Knowledge about Fiber Laser Welding Machine

Fiber laser welding machine is a type of welding machine that utilizes a laser beam to join two or more pieces of metal or thermoplastics. Unlike traditional welding methods that use heat generated by electrical arcs, fiber laser welding machines use a beam of high-intensity light to heat and melt the metal. This results in a cleaner, quicker, and more accurate weld with a higher degree of stability.

One of the main advantages of fiber laser welding machines is their ability to weld materials that are difficult to work with using traditional welding methods. This includes thin sheets of metal, aluminum, and other lightweight metals. The fiber laser’s ability to focus on a very small spot size also makes it ideal for welding intricate parts and components with very tight tolerances.

Another advantage of fiber laser welding machines is their speed. They are much faster than traditional welding methods and have a higher weld penetration rate, resulting in greater structural integrity. Moreover, fiber lasers consume less energy than traditional welding methods, making them more environmentally friendly.

Fiber laser welding machines also have a higher degree of precision and accuracy than traditional welding methods. This is because the laser beam has a narrower focus and allows for greater control over the welding process, resulting in fewer defects and errors.

In conclusion, fiber laser welding machines are becoming increasingly popular due to their numerous advantages over traditional welding methods. They offer greater speed, precision, accuracy, versatility, and energy efficiency. As technology continues to improve, we can expect fiber laser welding machines to become even more advanced and capable of welding a wider range of materials and parts.

