Knowledge about Fiber Laser Welder

Fiber laser welders are becoming increasingly popular, as they offer a number of advantages over conventional welding methods. They are capable of producing high-quality welds with minimal heat input, resulting in less distortion, less material damage, and less post-weld processing. Additionally, fiber laser welding can be performed on a wide variety of materials, including metals, plastics, and ceramics.

One of the most significant benefits of fiber laser welding is its speed. Fiber laser welders are extremely fast, allowing for quick and efficient production. This is particularly important in industries that require high-volume production, such as automotive or aerospace. Fiber laser welding is also more reliable than traditional welding methods, as it is less likely to produce defects or errors.

Another important advantage of fiber laser welders is their flexibility. They are capable of producing welds of varying depths, widths, and angles, making them ideal for a wide range of applications. Additionally, fiber laser welding is highly precise, meaning that it can produce welds with extremely tight tolerances.

However, to achieve the best results with fiber laser welding, it is important to have a solid understanding of the process. This includes knowledge of the laser’s power output, beam diameter, focal length, and pulse duration. It is also important to understand the properties of the materials being welded, as well as any potential challenges that may arise during the welding process.

Overall, fiber laser welding is a powerful and versatile welding technique that offers a number of benefits over traditional welding methods. By understanding the key principles of fiber laser welding, it is possible to achieve high-quality, efficient, and reliable welds in a wide range of applications.

Various Types of Fiber Laser Welder

Fiber laser welding has been gaining popularity in industries like automotive, aerospace, and medical. This is because it is a non-contact process that produces strong and precise welds. Here are some of the various types of fiber laser welders:

1. Continuous Wave (CW) Fiber Lasers – These are the most common type of fiber laser welders. They emit a continuous beam of energy that melts the materials to be joined. CW fiber lasers are best suited for welding thin metals and for applications that require high speed welding.

2. Pulsed Fiber Lasers – These lasers emit a series of high energy pulses. This type of fiber laser welder is suitable for welding thick materials as the pulses allow for deeper weld penetration. Pulsed fiber lasers are also useful for welding dissimilar materials where precise control of heat input is necessary.

3. QCW (Quasi-Continuous Wave) Fiber Lasers – These are a hybrid between CW and Pulsed Fiber lasers. They emit high-power pulses at regular intervals, which produces a similar effect to CW lasers but with added benefits of deep penetration and minimal heat input.

4. Multi-mode Fiber Lasers – These fiber lasers have a large core diameter which allows for high beam quality and high power output. Multi-mode fiber lasers are useful in welding thick materials, as they offer deep penetration and high speed welding.

5. Single-mode Fiber Lasers – These fiber lasers have a small core diameter which produces excellent beam quality and high precision welding. Single-mode fiber laser welders are ideal for welding thin materials as they offer precise control over heat input and minimize distortion.

In conclusion, fiber laser welding is a versatile and efficient way to join materials in industries that require high precision and speed. There are various types of fiber laser welders available to suit different applications, whether it is welding thin or thick materials, dissimilar metals, or requiring precise control of heat input.

FAQ sourcing Fiber Laser Welder manufacturer from China

If you’re interested in sourcing a fiber laser welder from a manufacturer in China, you may have a few questions about the process. Here are some frequently asked questions with answers to help guide you:

Q: What is a fiber laser welder?

A: A fiber laser welder is a type of welding machine that uses a fiber laser as its energy source. Fiber lasers are highly efficient and precise, making them ideal for welding a variety of materials.

Q: Why should I source a fiber laser welder from China?

A: China is known for having a large manufacturing industry and many companies that produce high-quality fiber laser welders. Sourcing from China can often be more cost-effective than sourcing from other countries.

Q: How do I choose a fiber laser welder manufacturer in China?

A: Do your research and read reviews from other customers to find a reputable manufacturer. Look for a company that has experience producing fiber laser welders and offers technical support and after-sales service.

Q: What materials can a fiber laser welder weld?

A: Fiber laser welders can weld a variety of materials, including stainless steel, aluminum, copper, brass, titanium, and more.

Q: What are some advantages of using a fiber laser welder?

