Introduce about gold laser cutting machine guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

Gold laser cutting machines are advanced tools used in various industries for precise and efficient cutting of different materials. This guide aims to provide essential information about gold laser cutting machines, including their quality, cost, suppliers, certifications, market trends, and some useful tips and frequently asked questions (FAQs).

Quality plays a crucial role in selecting a reliable and durable gold laser cutting machine. High-quality machines ensure accuracy, speed, and long-term performance. It is advised to choose a reputable supplier that offers top-notch machines with exceptional build quality and cutting-edge technology.

When considering the cost of a gold laser cutting machine, several factors should be taken into account, such as the machine’s specifications, power capacity, additional features, and the supplier’s pricing strategy. It is recommended to compare prices from different suppliers to ensure a reasonable cost without compromising quality.

Finding a reliable supplier is essential to guarantee the quality and after-sales service of the gold laser cutting machine. Trusted suppliers should have a strong market reputation, positive customer reviews, and a wide range of product options. Additionally, it is crucial to check if they provide comprehensive technical support and maintenance services.

Certifications play a vital role in assuring the machine’s adherence to industry standards. Look for gold laser cutting machines that have obtained relevant certifications, such as CE or ISO, which demonstrate their compliance with safety and quality regulations.

The market for gold laser cutting machines is rapidly growing due to their versatility and efficiency across diverse industries, including jewelry making, electronics, automotive, and signage. Keeping up with market trends and adopting innovative features and technologies can ensure business competitiveness.

Here are some tips to consider before purchasing a gold laser cutting machine: assess your specific requirements, consider the machine’s technical specifications and features, evaluate the supplier’s reliability, and compare prices and customer reviews.

Frequently Asked Questions (FAQs):

1. What materials can be cut using a gold laser cutting machine?

2. How does a gold laser cutting machine work?

3. What maintenance does a gold laser cutting machine require?

4. Can a gold laser cutting machine engrave as well?

5. What warranty is provided for a gold laser cutting machine?

By following this guide, one can make an informed decision when choosing a gold laser cutting machine that meets their needs, ensures high-quality performance, and provides excellent value for money.

Types of gold laser cutting machine

There are several types of gold laser cutting machines available in the market, each with its own unique features and capabilities. Here are some of the most common types:

1. Fiber Laser Cutting Machine: This type of machine uses a high-powered fiber laser to cut through gold. It is known for its high precision, speed, and efficiency. It is suitable for both thin and thick gold sheets and can produce intricate designs with excellent edge quality.

2. CO2 Laser Cutting Machine: A CO2 laser cutting machine uses a carbon dioxide laser to cut through gold. These machines offer flexibility, as they can be used on various thicknesses of gold sheets. They are also known for their high-quality cuts and smooth edges.

3. YAG Laser Cutting Machine: YAG (yttrium-aluminum-garnet) laser cutting machines use a solid-state crystal medium to generate laser beams for cutting gold. They are suitable for thin to medium gold sheets and are cost-effective compared to other types of laser machines.

4. UV Laser Cutting Machine: UV (ultraviolet) laser cutting machines are specifically designed for micro-cutting applications in the electronics and jewelry industry. They use a laser beam in the ultraviolet wavelength range for precise and fine cutting of gold materials.

5. Diode Laser Cutting Machine: Diode laser cutting machines use semiconductor diode lasers to cut through gold. They are commonly used for marking and engraving applications in the jewelry industry but can also be used for cutting thin gold sheets.

6. Pulsed Laser Cutting Machine: Pulsed laser cutting machines use short, high-energy laser pulses for cutting gold. They are suitable for precise and clean cutting of gold materials, especially in applications where heat-affected zones need to be minimized.

Each type of gold laser cutting machine has its own advantages and limitations, so it is important to consider specific application requirements before choosing the most suitable machine. Factors such as cutting speed, precision, versatility, and cost should be taken into account to ensure optimal performance and efficiency.

Pros and Cons of Using gold laser cutting machine

Using a gold laser cutting machine offers several advantages and disadvantages that should be considered before making a purchase.

Pros:

1. Precision: Gold laser cutting machines offer high precision, allowing for intricate and detailed cuts. This is especially important when working with delicate gold materials.

2. Speed: Laser cutting machines can quickly cut through gold, resulting in efficient production and reduced labor costs.

3. Versatility: These machines can cut through various types and thicknesses of gold materials, such as sheets, tubes, and even 3D shapes. They can also be used for etching, engraving, and marking gold items.

4. Cost-effective: While the initial investment may be high, gold laser cutting machines can provide long-term cost savings due to reduced material waste, increased productivity, and minimal maintenance requirements.

5. Non-contact process: The laser beam does not physically touch the gold material, reducing the risk of damage, scratches, or contamination of the product. This is especially important when working with high-value gold items.

Cons:

1. High initial cost: Gold laser cutting machines can be expensive to purchase and install, especially for small businesses or individuals. The cost may outweigh the benefits if the machine is not used frequently or for large-scale projects.

2. Safety precautions: These machines emit a powerful laser beam that can cause eye damage or burns if not used correctly. Adequate training and safety measures must be in place to ensure the wellbeing of operators and other employees.

3. Limited material compatibility: While gold laser cutting machines are versatile, they may not be suitable for cutting other materials like wood, plastic, or metal alloys. Separate equipment may be required for these materials.

4. Maintenance requirements: Like any machine, gold laser cutting machines require regular maintenance and servicing to ensure optimal performance. This can add additional costs and downtime for businesses.

5. Design restrictions: The cutting capabilities and thickness limitations of gold laser cutting machines may affect the design possibilities of certain projects. Complex designs or thick gold materials may be challenging to cut accurately.

In conclusion, using a gold laser cutting machine can offer numerous benefits, such as precision, speed, versatility, cost-effectiveness, and a non-contact process. However, the high initial cost, safety precautions, limited material compatibility, maintenance requirements, and design restrictions should also be carefully considered.

gold laser cutting machine Reference Specifications (varies for different product)

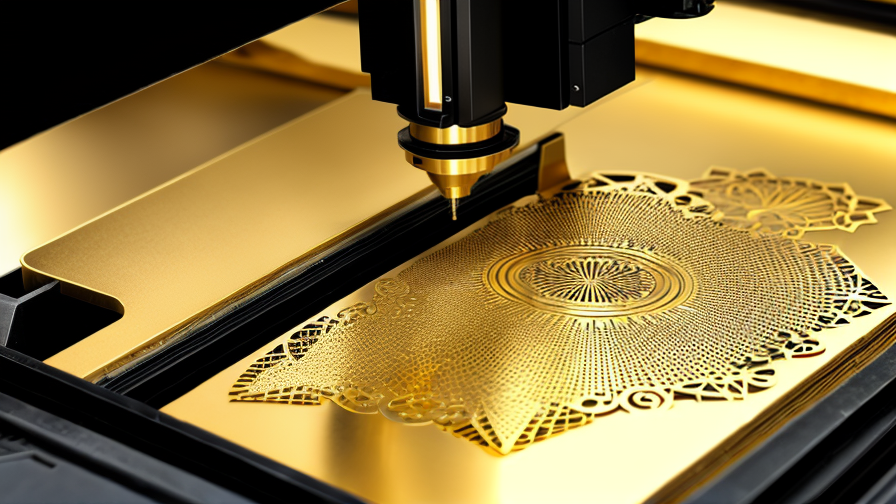

The gold laser cutting machine is a highly versatile and efficient tool that is specifically designed for precision cutting and engraving of various gold materials. This advanced machinery utilizes laser technology to deliver exceptional cutting accuracy and speed, making it an essential tool in the jewelry and goldsmith industry.

