Benefits of Gummy Manufacturing

When it comes to producing gummy supplements or vitamins, the manufacturing process offers plenty of benefits. From their versatility in shape, size, and flavor to their extended shelf life, it’s no wonder gummies have become a popular delivery method for health and wellness supplements. Let’s take a closer look at the benefits of gummy manufacturing.

Firstly, gummies are a versatile form of supplement delivery. They can be made in any shape or size, allowing for easy dosage control. This makes them a great choice for children or adults who have trouble swallowing pills. In addition, gummy vitamins can be made in a variety of flavors, such as strawberry, orange, and grape. This makes taking a supplement a more enjoyable experience, which can encourage compliance with a daily supplement regimen.

Secondly, gummies have a longer shelf life compared to other supplement forms, such as liquid or powder. They are less prone to spoiling or degrading over time and are easy to store for long periods of time. This is particularly important for manufacturers who distribute supplements worldwide, where products may sit in warehouses or on store shelves for extended periods.

Another benefit of gummy manufacturing is that they are easier to manufacture in large quantities compared to other supplement forms. Gummy vitamins can be made using a continuous manufacturing process, which allows for consistent product quality and faster production times. This makes it easier to meet high demand while maintaining quality.

Finally, gummies are a great way to add fun and variety to a supplement regimen. Many manufacturers have started to incorporate unique ingredients or functional benefits into their gummy supplements, such as energy-boosting ingredients, probiotics, and antioxidants. This provides consumers with a new way to enjoy their supplements while reaping the benefits of added ingredients.

In conclusion, gummy manufacturing offers a wide range of benefits, from their versatile shape and flavor, extended shelf life, ease of large-scale production, to their pleasant and unique delivery method. As consumers continue to look for new and exciting ways to take supplements, gummies are sure to remain a popular choice in the health and wellness industry.

Features of Gummy Manufacturing

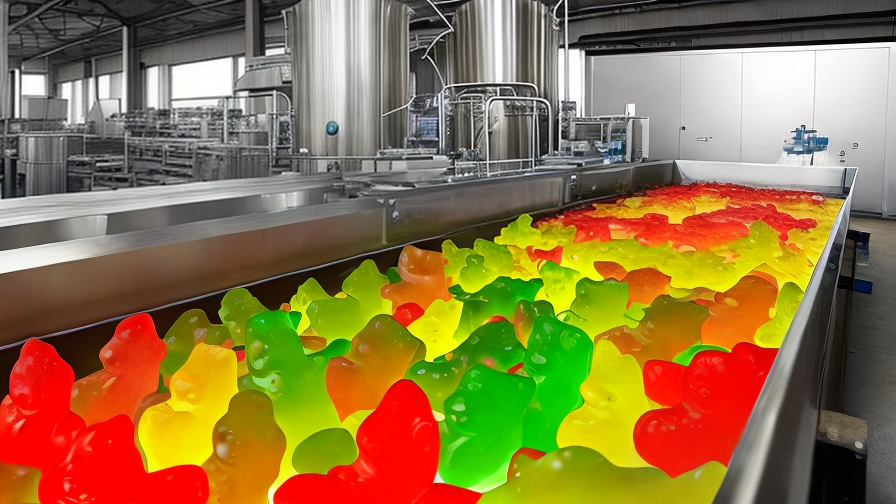

Gummy candy has become one of the most popular types of sweets around the world. This candy is a treat that is both fun to eat and visually attractive. The manufacturing process for gummies is complex but streamlined, which enables manufacturers to create thousands of sweet treats in a matter of minutes. This article will explore some of the features of gummy manufacturing.

One of the primary features of gummy manufacturing is the use of specialized equipment. This machinery is designed to mix and pour the ingredients needed for creating a gummy’s unique texture and flavor. The mixing systems also help regulate the temperature of the mixture so that it can be poured into molds and then cool down to set into the desired shapes.

