Introduce about fiber laser cutting machines guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

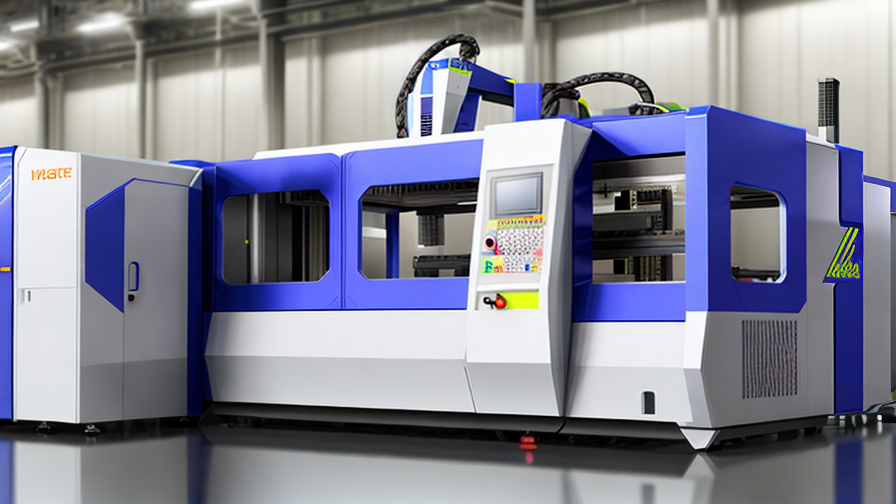

Fiber laser cutting machines have revolutionized the metal fabrication industry, providing more precise and efficient cutting solutions compared to traditional methods. This guide aims to provide a comprehensive overview of these machines, including their quality, cost, suppliers, certifications, market trends, tips, and frequently asked questions (FAQs).

When it comes to quality, fiber laser cutting machines are highly regarded for their exceptional cutting accuracy and speed. These machines utilize a high-powered fiber laser beam, which results in clean and precise cuts on a variety of materials, including stainless steel, aluminum, and brass.

In terms of cost, fiber laser cutting machines can vary depending on factors such as power output, bed size, and additional features. Generally, the cost of these machines ranges from a few thousand dollars for small-scale models to several hundred thousand dollars for industrial-grade machines.

Finding a reliable supplier is crucial to ensure the quality and after-sales support of your fiber laser cutting machine. Reputable suppliers offer comprehensive training, service, and parts replacement to ensure the longevity and optimal performance of your equipment.

Certifications are essential to ensure the safety and compliance of fiber laser cutting machines. Look for suppliers who provide machines that meet international safety standards, such as CE, ISO, and FDA certifications.

The market for fiber laser cutting machines is rapidly growing due to their numerous advantages over traditional cutting methods. Industries such as automotive, aerospace, electronics, and construction are increasingly adopting these machines for their efficiency, precision, and cost-effectiveness.

Here are some tips to consider when purchasing a fiber laser cutting machine:

1. Identify your specific cutting needs and materials to choose the right machine specifications.

2. Compare prices, quality, and after-sales service from different suppliers.

3. Consider the availability and cost of spare parts.

4. Evaluate the machine’s software and compatibility with design programs.

5. Check for warranty and service contracts offered by the supplier.

Frequently asked questions about fiber laser cutting machines:

1. What materials can be cut using fiber laser cutting machines?

2. What is the maximum cutting thickness of these machines?

3. How do fiber lasers compare to CO2 lasers in terms of performance and cost?

4. How long does it take to learn operating a fiber laser cutting machine?

5. What maintenance is required for these machines?

In conclusion, fiber laser cutting machines offer superior cutting quality and efficiency. When purchasing one, consider factors such as quality, cost, supplier support, certifications, and market trends. Following the provided tips and understanding common FAQs will guide you in making an informed decision for your specific cutting needs.

Types of fiber laser cutting machines

Fiber laser cutting machines are highly efficient and versatile tools used in a variety of industries to cut different materials with high precision and speed. There are several types of fiber laser cutting machines available in the market, each with its unique characteristics and applications.

1. CO2 Laser Cutting Machine: This type of laser cutting machine uses a CO2 gas mixture as the laser source. It is commonly used for cutting non-metallic materials, such as fabrics, wood, acrylic, and plastics. CO2 laser cutting machines are known for their high-quality cuts and smooth edges.

2. Solid-State Laser Cutting Machine: Solid-state laser cutting machines use a solid-state laser medium, typically made of crystal or glass, to generate the laser beam. These machines are primarily used for cutting metals, such as stainless steel, aluminum, and copper. They offer high cutting speeds, excellent beam quality, and are known for their long service life.

3. Fiber Laser Cutting Machine: Fiber laser cutting machines use a fiber laser source that is generated within an optical fiber. These machines are best suited for cutting thin to medium thickness metals. They provide exceptional cutting speed, higher energy efficiency, and lower maintenance requirements compared to other laser cutting machines. Fiber laser cutting machines are widely used in industries like automotive, aerospace, and electronics.

4. YAG Laser Cutting Machine: YAG (yttrium-aluminum-garnet) laser cutting machines employ a solid-state laser medium, typically a crystal rod made of yttrium aluminum garnet. Although they have been largely replaced by fiber laser cutting machines, YAG lasers are still used for cutting thicker metals and materials like ceramics and glass.

5. UV Laser Cutting Machine: UV (ultraviolet) laser cutting machines use a UV laser source to cut materials with high precision, especially heat-sensitive materials. They are commonly used in the electronics industry for cutting PCBs (printed circuit boards) and microelectronics.

Laser cutting machines have revolutionized the manufacturing industry, offering increased efficiency, precision, and productivity. The right type of fiber laser cutting machine depends on the intended application, material, and desired cut quality, making it important to choose the most suitable option for specific requirements.

Pros and Cons of Using fiber laser cutting machines

Fiber laser cutting machines have become increasingly popular in industries that require precision cutting of various materials. Here are the pros and cons of using fiber laser cutting machines:

Pros:

1. Precise and high-quality cuts: Fiber laser cutting machines use a concentrated beam of light that can achieve very accurate and clean cuts, ensuring high-quality end products.

2. Versatility: These machines can cut a wide range of materials, including metals like stainless steel, aluminum, brass, and copper, as well as non-metals such as plastics and wood.

3. Faster cutting speeds: Fiber lasers are known for their fast cutting speeds compared to other cutting technologies. This allows for increased productivity and shorter production times.

4. Low maintenance: Fiber laser cutting machines have fewer moving parts, reducing the need for regular maintenance and minimizing the risk of breakdowns and downtime.

5. Energy-efficient: Fiber lasers require less power to operate compared to other types of lasers, resulting in lower operational costs.

6. Economy of space: Fiber laser cutting machines are compact and take up less floor space compared to traditional cutting machines, making them suitable for smaller workshops or facilities.