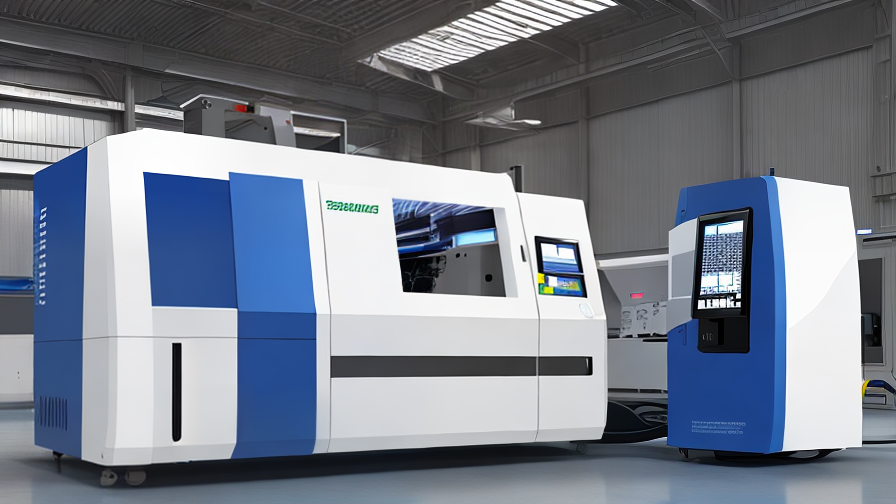

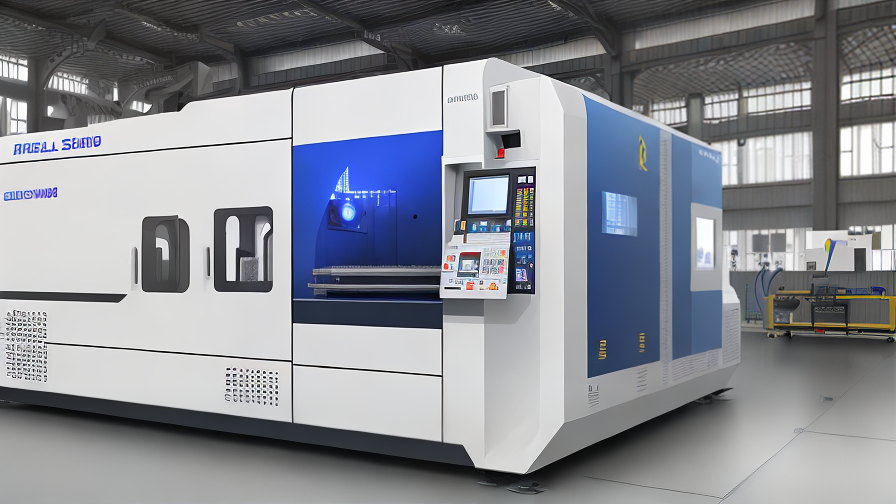

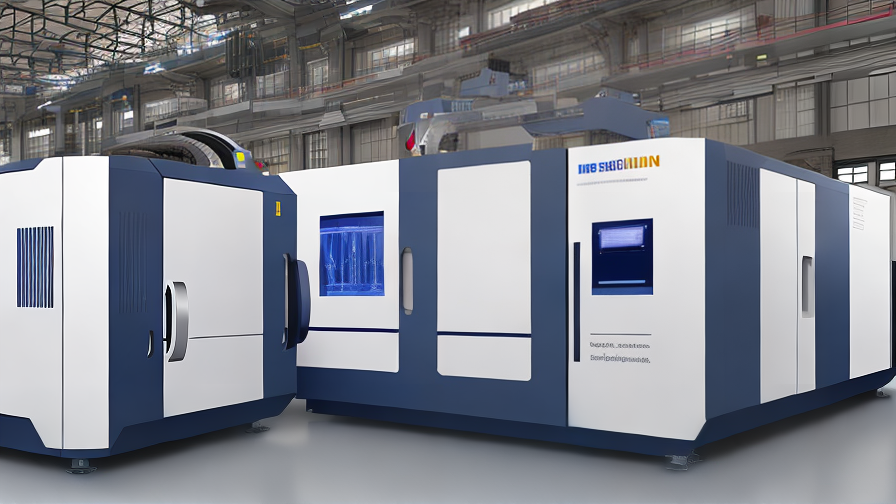

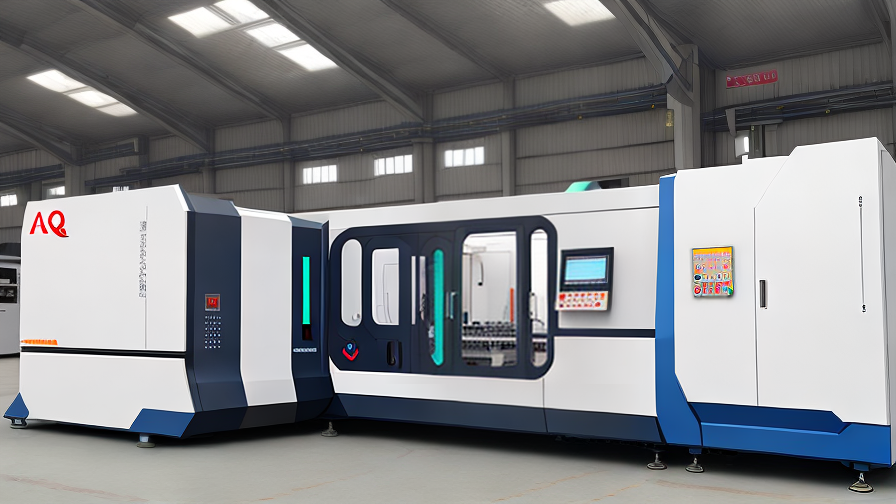

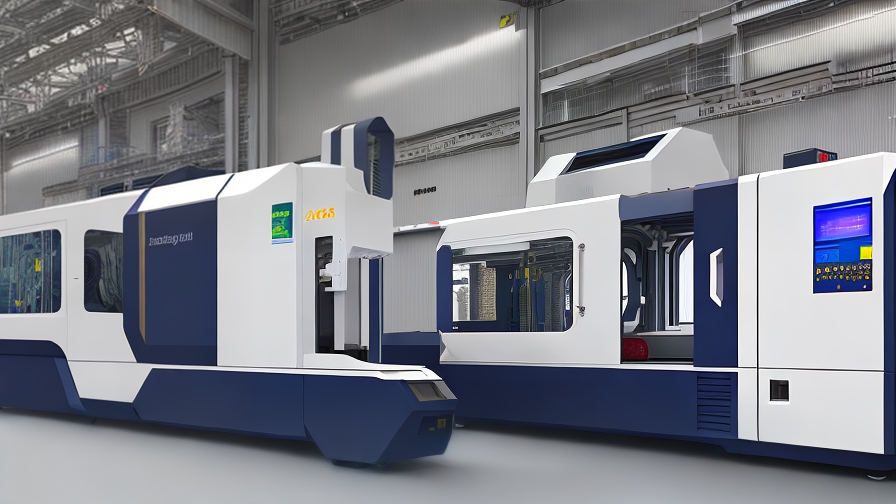

Various Types of Fiber Laser Welding Machine

Fiber laser welding machines are a popular choice for welding purposes that require high precision and speed. The fiber laser technology ensures that the output is consistent, and the welding is of high quality. Here are some of the different types of fiber laser welding machines.

