Knowledge about Fiber Laser Marking Machine

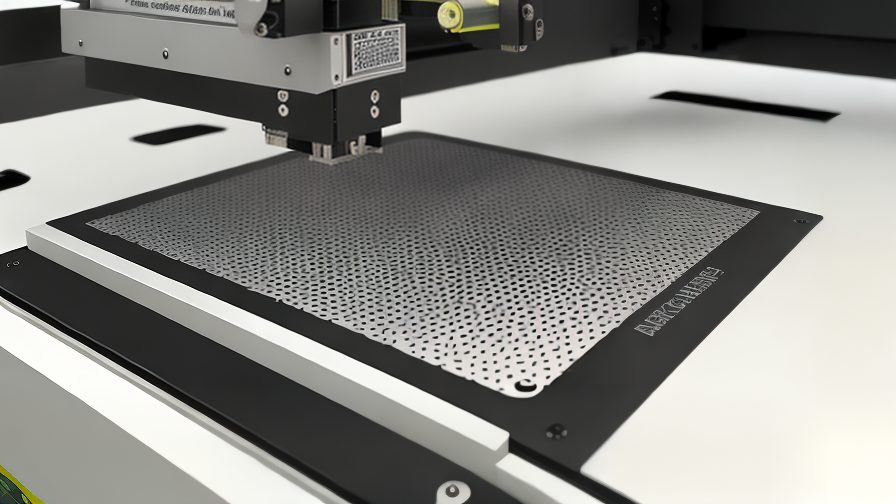

Fiber laser marking machines are a popular choice in the manufacturing industry due to their high accuracy and versatility. They are used to mark a variety of materials like metal, plastic, and wood.

These machines use fiber laser technology, which uses a laser beam to create marks or engravings on the surface of the material. The laser beam is focused on a small area, which vaporizes the material to create a permanent mark. The fiber laser marking machine is controlled by software, which allows for precise control of the marking process.

When using a fiber laser marking machine, it is important to choose the right settings for the material being marked. The power, frequency, and speed of the laser need to be adjusted to ensure that the mark is clear and permanent. It is also important to take into account the depth of the mark, the size of the mark, and the type of mark being made, such as a logo or serial number.

Fiber laser marking machines can be used in a variety of industries, including automotive, aerospace, medical, and electronics. In the automotive industry, they are used to mark engine parts, while in the medical industry, they are used to mark surgical instruments.

One of the key benefits of fiber laser marking machines is their speed. They are able to mark materials quickly and efficiently, which is important in manufacturing where time is often of the essence. They are also able to create high-quality marks that are permanent and resistant to wear and tear.

In conclusion, knowledge about fiber laser marking machines is important for anyone working in the manufacturing industry. Understanding how to choose the right settings for the material being marked, and how to use the machine efficiently, can help to improve productivity and quality. With their speed and accuracy, fiber laser marking machines are a valuable tool in modern manufacturing.

Various Types of Fiber Laser Marking Machine

Fiber laser marking machine is a type of laser engraving and marking equipment that uses high-powered fiber lasers to create precise and permanent markings on a variety of materials such as metals, plastics, and ceramics.

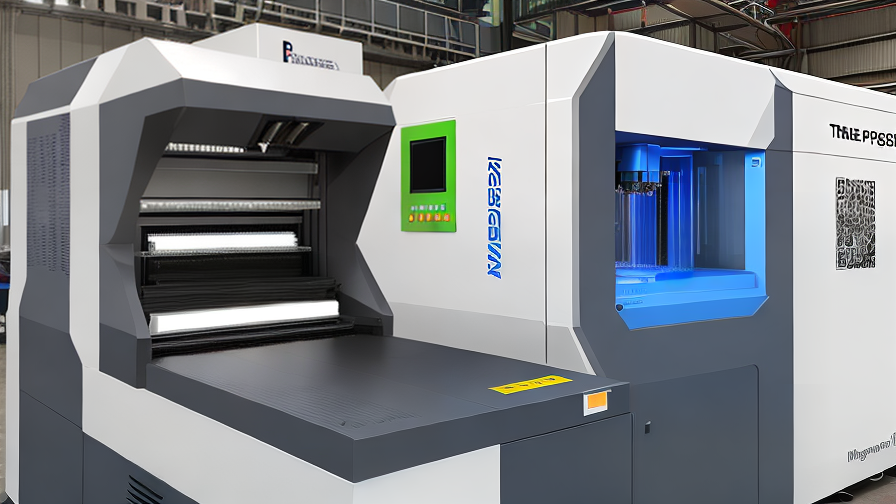

There are different types of fiber laser marking machines available in the market, each designed to meet specific needs and functions. For instance, some fiber laser marking machines are designed for heavy-duty use in large manufacturing plants, while others are built for smaller businesses or workshops.