Cons:

1. Higher upfront cost: Fiber laser cutting machines can have a higher initial investment compared to other cutting machines. However, this cost can be justified by their efficiency and long-term benefits.

2. Limited thickness capacity: Fiber lasers are more suitable for thin to medium thickness materials. If you primarily work with thicker materials, other cutting technologies like plasma or waterjet may be more suitable.

3. Limited 3D cutting capability: Fiber lasers are primarily designed for 2D cutting and may not be as effective for complex 3D cutting tasks.

4. Consumable replacement: Fiber laser cutting machines require the regular replacement of consumable parts such as nozzles and lenses, adding to the overall operational costs.

5. Sensitivity to reflective materials: Fiber lasers are sensitive to highly reflective materials like copper and aluminum. Additional safety precautions and special settings may be required when working with such materials.

In conclusion, fiber laser cutting machines offer numerous advantages in terms of precision, versatility, speed, and energy efficiency. However, they may not be ideal for all cutting applications and require careful consideration of the specific requirements and materials involved.

fiber laser cutting machines Reference Specifications (varies for different product)

Fiber laser cutting machines are advanced tools used in the industrial sector for precision cutting of various materials. These machines utilize a high-powered fiber laser as the cutting tool, providing increased accuracy, efficiency, and versatility compared to traditional cutting methods.

When it comes to the reference specifications of fiber laser cutting machines, these may vary depending on the specific product and manufacturer. However, some common specifications to consider include the laser power, cutting speed, positioning accuracy, working area, and material thickness capacity.

Laser power is an essential parameter as it determines the cutting capability of the machine. Higher power lasers can cut through thicker and harder materials with ease. Cutting speed is another crucial factor, determining how quickly the machine can process materials.

Positioning accuracy refers to the precision of the laser beam’s movement, ensuring accurate and clean cuts. A high positioning accuracy is crucial for intricate and complex cutting tasks. The working area specification denotes the size of the cutting bed, which determines the maximum dimensions of materials that can be processed.

Additionally, fiber laser cutting machines have different material thickness capacities. Some machines can cut thin materials, such as sheet metal, while others are capable of cutting thick materials, such as steel plates.

Apart from these specifications, other factors to consider include the control system, software compatibility, cooling system, and maintenance requirements. The control system should provide user-friendly operation and allow for easy customization of cutting parameters. Software compatibility ensures seamless integration with design and programming software. A reliable cooling system is necessary to prevent overheating and maintain the stability of the laser source.

Overall, fiber laser cutting machines are revolutionizing the industrial cutting processes with their high precision, speed, and versatility. These machines offer a wide range of specifications to cater to various cutting requirements, making them indispensable tools in industries like automotive, aerospace, electronics, and more.

Applications of fiber laser cutting machines

Fiber laser cutting machines have revolutionized several industries by offering high-precision cutting capabilities and efficient processing of various materials. Here are some key applications where fiber laser cutters are widely used:

1. Manufacturing and Metal Cutting: Fiber laser cutters are extensively employed in the manufacturing industry to cut and shape metals such as stainless steel, aluminum, copper, brass, and several alloys. These machines provide precise cutting, allowing manufacturers to create intricate designs, parts, and components for automotive, aerospace, electronics, and consumer goods industries.

2. Automotive Industry: Fiber laser cutting machines find extensive application in the automotive sector for cutting and shaping metal components used in vehicles. They are utilized to precisely cut frame parts, body panels, exhaust pipes, brackets, and other metal components required for improved structural integrity and aesthetic appearance.

3. Electronics and Semiconductor Manufacturing: Fiber laser cutting machines are utilized in manufacturing electronic components such as PCBs (Printed Circuit Boards) and semiconductor wafers. These machines offer remarkable precision and minimize material wastage, ensuring the high-quality production of electronic components.

4. Signage and Advertising: Fiber lasers are widely used in the signage and advertising industry for cutting various materials like acrylic, MDF, plywood, and plastics. These machines can create precise, intricate, and intricate designs for logos, letters, and other signage elements, enhancing visual impact and brand recognition.

5. Medical Industry: Fiber laser cutting machines play a crucial role in the medical field for fabricating surgical instruments, medical devices, implants, and prosthesis. They offer highly accurate cutting, enabling the creation of intricate medical tools and components that are essential for precise surgical procedures.

6. Jewelry Making: With their exceptional precision, fiber laser cutters have become indispensable tools in the jewelry making industry. They can cut a wide range of materials used in jewelry production, including gold, silver, platinum, and precious stones. These machines assist jewelers in creating intricate designs and patterns on various jewelry pieces.

7. Aerospace Industry: Fiber laser cutting machines are extensively utilized in the aerospace sector for manufacturing aircraft parts and components. They help in cutting complex geometries and composite materials used in aircraft structures, reducing material waste and improving overall efficiency.

In summary, fiber laser cutting machines have diverse applications across different industries. Their high precision, speed, and versatility have contributed to enhanced productivity, improved quality, reduced material wastage, and superior product designs.

The Work Process and how to use fiber laser cutting machines

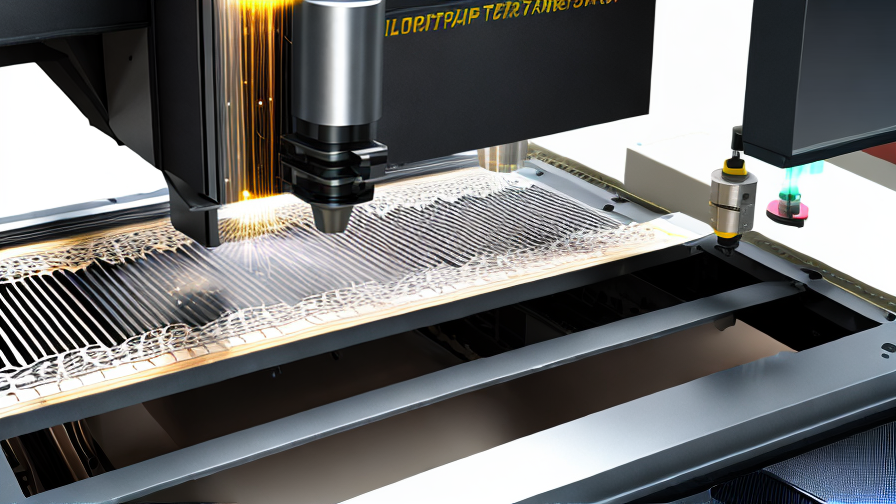

The work process of using fiber laser cutting machines involves several steps. Firstly, the material to be cut is placed onto the machine’s work table. Common materials that can be cut using fiber laser machines include metals like steel, aluminum, and copper.

Next, the operator selects the appropriate laser cutting parameters based on the thickness and type of material. These parameters include variables like power, feed rate, and assist gas pressure.

