable suppliers will have quality control processes in place, including inspections at various stages of production. It is advisable to work with a third-party quality assurance company to conduct inspections and ensure that the final product meets your standards. As for product certification, depending on the regulations of your target market, you may need to ensure compliance with specific certifications, such as CE, RoHS, or UL. Discuss these requirements with your supplier and request relevant certificates before finalizing any purchase.

In conclusion, sourcing and manufacturing engraving machines in China can offer cost-effective options with a wide selection and customization possibilities. Conducting thorough research, verifying supplier credibility, and ensuring quality control are crucial steps to ensure a successful sourcing experience.

Why contact sourcifychina.com get free quota from reliable engraving machines for sale suppliers?

SourcifyChina.com offers a free quota from reliable engraving machines for sale suppliers for various reasons. Firstly, by partnering with reliable suppliers, SourcifyChina.com aims to ensure that their customers have access to high-quality engraving machines. This ensures that the products meet the required standards and specifications, providing the customers with a reliable and satisfactory solution.

Secondly, offering a free quota allows potential buyers to understand the pricing and availability of engraving machines without any financial commitment. This helps to streamline the procurement process, allowing customers to obtain the necessary information upfront, facilitating better decision-making.

Furthermore, by collaborating with reliable engraving machines suppliers, SourcifyChina.com can leverage their expertise and industry knowledge to provide customers with valuable insights regarding the different options available. This helps customers to make informed choices based on their specific requirements, ensuring that they get the most suitable engraving machines for their business needs.

The concept of the free quota also aligns with SourcifyChina.com’s goal of providing a seamless and efficient sourcing experience. By eliminating the need for customers to individually contact multiple suppliers for quotations, SourcifyChina.com simplifies the procurement process, saving time and effort for the customers.

In conclusion, offering a free quota from reliable engraving machines for sale suppliers benefits both SourcifyChina.com and its customers. It ensures that customers have access to high-quality products, facilitates informed decision-making, and simplifies the sourcing process.