Knowledge about Foam Machinery

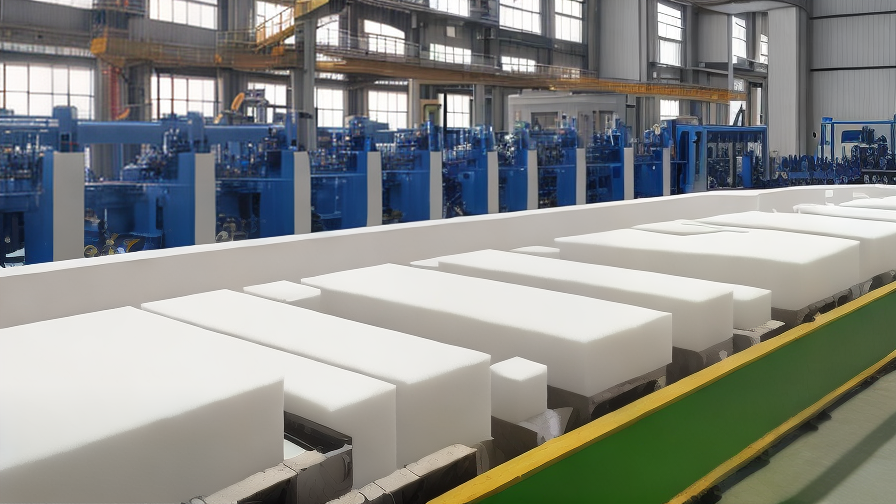

Foam machinery is an essential component in the manufacturing of foam-related products. It is a complex process that involves the use of assorted machinery to produce unique types and qualities of foam. Anyone interested in foam production needs to have a basic understanding of foam machinery and how it functions.

Foam machinery comes in different types, each with specific functions. Some of the most common types of foam machinery include the foam cutter, foam shredding machine, foam rebonding machine, and foam peeling machine. Each machine has unique features that enable it to perform a specific function in foam production.

In addition to understanding the different types of foam machinery, it is essential to know the various components and parts that make up foam machinery. These parts are integral in achieving high-quality foam products, and they include the mixing chamber, blending tank, conveyor belt, and cutter blades.

Safety is crucial when operating foam machinery. Ensure that you follow all safety precautions when handling foam machinery to avoid accidents. The use of protective clothing, such as gloves, aprons, and goggles, is necessary to prevent injuries.

Lastly, keep in mind the factors that can affect the quality of foam production. These factors include temperature, humidity, and pressure. Therefore, ensure that you operate the foam machinery within the recommended temperature and pressure ranges to obtain consistent and high-quality foam products.

Foam machinery is essential in the production of foam-related products. Understanding the basics of foam machinery, its different types, and the various parts and components is critical in achieving high-quality foam products. Remember to prioritize safety and adhere to recommended operating conditions to obtain desirable results.

Various Types of Foam Machinery

Foam machinery is an essential component in the production of a wide range of products that make use of foam materials. These machines allow manufacturers to create foam products in a cost-effective and efficient manner. There are various types of foam machinery available, each designed to cater to different production needs.

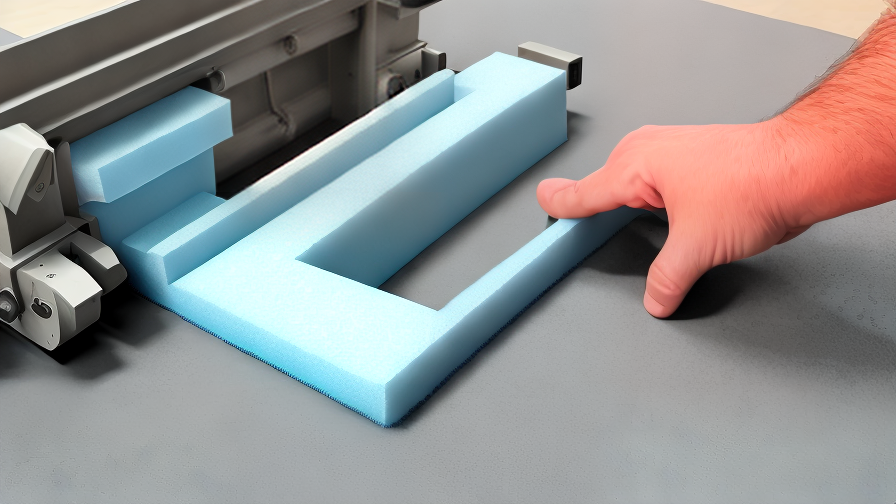

One of the most common types of foam machinery is the foam cutting machine. As the name suggests, this machine is used to cut foam into different shapes and sizes. Foam cutting machines come in different sizes and configurations, with some able to cut through multiple layers of foam at once. They are used in the manufacturing of products such as foam mattresses, cushions, and pillows.