Once the parameters are set, the machine’s computer program is used to create a cutting path. This path determines the trajectory and shape of the laser beam as it cuts through the material. The program may also include additional instructions for piercings or other specific cutting techniques.

After setting up the program, the operator initiates the cutting process. The fiber laser generates a concentrated beam of light that is directed onto the material. As the laser beam moves along the cutting path, it vaporizes or melts the material along the desired lines. The assist gas, which is typically oxygen or nitrogen, helps to blow away the molten material and achieve a clean cut.

During the cutting process, the machine’s cutting head is controlled and guided by advanced motion systems, ensuring precision and accuracy. The laser cutting machine may also incorporate additional features like automatic nozzle changers or sensors to enhance efficiency and productivity.

Once the cutting is complete, the operator inspects the finished parts for quality and accuracy. Any excess material or slag can be removed manually or through secondary processes like deburring or grinding.

To optimize the use of fiber laser cutting machines, operators should ensure proper machine maintenance, cleanliness, and safety practices. Regular maintenance tasks such as checking and replacing consumables, cleaning the lenses, and keeping the work area free from debris or dust are crucial to ensure optimal cutting performance.

In conclusion, fiber laser cutting machines offer a versatile and efficient solution for various industrial cutting applications. By following the necessary steps and maintenance protocols, users can achieve high-quality precision cuts on different materials with ease.

Quality Testing Methods for fiber laser cutting machines and how to control the quality

Quality testing methods for fiber laser cutting machines ensure that the final output meets the required standards. These methods include visual inspection, dimensional measurements, and material integrity evaluation.

Visual inspection is the most basic and common quality testing method. It involves scrutinizing the cut edges to check for any defects such as dross, burrs, or cracks. Visual inspection helps identify any variations in cut quality and ensures that the machine is calibrated correctly.

Dimensional measurements are crucial for assessing the accuracy and precision of the cuts. This can be done using specialized measuring tools to compare the dimensions of the actual cuts with the targeted ones. Deviations beyond the acceptable limits indicate the machine’s performance needs adjustment or maintenance.

Material integrity evaluation involves testing the strength and durability of the cut material. This can be done through various techniques such as tensile testing, bend testing, or hardness testing. These tests ensure that the machine has not compromised the material’s structural integrity during the cutting process.

To control the quality of fiber laser cutting machines, several measures can be implemented. First, regular maintenance and calibration of the machine are essential to ensure its proper functioning. This includes cleaning the optics, checking the beam quality, and verifying the focus alignment.

Second, implementing a robust quality control system is vital. This system should include routine and periodic quality checks, documentation of test results, and analysis of trends to identify any potential issues or deviations.

Third, regular training and skill development for machine operators are essential. They need to understand the importance of quality standards, be capable of identifying defects, and have the necessary knowledge to troubleshoot problems.

Moreover, using high-quality consumables, such as cutting nozzles and lenses, plays a significant role in ensuring consistent quality. Regularly replacing worn-out parts helps maintain optimal performance.

Lastly, continuous improvement practices, such as Six Sigma or Lean manufacturing principles, can be adopted to optimize the quality and efficiency of fiber laser cutting machines. These methodologies focus on identifying and eliminating defects, reducing variability, and ensuring smooth operations.

In conclusion, quality testing methods for fiber laser cutting machines include visual inspection, dimensional measurements, and material integrity evaluation. To control the quality, regular maintenance, a robust quality control system, operator training, using high-quality consumables, and adopting continuous improvement practices are essential.

fiber laser cutting machines Sample Policy and Post-Purchase Considerations for fiber laser cutting machines from China

Sample Policy:

When purchasing fiber laser cutting machines from China, it is important to consider the sample policy offered by the supplier. Most suppliers would provide samples to potential buyers upon request. However, it is crucial to clarify whether the sample is available for free or if there is a cost associated with it. It is also recommended to inquire about the shipping fees and whether they will be refunded upon placing a bulk order.

Post-Purchase Considerations:

After purchasing fiber laser cutting machines from China, there are a few post-purchase considerations to keep in mind. Firstly, it is crucial to inspect the machine upon delivery to ensure that it meets the specified requirements and is in good working condition. Any damages or discrepancies should be immediately reported to the supplier for resolution.

Secondly, it is recommended to schedule a training session with the supplier to understand the operations and maintenance of the machine. This will help ensure efficient usage and prolong the lifespan of the equipment. Additionally, obtaining user manuals and technical support contact information can be beneficial in case any issues arise in the future.

Lastly, it is essential to discuss the warranty and after-sales service provided by the supplier. Clarify the duration of the warranty and what it covers, including parts and labor. Understand the procedure for warranty claims and the availability of spare parts for potential repairs. Reliable after-sales support is crucial for minimizing downtime and maximizing productivity.

In conclusion, when purchasing fiber laser cutting machines from China, it is important to inquire about the sample policy and clarify any associated costs. After the purchase, conducting thorough inspections, receiving training, and understanding the warranty and after-sales service are key considerations for a successful and satisfactory purchase experience.

Sourcing fiber laser cutting machines from China: Opportunities, Risks, and Key Players

Sourcing fiber laser cutting machines from China presents numerous opportunities for businesses looking to acquire high-quality equipment at competitive prices. China has emerged as a significant player in the manufacturing sector, offering a wide range of laser cutting machines that cater to various industries including automotive, aerospace, electronics, and more.

One of the main advantages of sourcing from China is the cost-effectiveness. Chinese manufacturers can produce fiber laser cutting machines at comparatively lower prices due to factors like lower labor costs and abundant raw materials. This makes it an attractive option for businesses seeking affordable yet reliable equipment.

China also boasts a well-developed industrial infrastructure, including state-of-the-art research and development facilities. With a focus on technological advancements, Chinese companies have made substantial progress in laser cutting machinery. The quality of the machines has significantly improved, ensuring precision cutting and high productivity.

However, sourcing from China also comes with certain risks. The quality control processes of some Chinese manufacturers may not meet international standards. Therefore, it is crucial for businesses to conduct thorough due diligence and engage with reputable suppliers. Verifying the manufacturer’s certifications, inspecting factory facilities, and requesting product samples can help mitigate potential risks.

Despite the risks involved, several key players in the Chinese market have established a strong reputation for producing top-notch fiber laser cutting machines. Notable manufacturers include Han’s Laser, Bodor Laser, Trumpf, and HSG Laser. These companies offer a wide range of models with varying power capacities and cutting capabilities, catering to the diverse needs of different industries.

In conclusion, sourcing fiber laser cutting machines from China provides favorable opportunities for businesses in terms of competitive pricing and technological advancements. However, buyers should exercise caution and consider potential risks while selecting reliable manufacturers such as Han’s Laser, Bodor Laser, Trumpf, and HSG Laser. Conducting comprehensive research, due diligence, and quality assessment can help ensure a successful sourcing experience from China.