A: Fiber laser welders offer many advantages, including higher precision, faster welding speeds, cleaner welds, and less energy consumption compared to traditional welding methods.

Q: What is the price range for a fiber laser welder from a Chinese manufacturer?

A: The price range can vary depending on the specifications and features of the fiber laser welder. However, sourcing from China can often be more cost-effective than sourcing from other countries.

In conclusion, sourcing a fiber laser welder from a Chinese manufacturer can be a great option for those looking for a high-quality product at an affordable price. By doing your research and choosing a reputable manufacturer, you can be confident in your purchase and enjoy the advantages of using a fiber laser welder.

Applications of Fiber Laser Welder

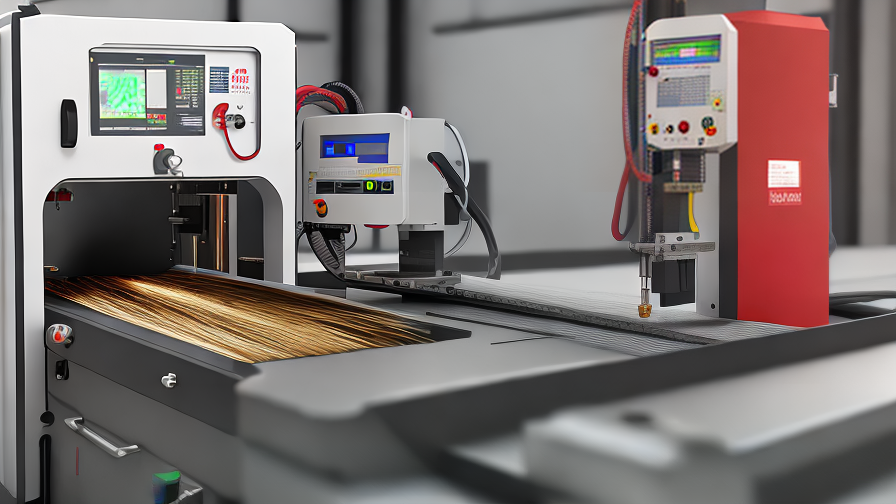

Fiber laser welders have revolutionized the welding industry with their remarkable precision, speed, and versatility. These machines use concentrated laser beams to fuse two or more materials together, and are widely used in manufacturing industries such as the automotive, aerospace, medical, and electronics sectors.

One of the most significant benefits of using fiber laser welders is their ability to join dissimilar materials. This includes metals, plastics, and composites that were previously difficult to join using traditional welding methods. Fiber laser welding is also used extensively in the production of electronic devices, where it is used to weld intricate components without damaging sensitive parts, such as circuit boards.

Another notable application of fiber laser welders is in the medical industry. These machines are used to weld small, intricate components, such as pacemakers and orthopedic implants, with a high degree of precision. Laser welding also eliminates the need for wires or soldering, which can increase the risk of contamination, and ensures that medical devices are hermetically sealed to prevent oxidation or infection.

In the automotive industry, fiber laser welders play a crucial role in the manufacturing of automobiles. They are used to weld car body panels, exhaust systems, and other components, with increased strength and precision. Fiber laser welding is also faster and more efficient than traditional welding methods, reducing production time and costs.

Finally, the aerospace industry also makes extensive use of fiber laser welders for the production of aircraft components such as engine parts, landing gear, and wings. Laser welding ensures that the parts are lightweight, strong, and aerodynamically efficient, making them ideal for use in modern aircraft.

In conclusion, fiber laser welders have a wide range of applications and are rapidly replacing traditional welding methods in many sectors of the manufacturing industry. The precision, speed, and versatility of these machines make them ideal for welding dissimilar materials, delicate components, and complex structures. As the technology continues to improve, we can expect to see even more revolutionary applications of fiber laser weld

Manufactured Products made of Fiber Laser Welder

Fiber laser welding has become a valuable tool for the modern manufacturing industry. It has enabled the production of high-quality, precision parts that meet the increasingly strict standards of the market. Welding with a fiber laser offers several advantages over traditional welding methods, including quicker production times, lower costs, and decreased material waste. As a result, manufactured products made with this technology have become more versatile, durable, and eco-friendly.