Another type of foam machinery is the foam pouring machine. This machine is used to create foam products by pouring a liquid mixture into a mold. The mixture then undergoes a chemical reaction that causes it to expand and solidify into a foam product. Foam pouring machines are used to produce products such as foam insulation, packaging materials, and toys.

Foam shredding machines are also common in the foam industry. These machines are designed to shred foam into smaller pieces, making it easier to recycle and reuse. Foam shredding machines are used in industries such as furniture manufacturing, packaging, and insulation production.

Foam rebonding machines are another type of foam machinery. They are used to create rebonded foam products by binding together small pieces of foam. These machines are used in the production of products such as carpet pads, gym mats, and automotive padding.

In conclusion, foam machinery plays a crucial role in the manufacturing of various foam products. There are different types of foam machinery available, each designed to cater to different production needs. Some popular examples include foam cutting machines, foam pouring machines, foam shredding machines, and foam rebonding machines.

FAQ sourcing Foam Machinery manufacturer from China

As the world’s leading manufacturing hub, China has become the go-to destination for various machinery and equipment, including those related to the foam industry. For businesses seeking to source foam machinery manufacturer from China, here are some frequently asked questions with answers to guide the process.

Q: What types of foam machinery are available from Chinese manufacturers?

A: Chinese manufacturers produce a broad range of foam machinery, including foaming machines, cutting machines, laminating machines, sealing machines, and packaging machines.

Q: How do I select a reliable foam machinery manufacturer from China?

A: The key to finding a reliable manufacturer is to conduct extensive research on potential suppliers. This includes checking their track record, certifications, reviews, and inspecting their quality control systems.

Q: Can I customize the foam machinery to meet my requirements?

A: Yes, many Chinese foam machinery manufacturers offer custom designs and specifications to meet the unique needs of their clients. This may involve modifications to the machine’s size, capacity, or functionality.

Q: How long does it take to get a foam machine from China?

A: The delivery time varies depending on the manufacturer, the complexity of the order, and shipping method. Typically, it takes between 20 to 60 days to receive a foam machine from China, including manufacturing and shipping time.

Q: What are the payment terms for foam machinery from China?

A: Chinese foam machinery manufacturers typically require a down payment, followed by a balance payment upon delivery. Some also offer credit terms, but these may require extensive due diligence and credit checks.

In conclusion, sourcing foam machinery from China can be a daunting task, but with proper due diligence and knowledge, it can be a fruitful venture. Businesses must do their research and seek advice from reputable experts to help them navigate the process and find the right manufacturer that meets their needs.

Applications of Foam Machinery

Foam machinery offers numerous applications in various industries, such as packaging, construction, automotive, and upholstery. Foam is a versatile material that provides a range of benefits, such as cushioning, insulation, buoyancy, and soundproofing. Here are some of the applications of foam machinery:

1. Packaging – Foam machinery is commonly used in making foam packaging materials, such as foam sheets, foam rolls, foam inserts, and foam blocks. These foam products provide excellent protection against shocks, vibrations, and impacts during transit and storage.

2. Construction – Foam machinery is also used in the construction industry for making insulation foam, spray foam, and foam concrete blocks. Insulation foam provides thermal and acoustic insulation, while spray foam provides air sealing and moisture control. Foam concrete blocks provide lightweight and durable building materials that reduce construction costs and environmental impacts.

3. Automotive – Foam machinery is used in the automotive industry for making seat foams, headliners, dashboards, and door panels. These foam products provide comfort, support, and aesthetic appeal to the interior of a car, truck, or bus.

4. Upholstery – Foam machinery is also used in the furniture industry for making foam cushions, foam mattresses, and foam pillows. These foam products provide comfort and support to users, and also add aesthetic value to furniture designs.

5. Medical – Foam machinery is used in the medical industry for making foam pads, foam cushions, and foam supports. These foam products provide comfort and pressure relief to patients who undergo surgical procedures or suffer from medical conditions that require immobilization or support.