How to find and select reliable fiber laser cutting machines manufacturers in China,use google search manufacturers and suppliers

When searching for reliable fiber laser cutting machine manufacturers in China, using Google search can be a helpful tool. Here are a few steps to follow when conducting your search:

1. Use relevant keywords: Begin by entering specific keywords related to fiber laser cutting machines, such as “fiber laser cutting machine manufacturers in China” or “reliable fiber laser cutting machine suppliers in China.”

2. Analyze search results: Look through the search results and visit the websites of potential manufacturers. Pay attention to their website design, content, and overall professionalism. Legitimate manufacturers usually have well-designed websites that provide detailed information about their products and services.

3. Assess manufacturer’s credibility: Look for information that shows the manufacturer’s credibility. Check if they are certified by relevant organizations and if they have ISO quality certifications. Also, look for any mentions of their manufacturing experience or customer testimonials to get an idea about their reputation.

4. Review product specifications: Evaluate the specifications, features, and capabilities of the fiber laser cutting machines they offer. Make sure the manufacturer’s machines meet your specific requirements and have the necessary cutting abilities for your desired materials and thickness.

5. Contact the manufacturer: Reach out to the manufacturers that seem promising and ask for more information or a quotation. Professional manufacturers will typically respond promptly to your inquiries and provide clear answers to your questions. Pay attention to their communication skills, as it reflects their commitment to customer service.

6. Evaluate after-sales support: Inquire about their after-sales services, such as warranty, technical support, and availability of spare parts. A reliable manufacturer will offer comprehensive after-sales support to ensure that their customers are satisfied with their products over the long term.

7. Compare prices and terms: Collect quotations from multiple manufacturers and compare their pricing, payment terms, and delivery options. Keep in mind that the cheapest option might not always be the best, so consider the overall value for money.

By following these steps, you can streamline your search for reliable fiber laser cutting machine manufacturers in China and choose a supplier that meets your requirements and provides high-quality products.

How to check fiber laser cutting machines manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To check the reliability of a fiber laser cutting machine manufacturer’s website, you can follow these steps:

1. Use Google Chrome: Open the website in Google Chrome, as it provides various features and extensions that can assist in evaluating the reliability of a website.

2. Install SEOquake Extension: Install the SEOquake extension in your Google Chrome browser. This extension allows you to view important SEO metrics and insights about a website.

3. Check Website Ranking: Once the SEOquake extension is installed, browse the manufacturer’s website and click on the SEOquake icon in your browser toolbar. A drop-down panel will appear, showing various statistics about the website, including its Google PageRank, Alexa Rank, and the number of indexed pages by search engines.

4. Verify Google PageRank: A higher Google PageRank indicates the website’s popularity and credibility. Check if the manufacturer’s website has a decent PageRank, preferably in the top 10 million websites globally. This implies that the website attracts a significant amount of traffic.

5. Evaluate Alexa Rank: Alexa Rank is another essential metric provided by SEOquake. It offers an estimate of a website’s popularity and traffic. A lower Alexa Rank generally signifies higher visitor engagement and relevance. Ensure the fiber laser cutting machine manufacturer’s website has a commendable Alexa Rank, preferably within the top 10 million websites.

6. Assess Indexed Pages: The number of indexed pages indicates the website’s visibility on search engines. More indexed pages generally imply better organic visibility and content depth. Verify that the manufacturer’s website has a substantial number of indexed pages by search engines, highlighting its credibility and online presence.

By using these methods, you can quickly assess the reliability of a fiber laser cutting machine manufacturer’s website in a concise manner, making an informed decision based on their rankings and online presence.

Top 10 fiber laser cutting machines manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Han’s Laser Technology Industry Group Co., Ltd.:

Han’s Laser offers a wide range of fiber laser cutting machines suitable for metal cutting applications. Their machines feature high cutting speed, precision, and low maintenance requirements. The company’s product lineup includes various models with different power options to meet different customer needs.

2. Jinan Bodor CNC Machine Co., Ltd.:

Jinan Bodor specializes in manufacturing fiber laser cutting machines with advanced technology and excellent cutting performance. Their machines are known for their high precision, efficiency, and reliability. Bodor offers a diverse range of models, including compact machines for small workshops and large-scale industrial cutting systems.

3. Wuhan Hans Goldensky Laser System Co., Ltd.:

Wuhan Hans Goldensky is a leading provider of fiber laser cutting machines in China. Their machines are designed to deliver high cutting speed, accuracy, and stability. Hans Goldensky offers a comprehensive range of models, including desktop machines for small businesses and large-scale industrial systems.

4. HGLASER Engineering Co., Ltd.:

HGLASER is known for its cutting-edge technology and innovative designs in fiber laser cutting machines. Their products offer precise cutting, high efficiency, and low energy consumption. HGLASER provides a wide range of models suitable for different industries, including automotive, aerospace, and electronics.

5. Suzhou Prima Laser Machinery Co., Ltd.:

Suzhou Prima Laser specializes in the production of fiber laser cutting machines with high-speed and high-precision cutting capabilities. Their machines are versatile and can handle various materials, including metal sheets, pipes, and tubes. Prima Laser offers a range of models in different sizes and power options.

6. Shenzhen DNE Laser Science and Technology Co., Ltd.:

DNE Laser is a leading manufacturer of fiber laser cutting machines with a focus on high cutting precision and efficiency. Their machines are equipped with advanced features like automatic edge detection and intelligent piercing control. DNE Laser offers a diverse range of models suitable for different industries and applications.

7. Jinan SENFENG Technology Co., Ltd.:

SENFENG Technology specializes in the production of fiber laser cutting machines with exceptional cutting performance and durability. Their machines offer high-speed cutting, smooth edges, and minimal heat-affected zones. SENFENG offers a variety of models in different power configurations to cater to various customer requirements.

8. JQ Laser CNC Equipment Co., Ltd.:

JQ Laser CNC Equipment is known for its reliable and efficient fiber laser cutting machines. Their products are designed to deliver high cutting quality, precision, and stability. JQ Laser offers a comprehensive range of models suitable for both small-scale and large-scale metal cutting applications.

9. Wuhan Huagong Laser Engineering Co., Ltd.:

Wuhan Huagong Laser Engineering specializes in the production of high-power fiber laser cutting machines for heavy-duty industrial applications. Their machines are capable of cutting thick metal sheets with high precision and speed. Huagong Laser offers a range of models with different power options to meet various customer requirements.