Here are a few common types of fiber laser marking machines:

1. Desktop fiber laser marking machines: These are small-sized machines that are perfect for marking small objects like jewelry, medical equipment, and electronic components, among others.

2. Portable fiber laser marking machines: These machines are designed to be mobile, and they are ideal for on-site marking of large objects, such as pipes or heavy equipment.

3. Handheld fiber laser marking machines: These machines are designed to be held in the hand, which makes them very portable and easy to use for marking objects in difficult-to-reach places.

4. 3D fiber laser marking machines: These machines are designed to create 3D markings on curved or uneven surfaces, making them a popular choice in the automotive and aerospace industries.

5. High-speed fiber laser marking machines: These machines are built for high-volume production environments, where speed and efficiency are critical.

When choosing a fiber laser marking machine, it is essential to consider your specific needs and intended applications. Factors like the size of the object to be marked, the materials being marked, and the volume of production should be considered before making a decision on which type of fiber laser marking machine to use.

In conclusion, fiber laser marking machines are versatile and effective tools for marking and engraving materials. Knowing the various types of fiber laser marking machines available in the market can help you choose the right equipment for your specific needs.

FAQ sourcing Fiber Laser Marking Machine manufacturer from China

Fiber laser marking machines have become widely popular in various industries because of their efficiency, accuracy, and speed in marking materials. China is one of the top manufacturers of these machines, but before deciding on which manufacturer to purchase from, it’s important to know the answers to some frequently asked questions. Here are some of them:

1. How can I make sure the fiber laser marking machine is high-quality?

The quality of the machine can be ensured by checking if it has passed internationally recognized standards such as CE, ISO, and FDA. It should also be made from high-quality components and subjected to rigorous testing.

2. How long is the warranty for the machine?

The warranty period depends on the manufacturer, but it typically ranges from 1-3 years.

3. What materials can be marked using fiber laser machines?

Fiber laser marking machines can mark various materials such as metals (stainless steel, aluminum, copper, brass, gold, silver), plastics, ceramics, and even some kinds of glass.

4. How much does a fiber laser marking machine cost?

The price of the machine can vary depending on the manufacturer and the specifications of the machine. Generally, they range from $3,000 to $50,000.

5. How long does it take to mark materials using fiber laser machines?

The speed of the machine depends on the material, depth of the marking, and the complexity of the design. Generally, fiber laser marking machines can mark materials at a speed of 7,000mm/s to 12,000mm/s.

In summary, when sourcing a fiber laser marking machine from China, it is important to consider the quality, warranty period, materials that can be marked, cost, and speed. These factors can help you find the right manufacturer that meets your requirements.

Applications of Fiber Laser Marking Machine

Fiber laser marking machines have become an essential part of modern industrial processes. The technology offers a more efficient and precise way of marking materials than traditional methods. The versatility of this technology and its applications have made it a popular choice across a broad range of industries.

One of the main applications of fiber laser marking machines is in the manufacturing industry. Production lines require the consistent and accurate marking of various components to ensure proper identification and traceability. The machines can quickly and easily mark multiple materials such as metals, plastics, ceramics, and composites. Additionally, the high-quality laser marking ensures that the markings remain visible even after exposure to harsh environmental conditions.

Medical device and equipment manufacturers also use fiber laser marking machines to mark medical implants, instruments, and devices. These markings are necessary to track and verify their authenticity, making them safe to use in medical procedures. The speed and precision of laser marking machines ensure that these markings are legible and permanent.

In automotive and aerospace industries, fiber laser marking is essential in the production of various parts such as engine components, gears, and aircraft parts. These parts require unique identification markings that need to remain visible throughout their lifetimes. The precision and high-speed capabilities of fiber laser markers make it an ideal choice for these applications.

Fiber laser marking machines also have applications in the jewelry and watchmaking industries. Precious metals and gems require precise and delicate marking, which can be achieved with a laser marker. This technology allows craftsmen to mark their creations with intricate details that are impossible with traditional methods, adding value to their work.

