Knowledge about Gas Filling Machine

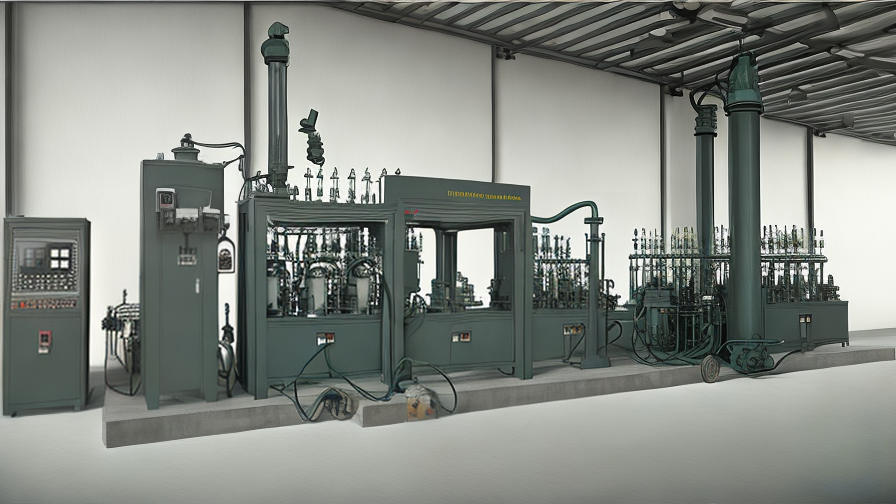

Gas filling machines are used in a variety of industries, including the medical sector, food industry, and automotive industry. These machines are designed to fill various types of gases into cylinders, such as oxygen, nitrogen, carbon dioxide, and helium, to name a few. Understanding the basics of these machines is crucial in ensuring they function properly and produce high-quality gas products.

The gas filling machine operates through a series of processes, which include purification, compression, and filling. The first step in the process is the purification of the raw gas. The purification process is done to remove any impurities that might be present in the gas. This helps in producing high-quality gas and also enhances the lifespan of the machine.

After the purification process, the gas is then compressed. The compression stage is where the gas is pressurized to a level that is sufficient to fill the cylinder. Gas filling machines use different types of compressors, such as diaphragm compressors, piston compressors, or rotary vane compressors. The type of compressor used will depend on the type of gas being compressed and the required level of pressure.

The last stage in the process is the filling stage. During this stage, the compressed gas is filled into the cylinder through a transfer hose. The filling speed and accuracy of the machine depend on the type of gas, cylinder size and the level of pressure required. It’s important to ensure that the volume of gas in the cylinder is correct, and the pressure is within the range specified.

In conclusion, knowledge about gas filling machines is essential, especially for those in industries that require these machines. This knowledge includes understanding the different types of gases, the stages of the filling process, and the components of the machine. With this knowledge, operators can ensure they produce high-quality gas products that meet the required standards.

Various Types of Gas Filling Machine

Gas filling machines are used in various industries such as automotive, pharmaceutical, food and beverage, and chemical industries to fill gas cylinders and bottles. There are various types of gas filling machines available in the market that cater to different industry requirements. Let’s take a closer look at some of the most popular types of gas filling machines.

1. Automatic gas filling machines – These machines are suitable for filling large quantities of gas cylinders quickly and accurately. They are fully automated and can be customized according to the specific industry requirements.

2. Semi-automatic gas filling machines – These machines require manual intervention to start and stop the filling process. They are suitable for filling smaller quantities of gas cylinders and are cost-effective compared to fully automatic filling machines.

3. High-pressure gas filling machines – These machines are designed to fill gas cylinders with high-pressure gases such as carbon dioxide, nitrogen, and oxygen. They are ideal for use in industries such as welding and metal fabrication, where high-pressure gases are required.

4. Nitrogen gas filling machines – These machines are specifically designed for filling nitrogen gas into bottles and cylinders. They are used in a variety of industries such as food and beverage, pharmaceuticals, and electronics.