One of the most common applications of fiber laser welding is in the automotive industry. Manufacturers use it to weld chassis, engine components, and other critical parts. The precision and accuracy provided by this technology ensure that the parts are durable and safe, and free of defects that could cause issues down the line. Additionally, the high-speed production capabilities of fiber laser welders enable manufacturers to keep up with the growing demand for automobiles.

Fiber laser welding has also gained popularity in the aerospace industry. Parts like turbine blades, fuel nozzles, and other critical components require precision welding to ensure their long-term stability and reliability. This technology enables manufacturers to create complex shapes and designs that were previously impossible, thanks to the high degree of control provided by fiber lasers.

The electronics industry is another sector that has embraced fiber laser welding. It is used to create parts for high-tech devices like smartphones and computers, where precise and intricate parts are required. The technology is also useful for welding and cutting circuit boards, ensuring signal and power conductivity and accuracy.

Fiber laser welders are also being used to create medical tools and devices, where precision and reliability are essential. The technology enables the production of intricate medical equipment like pacemakers, surgical instruments, and small implants with high accuracy, making them safe and reliable for medical professionals and patients alike.

In conclusion, fiber laser welding has revolutionized manufacturing, enabling the production of high-quality, precision parts in different industries like automotive, aerospace, electronics, and medical devices. The technology’s accuracy, speed, and low material waste have made it a valuable tool

The Evolution history of Fiber Laser Welder

The evolution of fiber laser welders can be traced back to the 1960s when the first laser was invented. However, it wasn’t until the 1980s that the first fiber laser was developed. At this time, fiber lasers were primarily used for research purposes and the technology was not yet fully matured.

In the early 2000s, the first fiber laser welders were introduced for industrial use. Compared to traditional welding technologies such as arc or gas welding, fiber laser welding offered several advantages. Fiber laser welders had higher precision, faster welding speeds, and required less heat, reducing the risk of damage to the material being welded. They also produced cleaner and stronger welds.

Over the next few years, fiber laser technology continued to evolve. Higher-powered fiber lasers were developed, making it possible to weld thicker materials. New advances in beam shaping and delivery allowed for improved precision and control, making the technology even more attractive for industrial manufacturing.

Today, fiber laser welders are widely used in a variety of industries, including automotive, aerospace, medical device manufacturing, and more. They have become an essential tool for high-precision welding applications, offering unparalleled speed, accuracy, and reliability.

Looking forward, the future of fiber laser welders promises even greater advancements in technology. Innovations such as real-time monitoring and feedback systems, automated systems, and on-the-fly adjustments based on material variations will further increase the efficiency and accuracy of fiber laser welding.

In conclusion, the evolution of fiber laser welders has been a fascinating journey, leading to the development of a highly advanced technology used in modern industrial manufacturing.

The Process of Fiber Laser Welder

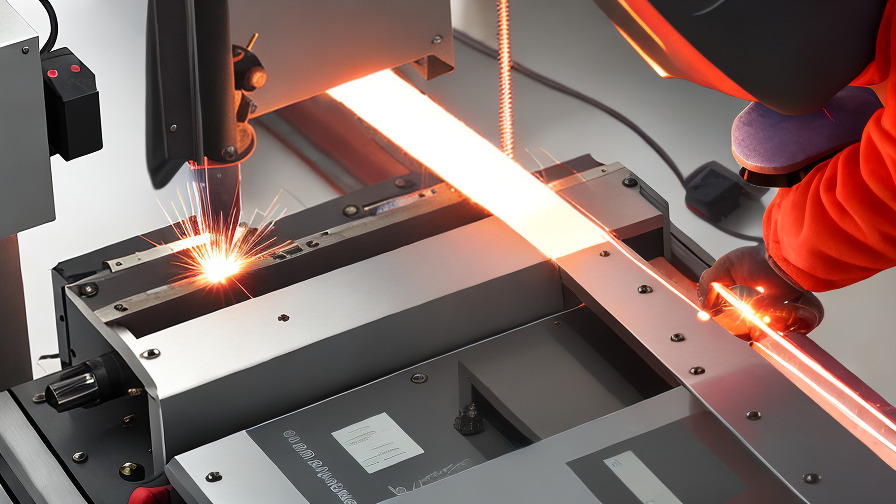

Fiber laser welding is a precision welding process that uses a high-energy beam of laser light, produced by an optical fiber, to melt and join two pieces of metal together. It’s a popular technique that has been used in the manufacturing industry for many years, due to its efficiency, speed, and precision.