1. Handheld fiber laser welding machines: These machines are suitable for welding small components, in remote areas, and for repair work. The welding spots can be adjusted easily, and the machine is easy to operate.

2. Continuous fiber laser welding machines: These machines are used for mass production of small components. The welding process is continuous, making it ideal for high-volume production.

3. Large-size fiber laser welding machines: These machines are ideal for welding larger components that cannot fit into a standard-sized welding machine. They are designed to handle heavy materials, and the welding process is automated.

4. Automated fiber laser welding machines: These machines are designed to deliver high precision and speed, making them ideal for mass production and high-volume manufacturing. They have an automatic positioning system that ensures high accuracy and consistency in the welding process.

5. Robot fiber laser welding machines: These machines are designed to be integrated with robotic systems. They are ideal for welding applications that require high flexibility and precision.

6. 3D fiber laser welding machines: These machines are designed to weld complex structures and shapes that require high precision. They are suitable for welding automotive parts, aerospace components, and medical devices.

In conclusion, fiber laser welding machines offer a reliable and efficient solution for high precision and speed welding. Various types of fiber laser welding machines are designed for different applications, making it possible to choose the right machine for the specific needs of the welding project.

FAQ sourcing Fiber Laser Welding Machine manufacturer from China

Fiber laser welding machines are widely used in various manufacturing industries. As China is one of the leading manufacturers of fiber laser welding machines, many buyers often have questions about sourcing them from China. Here are some frequently asked questions with multiple answers to help you understand better:

Q: How do I find a reliable fiber laser welding machine manufacturer in China?

A: There are various ways to find a reliable manufacturer in China, such as attending trade shows, searching on Alibaba, or using online sourcing platforms like Made-In-China or Global Sources. It’s always recommended to do thorough research and background checks before finalizing a manufacturer.

Q: What factors should I consider before choosing a fiber laser welding machine manufacturer in China?

A: You should consider the manufacturer’s expertise, experience, production capacity, quality control, customer service, certifications, and reputation in the market. It’s essential to ask for samples or visit their factory to ensure the quality of their products and their production process.

Q: What is the average price range of fiber laser welding machines made in China?

A: The price range varies depending on the type, power, and features of the machine. Generally, the price range can range from $10,000 to $100,000 or more.

Q: What are the delivery terms for buying fiber laser welding machines from China?

A: The delivery terms depend on the manufacturer’s shipping policy and the buyer’s location. It’s recommended to clarify the delivery terms, including the shipping method, delivery time, and insurance before placing an order.

Q: What is the warranty period for fiber laser welding machines made in China?

A: The warranty period varies from manufacturer to manufacturer. Generally, most providers offer a one-year warranty for their machines. It’s essential to clarify the warranty terms before finalizing the purchase.

In conclusion, sourcing fiber laser welding machines from China requires proper research, background checks, and inquiries. Consider all the factors before choosing a manufacturer to ensure the quality, cost-effectiveness, and timely

Applications of Fiber Laser Welding Machine

Fiber laser welding machine is a cutting-edge tool used in various industries because it brings a wide array of benefits such as high precision, speed, versatility, and cost-efficiency. Listed below are some of the most prominent applications of fiber laser welding machines:

1. Automotive industry – Fiber laser welding machines are commonly used for welding car bodies and parts such as door panels, sunroof, tailgates, and fuel tanks. The high precision and speed offered by the fiber laser technology make it possible to weld thin and complex sheet metals with absolute perfection.

2. Medical industry – The medical industry frequently makes use of fiber laser welding for the assembly of medical implants, medical devices, and equipment. The fiber laser welding machine ensures high precision, no contamination, and excellent surface finishing, which are vital factors in the medical field.

3. Aerospace industry – Fiber laser welding is vital in creating reliable, lightweight components from tough materials such as titanium, aluminum, and stainless steel. Components such as fuel tank vents, airframe parts, and rocket nozzles rely heavily on the high speed and precision offered by fiber laser welding machines.