5. LPG gas filling machines – These machines are designed to fill LPG gas cylinders used for cooking and heating purposes. They are widely used in households, restaurants, and hotels.

In conclusion, gas filling machines play a crucial role in various industries by ensuring accurate and efficient filling of gas cylinders and bottles. With advancements in technology, gas filling machines have become more efficient and user-friendly, making them an indispensable part of modern industrial practices.

FAQ sourcing Gas Filling Machine manufacturer from China

Sourcing a gas filling machine manufacturer from China can be a daunting task. With a vast number of manufacturers in the country, it can be challenging to find a reliable supplier. In this article, we have gathered the most frequently asked questions (FAQ) regarding finding a gas filling machine manufacturer in China with multiple answers to guide you on your search process.

Q: What kind of gas filling machine can I find in China?

A: China’s gas filling machine industry offers a wide range of machines designed for different gas filling needs. These include machines for filling oxygen, nitrogen, helium, carbon dioxide, and other types of gases.

Q: How can I determine the quality of a gas filling machine manufacturer from China?

A: Firstly, you should check if the manufacturer is certified and complies with international standards. Secondly, you can visit the factory to inspect the production process and quality control. Additionally, you can also check reviews and feedback from previous customers to gauge the quality of their products.

Q: What is the price range of gas filling machines in China?

A: The cost of a gas filling machine depends on its specifications, functions, and quality. Generally, gas filling machines from China are relatively affordable compared to those from other countries. However, the price can range from a few thousand to tens of thousands of dollars.

Q: How long does it take to manufacture a gas filling machine in China?

A: The production time varies depending on the complexity of the machine and the manufacturer’s capacity. However, the typical production time for a gas filling machine in China is between 30 to 90 days.

Q: Can I customize my gas filling machine from China?

A: Yes, most gas filling machine manufacturers in China offer customization services. You can work with the manufacturer to design a machine that meets your specifications.

In conclusion, sourcing a Gas Filling Machine manufacturer from China requires careful consideration of the available options. By asking the right questions and doing your due diligence, you can find a reliable supplier

Applications of Gas Filling Machine

A gas filling machine is a specialized device that is used to fill gas cylinders with different types of gases like oxygen, nitrogen, helium, and carbon dioxide. These machines are an essential part of the gas industry and are widely used in various applications.

One of the most common applications of gas filling machines is in the medical industry. Oxygen cylinders are used to provide life-supporting oxygen to patients in hospitals and clinics. The gas filling machine ensures that the oxygen cylinders are filled to the required pressure and are free from any contaminants that can cause harm to the patients.

Gas filling machines are also used in the welding industry. In welding, gases like argon, helium, and carbon dioxide are used to create an inert atmosphere that prevents oxidation and enhances the welding process. The gas filling machine ensures that the welding cylinders are filled with the right amount of gas at the correct pressure to ensure a stable, high-quality weld.

The food and beverage industry also uses gas filling machines to preserve and package food products. Carbon dioxide is used to preserve food products, and the gas filling machine ensures that the carbon dioxide is filled into the packaging in a controlled manner to achieve the desired shelf life and quality.

The automotive industry also uses gas filling machines to fill air conditioning systems with refrigerant gases like R134a. The machine ensures that the refrigerant gas is filled into the system at the right pressure and in optimal quantities to improve the performance and efficiency of the air conditioning system.

In conclusion, gas filling machines are essential devices that have a wide range of applications in various industries. From the medical and welding industries to the food and beverage and automotive industries, gas filling machines play a critical role in ensuring that gases are filled into cylinders in a controlled manner to achieve the desired results.

Manufactured Products made of Gas Filling Machine

Manufactured products made of gas filling machines are becoming an essential part of many industries worldwide. These machines are used to fill gases such as oxygen, nitrogen, argon, and carbon dioxide into cylinders, aerosol cans, and other containers. The gas filling machines work by using compressed gas, which is then directed into the container to be filled.