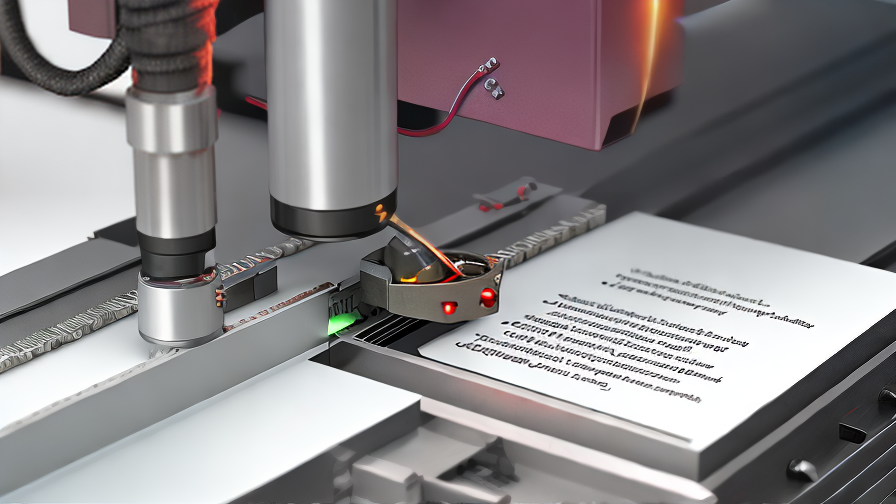

The process of fiber laser welding starts with the preparation of the materials to be joined. The two pieces of metal are cleaned and positioned together at the desired angle and orientation. Once the parts are properly aligned, the fiber laser is activated, and the beam is focused on the joint.

The laser energy heats and melts the metal at the joint, making it possible to fuse the two pieces together. The process is so precise that the strength and durability of the joint can often surpass that of the rest of the metalwork.

During the welding process, the intensity of the laser beam is carefully controlled to ensure that the metal is melted and fused together without causing damage or distortion. The beam is also precisely directed using mirrors and lenses, to ensure that the energy is focused in the exact location required.

One of the most significant advantages of fiber laser welding is its efficiency. The process is very fast, allowing for high volumes of welding to be completed in a short period. Additionally, the accuracy of fiber laser welding means that the need for rework or repairs is significantly reduced.

Another benefit of fiber laser welding is its versatility. The technique can be used to join a wide range of materials, including metal alloys, stainless steel, and even plastics. The process is widely used in industries such as automotive manufacturing, aerospace, and medical equipment fabrication.

In conclusion, fiber laser welding is a highly effective technique that offers many benefits to the manufacturing industry. Its efficiency, precision, and versatility make it a valuable tool for joining metal materials together. With continued advances in laser technology, fiber laser welding is only set to become more popular in the years ahead.

Benefits Advantages of Utilizing Fiber Laser Welder

Fiber laser welders have become increasingly popular in recent years. This is because they offer a range of benefits and advantages over traditional welding methods. Here are just a few of the reasons why you should consider utilizing a fiber laser welder:

1. Speed

One of the biggest advantages of fiber laser welders is their speed. They can perform welds up to ten times faster than traditional welding methods. This makes them ideal for high-volume production and manufacturing. They are also perfect for welding thin materials, which can be difficult to weld using traditional methods.

2. Accuracy

Fiber laser welders are incredibly accurate, which makes them perfect for high-precision work. They allow for precise control over the heat input, meaning you can achieve the exact weld you need every time. This makes them ideal for creating small, intricate components and welding delicate materials.