4. Jewelry making – Fiber laser welding is used in the jewelry industry to create intricate designs that are otherwise impossible with other welding methods. The ease of fine-tuning different parameters, combined with the high precision and minimal heat input, allows jewelers to make complex designs with no distortion or discoloration.

5. Electronics industry – The electronics industry uses fiber laser welding in the manufacture of various small components such as sensors, semiconductors, and connectors. The precision and speed offered by fiber laser welding technology make it possible to join tiny components without any thermo-mechanical impact, and also eliminates material waste.

As evident from the above applications, fiber laser welding technology has significantly improved productivity and quality in various industries. It can be used for welding a broad range of materials and has a wide array of applications even beyond the ones listed above. Fiber laser welding is undoubtedly a vital

Manufactured Products made of Fiber Laser Welding Machine

Fiber laser welding machines have dramatically changed the way manufacturers make products. The machines use high-intensity laser beams to fuse metals together, producing high-quality welds in seconds. As a result, fiber laser welding technology is now widely used in various manufacturing sectors and has become an essential tool for creating durable and reliable products.

One example of a manufactured product made using fiber laser welding machines is aircraft parts. Aerospace manufacturing requires high precision, consistency, and durability, and fiber laser welding machines deliver on all fronts. This technology is used to weld aircraft components such as engine housings, exhaust systems, wing and fuselage sections, and landing gear parts.

Another area where fiber laser welding is widely used is in the production of medical devices. Fiber laser welding machines are used to join medical device components such as needles, catheters, and surgical instruments. The high precision and consistency of the process ensure that these essential medical devices are reliable and durable, providing clinicians with the tools they need to treat patients.

Another impressive use of fiber laser welding machines is in the production of sports equipment. From high-end golf clubs to durable bicycle frames and snowboarding gear, fiber laser welding machines offer precision and reliability in manufacturing. The process creates strong bonds allowing the equipment to withstand tough conditions and last longer, which is crucial for sports equipment. With fiber laser welding technology, manufacturers can create sports equipment to meet the needs of customers and professional athletes.

In conclusion, fiber laser welding machines have revolutionized the manufacturing industry, producing high-quality, durable, and efficient products. From aerospace, medical devices to sports equipment, fiber laser welding machines provide solutions to the most complex manufacturing challenges. The technology offers manufacturers speed, efficiency, reliability, and precision, enabling them to create products that meet the highest standards of quality.

The Evolution history of Fiber Laser Welding Machine

Fiber laser welding technology has come a long way since its inception in the 1960s. The technology started out using CO2 lasers, which were bulky and had limited precision. However, with advancements in laser technology, fiber laser welding machines were developed in the late 1990s.

The first fiber laser systems were used for marking and engraving applications, but they quickly proved to have great potential for welding applications. Fiber lasers are highly efficient, and they can produce highly focused beams of laser energy. This allowed for greater accuracy and control in the welding process.

Over the years, fiber laser welding machines have continued to evolve. In the early 2000s, high-power fiber laser systems were introduced, capable of producing up to 10 kW of power. This increased power facilitated faster welding speeds, higher-quality welds, and deeper penetration.

In the mid-2000s, the concept of beam shaping was introduced, allowing for greater control over the welding process. By controlling the size and shape of the laser beam, it is possible to manipulate the heat input into the material during the welding process, resulting in improved weld quality.

Today, fiber laser welding machines are used in a variety of industries, including automotive, aerospace, medical, and consumer electronics. They offer benefits such as high precision, high speed, and cost-effectiveness.

In conclusion, the evolution history of fiber laser welding machines has been one of continuous improvement and innovation. From the first CO2 lasers to the highly sophisticated systems of today, fiber laser welding technology has revolutionized the welding industry and has increased the efficiency of welding processes while delivering high-quality welds.

The Process of Fiber Laser Welding Machine

Fiber laser welding is a modern technology used to join metal sheets together. It is a process that uses a beam of high-intensity laser light to heat and melt the metal to create a strong and durable bond. The process of fiber laser welding is complex yet precise, involving several steps and components.

The first step in fiber laser welding is selecting the right type of machine. The machine should have the right power level, beam quality, and beam diameter to ensure precision welding. Once the machine is set up, the metal sheets to be welded are prepared by cleaning, aligning, and clamping them in place.