The machine features a high-powered laser source that emits a concentrated beam of light, which is then directed onto the gold material. The intensity of the laser beam can be adjusted to ensure precise cutting and engraving. With its high power output, the machine can effortlessly cut through gold sheets and other gold materials in a matter of seconds.

The laser cutting machine is equipped with a high-precision motorized worktable that allows for easy positioning and movement of the gold material. The worktable can be easily adjusted to accommodate different sizes and thicknesses of gold material, providing maximum flexibility for various cutting and engraving needs.

To ensure utmost accuracy and efficiency, the machine is also equipped with a high-resolution digital control panel. This user-friendly interface allows operators to easily input cutting or engraving parameters, ensuring precise and consistent results. Additionally, the machine is integrated with advanced software that supports various design files, enabling operators to create intricate and complex designs with ease.

In terms of safety, the gold laser cutting machine is designed with a fully enclosed working area. This enclosure not only protects the operator from potential laser hazards but also prevents dust and debris from interfering with the cutting process, thus ensuring clean and quality cuts.

The gold laser cutting machine is an exceptional investment for businesses in the jewelry and goldsmith industry. Its fast and precise cutting capabilities, along with its user-friendly interface, make it an invaluable tool for creating intricate and delicate jewelry pieces. With its versatility and efficiency, this machine is poised to revolutionize the gold cutting and engraving process, providing unparalleled precision and quality.

Applications of gold laser cutting machine

Gold laser cutting machines are efficient and versatile tools used in a wide range of industries. The following are some applications of gold laser cutting machines:

1. Jewelry making: Gold laser cutting machines are extensively used in the jewelry industry. They can accurately cut intricate designs and shapes in gold, including pendants, earrings, bracelets, and rings. The machines offer precision cutting, ensuring minimal waste of precious gold material.

2. Electronics manufacturing: Gold laser cutting machines are utilized in the production of microelectronics and semiconductors. They enable the precise cutting of gold components used in electronic devices such as printed circuit boards (PCBs), sensors, and connectors. The machines can cut gold with high accuracy, ensuring tight tolerances for optimal performance.

3. Automotive industry: Gold laser cutting machines play a vital role in manufacturing specialized automotive parts. They are used to cut gold-plated components for fuel injectors, connectors, and switches. The machines offer the advantage of high-speed cutting and complex shape cutting, leading to increased productivity and efficiency in the automotive industry.

4. Medical equipment manufacturing: Gold laser cutting machines are crucial in the production of medical devices such as surgical instruments, implants, and hearing aids. They can accurately cut gold components used in these devices, ensuring precise fit and functionality. The machines also facilitate the creation of intricate patterns and designs required in advanced medical equipment.

5. Aerospace industry: Gold laser cutting machines find applications in the aerospace sector for cutting gold components used in aircraft interiors, avionics systems, and satellite technologies. They are capable of cutting gold materials with precision and repeatability, ensuring high-quality parts for critical aerospace applications.

6. Art and decoration: Gold laser cutting machines are used by artists and decorators to create unique and intricate designs on various materials such as wood, glass, acrylic, and leather. The machines can cut gold sheets and foils, allowing for the creation of customized art pieces, decorative objects, and signage.

In conclusion, gold laser cutting machines have diverse applications in industries such as jewelry making, electronics manufacturing, automotive, medical equipment, aerospace, and art. These machines offer high precision, accuracy, and efficiency in cutting gold materials, making them indispensable tools for many sectors.

The Work Process and how to use gold laser cutting machine

The work process of a gold laser cutting machine involves the use of a high-powered laser beam to precisely cut through gold material. The machine utilizes a computer-controlled system to guide the laser beam across the gold surface, allowing for intricate and accurate cuts.

To use a gold laser cutting machine, follow these steps:

1. Prepare the gold material: Make sure the gold material is clean and free from any contaminants that may affect the cutting process. Place the gold material securely onto the machine’s worktable, ensuring it is fixated and stable.

2. Set up the laser machine: Power on the machine and ensure all necessary safety measures are in place, such as wearing protective eyewear. Adjust the laser settings according to the thickness and type of gold being used.

3. Create a cutting design: Use design software compatible with the laser machine to create a cutting pattern or import an existing design. Customize the size, shape, and dimensions of the design to meet your requirements.

4. Load the design onto the machine: Transfer the cutting design to the laser machine’s control software. Ensure that the design is properly aligned and positioned on the gold material.

5. Start the cutting process: Double-check all the settings and safety measures before initiating the cutting process. Activate the laser beam through the control software and let it begin cutting based on the design specifications.

6. Monitor the cutting progress: Keep an eye on the cutting process to ensure accuracy and quality. Adjust any settings if necessary and address any issues that may arise, such as interruptions or machine errors.

7. Complete the cutting process: Once the laser machine has finished cutting the gold material, carefully remove it from the worktable. Inspect the quality of the cut and make any necessary finishing touches or additional procedures, such as polishing or engraving.

8. Clean and maintain the machine: Clean the gold laser cutting machine after each use to prolong its lifespan and prevent any buildup of debris. Regularly conduct maintenance procedures recommended by the manufacturer to ensure optimal performance.

By following these steps, you can effectively use a gold laser cutting machine to achieve precise and intricate cuts on gold material. It is essential to familiarize yourself with the machine’s specifications, safety instructions, and use proper techniques to maximize its efficiency and produce high-quality results.

Quality Testing Methods for gold laser cutting machine and how to control the quality

Quality testing methods for a gold laser cutting machine are vital to ensure the machine’s performance, accuracy, and durability. Several methods can be employed to control the quality effectively.

Firstly, the machine’s cutting precision can be tested by executing sample cuts on various materials. These test cuts should be conducted at different angles and speeds to evaluate accuracy, consistency, and smoothness. Using high-precision measuring tools, such as calipers or micrometers, the dimensions of the cut pieces can be analyzed to determine if they meet the required specifications.