There are several types of gas filling machines available in the market, which vary in size, capacity, and function. The most common types of gas filling machines are automatic, semi-automatic, and manual. The automatic gas filling machine is a fully automated machine that fills, seals, and caps the containers. The semi-automatic gas filling machine requires some human intervention and is mostly used for small production runs. Lastly, the manual gas filling machine is used for filling cylinders and containers with gas for laboratory purposes.

The industrial sector is one of the largest users of gas filling machines. Industries such as the food and beverage industry, pharmaceuticals, and medical equipment, and the petrochemical industry require gas filling machines to fill containers with inert gas, liquefied petroleum gas, and other gases. Examples of products manufactured using gas filling machines include fire extinguishers, aerosol sprays, welding gases, diving tanks, and many more.

The use of gas filling machines has significantly reduced human error during the filling process. As a result, this has led to high-quality and safe products. Moreover, gas filling machines are easy to maintain, which makes them a cost-effective solution for businesses.

In conclusion, the use of gas filling machines has become crucial for many industries globally. The machines are used to fill different types of gases into containers, which are then used in various products. The efficiency, accuracy, and safety offered by gas filling machines make them a great investment for businesses. By investing in gas filling machines, industries can improve their production processes and ensure quality products, thus improving customer satisfaction.

The Evolution history of Gas Filling Machine

The evolution of gas filling machines spans several decades of innovation, advancement, and technological advancements. The very first gas filling machines were manually operated, and for every gas filling operation, an operator had to open and close the valve to control the flow of gas.

In the 1950s, semi-automatic gas filling machines were introduced. These machines could partially control the filling process, thus reducing the reliance on operator skills. However, these machines still needed the operator to carry out some critical functions such as opening and closing the gas valve and monitoring the gauge readings.

In the 1970s, fully automated gas filling machines were introduced. These machines integrated electronic controls to improve the accuracy and speed of the filling process, along with greater control over the gas flow. They also offered increased efficiency and productivity due to minimal operator input and little need for manual intervention.

Today, the gas filling machines have become fully computerized and offer advanced functionalities such as real-time data tracking and analytics, customized gas mixtures, and remote control capabilities. They can fill various types of gases, including industrial gases, medical gases, and specialty gases, with extreme precision and accuracy.

Advancements in gas filling machines have led to cost savings, increased safety and quality, and improved productivity. They are now essential in various industries, including automobile, food processing, and pharmaceuticals.

In conclusion, the evolution of gas filling machines has seen significant advancements in the automation, precision, and speed of the filling process. With the current technological advancements and the ever-increasing demand for gas filling machines, it is clear that the future of gas filling machines is bright.

The Process of Gas Filling Machine

Gas filling machines are an essential type of equipment used in various manufacturing and industrial facilities to fill gas containers, bottles, cylinders and tanks with various types of gases. The process of gas filling involves several steps, and gas filling machines have been designed to simplify and automate these steps.

The first step is preparing the gas being filled, which involves selecting the right type of gas, ensuring its purity, and verifying that the amount of gas required is available. Once the gas has been prepared, the next step is to connect the gas cylinder to the filling machine. The machine will then check the weight of the empty cylinder and compare it to the known standard weight for that type of cylinder.

The machine will then initiate the filling process by opening the valve on the bulk tank, which releases the gas. The gas fills the cylinder from the bottom, and the machine continues to monitor the weight of the cylinder as it fills. When the weight of the cylinder reaches the correct amount, the machine will automatically close the valve and stop the filling process.

It’s important to note that gas filling machines are designed with several safety features to prevent over-filling, under-filling, and gas leaks. Additionally, the machines are made from high-quality materials that are resistant to corrosion and other chemical reactions that can occur when filling gases.