In conclusion, fiber laser marking machines offer numerous benefits across various industries. The technology provides a reliable and efficient way of marking materials, ensuring accurate and permanent markings. Its versatility and application across several sectors, from the automotive industry to jewelry-making, make it an important tool in modern industrial processes.

Manufactured Products made of Fiber Laser Marking Machine

Fiber laser marking machine technology has transformed the manufacturing industry by revolutionizing product identification techniques. The machines use advanced laser beam technology to precisely etch or engrave markings on different materials, including metals, plastics, ceramics, and composites. The result is a range of high-quality and durable manufactured products that feature detailed, permanent markings that serve various purposes.

One of the most common applications of fiber laser marking machines in the manufacturing sector is part identification. With stringent regulations and quality control requirements, it is crucial to ensure that every component or part of a product is correctly labeled, and the fiber laser marking machine delivers this efficiently. From serial numbers, part numbers, and barcodes to batch numbers and other identification marks, the marking machines streamline traceability and inventory management.

Another critical application of fiber laser marking machines is customization. The technology allows manufacturers to personalize their products with branding and customer-specific details. For instance, customized logos or graphical elements can be etched onto product parts, adding aesthetic appeal while increasing brand recognition.

Fiber laser marking machines also enhance product safety and compliance. The machines can etch essential details such as warning labels and safety instructions on different surfaces. This is particularly important for medical and pharmaceutical products where any slight deviations can cause harmful consequences.

The fiber laser marking machine also eliminates the need for labels, stamps, and ink markings that can wear off, fade, or peel. This translates to a significant reduction in production costs and a more sustainable production process.

In conclusion, fiber laser marking machines have revolutionized the manufacturing industry by providing an accurate, reliable, and cost-effective solution for product identification, customization, and compliance. As the technology continues to evolve, it is expected to increase the scope and quality of manufactured products in various industries, including aerospace, automotive, and electronics.

The Evolution history of Fiber Laser Marking Machine

Fiber laser marking machines utilize laser technology to leave marks on a range of surfaces, including metal, plastic, and glass. These machines were developed over a period of time, with many changes and advancements to the technology to achieve the optimal outcomes.

The earliest versions of laser marking machines date back to the 1960s, when carbon dioxide (CO2) lasers were used for engravings on wood and organic materials. However, because these lasers were bulky and slow, they were not suitable for industrial use. The next generation utilized a gas and solid-state laser, which were an improvement, yet still unsatisfactory for much industry.

In the 1990s, fiber optics technology was developed, resulting in the invention of fiber laser technology in 2000. This was the beginning of fiber laser marking machines as we know them today, essentially revolutionizing the marking industry. This new technology has more efficiency in power use and is more compact/explicit, offering a wide variety of capabilities for different materials. They can also work at high speeds, which substantially increased productivity levels.

Over the years, software and hardware have been upgraded as new technology became accessible, and the fiber laser marking machine has become more accurate, faster, and more user-friendly. Additionally, operators can program the machines to leave a range of markings, including QR codes, text, and graphics with improved readability.

As technology continues to advance, fiber laser marking machines will continue to evolve to meet market demands. Marking will become more specialized and more customized, and the machines will be able to work with different materials and surface finishes. As the machines become more advanced and the cost goes down, they’ll be more adaptable and beneficial for a variety of industries.

In summary, fiber laser marking machines have come a long way since their emergence nearly 20 years ago. They have advanced significantly in the software/hardware, engineering, and industrial applications, and experts are excited about the future of laser marking. Laser marking is a