Secondly, the machine’s power supply and electrical components should be thoroughly examined. Electrical tests, such as voltage checks, continuity tests, and insulation resistance measurements, can be performed to ensure that the machine operates safely and efficiently. Any signs of abnormality or inconsistency should be addressed promptly.

Thirdly, the overall structural integrity of the machine should be evaluated. This can be achieved through a visual inspection of the machine’s frame, gantry, and other mechanical components. Any signs of loose bolts or misalignment should be resolved to prevent potential malfunctions during operation.

Additionally, testing the cooling system, gas supply system, and laser beam alignment is crucial to maintain optimal performance. The cooling system should be checked for proper temperature control and circulation efficiency. The gas supply system, including gas pressure regulators and filters, must be inspected to ensure the laser gas is delivered at the correct pressure and purity. Laser beam alignment tests should be conducted regularly to verify that the beam stays focused on the desired cutting path.

To control the quality of a gold laser cutting machine, it is essential to establish and follow a robust quality control process. This includes periodic maintenance, adherence to manufacturing standards, and continuous monitoring of key performance indicators. Regular calibration and adjustment of the machine should be performed according to manufacturer’s guidelines. Additionally, collecting and analyzing data on machine performance, maintenance history, and customer feedback can help identify areas for improvement and enable proactive quality control measures.

By employing these quality testing methods and maintaining a rigorous quality control process, the performance and reliability of a gold laser cutting machine can be maximized, ensuring customer satisfaction and long-term success.

gold laser cutting machine Sample Policy and Post-Purchase Considerations for gold laser cutting machine from China

Sample Policy:

When purchasing a gold laser cutting machine from China, it is important to understand the sample policy of the supplier. Most suppliers offer samples for customers to test the machine’s functionality and performance before making a bulk order. It is advisable to communicate with the supplier and negotiate the terms of the sample policy.

Some common considerations regarding the sample policy include:

1. Sample cost: Suppliers may charge a certain fee for providing samples. It is essential to confirm the cost and ensure it is reasonable.

2. Sample delivery time: Understand the estimated time required by the supplier to deliver the sample. Consider whether it aligns with your project timeline.

3. Return policy: In case the sample does not meet your requirements, it is crucial to clarify the return or refund policy with the supplier.

Post-Purchase Considerations:

Once you have purchased a gold laser cutting machine from China, there are several key factors to consider:

1. Installation and training: Determine whether the supplier provides installation services and training for operating the machine. If not, ensure you have access to technical support or consider hiring an expert to assist with installation and training.

2. Warranty and after-sales service: Inquire about the warranty period for the machine and the supplier’s after-sales service. It is important to understand the terms and conditions of the warranty to be aware of any potential costs or limitations.

3. Spare parts availability: Check if the supplier can provide spare parts for the machine or if they can be easily sourced locally. Having access to spare parts is crucial for maintenance and repairs.

4. User manual and documentation: Ensure that the supplier provides a comprehensive user manual and documentation that includes maintenance instructions, troubleshooting guidelines, and safety precautions. This documentation will be invaluable for the proper and safe operation of the gold laser cutting machine.

5. Certification and compliance: If your industry requires specific certifications or compliance standards, ensure that the machine meets those requirements. Request relevant documentation or proof of compliance from the supplier.

By considering these sample policy and post-purchase considerations, you can make an informed decision when purchasing a gold laser cutting machine from China and ensure a smooth buying experience.

Sourcing gold laser cutting machine from China: Opportunities, Risks, and Key Players

China is a major player in the global market for gold laser cutting machines. The country offers numerous opportunities for businesses looking to source these machines due to its manufacturing capabilities, cost efficiency, and technological advancements.

One of the key opportunities is the vast network of suppliers and manufacturers in China. The country has a well-established infrastructure that supports the production and export of various machinery, including gold laser cutting machines. This means businesses have a wide range of options when selecting a supplier, allowing them to find a machine that suits their specific needs and budget.

Moreover, China offers competitive pricing for gold laser cutting machines. The lower labor and production costs compared to many other countries make Chinese suppliers more cost-effective. This affordability makes it easier for businesses to invest in these machines and expand their operations.

However, there are some risks associated with sourcing gold laser cutting machines from China. One major risk is the potential for counterfeit or low-quality products. Some manufacturers may cut corners to reduce costs, compromising the machine’s performance and durability. Therefore, it is crucial for businesses to conduct thorough research and due diligence when selecting a Chinese supplier.

Language and cultural barriers can also pose challenges when sourcing from China. Effective communication is essential to ensure proper specifications, quality standards, and timeliness. Working with a local agent or conducting frequent visits can help mitigate these risks and enhance communication and understanding.

Key players in the gold laser cutting machine market in China include Jinan Bodor CNC Machine Co., Ltd., Shenzhen DNE Laser Science and Technology Co., Ltd., and Wuhan Golden Laser Co., Ltd. These companies are well-known for their expertise in manufacturing high-quality laser cutting machines and have established a solid reputation in the industry.

In conclusion, sourcing gold laser cutting machines from China offers opportunities in terms of a wide range of suppliers and competitive pricing. However, businesses need to be mindful of the risks associated with counterfeit products and communication barriers. By conducting thorough research and working with reputable suppliers, businesses can benefit from the advantages that China offers in this market.

How to find and select reliable gold laser cutting machine manufacturers in China,use google search manufacturers and suppliers

Finding reliable gold laser cutting machine manufacturers in China can be a daunting task, but by utilizing Google search, you can easily narrow down the options. Here are some steps to follow in your search:

1. Use relevant keywords: Start by using specific keywords like “gold laser cutting machine manufacturers China” or “reliable gold laser cutting machine suppliers China.” These keywords will help you find the most relevant search results.

2. Refine the search: Once you conduct the initial search, you may get numerous results. To refine your search, include additional criteria such as “reliable,” “certified,” or “high-quality” to get more targeted results.

3. Assess the website: Open the websites of the manufacturers or suppliers that appear in the search results. Look for information about their company, manufacturing capabilities, certifications, and any additional services they offer. A professional and well-designed website is usually indicative of a reliable manufacturer.

4. Check product details: Explore the gold laser cutting machine specifications, features, and options available on their website. Verify if they offer customized solutions to meet your specific requirements.

5. Read customer reviews and testimonials: Look for testimonials or customer feedback shared on their website or review websites. Genuine feedback from previous customers can provide valuable insights into the quality and reliability of the manufacturer.

6. Contact manufacturers: Reach out to the shortlisted manufacturers using the provided contact details. Inquire about their production capacity, delivery timeframes, after-sales service, and any other queries you may have. Prompt and helpful responses are indicative of a reliable manufacturer.