Next, the laser beam is directed at the joint between the metal sheets. The beam is controlled by a computer system that determines the optimal beam speed, focus, and intensity to create the perfect weld. The laser beam heats the metal to a melting point, causing the surfaces to melt and bond together.

The process of fiber laser welding generates high heat, so it requires special cooling mechanisms. The machine has a water-cooling system that circulates water through the laser head to regulate temperature and prevent overheating.

Finally, after the welding is complete, the welded metal is inspected for quality assurance. The weld is checked for cracks, strength, and proper bonding. If any defects are found, the welding process is repeated until the desired quality is achieved.

In conclusion, fiber laser welding is an advanced technology that has revolutionized metal fabrication. It is a precise and efficient process that requires specialized equipment and expertise to ensure quality welding. With its ability to produce strong and durable welds, fiber laser welding has become a go-to technology for welding metal sheets.

Benefits Advantages of Utilizing Fiber Laser Welding Machine

Fiber laser welding is a highly advanced welding technology that has gained immense popularity in recent years. This technology is utilized in modern industrial operations due to its numerous benefits, including high welding speeds, exceptional precision, and low energy consumption.

One major benefit of fiber laser welding is its high welding speeds. This technology performs welding at an accelerated speed compared to other welding methods, which means faster production and less downtime. This makes it ideal for mass production processes in the automotive, electronics, and aerospace industries.

Another significant advantage of fiber laser welding is its exceptional precision. This technology produces welds with a high degree of accuracy, which reduces the need for secondary operations, further saving time and money for businesses. Fiber laser welding’s exceptionally low heat-affected zone ensures that the material remains undamaged during the welding process, producing high-quality welds.

Fiber laser welding machines consume considerably less energy, making them cost-effective and eco-friendly alternatives to traditional welding methods. The lower energy consumption also helps in reducing the impact on the environment, which is a requirement for most modern businesses.

Fiber laser welding machines offer exceptional flexibility and versatility in welding a variety of materials that were previously difficult to weld. These materials include copper, brass, titanium, and aluminium, among others. This flexibility makes it possible to handle a wide range of welding jobs, producing high-quality results.

In conclusion, the benefits of utilizing fiber laser welding machines in modern industrial operations cannot be overemphasized. With high welding speeds, exceptional precision, low energy consumption, and flexibility to work on a range of different materials, these machines are an essential component in the manufacturing process. Businesses that adopt fiber laser welding technology will experience significant cost savings, increased productivity, and improved quality control.

Disadvantages Fiber Laser Welding Machine

Fiber laser welding machines have been gaining popularity in recent years as they offer various benefits over traditional welding methods. But it’s not all sunshine and rainbows. There are some disadvantages to using a fiber laser welding machine.

First and foremost, the equipment used in fiber laser welding can be expensive. This is because the lasers used in fiber laser welding require complex components that are built to last for a long time.

Another disadvantage is that the process is very sensitive to sharp angles on the workpiece. This can lead to irregularities and unwanted modifications in the area of the weld. It’s essential to ensure that there are no sharp edges on the workpiece.

Fiber laser welding also requires specialized training for technicians to operate safely and effectively. The lasers used in fiber laser welding are strong and can cause serious injuries if mishandled.

Moreover, fiber laser welding machines require a significant amount of electricity to function. This can result in high electricity bills, making it a significant investment for companies that require frequent use of the machine.

Lastly, fiber laser welding is not ideal for welding thick and heavy materials. It is more suited for thin and small parts, making it unsuitable for heavy-duty welding requirements.

In conclusion, while fiber laser welding machines offer several benefits, it is crucial to assess their drawbacks before making the investment. The cost of equipment, sensitivity to sharp angles, need for specialized training, high electricity usage, and inability to handle heavy-duty welding requirements are some of the disadvantages to consider. It’s best to weigh the pros and cons to determine if fiber laser welding is the best-suited method for your welding requirements.

Selecting the Ideal Manufacturer Fiber Laser Welding Machine

Selecting the ideal manufacturer fiber laser welding machine is crucial for any business that requires fast and precise welds. With so many manufacturers in the market, it can be challenging to choose the perfect machine for your specific needs. Here are a few factors to consider when selecting the ideal manufacturer fiber laser welding machine.