In conclusion, foam machinery offers a wide range of applications in various industries, such as packaging, construction, automotive, upholstery, and medical. These foam products provide numerous benefits, such as cushioning, insulation, buoyancy, and soundproofing. Hence, companies that utilize foam machinery can improve their products’ quality, efficiency, and competitiveness in the market.

Manufactured Products made of Foam Machinery

Foam machinery has revolutionized the manufacturing industry with the production of foam-based products. Foam made by foam machinery is an ideal component for use in a wide range of industries such as automotive, electronics, packaging, construction, and healthcare.

One of the most popular manufactured products made with foam machinery is foam insulation. Insulation foam is an excellent material, mostly used in construction projects. It helps to save heating and cooling costs, as well as increase energy efficiency in buildings. Such insulation foam made with foam machinery helps to reduce energy consumption and overall greenhouse gas emissions from buildings.

Another manufactured product made with foam machinery is foam packaging. Foam packaging is widely used in various industries due to its shock-absorbing quality. It is widely used to protect fragile products during transport, such as electronic equipment, artwork, and medical supplies. Foam machinery also produces foam packaging that is reusable, recyclable, and biodegradable.

The automotive industry also benefits significantly from foam machinery-produced foam products. Foam is used as cushion material in car seats and car interiors, providing comfort and durability. It is a cost-effective alternative to traditional leather and fabric upholsteries. Also, foam machinery produces foam tapes that are used for sealing windows, doors, and other parts of an automobile.

In the healthcare industry, foam machinery produces foam mattresses and pillows that provide excellent support and ensure patient comfort. Foam can also be used in wheelchair cushions that help relieve pressure points and prevent pressure ulcers.

In conclusion, foam machinery has become an integral part of different manufacturing industries, thanks to the flexibility and efficiency in producing foam-based products. The use of foam and foam machinery has revolutionized a wide range of industries with several innovative applications. The development of eco-friendly, recyclable, and biodegradable foam products continues to shed light on the bright future of foam machinery in modern manufacturing.

The Evolution history of Foam Machinery

The development of foam machinery has evolved over the years to meet the changing demands of foam production. The earliest foam machinery is believed to have been developed in the 1920s, and it was typically used for the production of foam rubber products. These machines were simple and primitive compared to the sophisticated technology used today.

During the 1950s, foam molding machines were developed, which allowed for the creation of more complex foam products. These machines could produce foam with varying densities and hardness, which made them suitable for use in a wider range of applications. As the demand for foam products increased, so did the need for more efficient foam machinery.

The 1960s saw the introduction of continuous foam production, which allowed for the creation of foam sheets and rolls. This technology allowed for greater flexibility and efficiency in foam production, and it remains a popular method today. In the 1970s, computerized systems were introduced to control the various aspects of foam production, including temperature, pressure, and density. This made foam production more efficient and allowed for higher quality foam products to be produced.

Today, foam machinery has evolved to enable the creation of a wide variety of foam products, including packaging materials, insulation, and cushioning products. The machines used today are highly sophisticated, and they are capable of producing foam with precise properties for specific applications. They incorporate advanced technology, such as computer-controlled sensors and automated systems, to ensure the highest level of precision and efficiency in foam production.

The evolution of foam machinery has been driven by the increasing demand for foam products in a diverse range of industries. As technology continues to advance, it is likely that foam machinery will continue to improve, enabling the creation of even more advanced foam products.

The Process of Foam Machinery

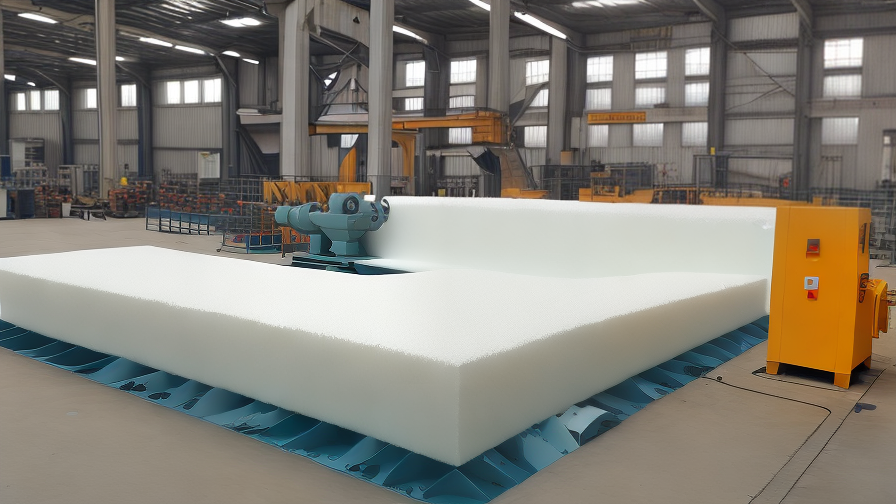

Foam machinery is a type of machinery that produces foam products, such as foam insulation, foam packaging, foam cushions, and foam mattresses. The process of foam machinery involves several steps, including mixing, pouring, molding, and curing.