10. Nanjing Speedy Laser Technology Co., Ltd.:

Nanjing Speedy Laser Technology focuses on the development and production of fiber laser cutting machines with innovative features and reliable performance. Their machines offer high cutting accuracy, speed, and stability. Speedy Laser offers a range of models suitable for different industries, including automotive, aerospace, and fabrication.

| Manufacturer Name | Key Features |

|——————————-|—————————————————————-|

| Han’s Laser Technology | High cutting speed, precision, and low maintenance |

| Jinan Bodor CNC Machine | Advanced technology, high precision, and efficiency |

| Wuhan Hans Goldensky Laser | High cutting speed, accuracy, and stability |

| HGLASER Engineering | Cutting-edge technology and low energy consumption |

| Suzhou Prima Laser | High-speed and high-precision cutting capabilities |

| Shenzhen DNE Laser Science | Advanced features like automatic edge detection |

| Jinan SENFENG Technology | Exceptional cutting performance and durability |

| JQ Laser CNC Equipment | Reliable and efficient cutting machines |

| Wuhan Huagong Laser | High-power machines for heavy-duty industrial applications |

| Nanjing Speedy Laser | Innovative features and reliable performance |

Background Research for fiber laser cutting machines manufacturers Companies in China, use qcc.com archive.org importyeti.com

China is known as a major hub for manufacturing various industrial machinery, including fiber laser cutting machines. To conduct background research on fiber laser cutting machine manufacturers in China, three reliable platforms can be utilized: qcc.com, archive.org, and importyeti.com.

Qcc.com, also known as the QualityChinaSuppliers, is a comprehensive B2B platform that provides information about Chinese companies and their products. By visiting Qcc.com, one can access a large database of fiber laser cutting machine manufacturers in China. The platform offers detailed company profiles, including contact information, product catalogs, and company certifications.

Archive.org, also known as the Internet Archive, is a non-profit digital library that offers access to a wide range of historical web pages. By utilizing Archive.org, one can access previous versions of websites belonging to fiber laser cutting machine manufacturers in China. This can help trace the development and growth of these companies over time.

Importyeti.com is a platform that provides import and export data on various products and companies worldwide. By using Importyeti.com, one can obtain information about the shipment records of fiber laser cutting machines imported into different countries from China. This database can provide insights into the export activities of Chinese manufacturers and their global reach.

By combining the information collected from these platforms, researchers can gain valuable insights into the background and operations of fiber laser cutting machine manufacturers in China. The Qcc.com platform provides details about manufacturers, while Archive.org and Importyeti.com offer historical web data and import/export records, respectively. This comprehensive background research can support further analysis and decision-making for potential partnerships or sourcing opportunities.

Leveraging Trade Shows and Expos for fiber laser cutting machines Sourcing in China

Trade shows and expos are valuable platforms for sourcing fiber laser cutting machines in China due to several reasons. Firstly, these events provide a concentrated gathering of suppliers and manufacturers, allowing buyers to compare and evaluate different options under one roof. This saves time and effort in visiting multiple factories or conducting extensive online research.

Secondly, trade shows and expos offer opportunities for face-to-face interactions with suppliers. This enables buyers to establish relationships, negotiate pricing and terms, and gain a better understanding of the quality and capabilities of the fiber laser cutting machines on display. Direct communication also facilitates clarifying any doubts and addressing concerns.

Moreover, attending trade shows and expos in China provides firsthand exposure to the latest trends, technologies, and innovations in the fiber laser cutting machine industry. This knowledge enables buyers to stay up-to-date and make informed decisions about the most suitable machines for their specific requirements. Additionally, attending these events allows buyers to network with industry experts, seek recommendations, and learn from peers’ experiences.

To make the most of trade shows and expos, proper planning and research are essential. Buyers should identify relevant events and research participating exhibitors in advance. It is advisable to create a list of potential suppliers based on their reputation, product range, and customer reviews. Setting up meetings or appointments with shortlisted suppliers in advance ensures effective use of time during the event.

In conclusion, leveraging trade shows and expos for sourcing fiber laser cutting machines in China offers numerous advantages, including concentrated supplier options, face-to-face interactions, exposure to industry trends, and networking opportunities. By utilizing these platforms efficiently, buyers can save time, make informed decisions, and establish reliable partnerships with reputable Chinese suppliers.

The Role of Agents and Sourcing Companies in Facilitating fiber laser cutting machines Purchases from China

Agents and sourcing companies play a vital role in facilitating the purchase of fiber laser cutting machines from China. These entities act as intermediaries between the buyers and the manufacturers, streamlining the entire procurement process and ensuring a smooth transaction.

One of the main advantages of using agents and sourcing companies is their in-depth knowledge of the Chinese market and the manufacturing industry. They have extensive networks and connections with reliable manufacturers, making it easier for buyers to find reputable suppliers for fiber laser cutting machines. This saves buyers the time and effort required to conduct extensive research and due diligence.

Agents and sourcing companies also serve as a bridge for effective communication. Language and cultural differences can often create barriers between international buyers and Chinese manufacturers. Agents act as interpreters, facilitating clear and concise communication between both parties. They help buyers convey their specific requirements, negotiate prices, and ensure that all terms and conditions are properly understood.

Moreover, agents and sourcing companies assist in quality control and inspection processes. They have professional teams that can conduct factory audits, assess production capabilities, and inspect the quality of the finished products. This ensures that buyers receive high-quality fiber laser cutting machines that meet their expectations.

Another significant advantage of using agents and sourcing companies is their expertise in navigating the complex logistics involved in international trade. They handle all documentation, shipping arrangements, customs clearance, and any other logistical challenges that may arise. This relieves buyers from the burden of dealing with these intricacies and allows them to focus on their core business activities.

In summary, agents and sourcing companies play a crucial role in facilitating the purchase of fiber laser cutting machines from China. They provide market expertise, effective communication, quality control, and logistical support. By leveraging their services, buyers can confidently source and import these machines, ensuring a successful and hassle-free procurement process.

Price Cost Research for fiber laser cutting machines manufacturers Companies in China, use temu.com and 1688.com

When it comes to purchasing fiber laser cutting machines, China is one of the leading manufacturing hubs in the world. If you are looking for reliable manufacturers in China, two popular platforms to explore are Temu.com and 1688.com.

Temu.com is a reputable online marketplace that connects buyers with verified suppliers in China. Many fiber laser cutting machine manufacturers can be found on this platform. To conduct price cost research on Temu.com, follow these steps:

1. Visit the Temu.com website and create an account if you haven’t already.

2. Use the search bar on the homepage to look for “fiber laser cutting machines.”

3. Click on the relevant category to view the available options.

4. Browse through the supplier profiles and product listings to gather information about the machines and their prices.

5. Contact multiple suppliers to inquire about price quotations, specifications, and any other relevant details.

1688.com, on the other hand, is a prominent wholesale marketplace owned by Alibaba Group. It is primarily in Chinese, so using a translation tool like Google Translate can be helpful. Here’s how to utilize 1688.com for price cost research:

1. Go to the 1688.com website and sign in or create an account if required.

2. Use keywords like “光纤激光切割机” (fiber laser cutting machine) in the search bar.

3. Browse through the search results, supplier profiles, and product listings.

4. Note down the prices, features, and contact information of the manufacturers that suit your requirements.

5. Use translation tools or communicate with the suppliers via professional sourcing agents who are familiar with the Chinese language.