3. Efficiency

Fiber laser welders are very efficient, which means they use less energy than traditional welding methods. This can help to reduce your energy bills and your carbon footprint. They also require less maintenance than traditional welding methods, which saves you time and money in the long run.

4. Versatility

Fiber laser welders are incredibly versatile, which makes them perfect for a wide range of applications. They can be used to weld a variety of materials, including stainless steel, aluminum, copper, and titanium. They are also great for welding dissimilar materials, which can be difficult using traditional welding methods.

5. Safety

Fiber laser welders are very safe to use. They produce less smoke, fumes, and radiation than traditional welding methods, meaning they are better for the environment and the health of the welder. They also produce less heat, which reduces the risk of burns and heat-related injuries.

Overall, utilizing a fiber laser welder has many benefits and advantages. They are fast, accurate, efficient, versatile, and safe, making them the perfect choice for a wide range of applications.

Disadvantages Fiber Laser Welder

Fiber laser welding has become increasingly popular in recent years due to its accuracy and efficiency. However, like any technology, there are some disadvantages that should be considered.

One of the main disadvantages of fiber laser welding is its cost. Fiber laser welders are typically more expensive than traditional welding machines, which can be a deterrent for some companies or individuals. Additionally, the maintenance and repair costs for fiber laser welders can also be high.

Another disadvantage is the limited thickness range that can be welded. Fiber laser welders are ideal for thin materials, but they may not be suitable for thicker materials. This can limit the range of applications for which fiber laser welding can be used.

Fiber laser welders also require skilled operators who are trained in the technology. This can be a challenge for companies that do not have staff with the necessary expertise. Additionally, the learning curve for fiber laser welding can be steep, and it may take time for operators to become proficient in using the technology.

Finally, fiber laser welding can also be affected by environmental factors. Dust, humidity, and temperature can all impact the performance of fiber laser welding machines. This can result in inaccurate welds and decreased efficiency.

In conclusion, while fiber laser welding offers many advantages, it is important to consider the potential disadvantages as well. Companies should carefully weigh the costs and benefits of this technology to determine if it is the right choice for their specific applications.

Selecting the Ideal Manufacturer Fiber Laser Welder

Selecting the ideal manufacturer fiber laser welder is crucial in maintaining product quality and optimizing production efficiency. With numerous manufacturers in the market, it can be challenging to make the right choice. However, considering some critical factors can help you make an informed decision.

Firstly, examine the welder’s power capabilities. The welder should have enough power to handle the thickness and type of materials in your production line.

Secondly, consider the welder’s efficiency and accuracy. Look for a welder with high beam quality and minimal beam divergence for precise welding results. The welder should be swift in delivering accurate welds, reducing production time and maximizing throughput.

Thirdly, consider the manufacturer’s reputation in the market. Selecting a manufacturer with a proven track record of producing durable and effective welders guarantees quality workmanship and outstanding performance.

Fourthly, factor in the maintenance and operational costs of the laser welder. Choose a manufacturer that designs cost-effective and easily maintainable machines that guarantee longer service life, which should help you maximize productivity.

Lastly, evaluate the manufacturer’s customer service support, including maintenance, training, and warranty. The manufacturer should have a dependable customer service program and support systems that ensure you get the most from your investment.

In conclusion, selecting an ideal fiber laser welder from a reputable manufacturer requires careful consideration of various factors. By examining the welding machine’s power, efficiency, accuracy, reputation, maintenance and operational costs, and customer service support, you will be better placed to make an informed decision that will guarantee optimal productivity and quality workmanship.

Things to Consider When Purchasing Fiber Laser Welder

Fiber laser welding has gained popularity in the welding industry due to its high precision, speed, and versatility. It is an ideal tool for welding a wide range of materials, including metals, plastics, ceramics, and more. However, investing in a fiber laser welder can be a daunting task, especially for those who are new to the technology. Here are some things to consider when purchasing a fiber laser welder.

1. Power output: Power output is an important factor to consider when purchasing a fiber laser welder. It will determine the thickness of the material that can be welded effectively. A higher power output means a thicker material can be welded. Ensure the fiber laser welder has enough power output to meet your welding requirements.