The first step in the process of foam machinery is mixing. The mixing process involves combining the foam ingredients, such as chemicals, water, and gases, in a large mixing tank. The ingredients are mixed together to create a foam liquid that will eventually solidify into the desired foam product.

The next step in the process of foam machinery is pouring. Once the foam liquid is mixed, it is poured into a mold. The mold is typically made of metal or plastic and is shaped to the desired size and shape of the foam product. The foam liquid is carefully poured into the mold to ensure it fills all the corners and crevices of the mold.

After pouring, the foam product is then molded into the desired shape. This process involves applying pressure and heat to the foam product to help it maintain its shape. The foam is cured in the mold for a specific amount of time, depending on the type of foam product being produced.

The final step in the process of foam machinery is curing. This step involves allowing the foam product to cool and harden. The curing process can take a few hours to several days, depending on the type of foam product being produced.

In conclusion, the process of foam machinery involves several steps, including mixing, pouring, molding, and curing. These steps are essential in producing high-quality foam products that meet specific requirements and standards. Foam products are used in various industries, such as construction, packaging, and furniture, and play a critical role in daily life.

Benefits Advantages of Utilizing Foam Machinery

Utilizing foam machinery can be a practical solution for many industries. These machines are designed to produce foam products efficiently and precisely. Here are some benefits and advantages of utilizing foam machinery.

Cost-Effective

Foam machinery can produce a large amount of foam products in a short amount of time, which can save on labor costs. It takes only a few operators to manage the machine, which can save money in the long run. Additionally, foam machinery requires minimal maintenance and has a long lifespan, which means fewer repair and replacement costs.

Customization

Foam machinery can produce foam products in various shapes and sizes, allowing you to design products that fit your specific requirements. This means you can make customized products that meet your customers’ needs and preferences. This is particularly useful for industries such as furniture and packaging, where products come in different shapes and sizes.

Efficiency

Foam machinery is a faster and more efficient way of producing foam products compared to manual labor. This is because foam machinery can work non-stop, and it is less prone to mistakes. Additionally, foam machinery can produce products that have consistent quality, which can improve customer satisfaction and reduce returns due to faulty products.

Versatility

Foam machinery can be used to produce various foam products, such as foam padding, foam mattresses, foam packaging, and even insulation. This flexibility allows you to expand your product line and provide more value to your customers.

Environmentally Friendly

Foam products made from foam machinery are often eco-friendly, which is a growing concern for many customers. These machines use less energy and produce less waste, making them more sustainable than traditional foam manufacturing methods.

In conclusion, utilizing foam machinery is a practical and beneficial solution for many industries. It is cost-effective, efficient, customizable, versatile, and environmentally friendly. Investing in foam machinery can improve the quality of your products and increase your profits in the long run.

Disadvantages Foam Machinery

Foam machinery is widely used in various industries for manufacturing foam-based products. Although it has several advantages, there are also some notable disadvantages that cannot be ignored. In this article, we will focus on some of the most common disadvantages of foam machinery.

One of the main drawbacks of foam machinery is its high initial cost. Unlike other types of machinery, foam machinery can be quite expensive. This can be a significant barrier for small businesses or startups that may not have the necessary capital to invest in the equipment. Additionally, foam machinery requires regular maintenance, which can add to the overall cost.

Another significant disadvantage of foam machinery is its reliance on chemical and petroleum-based products. The production of foam requires the use of chemicals and petroleum derivatives that can be hazardous to the environment. The chemicals used in foam production can also be harmful to human health, especially for those who work with the machinery on a daily basis.

Foam machinery also has a limited lifespan. Like any other machinery, foam machinery has a certain lifespan and will eventually need to be replaced or upgraded. This can be a significant cost for businesses that rely heavily on foam production.