In conclusion, gas filling machines are crucial pieces of equipment used in various industries to fill gas containers, bottles, cylinders and tanks with several types of gases. The process of filling a gas cylinder involves several steps, including selecting the right type of gas, connecting the cylinder to the machine, and filling the cylinder while monitoring the weight to ensure it’s not under-filled or over-filled. Gas filling machines are designed with safety features to ensure that the process is safe and efficient.

Benefits Advantages of Utilizing Gas Filling Machine

Gas filling machines are an essential technological breakthrough in the gas industry. This machine has simplified the process of filling gas in a convenient and efficient manner. Gas filling machines work by compressing gas from a cylinder into a container or other gas sources. There are countless benefits associated with utilizing gas filling machines, some of which are discussed below.

Firstly, gas filling machines guarantee accurate measurement and delivery of gas. This ensures that you get the exact amount of gas you need for your appliance, without any wastage. The machines come with a pressure gauge which enables you to check and adjust the pressure of the gas to perfectly match the needs of your application. This not only saves you time and money but also ensures a safe and uninterrupted gas supply.

Secondly, gas filling machines provide convenience and flexibility. They can be used for filling gas in cylinders, tanks, and other gas sources. This means that you can use the machine to fill up cylinders for your home or business use, and also fill up tanks for industrial applications. This flexibility is crucial for businesses that deal with a wide range of clients and need to meet specific demands.

Thirdly, gas filling machines are reliable and durable. They are designed to withstand harsh industrial environments and are made from high-quality materials. This reduces the need for frequent maintenance, which can save you time and money in the long run.

Lastly, gas filling machines are environmentally friendly. The machines use clean and renewable energy, which reduces the carbon footprint. This is important in today’s world where the environment is a major concern.

In conclusion, gas filling machines are essential tools for the gas industry. They offer a range of benefits that include accuracy, convenience, flexibility, reliability, and environmental friendliness. By investing in a gas filling machine, you can save time and money while ensuring that your gas supply is safe, uninterrupted, and efficient.

Disadvantages Gas Filling Machine

Gas filling machines have brought great convenience to multiple industries, such as HVAC, automotive, and food packaging. The machines allow efficient and accurate filling of gas into containers, reducing manual labor and time consumed. While there are many advantages to using gas filling machines, there are also several disadvantages.

Firstly, gas filling machines can be expensive to purchase and maintain. These machines require significant investment as they are complex pieces of equipment that require regular servicing and upkeep. Companies that cannot afford these machines may find themselves at a disadvantage with competitors who do have them.

Secondly, gas filling machines can be difficult to operate. They require specialized training to operate effectively and safely. If operators are not adequately trained, they could cause avoidable accidents or damage to the machinery.

Thirdly, gas filling machines have limited flexibility. They are typically designed for one specific type of gas or container size. If a company needs to fill multiple types of gas or containers, they may require multiple filling machines, which can be costly.

Lastly, gas filling machines may not be environmentally friendly. They can release harmful emissions into the atmosphere during the filling process, contributing to air pollution. They also consume large amounts of energy during operation, which can increase a company’s carbon footprint.

In conclusion, gas filling machines have revolutionized the way we fill gas into containers, but they also have several disadvantages. They are expensive, difficult to operate, limited in flexibility, and potentially harmful to the environment. Companies must weigh the pros and cons of using such machines and determine if they are worth the investment or not.

Selecting the Ideal Manufacturer Gas Filling Machine

When it comes to selecting the ideal manufacturer gas filling machine, there are a number of factors that need to be taken into consideration. While quality and reliability are obviously important, there are also other factors such as price and ease of use that need to be considered.

One of the key factors to consider when selecting a gas filling machine is the reliability of the machine. This means selecting a machine from a manufacturer who has a reputation for producing high-quality, reliable equipment that can stand up to the demands of the industry. This will ensure that the machine operates efficiently, reducing downtime and costly repairs.

Another important factor to consider when selecting a gas filling machine is ease of use. A machine that is easy to operate and maintain will help to increase productivity and reduce the risk of errors. It is also important to select a machine that comes with a comprehensive user manual and technical support from the manufacturer to ensure that any issues can be quickly resolved.