In conclusion, both Temu.com and 1688.com are valuable platforms to research and find fiber laser cutting machine manufacturers in China. While Temu.com offers a more English-friendly interface, 1688.com provides an extensive range of options at competitive prices. By leveraging these platforms, you can effectively gather price cost information and connect with reliable suppliers for your fiber laser cutting machine needs.

Shipping Cost for fiber laser cutting machines import from China

The shipping cost for importing fiber laser cutting machines from China depends on several factors. The main factors include the weight and dimensions of the machines, the shipping method chosen (air, sea, or land), and the destination country.

For lighter and smaller machines, air freight is usually the preferred shipping method. The cost of air freight is higher compared to sea or land freight, but it is much faster, making it a popular choice for urgent shipments. Air freight charges are based on the weight and volume of the cargo, as well as the distance between the origin and destination airports.

For larger and heavier machines, sea freight is a more economical option. The cost of sea freight is calculated based on the volume (in cubic meters) or weight (in tons) of the cargo. Additional charges may apply for the use of containers, handling at the ports, and customs clearance. The shipping time for sea freight can range from a few weeks to a couple of months, depending on the distance and the efficiency of the shipping line.

Land freight is another option for nearby countries or regions. It is usually less expensive than air or sea freight and can be faster than sea freight. The cost of land freight is based on the distance and the type of transportation used, such as trucks or trains.

It is important to note that certain additional costs may apply when importing from China, such as customs duties, taxes, and handling fees. These costs vary depending on the destination country and the value of the machines.

To get an accurate estimate of the shipping cost, it is recommended to contact shipping companies or freight forwarders who specialize in international shipments. They can provide detailed quotations based on the specific requirements and provide guidance on the import process, documentation, and any additional costs that may be incurred.

Compare China and Other fiber laser cutting machines Markets: Products Quality and Price,Visible and Hidden Costs

China is recognized as a major player in the fiber laser cutting machines market. The country offers a wide range of products with varying quality and prices. Chinese manufacturers have gained a strong reputation for producing cost-effective machines, making it a popular destination for buyers looking for affordable options.

The quality of Chinese fiber laser cutting machines has significantly improved over the years. Many manufacturers have invested in advanced technologies and equipment to enhance the precision and performance of their products. Some Chinese brands have even achieved international recognition for their high-quality machines.

However, it is important to note that not all Chinese manufacturers offer the same level of quality. Some lower-priced machines may lack durability and precision, which can affect their longevity and performance. Buyers should carefully research and evaluate the reputation and track record of specific manufacturers before making a purchase.

When comparing the price of Chinese fiber laser cutting machines to those from other markets, it is generally observed that China offers highly competitive prices. This affordability factor has contributed to the country’s popularity as a global supplier. Buyers can often find lower-priced machines in China compared to other markets, making it an attractive destination for cost-conscious customers.

In terms of visible costs, Chinese manufacturers typically offer transparent pricing structures that include the base product price, additional features or accessories, and shipping costs. Buyers can easily compare and calculate the total cost of the machine before making a purchase.

However, hidden costs can sometimes arise when purchasing from China. Import duties, taxes, and customs charges can significantly impact the final cost. Additionally, buyers may face challenges related to warranty and after-sales services when dealing with Chinese manufacturers. It is crucial for buyers to factor in these potential hidden costs and carefully assess the risks involved.

In conclusion, China is a prominent player in the fiber laser cutting machines market, known for offering a wide range of products with varying quality and prices. While the country has made significant advancements in terms of product quality, buyers should exercise caution and thoroughly evaluate specific manufacturers to ensure they receive a machine that meets their requirements. China’s affordability factor is a strong advantage, but it is essential to consider potential hidden costs such as import duties and after-sales service limitations.

Understanding Pricing and Payment Terms for fiber laser cutting machines: A Comparative Guide to Get the Best Deal

When purchasing a fiber laser cutting machine, understanding the pricing and payment terms is crucial to ensure you get the best deal. This comparative guide aims to provide valuable insights in less than 300 words.

Pricing for fiber laser cutting machines can vary significantly based on various factors such as power, size, and brand. Generally, higher power machines are more expensive. Additionally, machines with larger work areas and advanced features tend to have higher price tags.

When comparing prices, it is important to consider the overall value rather than just the initial cost. A machine with a higher price may offer better quality, durability, and performance, which can result in long-term cost savings by reducing maintenance and downtime.

Payment terms for fiber laser cutting machines can also vary. Most suppliers offer different payment options, including upfront payment, installment plans, or leasing arrangements. Upfront payment typically offers the advantage of lower overall costs, as it eliminates interest charges. However, this option may not be feasible for all businesses, especially those with limited capital.

Installment plans allow the machine to be paid in multiple payments over a specified period. This option can be beneficial for businesses with restricted budgets, as it spreads the cost over time. However, it is important to inquire about any interest or additional fees associated with installment plans.

Leasing arrangements involve paying a fixed monthly fee while using the machine. This option allows businesses to conserve capital and provides flexibility to upgrade equipment in the future. However, leasing may result in higher overall costs compared to purchasing the machine outright.

In addition to pricing and payment terms, it is essential to consider after-sales support, warranty coverage, and maintenance services offered by the supplier. A reputable supplier should provide comprehensive support to ensure the smooth operation of the machine.

In conclusion, when purchasing a fiber laser cutting machine, it is crucial to consider pricing, payment terms, overall value, and after-sales support. Careful evaluation of these factors will help you secure the best deal and enable your business to leverage the benefits of this highly efficient and versatile technology.

Chinese Regulations and Industry Standards Certifications for fiber laser cutting machines,Import Regulations and Customs for fiber laser cutting machines from China

China has specific regulations and industry standards certifications for fiber laser cutting machines. The most prominent certification is the China Compulsory Certification (CCC), also known as the 3C certification. This certification is mandatory for all products imported, sold, or used in China and ensures that the products meet safety, health, and environmental protection requirements.

In addition to CCC certification, there are industry standards certifications like ISO 9001, which ensures the quality management system of the manufacturer, and ISO 14001, which certifies the environmental management system. These certifications assure the buyer that the fiber laser cutting machine meets international standards.

When importing fiber laser cutting machines from China, it is important to understand the import regulations and customs procedures. The first step is to conduct research and identify the specific regulations governing the import of such machinery in your country. This may involve compliance with safety and quality standards, customs tariffs, and documentation requirements.

Customs clearance is a crucial process when importing fiber laser cutting machines. It involves providing the necessary shipping documents, such as a bill of lading, commercial invoice, packing list, and import licenses or permits. It is important to work with a reputable freight forwarder or customs broker who can assist in fulfilling the customs requirements.