2. Beam quality: The quality of the laser beam is crucial to the precision and accuracy of the welding process. A high-quality beam ensures that the weld is strong, and there is minimal distortion on the material. Ensure you check the beam quality specification of the fiber laser welder.

3. Cooling system: Fiber laser welding generates a significant amount of heat, and a cooling system is necessary to dissipate the heat generated. It would help if you considered the cooling system of the fiber laser welder before purchasing it. Ensure that the cooling system can handle the heat generated effectively and efficiently.

4. Ease of use: A fiber laser welder can be complicated to use, especially for beginners. Ensure that the laser welder you purchase has an easy-to-use interface and comes with all the necessary software and tools.

5. Maintenance: A fiber laser welder is a significant investment and requires maintenance to ensure optimal performance. Ensure that the manufacturer offers adequate support in terms of maintenance and repair services.

In conclusion, purchasing a fiber laser welder can be overwhelming. Still, by considering the factors mentioned above, you can make an informed decision and purchase a fiber laser welder that meets your welding needs.

Properties of Fiber Laser Welder

Fiber laser welding technology has rapidly gained popularity in many industries due to its many useful properties. In particular, fiber laser welding is preferred over other welding methods because it produces high-quality and precise finishes on materials. Here are some of the properties of fiber laser welding that make it such a popular and effective welding method.

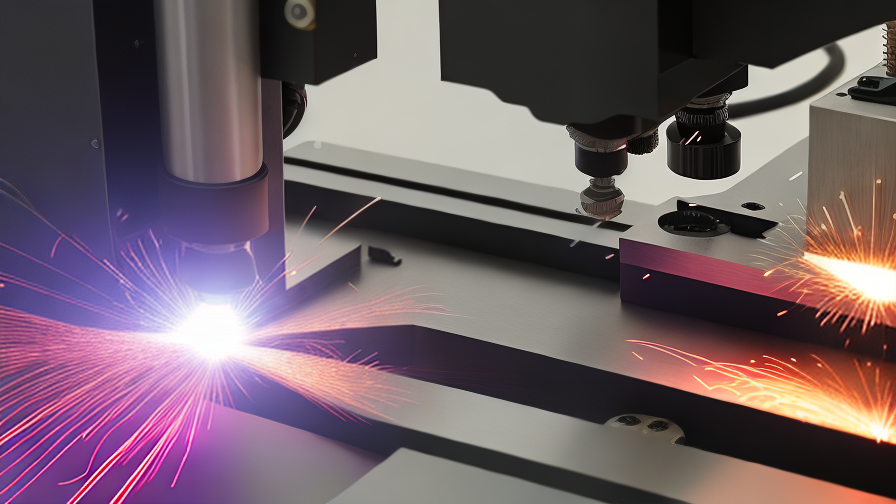

Precision Welding:

One of the most important properties of fiber laser welding is its high precision. This is because fiber lasers produce a narrow and focused beam of light, which can be accurately directed to the exact location where it is needed. This characteristic makes it possible to weld small and complex parts without damaging the surrounding material.

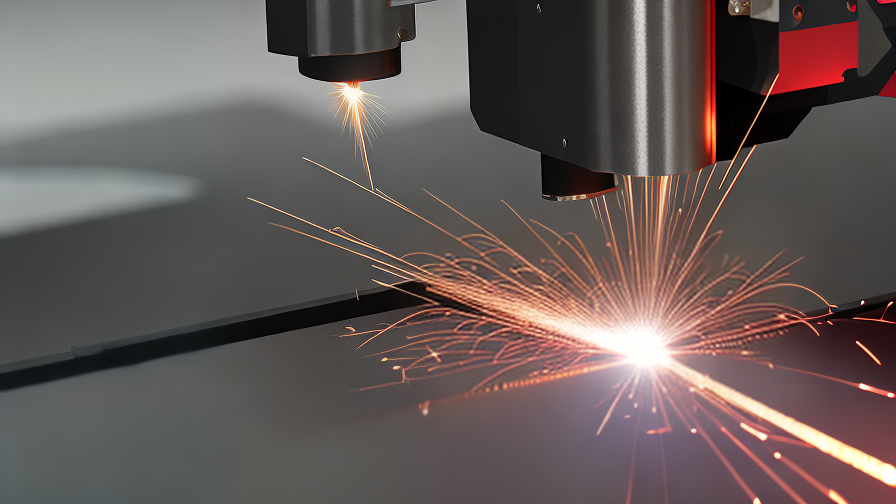

High Speed:

Fiber laser welding is a fast and efficient process that can handle large volumes of work in a short time. This is because fiber lasers generate very high amounts of energy that can be rapidly delivered to the workpiece, resulting in a fast welding process. Additionally, the use of automated robots increases the speed of the welding process even further, making it suitable for mass production.

Low Heat Affected Zone (HAZ):

The low Heat Affected Zone of fiber laser welding is another excellent property of this welding method. The small laser beam size means that only a small area around the weld is affected, reducing deformations and minimizing the heat-affected zone. This precise and controlled heat input results in less distortion and changes in the metal microstructure, which is critical for preserving the integrity of the material being welded.

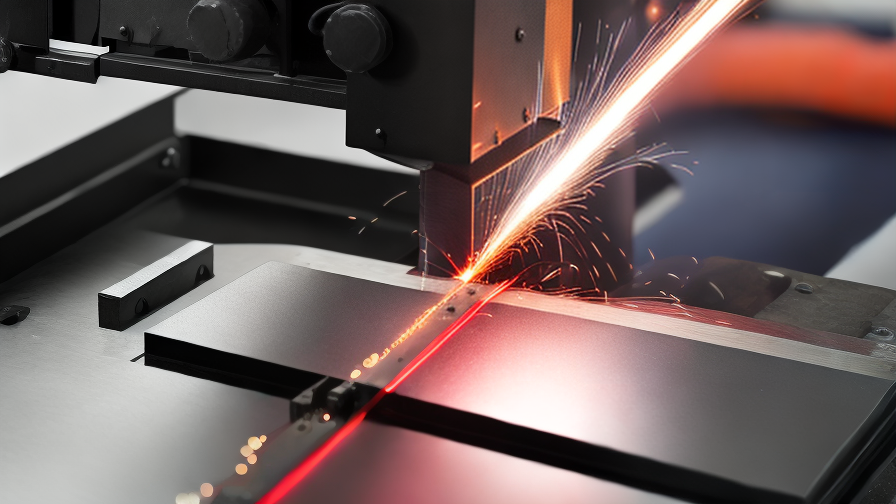

Versatile Welding:

Fiber laser welding machines can work on a wide range of materials, including aluminum, stainless steel, carbon steel, brass, copper, and titanium. It also welds dissimilar metals, so manufacturers have the freedom to use different materials in one project. This versatile method can produce smooth, strong welds with no porosity or cracks.

In conclusion, fiber laser welding has excellent properties that make it popular among manufacturers. Its precision, speed, low heat-affected zone, and versatility make fiber laser welding an excellent

How to use Fiber Laser Welder

Fiber laser welders are becoming increasingly popular across various industries due to their efficiency and precision. Here are some tips on how to use a fiber laser welder:

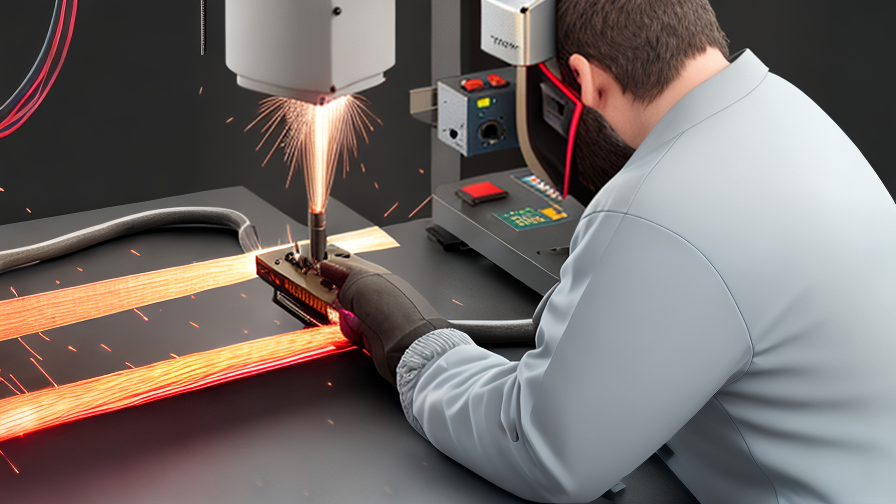

1. Safety first: Before starting the welding process, make sure the area is well-ventilated, and all necessary safety equipment, such as protective eyewear and gloves, are worn.