7. Compare multiple options: Compare the offers, prices, and services provided by different manufacturers. Consider factors like their reputation, experience in the industry, quality certifications, warranty terms, and any additional services they may offer.

By following these steps, you can select a reliable gold laser cutting machine manufacturer in China who can meet your specific needs and provide high-quality products. Ensure thorough research and due diligence before making any final decision.

How to check gold laser cutting machine manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To determine the reliability of a gold laser cutting machine manufacturer’s website, you can follow these steps:

1. Open the website in Google Chrome browser: Start by visiting the manufacturer’s website using the Google Chrome browser. This browser is known for its compatibility with various website elements and offers useful extensions.

2. Install the SEOquake extension: Go to the Chrome Web Store and search for the “SEOquake” extension. Download and install it to enable additional SEO analysis tools within your browser.

3. Check the website’s ranking: Once the extension is successfully installed, refresh the manufacturer’s website and activate the SEOquake extension by clicking on its icon in your browser toolbar. Look for the “Alexa Rank” field, which provides data on the website’s popularity and ranking. If the manufacturer’s website is within the top 10 million websites, it indicates a greater level of reliability as it implies a higher visitor traffic and overall online presence.

4. Assess the website’s appearance and functionality: Pay attention to the design and layout of the website. A reliable manufacturer tends to invest in a professional and user-friendly website. Check if the website is free of errors, loads quickly, and has proper navigation to ensure a pleasant browsing experience.

5. Look for relevant information: Browse through the website and ensure that it contains comprehensive and relevant information about the gold laser cutting machines, including specifications, features, capabilities, and pricing. A reliable manufacturer will provide detailed and transparent information, boosting credibility.

6. Verify contact details: Check if the website includes a valid physical address, a contact number, and an email address. This information allows you to reach out to the manufacturer in case of inquiries or support needs. A lack of contact details may raise suspicions about the manufacturer’s reliability.

7. Read customer reviews and testimonials: Look for any customer reviews or testimonials available on the website. Genuine feedback from other buyers helps you evaluate the quality and reliability of the manufacturer’s products and services.

By following these steps and ensuring that the website ranks within the top 10 million, appears professional and functional, provides comprehensive information, offers valid contact details, and showcases positive customer reviews, you can have more confidence in the reliability of the gold laser cutting machine manufacturer’s website.

Top 10 gold laser cutting machine manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Han’s Laser Technology Industry Group Co., Ltd.

Han’s Laser is a leading manufacturer of gold laser cutting machines in China. Their products offer high precision and fast cutting speeds, making them suitable for various applications in the jewelry industry. The machines are equipped with advanced fiber lasers that ensure optimal performance and longevity.

2. Perfect Laser (Wuhan) Co., Ltd.

Perfect Laser is another major player in the Chinese gold laser cutting machine market. Their machines are known for their exceptional cutting quality and high efficiency. They utilize cutting-edge laser technology and have a user-friendly interface, enabling precise control over the cutting process.

3. Maxphotonics Co., Ltd.

Maxphotonics specializes in manufacturing gold laser cutting machines equipped with intelligent control systems. Their products are highly efficient, providing fast and accurate cutting for gold and other precious metals. The machines are designed for easy operation and maintenance, ensuring a smooth workflow.

4. Prima Laser Technology Co., Ltd.

Prima Laser Technology offers a wide range of gold laser cutting machines suitable for different gold processing requirements. Their machines feature advanced cutting heads and power systems that enhance cutting accuracy and reduce waste. Prima Laser Technology focuses on innovation and constantly improves their products to meet evolving customer needs.

5. HGLaser Co., Ltd.

HGLaser is known for its high-quality gold laser cutting machines that deliver precise cutting results. Their machines are designed with user-friendly interfaces and advanced motion control systems, allowing for efficient and reliable operation. HGLaser offers customized solutions to meet specific customer requirements.

6. Wuhan Golden Laser Co., Ltd.

Wuhan Golden Laser specializes in the production of gold laser cutting machines designed for jewelry manufacturing. Their machines offer high cutting speeds and precise cutting quality, ensuring excellent results. Wuhan Golden Laser focuses on customer satisfaction and provides comprehensive training and after-sales support.

7. Tianqi Laser Equipment Manufacturing Co., Ltd.

Tianqi Laser is a leading manufacturer of gold laser cutting machines, delivering advanced laser technology and superior cutting performance. The company’s products feature high stability, energy efficiency, and low maintenance requirements. Tianqi Laser provides comprehensive solutions for jewelry processing needs.

8. Wuhan Huagong Laser Engineering Co., Ltd.

With years of experience in laser technology, Wuhan Huagong Laser Engineering produces high-quality gold laser cutting machines. Their products offer high cutting precision and efficiency, enabling precise shaping of gold materials. They also provide excellent technical support and after-sales services.

9. Chutian Laser Group Co., Ltd.

Chutian Laser Group specializes in the production of gold laser cutting machines with cutting-edge technology. Their machines are widely used in the jewelry industry and offer exceptional cutting speeds, accuracy, and reliability. Chutian Laser Group provides professional training and technical support to ensure customer satisfaction.

10. Shenzhen Superwave Laser Technology Co., Ltd.

Shenzhen Superwave Laser Technology manufactures gold laser cutting machines that combine high cutting speed and precision. Their machines are equipped with imported lasers and offer flexible cutting capabilities for various jewelry designs. Superwave Laser Technology focuses on product quality and ensures timely customer support.

| Manufacturer | Product | Cutting Accuracy | Cutting Speed | User-Friendly Interface |

|———————————————–|———————————–|——————————-|———————————|——————————————-|

| Han’s Laser Technology Industry Group Co., Ltd. | High-precision, fast cutting | High | Fast | Yes |

| Perfect Laser (Wuhan) Co., Ltd. | Exceptional cutting quality | High | High | Yes |

| Maxphotonics Co., Ltd. | Intelligent control system | High | Fast | Yes |

| Prima Laser Technology Co., Ltd. | Advanced cutting heads and power systems | High | Fast | Yes |

| HGLaser Co., Ltd. | User-friendly interface | High | Fast | Yes |

| Wuhan Golden Laser Co., Ltd. | Designed for jewelry manufacturing | High | High | Yes |

| Tianqi Laser Equipment Manufacturing Co., Ltd. | Superior cutting performance | High | Fast | Yes |

| Wuhan Huagong Laser Engineering Co., Ltd. | High cutting precision and efficiency | High | Fast | Yes |

| Chutian Laser Group Co., Ltd. | Cutting-edge technology | High | Fast | Yes |

| Shenzhen Superwave Laser Technology Co., Ltd. | High cutting speed and precision | High | High | Yes |

In this table, the basic information of the top 10 gold laser cutting machine manufacturers in China is compared. The key criteria for comparison include cutting accuracy, cutting speed, and user-friendly interface. Each manufacturer offers unique features and technologies that cater to different customer needs.