The Process of Fiber Laser Marking Machine

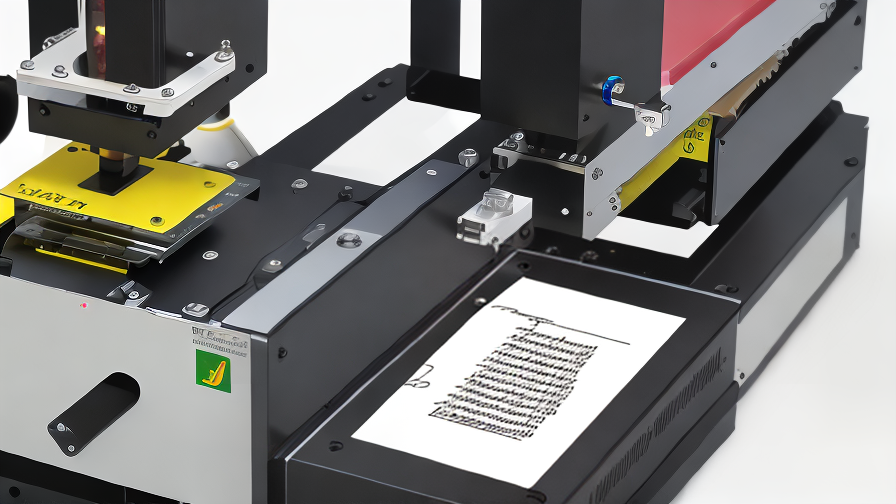

Fiber laser marking machines are essential tools in the modern manufacturing industry. These machines utilize fiber laser technology to mark a wide range of materials, such as plastic, metals, ceramics, and even organic materials. The process of fiber laser marking involves several stages that ensure precise and permanent markings on the surface of the material.

The first stage involves the preparation of the material. The surface of the material to be marked must be clean and free from any debris or oils that can interfere with the laser marking process. This is done by using a cleaning solution and wiping the surface of the material, or in some cases, washing it.

The second stage involves setting up the laser marking machine. The settings of the machine vary, depending on the type of material and the desired markings. The laser beam is directed towards the surface of the material using a lens, which focuses the beam to a specific point.

In the third stage, the laser beam penetrates the surface of the material, creating a permanent mark. The energy of the laser beam heats up the material, causing it to vaporize or melt. The resulting mark depends on the type of material and the power of the laser beam.

The final stage is the inspection of the marked material. The markings are inspected for accuracy, depth, and consistency. The quality of the markings is ensured using specialized equipment, such as a microscope or a gauge.

In conclusion, fiber laser marking machines offer an efficient and precise way of marking different materials. The process of fiber laser marking involves four stages: material preparation, machine setup, laser marking, and inspection. With the increasing demand for permanent and high-quality markings in the manufacturing industry, fiber laser marking machines have become a must-have tool for any serious manufacturer.

Benefits Advantages of Utilizing Fiber Laser Marking Machine

Fiber laser marking machines have revolutionized marking technology by offering a quick, efficient, and cost-effective way of etching, engraving, and marking various types of materials. They work by using a laser beam to mark the surface of a material with high precision and accuracy. Below are some of the benefits of using fiber laser marking machines.

Versatility

Fiber laser marking machines are versatile and can mark a variety of materials such as metals, plastics, ceramics, and many more. They can also mark complex shapes, angles, and curved surfaces, making them ideal for a wide range of applications.

High Precision

Fiber laser marking machines are incredibly accurate and produce high-quality markings with clean, crisp lines. The laser beam is extremely precise, making it possible to create intricate designs or markings that are difficult to achieve using traditional marking methods.

Durability

Fiber laser markings are permanent and do not fade or wear off over time. This is because the marking process involves creating a deep, permanent, and high-contrast mark on the surface of the material, which ensures that the marking will last forever.

Low Maintenance

Fiber laser marking machines require minimal maintenance because they have no moving parts that wear out. They are also designed to last for many years, and with proper care and maintenance, they can keep working efficiently for a long time.

Speed

Fiber laser marking machines are incredibly fast and can mark materials in a matter of seconds. This makes them ideal for use in high-volume production environments where speed and efficiency are critical.

Cost-Effective

Fiber laser marking machines are cost-effective because they require minimal maintenance and have a low cost of ownership. They also have a low energy consumption, which means they are environmentally friendly and cost-efficient to operate.

In conclusion, the benefits of using fiber laser marking machines are numerous, and they provide many advantages when compared to traditional marking methods. They are versatile, accurate, durable, low maintenance, fast, and cost-effective. Investing in a fiber laser

Disadvantages Fiber Laser Marking Machine

Fiber laser marking machines have become a popular choice in the market due to its high accuracy, low maintenance, and high-speed marking capabilities. However, just like any other technology, it also comes with its disadvantages.

One of the major disadvantages of fiber laser marking machines is the cost. They are expensive compared to other marking machines available in the market. The cost of fiber laser marking machines is high due to the high power lasers utilized in the machines, which leads to a higher production cost.

Another disadvantage is that fiber laser marking machines have low thermal conductivity. This means that the machine cannot handle high-temperature materials, such as metals, as the heat produced during the marking process can damage the machine’s components. As a result, the marking quality of such materials may not be up to standards.

Fiber laser marking machines can also create markings that are too small or too complex, which can be difficult to read or comprehend. This may lead to problems in industries where readings and markings must be clear and legible.