Regarding the transportation of the machinery, it is essential to ensure proper packaging and labeling to prevent any damage during transit. The packaging should conform to international standards, and special care must be taken to protect delicate components.

In conclusion, importers of fiber laser cutting machines from China must adhere to the specific regulations and industry standards certifications in both countries. Understanding and complying with these requirements will enable a smooth and successful import process.

Sustainability and Environmental Considerations in fiber laser cutting machines Manufacturing

Sustainability and environmental considerations are becoming increasingly important in the manufacturing industry, including in the production of fiber laser cutting machines. These considerations focus on reducing the environmental impact of manufacturing processes and products, conserving resources, and promoting sustainable practices.

One important aspect of sustainability in the manufacturing of fiber laser cutting machines is the efficient use of materials. By implementing design strategies that minimize waste and optimize material usage, manufacturers can reduce the consumption of raw materials and minimize the generation of waste. This can be achieved through techniques such as computer-aided design (CAD) software, which allows for precise material calculations, and nesting software, which optimizes the arrangement of parts on a sheet of material to minimize waste.

Another key consideration is energy efficiency. Fiber laser cutting machines require significant amounts of energy to operate, and improving their energy efficiency can make a substantial difference in reducing their overall environmental impact. Manufacturers can achieve this by implementing energy-saving technologies, such as high-efficiency motors and power management systems. Additionally, optimizing the operational parameters of the machines, such as laser power and cutting speed, can also help minimize energy consumption.

The choice of materials used in the manufacturing process also plays a crucial role in sustainability. Manufacturers can opt for environmentally friendly materials, such as recycled or recyclable metals and plastics, to reduce the environmental impact of their products. Additionally, the use of eco-friendly coatings or finishes can further enhance the sustainability of fiber laser cutting machines.

In terms of the manufacturing process itself, reducing water consumption and properly managing wastewater are important considerations. Implementing water-saving measures, such as using closed-loop cooling systems and recycling water whenever possible, can help minimize water usage. Proper treatment of wastewater and adherence to local environmental regulations are also essential to prevent pollution and ensure sustainable manufacturing practices.

Overall, incorporating sustainability and environmental considerations in the manufacturing of fiber laser cutting machines not only reduces their environmental impact but also aligns with the increasing global emphasis on sustainable practices. By adopting efficient material usage, energy-saving technologies, and environmentally friendly materials, manufacturers can contribute to a greener manufacturing industry and meet the growing demand for sustainable products.

List The Evolution history of “fiber laser cutting machines”

Fiber laser cutting machines have undergone significant evolution since their introduction in the late 1990s. Initially, these machines faced various challenges that limited their efficiency and capabilities. However, continuous advancements in technology have revolutionized the field, resulting in highly efficient and versatile fiber laser cutting machines.

In the early stages, fiber lasers faced difficulties with beam quality and power output limitations. These challenges affected both the precision and cutting speed of the machines. As a result, fiber lasers were primarily used for thinner materials and lower power applications.

The introduction of high-power fiber lasers in the early 2000s marked a significant milestone in the evolution of these machines. With increased power output, fiber lasers became more capable of cutting thicker materials and achieving faster cutting speeds. This development opened up new possibilities in various industries, including automotive, aerospace, and manufacturing.

Another key advancement was the development of beam delivery systems. Traditional fiber laser cutting machines utilized rigid beam delivery systems such as hard optics, which restricted the flexibility and movement of the laser beam. However, with the introduction of flexible fiber optic cables, beam delivery became more versatile and allowed for greater maneuverability, enhancing the cutting precision and efficiency.

In recent years, the integration of artificial intelligence and automation technologies has further transformed fiber laser cutting machines. AI-based software and control systems enable real-time monitoring, predictive maintenance, and optimization of cutting parameters. This results in improved cutting accuracy, reduced downtime, and increased productivity.

Furthermore, the evolution of fiber laser cutting machines has also seen advancements in the design of machine structures and cutting heads. Lightweight structures and advanced cooling systems have reduced energy consumption and increased the longevity of these machines. The development of high-speed cutting heads with improved focusing abilities has enhanced the overall cutting quality and efficiency.

Overall, the evolution of fiber laser cutting machines has been driven by advancements in laser technology, beam delivery systems, AI integration, and machine design. These developments have transformed these machines into highly efficient, versatile, and precise tools, capable of handling a wide range of materials and applications. With ongoing research and innovation, the future of fiber laser cutting machines holds the promise of even greater advancements, pushing the boundaries of what is possible in the field of laser cutting.

The Evolution and Market Trends in fiber laser cutting machines Industry

The fiber laser cutting machines industry has witnessed significant evolution and market trends over the years. Fiber lasers have become increasingly popular and have gained a significant market share due to their superior performance in cutting various materials.

One of the key evolution trends in the industry is the shift from traditional CO2 lasers to fiber lasers. Fiber lasers offer several advantages such as high precision cutting, faster speeds, lower operating costs, and better energy efficiency. These features have made fiber lasers the preferred choice for many industries, including automotive, aerospace, and manufacturing.

Furthermore, advancements in fiber laser technology have led to the development of high-power fiber lasers. These lasers offer even greater cutting capabilities and can handle thicker materials. This has expanded the application range of fiber lasers and increased their appeal to industries that require heavier-duty cutting.

Alongside technological advancements, there have been market trends influencing the fiber laser cutting machines industry. One such trend is the increasing demand for automation in manufacturing processes. This has led to the integration of fiber laser cutting machines with robotic and CNC systems, allowing for improved efficiency, accuracy, and productivity.

Another notable market trend is the rising focus on sustainability and environmental consciousness. Fiber lasers are more environmentally friendly compared to traditional cutting methods. They produce minimal waste, consume less energy, and do not require the use of harmful gases. As sustainability becomes a priority for many industries, the demand for fiber laser cutting machines is expected to grow.

In terms of the market outlook, the fiber laser cutting machines industry is projected to experience steady growth in the coming years. The automotive and aerospace sectors, in particular, are expected to drive this growth due to their increasing adoption of fiber lasers for precision cutting applications.

Overall, the evolution and market trends in the fiber laser cutting machines industry highlight the continuous improvements in technology, the shift towards sustainability, and the growing demand for automation. These factors contribute to the expanding market share and bright future prospects for fiber laser cutting machines.

Custom Private Labeling and Branding Opportunities with Chinese fiber laser cutting machines Manufacturers

Chinese fiber laser cutting machine manufacturers offer excellent opportunities for custom private labeling and branding. With their expertise and advanced manufacturing capabilities, they can create customized machines that meet specific requirements. Private labeling allows companies to have their logo, brand name, and unique designs on the machines, which enhances brand visibility and recognition in the market.

Chinese manufacturers understand the importance of branding and can provide a range of customization options. This includes designing machines in various sizes, power capacities, and cutting capabilities to cater to specific industry needs. They can also incorporate additional features and accessories based on customer preferences.