Background Research for gold laser cutting machine manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to gold laser cutting machine manufacturers in China, there are numerous companies to choose from. To conduct background research on these manufacturers, three websites can be utilized: qcc.com, archive.org, and importyeti.com.

One of the primary sources for researching Chinese companies is qcc.com. This platform provides comprehensive company profiles, including basic information such as company name, registration number, address, and contact details. Additionally, qcc.com offers financial information, business scope, and records of legal disputes, which can help evaluate the reliability and credibility of a manufacturer.

Archive.org, on the other hand, is a tool that allows users to access saved snapshots of websites over time. By using this website, researchers can track the changes and development of a company’s website, marketing strategies, and product offerings over the years. This can provide valuable insights into the company’s growth and stability.

Importyeti.com is a database that focuses on import and export data. Users can search for specific products, including gold laser cutting machines, to find information on manufacturers, suppliers, and buyers. This website displays shipment details, such as the quantity, value, and country of origin. Such information can be used to assess the export capabilities and market presence of potential manufacturers.

By combining these three sources, researchers can gain a comprehensive understanding of gold laser cutting machine manufacturers in China. Qcc.com provides detailed company profiles and financial information, while archive.org offers historical data on a company’s website and marketing efforts. Importyeti.com provides import-export data to analyze a manufacturer’s global presence. It is crucial to utilize these resources to make informed decisions and choose trustworthy and reputable manufacturers in China.

Leveraging Trade Shows and Expos for gold laser cutting machine Sourcing in China

Trade shows and expos can be excellent platforms for sourcing a gold laser cutting machine in China. These events offer the opportunity to connect with a wide range of suppliers, compare different products, negotiate deals, and gain valuable industry insights.

One of the most significant advantages of attending trade shows and expos is the ability to see and test the gold laser cutting machines in person. This hands-on experience allows buyers to assess the quality, features, and performance of various machines, helping them make informed decisions. Moreover, trade shows often showcase the latest advancements in laser cutting technology, providing buyers with access to cutting-edge solutions.

In China, there are several trade shows and expos that specialize in machinery, equipment, and technology, including laser cutting machines. Some renowned events include the Canton Fair, Shanghai International Laser Technology and Equipment Exhibition, and China International Industry Fair. These exhibitions attract numerous manufacturers, suppliers, and industry professionals from around the world, creating a diverse sourcing opportunity.

When attending these events, it is essential to prepare in advance. Buyers should thoroughly research the companies and products they are interested in, create a list of potential suppliers to visit, and make appointments if possible. It is also beneficial to bring along product specifications, samples, and any specific requirements to facilitate discussions and negotiations.

Networking is another major advantage of trade shows and expos. Buyers can connect with industry experts, distributors, and other buyers, establishing valuable relationships for future collaborations. Moreover, attending seminars and conferences held alongside these events can provide valuable insights into market trends, technological developments, and best practices.

While trade shows and expos are valuable sourcing channels, careful due diligence is crucial. Buyers should verify suppliers’ credentials, assess the quality of their products, inquire about manufacturing capabilities and after-sales services, and negotiate favorable terms and prices. It is also essential to conduct inspections and perform sample testing before finalizing any deals.

In conclusion, trade shows and expos in China provide an excellent opportunity to source gold laser cutting machines. They offer the chance to see the machines in person, compare options, and connect with a wide range of suppliers. However, thorough preparation, due diligence, and effective networking are essential to make the most of these events and secure optimal sourcing outcomes.

The Role of Agents and Sourcing Companies in Facilitating gold laser cutting machine Purchases from China

Agents and sourcing companies play a crucial role in facilitating gold laser cutting machine purchases from China. China has emerged as a global hub for manufacturing various industrial equipment, including laser cutting machines. However, navigating the complexities of the Chinese market and identifying reliable suppliers can be challenging for international buyers. Agents and sourcing companies act as intermediaries, connecting buyers with appropriate suppliers and ensuring a smooth purchasing process.

One of the key roles of agents and sourcing companies is to conduct thorough supplier research and vetting. They have a deep understanding of the Chinese market and can identify reliable and reputable manufacturers of gold laser cutting machines. This involves assessing factors such as the supplier’s production capacity, quality control measures, technological capabilities, and their track record in delivering products on time.

Agents and sourcing companies also provide comprehensive support in communication and negotiation. They bridge the language and cultural barriers that may exist between buyers and suppliers, facilitating effective communication and minimizing misunderstandings. They can also negotiate pricing and other terms on behalf of the buyer to ensure a fair and favorable deal.

Furthermore, agents and sourcing companies offer extensive logistical support. They handle the entire supply chain, from coordinating shipping and customs clearance to ensuring timely delivery. This includes arranging for packaging, documentation, and transportation, relieving the buyer of the complexities involved in international trade.

Additionally, agents and sourcing companies provide valuable post-purchase support. They help with after-sales services, such as warranty claims, technical support, and spare part replacements. This ensures that buyers receive timely assistance and support in case of any issues or concerns with the purchased gold laser cutting machines.

In conclusion, agents and sourcing companies play a crucial role in facilitating gold laser cutting machine purchases from China. Their expertise, knowledge of the Chinese market, and comprehensive support services help buyers navigate the complexities of international trade, ensuring a smooth and successful purchasing experience.

Price Cost Research for gold laser cutting machine manufacturers Companies in China, use temu.com and 1688.com

When it comes to gold laser cutting machine manufacturers in China, two popular platforms to conduct price cost research are temu.com and 1688.com. These platforms offer a wide range of options and facilitate easy comparison among different suppliers.

On temu.com, users can navigate through a comprehensive database of Chinese manufacturers, including those specializing in gold laser cutting machines. The platform provides detailed product descriptions, specifications, and price ranges. Users can filter search results based on specific requirements such as certification, location, and minimum order quantity.

Similarly, 1688.com, which is part of Alibaba Group, is a leading B2B platform in China known for its extensive supplier network. Users can find numerous gold laser cutting machine manufacturers by searching for relevant keywords and analyzing product listings. The platform also allows users to directly communicate with suppliers, negotiate prices, and request quotations.

When conducting price cost research, it is advisable to compare prices from several manufacturers to get a better understanding of the market average. Additionally, it is crucial to consider factors such as quality, warranty, shipping options, and after-sales service while evaluating suppliers.

To ensure a successful sourcing experience, buyers can utilize additional tools available on these platforms. Features like supplier ratings and reviews, transaction history, and buyer protection programs can provide valuable insights into the reliability and credibility of the suppliers.