Furthermore, fiber laser marking machines may require technical expertise to operate, which can be a disadvantage for small businesses that cannot afford to hire experts or train their employees to use the machine.

In conclusion, even though fiber laser marking machines offer several advantages over traditional marking machines, they do have their disadvantages. These disadvantages, such as high cost, low thermal conductivity, difficult-to-read markings, and technical expertise requirements, must be evaluated alongside the benefits of the machine before deciding to invest in it.

Selecting the Ideal Manufacturer Fiber Laser Marking Machine

When it comes to fiber laser marking, selecting the right manufacturer is crucial in ensuring quality results. With many options in the market, it is important to consider several factors to help find the ideal manufacturer for your fiber laser marking machine.

Firstly, look for manufacturers with years of industry experience, as they have better knowledge and expertise in understanding customer needs. Secondly, consider the type of materials you will be marking, as different machines are designed for different materials such as metals, plastics, and ceramics.

Another important factor to consider is the power of the machine, which determines the depth and speed of markings. Depending on your application requirements, choose a machine with adequate power to meet your needs.

Technology advancements have led to the development of fiber laser marking machines with unique features such as portability, automation, and intelligence. Consider these features when selecting a machine, as they can improve efficiency, accuracy, and reduce human errors.

A good manufacturer should also provide excellent technical support and after-sales services to ensure your machine operates optimally at all times. Check for reviews from previous clients to gauge their level of customer service.

Finally, consider the cost of the machine, including maintenance and repair costs. Select a manufacturer with high-quality machines that offer value for money, rather than those offering low-cost machines that may require frequent repairs and replacements.

In conclusion, selecting the right manufacturer for your fiber laser marking machine is vital in achieving high-quality results. Consider factors such as experience, power, material compatibility, machine features, technical support, and cost to ensure you get the best value for your investment.

Things to Consider When Purchasing Fiber Laser Marking Machine

Fiber laser marking machines are highly sought after for their ability to create intricate markings on a variety of materials. When purchasing one, there are several things to consider to ensure you get the right machine for your needs.

The first factor to consider is the power of the machine. Higher power machines can deliver deeper markings in materials like metal, whereas lower power machines are better for softer materials like plastics. It’s important to choose the right power level for the materials you’ll primarily be marking.

Another important factor is the size of the marking area. Consider the size of the items you’ll be marking and make sure the machine’s marking area can accommodate them.

The ease of use and software compatibility is also important to consider. Look for a machine with user-friendly software and compatibility with a variety of design programs.

The machine’s durability is also important to consider, as it can impact the longevity and effectiveness of the machine. Look for machines made with high-quality materials and components.

Finally, consider the after-sales service and support offered by the manufacturer. Make sure they offer proper training and support for your machine and are available for any necessary repairs or maintenance.

Purchasing a fiber laser marking machine can be a significant investment, so it’s important to consider all these factors before making a decision. With the right machine, you can create high-quality markings on a variety of materials with ease.

Properties of Fiber Laser Marking Machine

Fiber laser marking machines are widely used for marking and engraving materials such as metals, plastics, ceramics, and more because of their accuracy and speed. These machines employ fiber lasers, which use a high-powered laser beam to create marks, engravings, and identification codes on surfaces. Here are some of the properties of fiber laser marking machines that make them the preferred choice in many industries:

1. High precision: Fiber laser marking machines offer high precision when marking or engraving materials. This means that they can create detailed, intricate designs with high levels of precision.

2. Fast marking speed: Fiber laser marking machines can mark materials at a faster rate than other marking methods, such as chemical etching, inkjet printing, or mechanical engraving.

3. Long lifespan: Fiber laser marking machines have a long lifespan because they are very efficient and use minimal power. This means that they require little maintenance, which translates into cost savings for businesses in the long run.

4. Versatility: Fiber laser marking machines can mark or engrave on a wide range of materials, including metals, plastics, ceramics, glass, and more. This versatility makes them ideal for various applications across different industries.

5. Low heat dissipation: Fiber lasers produce very little heat when marking materials, which reduces the risk of material damage. This property makes it possible to create high-quality marks on heat-sensitive materials such as plastics, without causing any damage.

In conclusion, fiber laser marking machines are popular among businesses for their high precision, fast speed, long lifespan, versatility, and low heat dissipation. These properties make them an ideal choice for businesses across various industries such as automotive, aerospace, electronics, medical devices, and more. By investing in a fiber laser marking machine, businesses can enjoy the benefits of efficient and accurate marking, improved product traceability, enhanced brand recognition, and increased productivity.