In addition to its limitations and costs, foam machinery can also be quite inefficient. Foam production requires a significant amount of energy, which can increase energy costs for businesses. Moreover, the production process can be time-consuming, which can lead to long lead times and reduced productivity.

Finally, foam machinery can result in various environmental impacts. Foam waste is not biodegradable, which means that it can accumulate in landfills over time. Foam waste can also be difficult to recycle, as it must be separated from other materials and processed separately.

In conclusion, while foam machinery has many advantages, it also has several significant drawbacks that cannot be ignored. Its high cost, reliance on chemicals and petroleum products, limited lifespan, inefficiency, and environmental impacts make foam machinery a less desirable option for some businesses. As such, businesses must consider these disadvantages when choosing which machinery to use for their foam

Selecting the Ideal Manufacturer Foam Machinery

Selecting the ideal manufacturer foam machinery is essential for those who want to start their own foam production business. Foam is widely used in various industries, including furniture, automotive, construction, and medical. Therefore, it is crucial to invest in reliable and efficient foam machinery that can meet the demands of the market.

The first thing to consider when selecting a foam machinery manufacturer is their experience and reputation in the industry. Look for manufacturers who have been in the business for a long time and have a good reputation for producing high-quality machinery. Check their customer reviews and ratings to see if they have satisfied clients.

Another factor to consider is the type of foam machinery offered by the manufacturer. There are various types of foam machinery, including block foam machines, shape molding machines, and continuous foam production lines. Select a manufacturer that provides the specific type of machinery that you need for your business.

The efficiency and productivity of the machinery are also essential considerations. The machinery should be capable of producing a high volume of foam with minimal waste and downtime. Look for manufacturers that use advanced technology and techniques to ensure their machinery is efficient and productive.

Additionally, select a manufacturer that offers excellent customer support and maintenance services. The machinery may require routine maintenance and repairs to ensure it is in good working condition. Reliable customer support can ensure that any issues are resolved quickly, minimizing any downtime and associated losses.

Lastly, consider the cost of the machinery and any additional services offered by the manufacturer. Look for a manufacturer that offers reasonable pricing while providing top-quality machinery and services.

In conclusion, selecting the ideal manufacturer foam machinery is essential for the success of any foam production business. Consider the manufacturer’s experience, reputation, type of machinery offered, efficiency, productivity, customer support, and maintenance services, and cost when making your decision.

Things to Consider When Purchasing Foam Machinery

Purchasing foaming machinery can be a tricky process. While there are many factors to consider, there are some key things to keep in mind. First, determine the type of foam you want to produce. There are different types of foam like polyurethane foam, polystyrene foam, and PVC foam. Each foam type requires a specific type of machinery, so it’s important to know what you need before making a purchase.

Second, consider the capacity of the machine. The capacity of the foam machine depends on the type of foam you are producing and the amount of foam you want to produce. If you are running a large-scale operation, you will need a high-capacity machine, but this will also increase the cost of the machinery.

Third, ensure the machinery is efficient. A good foam machine should consume less energy and produce high-quality foam. Consider the heating system, pump, and the motor of the machine, they should be energy-efficient and of high quality.

Fourth, check the price and warranty. Foam machines vary in price, and it’s important to compare various brands and models to choose the right one for you. Additionally, a good foam machine should come with a warranty to cover any damages or repairs that may arise after purchase.

Lastly, consider the ease of operation and maintenance. The machine should be easy to operate and maintain. The machine manual should be easy to read and understand, and the machine should have readily available spare parts.

In conclusion, purchasing a foam machine should be a well-thought-out process. Ensure you consider the type of foam you want to produce, the capacity of the machine, efficiency, price, warranty, and ease of operation and maintenance before making a purchase. With careful consideration, you can select a high-quality machine that is perfect for your needs.

Properties of Foam Machinery

Foam machinery is used in various industries such as construction, packaging, automotive, and many more. The use of foam has increased over the years due to its numerous benefits such as lightweight, sound insulation, and thermal insulation. Hence, foam machinery becomes essential in producing foam products. The following are some of the properties of foam machinery.

1. Versatile: Foam machinery is capable of producing different types of foam products such as rigid foam, flexible foam, and integral skin foam. This versatility makes it possible to cater to varying needs of different industries.

2. Efficiency: Foam machinery is designed to produce foam products in high volumes and with high precision. Additionally, the machinery can produce foam products in different sizes and shapes making it efficient in meeting specific needs.