Price is also an important consideration when selecting a gas filling machine. It is important to select a machine that is within your budget, but it is also important not to sacrifice quality for price. It is always best to invest in a high-quality machine that will last for many years, even if it means paying a little more upfront.

Finally, it is important to select a gas filling machine from a manufacturer that offers good after-sales support. This can include technical support, spare parts, and servicing. This will help to ensure that the machine continues to operate efficiently for many years, reducing the need for costly repairs or replacement.

In conclusion, selecting the ideal manufacturer gas filling machine is a complex process that requires careful consideration of a number of factors. By selecting a high-quality, reliable machine from a reputable manufacturer, you can ensure that your gas filling needs are met efficiently and effectively, reducing downtime and increasing productivity.

Things to Consider When Purchasing Gas Filling Machine

When it comes to purchasing a gas filling machine, there are several things that need to be taken into consideration. Whether you are looking to fill gas cylinders for your business or for personal use, it is important to choose a machine that is safe, efficient, and reliable.

1. Size and Capacity: The first thing to consider when purchasing a gas filling machine is the size and capacity of the machine. You need to make sure that the machine is large enough to accommodate the size and number of gas cylinders that you need to fill.

2. Safety Features: Safety should always be a top priority when choosing a gas filling machine. Look for machines that are equipped with safety features such as pressure relief valves, flame arrestors, and emergency shut-off switches.

3. Durability: A gas filling machine is a heavy-duty piece of equipment that will be subjected to constant use, wear and tear. Look for machines that are made from high-quality materials and are built to withstand heavy use.

4. Ease of Use: You want to make sure that the gas filling machine you choose is easy to operate and maintain. Look for machines that come with clear instructions and have easily accessible maintenance points.

5. Cost: The cost of a gas filling machine can vary widely depending on its size, capacity, and features. Consider your budget and shop around for machines that offer the best value for your money.

6. Customer Support: Choose a gas filling machine manufacturer that provides excellent customer support. This will ensure that you have access to technical assistance and replacement parts if needed.

In conclusion, choosing the right gas filling machine is critical to ensure safe and efficient gas cylinder filling operations. Take the time to consider the above factors before making a purchase, and you will be well on your way to finding a machine that meets your needs and exceeds your expectations.

Properties of Gas Filling Machine

Gas filling machines are an essential part of the industrial process. These machines are used to fill a variety of gases into various containers for use, including oxygen, nitrogen, carbon dioxide, and other gases. The properties of a gas filling machine are critical in determining its efficiency, accuracy, and safety.

One of the main features of a gas filling machine is its accuracy. The machine must be capable of measuring the gas precisely and fill the container accordingly. This accuracy ensures that the desired amount of gas is present in the container, and the user gets the desired results.

The second important factor is the speed of the machine. In an industrial process, time is an essential factor, and the gas filling machine must fill the container with the required amount of gas as quickly as possible. This speed ensures that the process is not slowed down, and the production targets are met.

Safety is another critical feature of a gas filling machine. These machines handle gases that can be harmful, and a reliable safety system must be in place to prevent accidents. The machine must be designed to prevent gas leaks, and it should have safety features such as an emergency stop button and safety interlocks.

The fourth crucial factor is the flexibility of the machine. The machine must be adaptable to fill various gas types and different container sizes. This flexibility ensures that the machine can be used for multiple applications and can meet the needs of different users.

In conclusion, the properties of a gas filling machine such as accuracy, speed, safety, and flexibility are essential in ensuring that the machine can perform efficiently and meet the needs of various users. Companies must carefully consider these properties before purchasing a gas filling machine to ensure that they are making the right investment.

How to use Gas Filling Machine

A gas filling machine is a simple but effective tool to fill gas cylinders. Gas filling machines are commonly used in industries such as welding, medical, and scientific research. These machines come in various sizes and models to fit different types of gas cylinders.