How to use Fiber Laser Marking Machine

Fiber laser marking machines have taken the manufacturing and industrial sector by storm. They provide a more efficient, accurate, and cost-effective way of marking a variety of materials such as metals, plastics, and ceramics. If you’re considering using a fiber laser marking machine but don’t know how, this article provides a handy guide.

First, ensure that you have set up the machine correctly. Place the material to be marked on the marking area, adjust the focus lens, and set the marking parameters. The latter usually involves selecting the power, frequency, and marking speed that are most suitable for the material.

Next, create the design or image to be marked using computer-aided design (CAD) software. The design can include text, logos, barcodes, and serial numbers, among other things. Import the design into the laser marking software, which will show you a preview of how the image will look once marked.

After verifying that the design is correct, run the marking process. The fiber laser emits a beam of light that vaporizes the material on the surface to be marked. The heat generated by the laser also causes changes in the chemical structure of the material, resulting in a permanent mark.

During the marking process, ensure that the material remains stable and that any movement is minimized. Also, pay attention to any warnings or alerts that the machine may give. A well-maintained fiber laser marking machine should last for years with minimal breakdowns or maintenance requirements.

In conclusion, using a fiber laser marking machine is a straightforward process that involves setting up the machine, creating the design, and running the marking process. With proper maintenance and usage, it should serve you well for years to come.

Glossary Terminology Terms for Fiber Laser Marking Machine

Glossary Terminology Terms for Fiber Laser Marking Machine

Fiber laser marking machines use a high-powered laser beam to engrave or mark different types of materials. As technology progresses, the terminology for fiber laser marking machines continues to evolve. Here are some of the most common terms you may come across when researching or discussing fiber laser marking machines.

– Marking speed: This is the speed at which the laser beam engraves or marks the material. It’s typically measured in inches per minute (IPM) or meters per minute (MPM).

– Wattage: This refers to the power output of the laser, measured in watts. The higher the wattage, the more powerful the laser, and the faster it can mark or engrave materials.

– Fiber laser source: This refers to the laser that generates the beam used for marking. Fiber lasers are known for their high-quality marks and reliability.

– Beam quality: Refers to the characteristics of the laser beam, such as its shape, size, and intensity.

– Engraving depth: This is how deep the laser beam can engrave into the material. This can vary depending on the type of material being marked and the power of the laser.

– Marking area: This is the size of the area that can be marked by the laser. The marking area can vary depending on the machine’s capabilities and the type of material being marked.

– Cooling system: This is the system that maintains the laser at the right temperature to prevent damage to the laser and ensure consistent marking.

– Scan head: This is the part of the machine that moves the laser over the material being marked. The scan head can vary in speed and accuracy depending on the machine’s capabilities.

– F-Theta lens: This is the lens that focuses the laser beam onto the material being marked. The lens can impact the quality and accuracy of the mark.

– Marking software: This is the software used to control the laser and create the designs to be

Fiber Laser Marking Machine Price

Fiber laser marking machines are becoming increasingly popular in many industries due to their high precision, speed, and compatibility with a wide range of materials. When looking for a fiber laser marking machine, price is an important consideration. The cost of a fiber laser marking machine can vary greatly depending on several factors.

Firstly, the wattage of the laser source will greatly affect the price of the machine. Higher wattage machines are more powerful and can mark at faster speeds with greater depth. However, they are also more expensive. Lower wattage machines are more affordable but may not be suitable for all applications.

Secondly, the size of the machine will also impact the price. Smaller machines are generally cheaper, but they may not have the same capabilities as larger machines.

Another factor that can affect the price is the brand and quality of the machine. High-end machines from well-known brands will typically have a higher price tag due to their superior quality and features. Cheaper machines from lesser-known brands may be more affordable, but they may not have the same performance or reliability.

In general, fiber laser marking machines can range from a few thousand dollars to tens of thousands of dollars. It is important to carefully consider your needs and budget before investing in a machine. Cheaper machines may be suitable for small businesses or hobbyists, while more expensive machines may be necessary for high-volume production and demanding applications.

In conclusion, fiber laser marking machine prices can vary greatly depending on several factors, including wattage, size, brand, and quality. It is important to carefully consider your needs and budget before investing in a machine to ensure you get the best value for your money.