The first factor to consider is the welding speed required. You must understand the production capacity of your business and ensure that the machine you select offers the required welding speed to match your demand. The typical speed of a fiber laser welding machine is between 0.5 to 70 meters per minute.

The second factor is the laser power. The laser power required will depend on the thickness and nature of the material you will be welding. A higher power laser would be ideal for thicker materials, while a lower power laser would be suitable for thinner materials.

The third factor is the machine’s size and weight. Consider the available space in your workshop and the machine’s dimensions. A larger machine would require more space but may have more features than a smaller one.

Fourthly, consider the machine’s maintenance and operating costs. The maintenance of the machine will require regular replacement of consumables such as lenses and nozzles. Also, consider the cost of maintenance and the frequency of replacement before selecting the machine.

Lastly, research the manufacturer’s reputation in the market for supplying reliable and high-quality machines. Go through reviews from current and past customers to gauge their satisfaction level with the machine’s performance.

In conclusion, selecting the ideal manufacturer fiber laser welding machine requires careful consideration of various factors such as welding speed, laser power, size and weight, maintenance and operating costs, and the manufacturer’s reputation. Choose wisely to ensure that you acquire a machine that suits your welding needs and project demands.

Things to Consider When Purchasing Fiber Laser Welding Machine

Fiber laser welding machines are becoming increasingly popular for their precision, speed, and low maintenance. However, when purchasing one, several factors must be taken into account to ensure the machine’s effectiveness and longevity.

Firstly, the power output of the fiber laser welding machine must be considered. A higher wattage machine will allow for greater depth of penetration and faster processing speed, but it also comes with a higher price tag. A lower wattage machine may be more cost-efficient, but it may not be able to handle thicker materials.

The size and type of the workpiece is also crucial. The machine should be able to accommodate the size and shape of the workpiece. Additionally, the machine’s focus lens should be appropriate for the thickness of the workpiece. The wrong lens may result in poor weld quality or structural integrity issues.

The laser source and cooling system are also essential to consider. The laser source’s quality will directly affect the machine’s performance and maintenance costs. The cooling system must also be capable of keeping the machine cool during prolonged use.

The accessibility and ease of maintenance of the machine should also be evaluated. A machine with easy access to its internal components will make repairs and maintenance less of a hassle. Additionally, the machine should have essential features such as automatic calibration and adjustments, reducing the need for manual adjustments.

Lastly, the machine’s cost and warranty should be considered. A quality fiber laser welding machine can be a significant investment, but the cost should be within your budget. The warranty should also be comprehensive, covering potential manufacturing defects and other issues.

Purchasing a fiber laser welding machine can be a significant investment, and considering these factors before making a purchase will help ensure that your machine is effective, efficient, and long-lasting.

Properties of Fiber Laser Welding Machine

Fiber laser welding machine is a versatile and sophisticated tool used in many industries such as medical, automotive, aerospace, and more recently, in additive manufacturing. The properties of this machine make it a preferred choice for welding metal materials.

One of the key properties of fiber laser welding machines is their ability to produce high-quality welds with minimal heat input. The machine uses a laser beam to melt the metal material under intense heat, resulting in a precise and clean weld. This allows for smaller heat-affected zones and lower distortion rates, making it ideal for welding thin materials.

Another notable property of fiber laser welding machines is their high processing speed. The machine uses a high-powered laser beam that can weld at speeds of up to several meters per minute. This level of speed is unmatched by traditional welding methods such as MIG, TIG, or arc welding, thus significantly reducing the overall welding time.

Fiber laser welding machines also have a high level of precision, making them suitable for welding intricate designs and achieving high levels of detail. The machine’s accuracy of up to 0.1mm makes it ideal for welding small components that require a high level of precision.

Additionally, fiber laser welding machines are highly versatile and can weld a wide range of materials, including stainless steel, aluminum, copper, and even plastics. This versatility makes them ideal for a wide range of applications, from aerospace to automotive industries.

In conclusion, fiber laser welding machines offer several unique properties that make them a preferred choice in the welding industry. From high processing speeds to high precision, versatility, and minimal heat input, these machines are revolutionizing manufacturing and fabrication processes. As technology advances, fiber laser welding machines will continue to play a significant role in manufacturing processes worldwide.