The first step in using a gas filling machine is to ensure that the machine is properly grounded. This is to prevent any electrical hazards to the operator or the surrounding environment. Next, ensure that the cylinder valve is tightly closed to prevent any gas leaks.

Attach the filling hose to the cylinder valve and open the machine’s gas valve. The gas filling machine should have an automatic shutoff valve that stops the gas flow when the cylinder is full. Check that the filling pressure matches the recommended pressure for the particular gas being filled.

After filling the cylinder, remove the hose from the valve and close the machine’s gas valve. Check the cylinder for any leaks using a gas detector or soapy water solution. Finally, label the cylinder with the name of the gas, the filling date, and the filling pressure.

It is important to regularly maintain the gas filling machine to ensure its optimal performance. Regular maintenance includes cleaning the machine, replacing worn-out parts, and checking for any gas leaks. Also, ensure that the cylinder is not overfilled to prevent any explosion hazards.

In conclusion, using a gas filling machine is a simple and straightforward process. Always ensure that the machine is properly grounded, the cylinder valve is tightly closed, and the filling pressure matches the recommended pressure. Regular maintenance is essential to ensure the machine’s optimal performance and prevent any hazards.

Glossary Terminology Terms for Gas Filling Machine

A gas filling machine is a vital piece of equipment used in the production and distribution of various industrial products ranging from gas cylinders to the food and beverage industry. To effectively operate and understand the unique features and functions of a gas filling machine, understanding the various glossary terminology terms is necessary.

Firstly, the filling accuracy refers to the capacity of the machine to fill a gas cylinder with the exact amount of gas required. Additionally, the filling speed depicts the rate at which the machine fills the gas cylinders. The filling pressure refers to the pressure at which the gas cylinder is filled, while the filling temperature relates to the temperature of the gas during the filling process.

The vent valve refers to the valve that releases gas at once when the machine fills a gas cylinder to its maximum capacity or when an emergency occurs. The safety valve is responsible for preventing the pressure within the gas cylinder from exceeding the acceptable safety limit. The auto-inflating valve is a feature in the gas filling machine that inflates the gas cylinder automatically to the desired level.

Moreover, the gas filling machine comprises a pressure gauge that measures the pressure within the gas cylinder during the filling process. The gas flow meter measures the number of gas molecules passing through the pipeline during the filling process. The temperature gauge measures the gas temperature during the filling process.

Finally, the safety features also include a shutdown system, which automatically stops the filling process if the machine senses an anomaly in the filling process. The emergency stop button also halts the filling process when pressed, providing another layer of safety.

In conclusion, operating a gas filling machine requires an understanding of the various glossary terminology terms mentioned above. This knowledge is crucial in ensuring the safety and efficiency of the gas filling process.

Gas Filling Machine Price

Gas filling machines are utilized to fill liquefied petroleum gas (LPG) into cylinders and tanks utilizing various techniques. Industries and households are two main segments that use gas filling machines. These machines have numerous advantages over conventional gas filling techniques and are popular across various industries.

Gas filling machines come in different sizes and capacities as per the requirements of the customers. The prices of these machines can vary according to their size, capacity, and features. The cost of these machines also depends on factors such as the market demand, production capabilities, and quality of the machine.

A comprehensive gas filling machine for industrial purposes could cost anywhere between $5,000 to $50,000, depending on the features and capabilities that are required. In some cases, smaller machines can cost as little as $1,500. These prices can vary widely, and one must consider their budget and requirements before investing in these machines.

It is recommended for buyers to do thorough research on the available options in the market before making a purchase. They must consider factors such as the features, quality, capacity, and price of the gas filling machines before making a decision. Additionally, they should compare different options available in the market to ensure they are getting a good deal.

In conclusion, gas filling machines have become crucial in various industries and households to fill LPG into cylinders and tanks. Their prices depend on several factors such as their size, capacity, and features. It is important for buyers to do thorough research and make an informed decision that aligns with their requirements and budget.