2. Prepare the workpiece: Clean and prepare the surfaces being joined. Make sure the pieces are properly aligned and that any gaps or inconsistencies are removed.

3. Set up the fiber laser welder: Ensure that the fiber laser welder is properly installed and set up before use. This includes checking and calibrating the machine’s power, pulse width, and focus spot size.

4. Test the welder: Before welding the actual workpieces, test the welder on a sample piece of material to ensure the settings are correct and to fine-tune the machine’s parameters.

5. Start welding: Once everything is set up, start welding the workpiece by moving the laser beam slowly along the joint, paying close attention to the weld pool and making adjustments as necessary.

6. Finish the weld: Once the welding process is complete, allow the workpiece to cool down before removing it from the machine. Inspect the weld and make any necessary adjustments before moving on to the next step.

7. Post-weld treatment: Depending on the application, the completed weld may require post-weld treatments such as grinding, polishing, or cleaning.

In summary, fiber laser welders are a powerful and efficient tool for joining materials. By following the above tips, you can ensure successful and precise results with your fiber laser welder.

Glossary Terminology Terms for Fiber Laser Welder

Fiber laser welding has become an increasingly popular method in the manufacturing industry. But, the terminology can be confusing for those who are new to the process. To help you better understand the vocabulary involved in fiber laser welding, here are some of the essential terms to know:

1. Fiber Laser – A type of laser that utilizes a fiber optic cable as the active medium. They are often used in welding and cutting applications.

2. Beam Delivery System – The optical components that deliver the laser beam to the workpiece. This can include mirrors, lenses, and fiber optic cables.

3. Focal Length – The distance between the focus point of the laser beam and the surface of the workpiece. This distance can affect the weld penetration and bead shape.

4. Pulse Frequency – The number of laser pulses emitted per second. This can impact the weld quality, speed, and energy consumption.

5. Peak Power – The maximum power output of a laser during a single pulse. This value can affect the weld penetration and material absorption.

6. Weld Pool – The molten metal that is formed during the welding process. This is typically controlled by adjusting the laser beam parameters.

7. Gas Shielding – The use of a gas, such as argon, to protect the weld from atmospheric contamination. This can improve the quality and durability of the weld.

8. Keyhole Welding – A type of welding process where a hole is melted and filled with molten metal. This can create a deep and narrow weld.

9. Back Reflection – The reflection of the laser beam back towards the laser source. This can damage the laser or cause unwanted reflections in the workpiece.

These are just some of the fundamental terms that anyone new to fiber laser welding should know. By understanding these terms, you can better communicate with others in the industry and ensure that your welding projects are successful.

Fiber Laser Welder Price

Fiber laser welder prices vary depending on the brand, power output, and features. Generally, prices range from around $25,000 to over $100,000. However, it is important to keep in mind that investing in a high-quality fiber laser welder can result in significant cost savings in the long run.

When considering purchasing a fiber laser welder, it is important to evaluate your specific needs and budget. Factors such as the type of material being welded, the thickness of the material, and the required production speed should all be taken into account when choosing a laser welder.

In addition to the initial purchase price, it is also important to consider the ongoing maintenance costs. Higher-end machines tend to require less frequent maintenance and have a longer lifespan than lower-end machines.

Overall, purchasing a fiber laser welder is a sound investment for businesses that require high-quality welding operations. The added efficiency and speed provided by the machine can help increase productivity and reduce costs in the long run. It is important to carefully consider your needs and budget when choosing a machine and to select a reputable manufacturer that provides quality support and service.