How to use Fiber Laser Welding Machine

Fiber laser welding machines are a popular choice for industrial applications, as they offer control, speed, and precision. Here is an overview of how to use one.

1. Preparation: Before beginning to weld, ensure that you have the proper safety equipment, such as gloves and a mask, and that the workpiece is clean and free of debris, rust, or coatings that may prevent a clean weld.

2. Set-up: Adjust the welding parameters, such as power and speed, based on the thickness, type, and material of the workpiece. Make sure that the focus of the laser beam is in the correct position and that the welding nozzle is at the correct distance from the workpiece.

3. Welding: Once you have everything set up, begin welding. Move the welding nozzle along the weld seam at a constant speed, making sure the laser melts the edges of the material. If you are welding in overlapping sections, ensure that they are properly aligned to produce a strong joint.

4. Post-welding: After welding, allow the workpiece to cool naturally. Check the weld seam to make sure it has a smooth surface and is free of defects, such as cracks or voids. Clean up any spatter or debris left by the welding process.

Overall, the key to successful fiber laser welding is precision and attention to detail. Proper preparation and set-up are crucial steps that will affect the quality and durability of the weld. By following these steps, you can operate a fiber laser welding machine with confidence and produce high-quality, strong welds in a safe and efficient manner.

Glossary Terminology Terms for Fiber Laser Welding Machine

Fiber laser welding has revolutionized the welding industry, offering precise and efficient welding solutions for a wide range of industries. To understand the various aspects of fiber laser welding machines, it is essential to comprehend the technical jargon involved. Here are some of the common glossary terminology terms for fiber laser welding machines.

1. Fiber laser source: It is the component of the laser welding machine that generates the laser beam.

2. Beam diameter: It is the diameter of the laser beam, which is a crucial factor in determining the weld size.

3. Focal point: It is the point where the laser beam converges at its smallest diameter.

4. Spot size: It is the area of the laser beam at the welding point.

5. Pulse duration: It is the length of time that the laser beam is on during a pulse.

6. Pulse frequency: It is the number of laser pulses per second and is measured in Hertz (Hz).

7. Pulse energy: It is the energy delivered by each laser pulse and is measured in Joules (J).

8. Laser beam quality: It is the homogeneity of the laser beam that defines how efficiently the laser energy is transferred to the weld.

9. Shield gas: It is the gas used to protect the weld from oxidation and contamination.

10. Wire feed rate: It is the speed at which the welding wire is fed into the weld pool.

11. Welding speed: It is the speed at which the welding is carried out and is measured in millimeters per second.

12. Welding depth: It is the thickness of the material welded through by the laser.

13. Welding width: It is the width of the weld.

14. Laser power: It is the total power delivered by the laser and is measured in watts.

Understanding these terminologies plays a crucial role in effectively operating and optimizing the fiber laser welding machine. Before investing in a fiber laser welding machine, it is essential to have a basic understanding of these

Fiber Laser Welding Machine Price

Fiber laser welding machine is a widely used technology in various industries for welding and cutting metals. Its popularity has increased because of the precision and efficiency it offers. But when it comes to investing in a fiber laser welding machine, one of the most vital considerations is its price.

The price of a fiber laser welding machine depends on several factors, such as the power output, beam quality, and brand. Generally, the higher the power output and beam quality, the higher the cost of the machine. The reputed brands tend to offer more expensive machines than not-so-reputed brands. The entry-level fiber laser welding machines can cost around $15,000, whereas the advanced and high-powered machines can cost up to $200,000 or even more.

It is crucial to understand that the cost of a fiber laser welding machine is not only the initial investment. The total cost of ownership includes various factors like maintenance, repair, and consumables. The machines with lower cost might seem an ideal option initially however, they can become more expensive later in their lifetime.

Moreover, there are many suppliers with varying prices in the market. When deciding on the supplier, it is essential to keep in mind the quality and reputation of the supplier. Look for a supplier who offers quality machines and excellent customer support. That will ensure the machine is reliable and offer consistent performance in the long-term.

In conclusion, investing in a fiber laser welding machine requires careful consideration of the cost and long-term benefits. Make sure to analyze short-term and long-term costs, including maintenance and consumables. Moreover, selecting a quality and reputable supplier should be the utmost priority.