In summary, temu.com and 1688.com are excellent platforms to conduct price cost research for gold laser cutting machine manufacturers in China. With extensive product listings and search filters, buyers can efficiently find suitable suppliers for their specific requirements. It is essential to balance price considerations with factors like quality and service while selecting a supplier.

Shipping Cost for gold laser cutting machine import from China

The shipping cost for importing a gold laser cutting machine from China can vary depending on several factors. Generally, the cost is determined based on the weight, dimensions, shipping method, and destination of the item.

When calculating shipping costs, it is crucial to consider the packaging, as it needs to be suitable for ensuring the safety of the machine during transit. The use of sturdy crates or pallets is recommended to minimize the risk of damage.

Regarding the shipping method, there are two primary options – air freight and sea freight. Air freight is generally more expensive but offers faster delivery times, typically within a week. On the other hand, sea freight is more cost-effective but considerably slower, with delivery times ranging from a few weeks to a couple of months.

For a gold laser cutting machine, considering its weight and dimensions, it is likely to be categorized as a heavy or bulky item. Consequently, sea freight might be the more suitable and economical option.

In terms of costs, sea freight for a gold laser cutting machine from China to, for instance, the United States can range from $800 to $3,000, depending on various factors such as the departure and arrival ports, the shipping company chosen, and any additional services required. However, it is important to note that these figures are estimates and can vary.

In addition to the shipping cost, it is essential to factor in other expenses such as customs duties, taxes, insurance, and handling fees, which can further increase the overall import cost of the gold laser cutting machine.

It is advisable to consult with shipping companies or freight forwarders who specialize in international shipping to obtain accurate quotes and guidance tailored to your specific needs.

Compare China and Other gold laser cutting machine Markets: Products Quality and Price,Visible and Hidden Costs

China is one of the most prominent players in the gold laser cutting machine market, alongside other key markets worldwide. When comparing China with other markets in terms of product quality and price, as well as visible and hidden costs, several factors come into play.

In terms of product quality, China has made significant strides in recent years. Chinese manufacturers have improved their manufacturing processes and adopted advanced technologies, resulting in gold laser cutting machines of comparable quality to those produced by other global players. Some Chinese manufacturers even offer high-end models with innovative features, making their products highly competitive on the global stage.

Regarding price, China has gained an advantage due to its relatively lower labor and operational costs. As a result, gold laser cutting machines manufactured in China are often priced more competitively compared to those produced in other markets. This affordability has made Chinese machines popular among buyers looking for cost-effective solutions without compromising quality.

However, it is crucial to consider visible and hidden costs when evaluating gold laser cutting machines. Visible costs include the initial purchase price, shipping, and import taxes. Chinese manufacturers often provide competitive pricing on the product itself, but shipping and import taxes can vary significantly depending on the buyer’s location. Therefore, buyers must factor these costs into their decision-making process.

Hidden costs encompass factors such as maintenance, repair, and after-sales service. While some Chinese manufacturers offer reliable after-sales support, others might fall short in this department. Choosing a reputable manufacturer with a proven track record can mitigate the risk of encountering hidden costs associated with maintenance and repairs.

In conclusion, China has emerged as a market leader in gold laser cutting machines, offering products of comparable quality at competitive prices. However, buyers should carefully consider visible and hidden costs when making purchasing decisions. By conducting thorough research and engaging with reputable manufacturers, buyers can ensure they make an informed choice that aligns with their specific requirements.

Understanding Pricing and Payment Terms for gold laser cutting machine: A Comparative Guide to Get the Best Deal

When purchasing a gold laser cutting machine, understanding pricing and payment terms is crucial to ensure you get the best deal. This comparative guide will help you navigate the process effectively.

1. Research Different Suppliers: Start by researching various suppliers to get an idea of the market prices. Compare the features, specifications, and reputation of different manufacturers to narrow down your options.

2. Request Detailed Quotations: Reach out to shortlisted suppliers and request detailed quotations for their gold laser cutting machines. These quotations should include the machine’s price, delivery charges, and any additional costs such as installation or training fees.

3. Compare Prices: Once you have collected multiple quotations, compare the prices offered by different suppliers. Keep in mind that the cheapest option may not always be the best choice, as quality and after-sales service should also be considered.

4. Negotiate: Don’t hesitate to negotiate with suppliers to get a better deal. If you have received lower quotes from other suppliers, use this as leverage to negotiate a lower price or additional value-added services.

5. Analyze Payment Terms: Carefully examine the payment terms offered by different suppliers. Some may require full payment upfront, while others may offer installment plans or financing options. Consider your budget and financial capabilities to choose the most suitable payment term.

6. Understand After-Sales Support: A gold laser cutting machine is a significant investment, so it’s crucial to understand the after-sales support provided by the supplier. Check if they offer warranties, technical support, and spare parts availability. This will ensure a smooth operation and minimize downtime in case of any issues.

7. Consider Additional Costs: In addition to the machine’s price, consider other expenses such as shipping, customs duties, taxes, and maintenance costs. These additional costs can significantly impact the overall price of the machine.

8. Seek Recommendations: Reach out to industry experts or colleagues who have previously purchased gold laser cutting machines. Seek their advice and recommendations on suppliers and payment terms.

By following these steps, you can ensure that you fully understand the pricing and payment terms for a gold laser cutting machine. This will enable you to make an informed decision and secure the best possible deal. Remember to thoroughly research and compare suppliers to find a reliable supplier that offers competitive pricing and favorable payment terms.

Chinese Regulations and Industry Standards Certifications for gold laser cutting machine,Import Regulations and Customs for gold laser cutting machine from China

When it comes to importing a gold laser cutting machine from China, it is important to be aware of the Chinese regulations and industry standards certifications, as well as the import regulations and customs procedures involved. Here is a brief overview:

Chinese Regulations and Industry Standards Certifications:

1. CCC Certification: China Compulsory Certification is required for certain products, including laser cutting machines, to ensure their safety, quality, and compliance with Chinese standards.

2. CE Certification: Although not mandatory in China, CE certification indicates that the product meets the European Union’s health, safety, and environmental protection requirements.

3. ISO Certification: ISO 9001 certification signifies that the manufacturer has implemented a quality management system, ensuring consistent quality control and customer satisfaction.

Import Regulations and Customs:

1. Import Permit: Before importing, a valid import permit or license may be required from the government authorities in the destination country.

2. Customs Duties and Taxes: Importers need to be familiarized with the applicable customs duties and taxes, which vary depending on the destination country. These charges need to be accounted for in the overall import cost.

3. Documentation: Appropriate documentation such as commercial invoice, packing list, bill of lading, and certificates of origin should be prepared accurately to comply with customs regulations.

4. Customs Clearance: The importer needs to hire a licensed customs broker or customs agent to facilitate the customs clearance process, ensuring compliance with all regulations and submission of the required paperwork.