Moreover, Chinese manufacturers offer cost-effective solutions for private labeling and branding. With their competitive pricing and large-scale production capabilities, they can provide high-quality machines at a lower cost compared to manufacturers in other countries.

Collaborating with Chinese fiber laser cutting machine manufacturers for private labeling and branding also allows companies to benefit from their expertise and experience. These manufacturers have a deep understanding of the laser cutting technology and market trends. They can provide valuable insights and suggestions to improve the design and performance of the machines.

In conclusion, Chinese fiber laser cutting machine manufacturers offer attractive opportunities for custom private labeling and branding. Their manufacturing capabilities, customization options, competitive pricing, and industry expertise make them an ideal partner for companies looking to establish their brand presence and offer specialized laser cutting solutions to their customers.

Tips for Procurement and Considerations when Purchasing fiber laser cutting machines

When it comes to purchasing a fiber laser cutting machine, there are several important considerations to keep in mind. Here are some tips and factors to consider:

1. Machine specifications: Look for a machine that meets your specific requirements in terms of cutting speed, cutting thickness, and bed size. Consider your current and future needs to ensure the machine can handle your workload.

2. Power source: Fiber laser cutting machines use either a solid-state laser or a gas laser. While gas lasers are more affordable, solid-state lasers offer higher cutting precision and lower maintenance requirements.

3. Manufacturer reputation and support: Research the reputation and track record of the manufacturer you are considering. Choose a reputable brand that offers reliable customer service, technical support, and spare parts availability.

4. Machine build quality: Consider the build quality of the machine, as it will directly impact its performance and lifespan. Look for machines built with durable materials and sturdy construction.

5. Software compatibility: Ensure that the laser cutting machine is compatible with your existing software systems. Compatibility issues can cause delays and inefficiencies in your workflow.

6. Safety features: Look for safety features such as protective enclosures, interlocks, and emergency stop buttons. Safety should be a top priority to protect both the operators and the machine.

7. Price and budget: Consider your budget and the long-term return on investment. While cheaper machines may seem appealing, they may lack the necessary features or have higher maintenance costs in the long run.

8. Training and support: Ensure that the manufacturer or supplier provides comprehensive training for your operators. Also, inquire about ongoing technical support to address any issues that may arise.

9. Warranty and service: Review the warranty provided with the machine and understand the coverage it offers. Also, check if additional service agreements are available.

10. Performance and reviews: Look for customer reviews and testimonials for the specific model you are considering. Learning from the experiences of others can help you make an informed decision.

By considering these factors and doing thorough research, you can purchase a fiber laser cutting machine that meets your needs, provides reliable performance, and offers a good return on investment in the long term.

FAQs on Sourcing and Manufacturing fiber laser cutting machines in China

Q: Why should I consider sourcing fiber laser cutting machines from China?

A: China is one of the largest manufacturers of industrial machinery, including fiber laser cutting machines. It offers a wide range of options at competitive prices due to economies of scale, abundant raw materials, and experienced labor force. Additionally, many Chinese manufacturers have a good reputation for producing high-quality and reliable machines.

Q: How do I find reliable suppliers of fiber laser cutting machines in China?

A: There are various ways to find reliable suppliers in China. One option is to attend industry exhibitions and trade shows, such as the Canton Fair, where you can establish direct connections with manufacturers. Online platforms like Alibaba and Made-in-China are also popular for sourcing products from Chinese suppliers. It is essential to thoroughly research potential suppliers, read customer reviews, and request samples or visit their factories before making a decision.

Q: What should I consider when choosing a fiber laser cutting machine supplier in China?

A: When selecting a supplier, it is crucial to consider factors such as the company’s experience in manufacturing laser cutting machines, their technical expertise, production capacity, and certifications. Ensuring that the supplier has a robust quality control process in place is important to guarantee the reliability and precision of the machines. It is also advisable to inquire about after-sales services and warranty options.

Q: Are there any potential challenges or risks associated with sourcing fiber laser cutting machines from China?

A: Some of the challenges include language barriers, cultural differences, and the need for effective communication. It is essential to clearly communicate your requirements, specifications, and quality expectations with the supplier to avoid misunderstandings. Another potential risk is intellectual property infringement, so it is advisable to work with reputable and licensed manufacturers.

Q: What are the average lead times for manufacturing fiber laser cutting machines in China?

A: The lead times for manufacturing fiber laser cutting machines in China can vary depending on several factors, including machine complexity and customization requirements. On average, it can take around 30 to 60 days from placing the order to shipment. However, it is recommended to confirm the lead times with the supplier beforehand.

Q: Are there any additional costs or considerations I should be aware of?

A: In addition to the machine cost, it is crucial to consider additional costs such as shipping, import duties, customs clearance, and any necessary certifications or registrations. These costs may vary depending on your country’s regulations and requirements. It is advisable to work with a freight forwarder or logistics expert to handle the import process smoothly.

In conclusion, sourcing and manufacturing fiber laser cutting machines in China can offer various benefits in terms of cost-effectiveness and a wide range of options. However, it is crucial to conduct thorough research, due diligence, and communication with potential suppliers to mitigate any risks or challenges involved.

Why contact sourcifychina.com get free quota from reliable fiber laser cutting machines suppliers?

Sourcifychina.com may receive a free quota from reliable fiber laser cutting machines suppliers for several reasons:

1. Building partnerships: Sourcifychina.com aims to establish solid relationships with trustworthy fiber laser cutting machine suppliers. By offering a free quota, suppliers can showcase their product quality and demonstrate their commitment to long-term cooperation.

2. Demonstrating reliability: By allowing Sourcifychina.com to test and verify their fiber laser cutting machines through a free quota, suppliers can demonstrate the reliability and performance of their products. This helps build trust with potential customers and provides evidence of their capabilities.

3. Market exposure: Sourcifychina.com serves as a platform connecting global buyers with Chinese suppliers. By providing a free quota, suppliers can increase their market exposure and reach a wider audience. It allows them to showcase their products to potential buyers who might not have otherwise considered them.

4. Competitive advantage: In a highly competitive market, offering a free quota gives suppliers a competitive edge. It allows potential buyers to compare different suppliers’ products and services without any upfront costs. Suppliers can stand out by providing a free quota, which can attract more customers and potentially lead to future orders.

5. Customer satisfaction: By offering a free quota, suppliers prioritize customer satisfaction. It allows buyers to assess the quality, precision, and efficiency of the fiber laser cutting machines before making a purchase. This helps ensure that customers are satisfied with their investment and are more likely to make repeat purchases or recommend the supplier to others.

In conclusion, providing Sourcifychina.com with a free quota allows reliable fiber laser cutting machine suppliers to build partnerships, demonstrate reliability, gain market exposure, gain a competitive advantage, and prioritize customer satisfaction. It is a mutually beneficial arrangement that can lead to long-term business relationships.