3. Safety: Foam machinery has safety measures put in place to prevent accidents. For instance, the machinery stops automatically when components are running low or when there is a malfunction.

4. Cost-effective: The production cost of foam products is relatively low due to the efficiency of the machinery. Additionally, the ability to produce products in different sizes and shapes makes it cost-effective.

5. High-quality products: The machinery is designed to produce foam products with consistent quality. The use of computer numerical control (CNC) machines ensures that products are produced with high precision.

6. Easy to maintain: Foam machinery requires minimal maintenance due to its durable nature. Manufacturers provide manuals and guidelines on how to perform repairs and maintenance.

In conclusion, foam machinery is an important tool used in producing foam products. Its versatility, efficiency, safety measures, cost-effectiveness, high-quality products, and easy maintenance make it an ideal choice for industries requiring foam products.

How to use Foam Machinery

Foam machinery is used to create foam products such as mattresses, cushions, and packaging material. It’s a versatile tool that can help you create different types of foam products easily. Here’s how to use foam machinery.

First, make sure you have the right materials. Foam machinery typically uses foam blocks, which are available in different densities and sizes to choose from.

Next, set up the machine according to the manufacturer’s instructions. Make sure that you have enough space to move and that the machine is properly grounded.

Load the foam block onto the machine, and turn it on. The machine will then start to heat and shape the foam block into the desired shape depending on the type of foam product you’re making.

Once the foam has been shaped, cut it to the desired size and shape using a foam cutter or saw. Be sure to follow proper safety precautions when handling sharp tools.

Finally, if you’re making a foam product that requires stitching, use an upholstery sewing machine to sew the foam pieces together. You can also apply different types of fabrics and foam to create more intricate designs.

In conclusion, using foam machinery requires careful attention to detail and proper safety precautions. With the right materials and techniques, you can create a variety of foam products that meet your needs.

Glossary Terminology Terms for Foam Machinery

When it comes to foam machinery, there are many technical terms used that can be confusing to those who are not familiar with the industry. Understanding these terms is essential for successful foam production. Here are some glossary terminology terms for foam machinery:

1. Density: The weight of foam in a given volume.

2. Compression: The process of reducing the volume of foam by applying pressure.

3. Die: The tool used to shape foam into specific forms.

4. Blending: The process of mixing different types of foam to obtain desired characteristics.

5. Feedstock: The raw materials used in the production of foam.

6. Curing: The process of hardening foam to enhance its durability.

7. Expansion Ratio: The ratio of the volume of the foam to the volume of the liquid used to produce it.

8. Foaming Agent: The substance that creates gas bubbles in the foam.

9. Polymerization: The process of converting liquid foam into solid foam.

10. R-value: The measure of a material’s capacity to resist heat flow.

11. Surface Tension: The force that holds the surface of a liquid together.

12. Viscosity: The resistance to flow exhibited by a liquid.

Understanding these terms is vital to the successful operation of foam machinery. Each term plays a critical role in the quality and consistency of foam production. By speaking the same language when discussing foam machinery, manufacturers, and customers can ensure that their needs are communicated effectively. Ultimately, this leads to the production of high-quality foam products that meet customer expectations. Whether you’re a foam production expert or a newcomer to the industry, understanding the terminology used in foam machinery is essential.

Foam Machinery Price

Foam machinery price is an essential factor to consider when purchasing equipment for foam production. The pricing of foam machinery differs according to the type and specifications of the machinery. There is no fixed price for foam machinery, and it varies from brand to brand, as well as the quality of the machinery.

In the foam manufacturing industry, the price of foam machinery can range from thousands to millions of dollars. The cost of foam machinery is determined by the features, efficiency, and reliability of the machine. Foam machinery price also depends on the manufacturer’s pricing policy, production scale, and availability of spare parts.

The initial cost of purchasing foam machinery might seem high, but it is a long-term investment that pays off. Nonetheless, it is essential to conduct extensive research before making any purchase to ensure that the foam machinery meets the factory’s specific needs. It is advised to work with a reputable supplier that provides complete technical support, installation, and after-sales services.

In summary, foam machinery price varies on several factors. The cost of foam machinery depends on the complexity of the machinery, quality, features, and efficiency. It is always vital to acquire a good quality machine that has a fair price, as the efficiency and productivity of the factory relies heavily on the machinery’s durability and effectiveness. Therefore, it is best to conduct thorough research, consider your production scale, and have an expert opinion before making a purchase.