5. Environmental and Safety Standards: Ensure that the imported gold laser cutting machine complies with environmental and safety standards set by the destination country to avoid any legal complications.

In summary, importing a gold laser cutting machine from China requires adherence to Chinese regulations such as CCC, CE, and ISO certifications, along with compliance with import regulations and customs procedures. It is crucial to research and understand these requirements to ensure a smooth and legally compliant import process within the specified 300-word limit.

Sustainability and Environmental Considerations in gold laser cutting machine Manufacturing

In recent years, there has been a growing emphasis on sustainability and environmental considerations in manufacturing processes. The gold laser cutting machine industry is no exception, as it strives to align its operations with sustainable practices. These considerations primarily revolve around reducing energy consumption, minimizing waste generation, and using eco-friendly materials.

Firstly, manufacturers are increasingly focusing on developing energy-efficient gold laser cutting machines. This involves investing in technologies that consume less electricity without compromising on the machine’s performance. By utilizing energy-saving components and optimizing the machine’s design, manufacturers can significantly reduce their carbon footprint and operating costs.

Secondly, waste reduction is a key aspect of sustainable gold laser cutting machine manufacturing. Efforts are made to minimize the amount of waste generated during production processes. This can be achieved through various practices such as recycling scrap materials, implementing lean manufacturing techniques, and conducting regular maintenance to extend the lifespan of machine parts. Additionally, manufacturers may explore partnerships with recycling companies to ensure responsible disposal of any waste generated.

Lastly, eco-friendly materials are being considered in the manufacturing of gold laser cutting machines. This includes selecting materials that have a lesser impact on the environment, such as using recycled or sustainably sourced metals. Manufacturers may also opt for non-toxic coatings and paints, ensuring that harmful chemicals are not released during the machine’s lifespan.

In conclusion, sustainability and environmental considerations in gold laser cutting machine manufacturing are becoming increasingly important. By implementing energy-efficient technologies, minimizing waste generation, and choosing eco-friendly materials, manufacturers can reduce their environmental impact while meeting the demands of the market. These efforts will not only benefit the environment but also contribute to long-term cost savings and enhance the industry’s reputation for sustainable practices.

List The Evolution history of “gold laser cutting machine”

The history of gold laser cutting machines dates back to the mid-1960s when the technology of lasers was first being developed. Initially, lasers were primarily used for scientific research and military applications. However, as the technology advanced, its potential for industrial uses was realized.

In the 1970s, the first lasers capable of cutting metals, including gold, were introduced. These early machines had limited power and precision, making them suitable for basic cutting tasks. However, they laid the foundation for further advancements in laser cutting technology.

Throughout the 1980s and 1990s, significant improvements were made in laser cutting machines. Higher power lasers were developed, allowing for faster and more efficient cutting of various metals, including gold. Precision and accuracy were also enhanced, enabling the creation of intricate designs and delicate cuts in gold materials.

In the early 2000s, the introduction of computer numerical control (CNC) systems revolutionized the capabilities of gold laser cutting machines. CNC systems allowed for precise control and automation of the cutting process, enabling intricate and complex designs to be executed with ease. This advancement opened up new possibilities in jewelry making, enabling designers to create highly detailed and customized pieces.

In recent years, further advancements have been made in the field of gold laser cutting machines. Fiber lasers, which utilize fiber optic technology, have emerged as a popular choice due to their high power and efficiency. These machines can cut through gold with exceptional precision, resulting in clean and accurate cuts. Additionally, advancements in software and control systems have made the machines more user-friendly and versatile, allowing for a wide range of applications in the jewelry industry.

In summary, the evolution of gold laser cutting machines has seen significant advancements in power, precision, and automation. From their humble beginnings in the 1960s, these machines have transformed the gold industry by enabling intricate designs and precise cuts, revolutionizing the way jewelry is manufactured.

The Evolution and Market Trends in gold laser cutting machine Industry

The gold laser cutting machine industry has witnessed significant evolution and market trends in recent years. Technological advancements have revolutionized the manufacturing processes, making gold laser cutting machines more efficient and accurate.

One of the major evolutions in the industry is the development of fiber laser cutting technology. Compared to traditional CO2 laser cutting machines, fiber laser cutting machines offer higher cutting speeds, improved precision, and reduced energy consumption. This evolution has enabled manufacturers to achieve higher productivity levels and better quality finish in gold cutting operations.

Furthermore, the market trends in the gold laser cutting machine industry reflect the increasing demand for customization and intricate designs. As consumers become more conscious of individuality and uniqueness, there is a growing need for personalized jewelry and accessories. Gold laser cutting machines provide the flexibility to create intricate patterns, shapes, and engravings on gold surfaces, meeting the demands of this market trend.

Integration of automation and artificial intelligence (AI) is another prevailing trend in the industry. Manufacturers are incorporating features like automatic material handling, intelligent image recognition, and optimized cutting paths. This not only improves the efficiency of gold cutting processes but also reduces labor costs and human errors. Additionally, AI algorithms enhance the machine learning capabilities of gold laser cutting machines, allowing them to adapt and optimize cutting parameters based on different gold alloys and thicknesses.

Moreover, sustainability and environmental concerns have influenced the market trends in the gold laser cutting machine industry. Laser cutting is a more eco-friendly alternative to traditional cutting methods, as it produces minimal waste and consumes less energy. As a result, manufacturers are emphasizing the use of eco-friendly materials and energy-efficient laser cutting machines to meet the growing demand for sustainable jewelry manufacturing.

In conclusion, the gold laser cutting machine industry has experienced significant evolution due to advancements in technology. Market trends reflect the demand for customization, automation, and sustainability, driving manufacturers to develop more efficient and environmentally friendly machines. With the continuous development of laser cutting technology, the industry is expected to witness further advancements and market growth.

Custom Private Labeling and Branding Opportunities with Chinese gold laser cutting machine Manufacturers

Chinese gold laser cutting machine manufacturers offer excellent opportunities for custom private labeling and branding. With their advanced technology and expertise in laser cutting machines, these manufacturers can provide customizable solutions to meet the specific needs of businesses.

Private labeling allows businesses to promote and sell products under their own brand name. Chinese manufacturers can work with businesses to design and produce laser cutting machines with custom branding elements, including logos, colors, and packaging. This enables companies to establish a strong brand identity and differentiate themselves in the market.

In addition to private labeling, Chinese manufacturers also offer custom branding opportunities. This involves incorporating unique features and specifications into the laser cutting machines to meet the specific requirements of businesses. Manufacturers can customize various aspects of the machine, such as cutting capabilities, engraving options, and software functionalities, to provide a tailored solution that aligns with the brand image and target market of the business.

Another advantage of working with Chinese manufacturers is their cost-effective production capabilities. They have access to advanced manufacturing techniques and economies of scale, allowing them to offer competitive pricing for customized laser cutting machines. This enables businesses to enhance their brand value without compromising on quality or budget.

Furthermore, Chinese manufacturers often have extensive experience in exporting their products worldwide. They can assist businesses in navigating international markets, ensuring compliance with quality standards and regulations. Collaborating with Chinese manufacturers also opens up opportunities for businesses to tap into the booming market in China and leverage its manufacturing capabilities.

In conclusion, Chinese gold laser cutting machine manufacturers provide excellent opportunities for businesses to engage in custom private labeling and branding. With their advanced technology, cost-effective production capabilities, and experience in international markets, these manufacturers can help businesses establish a strong brand identity and gain a competitive edge in the industry.

Tips for Procurement and Considerations when Purchasing gold laser cutting machine

When purchasing a gold laser cutting machine, there are several considerations and tips that can help ensure you make the right procurement decision. Here are some important factors to keep in mind:

1. Purpose and Requirements: Determine the specific purpose for which you need the gold laser cutting machine. Evaluate the size, thickness, and type of gold materials you will be working with, as this will impact the specifications required for the machine.

2. Quality and Performance: Look for a machine that is known for its quality and performance. Consider the reputation and track record of the manufacturer, and read reviews or testimonials from other users to gain insights into the machine’s reliability and accuracy.

3. Laser Power: The laser power of the machine is crucial in determining its cutting capabilities. Ensure that the laser power is sufficient for cutting through the thickness of gold you work with, and consider any future requirements as well.

4. Precision and Accuracy: Gold laser cutting often requires precise and accurate cuts. Look for a machine that offers high levels of precision and accuracy, allowing for intricate designs and fine details in the gold material.

5. Ease of Use and Software: Consider the user interface and software provided with the machine. An intuitive interface and user-friendly software can make the operation of the machine much easier, reducing the learning curve and increasing efficiency.

6. Support and Warranty: Ensure the manufacturer provides adequate support and warranty for the gold laser cutting machine. Good after-sales service, technical support, and warranty coverage will help in case of any issues or breakdowns.

7. Training and Maintenance: Evaluate the availability of training and maintenance from the manufacturer. Proper training for operators and regular maintenance can extend the lifespan of the machine and ensure optimal performance.

8. Price and Budget: Consider your budget and compare prices from different manufacturers. Don’t compromise on quality for a lower price, as a reliable and high-performing machine will be a more cost-effective investment in the long run.

9. Safety Features: Laser cutting machines can present safety hazards. Look for machines with safety features such as automatic shut-off, protective enclosures, and emergency stop buttons to ensure the safety of operators and the surrounding environment.

10. Future Expansion and Upgrades: Consider the potential for future expansion and upgrades. Look for a machine that allows for scalability and the addition of new features or technologies as your business grows.

By considering these tips and factors, you can make an informed decision when purchasing a gold laser cutting machine that meets your requirements and helps enhance your business productivity.

FAQs on Sourcing and Manufacturing gold laser cutting machine in China

1. Can I source a gold laser cutting machine in China?

Yes, China is one of the leading countries in manufacturing and exporting laser cutting machines, including those designed specifically for gold materials.

2. What are the advantages of sourcing from China?

Sourcing from China provides several advantages, including competitive pricing due to lower production costs, a wide range of options and customization capabilities, and access to a large pool of experienced manufacturers.

3. How do I find reliable gold laser cutting machine suppliers in China?

To find reliable suppliers, you can start by conducting thorough research online and utilizing B2B platforms like Alibaba or Made-in-China. It is crucial to verify supplier credentials, read customer reviews, and request samples or machine specifications before making a final decision.

4. What factors should I consider when choosing a gold laser cutting machine manufacturer in China?

Important factors to consider include the manufacturer’s reputation and experience in producing laser cutting machines, their quality control measures, the machine’s technical specifications and capabilities, after-sales service, and pricing.

5. Can I customize the gold laser cutting machine according to my specific requirements?

Yes, most manufacturers in China offer customization services. You can discuss your requirements and modifications with the supplier to ensure the machine meets your specific needs.

6. What certifications or standards should I look for in a gold laser cutting machine manufacturer?

Look for manufacturers that comply with international quality standards such as ISO 9001 and CE certification. These certifications ensure that the machines meet certain quality and safety standards.

7. How can I ensure product quality and avoid scams or low-quality machines?

To ensure product quality, it is recommended to request samples, visit the manufacturer’s facility, or hire a professional inspector. Building a long-term relationship with the supplier and obtaining references from other customers can also help reduce the risk of scams or low-quality machines.

8. What is the lead time for manufacturing and shipping a gold laser cutting machine from China?

Lead times vary depending on machine specifications, customization requirements, and the manufacturer’s production capacity. It is important to discuss lead times and shipping methods with the supplier in advance to manage expectations.

9. What payment terms are commonly used when importing gold laser cutting machines from China?

Common payment terms include T/T (Telegraphic Transfer) or a letter of credit. It is advisable to negotiate payment terms that are mutually beneficial and secure for both parties.

10. Do Chinese manufacturers provide after-sales support and warranty for their gold laser cutting machines?

Most reputable manufacturers provide after-sales support, technical assistance, and warranties for their machines. It is recommended to discuss these aspects with the supplier before finalizing the purchase.

Why contact sourcifychina.com get free quota from reliable gold laser cutting machine suppliers?

Sourcifychina.com is a platform that connects buyers with reliable suppliers in China. They offer a range of services to help buyers find the most suitable suppliers for their needs. One of the services they provide is connecting buyers with gold laser cutting machine suppliers.

In order to attract more buyers and provide them with the best options, sourcifychina.com offers a free quota for contacting reliable gold laser cutting machine suppliers. This allows buyers to get in touch with potential suppliers without any cost or commitment.

The reason sourcifychina.com is able to offer this free quota is because they have established relationships with trusted and reputable suppliers. They have vetted these suppliers to ensure they meet certain criteria, such as having a good track record, high-quality products, and reliable customer service. By partnering with these suppliers, sourcifychina.com is able to offer a valuable service to buyers and build trust in their platform.

The free quota allows buyers to explore their options and communicate with suppliers to gather more information about their products, prices, and capabilities. This helps buyers make informed decisions and find the best supplier for their specific requirements.

By offering a free quota, sourcifychina.com not only benefits the buyers but also the suppliers. It provides suppliers with a platform to showcase their products and services to a wider audience, increasing their chances of finding potential customers and growing their business.

In conclusion, sourcifychina.com offers a free quota for contacting reliable gold laser cutting machine suppliers to attract more buyers to their platform and provide them with a seamless sourcing experience. By partnering with trusted suppliers, sourcifychina.com ensures that buyers have access to high-quality options and suppliers have the opportunity to expand their customer base.