Another feature of gummy manufacturing is the use of high-quality ingredients. These ingredients include gelatin, sugars, flavorings, and colors. During the manufacturing process, the ingredients are carefully measured to ensure the right balance of flavors and textures. The ingredients are also tested to ensure that they are safe and of the appropriate quality.

Gummy manufacturing also involves using different types of molds to create different shapes and sizes of gummies. Using specialized molds enables manufacturers to create unique designs, textures, and colors, making gummies even more fun and visually appealing. The molds can be made from different materials like metal, silicon, or plastic.

Finally, gummy manufacturers employ strict quality control procedures to ensure that their products meet high standards. These procedures include regular testing of machines, ingredients, and finished products. Any defects spotted during production are discarded, and the production process is adjusted to ensure a high-quality end product.

In conclusion, gummy manufacturing is a complex process that requires specialized machinery, high-quality ingredients, various molds, and stringent quality control procedures. These features enable manufacturers to create distinctive and delicious treats that can be enjoyed by people of all ages. Gummy candy has become a popular favorite in the candy industry, and the production of these sweet treats is continually evolving to create new, innovative designs, textures, and flavors.

Various Types of Gummy Manufacturing

Gummy manufacturing has become a popular process in the food industry. There are different types of gummy manufacturing that manufacturers use to produce various gummy products.

The first type is traditional or boiled gummy manufacturing. In this process, the manufacturer boils sugar, glucose syrup, gelatin, and water at high temperatures to form a thick syrup. The syrup is then put into molds and cooled to form the gummy candies.

The second type is starchless depositing or soft chew gummy manufacturing. This process involves mixing the gummy ingredients, including sugar, glucose syrup, and gelatin, at room temperature. The mixture is then pumped into a depositing machine, where it is shaped and cut into the desired gummy shapes.

The third type is fortified gummy manufacturing. In this process, manufacturers add vitamins and nutrients to the gummy mixture to create a product with added health benefits.

The fourth type is vegan or gelatin-free gummy manufacturing. This process replaces animal-based gelatin with plant-based ingredients such as pectin, agar-agar, or carrageenan to make gummy products suitable for vegans.

The fifth type is sugar-free gummy manufacturing. This process uses sugar substitutes such as stevia, erythritol, and xylitol to create gummy products with significantly fewer calories than traditional gummies.

Overall, gummy manufacturing has come a long way from its traditional roots. The different types of gummy manufacturing provide manufacturers with flexibility, creativity, and the ability to cater to a diverse range of customer needs.

Applications of Gummy Manufacturing

Gummy manufacturing has become a popular method of producing candy with various applications. These candies are made from gelatin, sugar, and flavors, and have a chewy texture that has made them popular with all ages. Gummies have been used in many different ways, from medicinal purposes to simply satisfying a sweet tooth.

One of the primary applications of gummy manufacturing is in the production of vitamins and supplements. These gummies are proven to be a popular and effective way of supplementing nutrients, especially among children who have difficulty swallowing pills. The gummies come in a variety of flavors, and they are easy to consume, making them more attractive to many.

Gummies are also widely used as treats for kids. These candies come in a variety of shapes, colors, and flavors. The texture of gummies is such that it does not stick to teeth, making it a more child-friendly choice than other types of candies. Moreover, gummies are safer as they are less likely to cause choking accidents.

Another application of gummy manufacturing is in the medicinal field. Medicines like aspirin and acetaminophen can be turned into gummies. This method is quite helpful for people who have trouble swallowing pills. Gummies containing aspirin or acetaminophen will not only provide the required medication but also ensure that the medication is not contaminated.

In conclusion, gummy manufacturing has several applications ranging from dietary supplements to medicinal purposes. The child-friendly texture and wide variety of flavors make them a popular choice among all ages. Additionally, gummies are more secure and less prone to choking accidents, making them a safer option for kids. With their reliable and user-friendly attributes, gummies are an excellent option for a variety of industries.

The Process of Gummy Manufacturing

Gummy bears, worms, and other shapes are some of the most popular candies around the world. But have you ever wondered how they are made? Gummy manufacturing is a complex process that involves many steps and ingredients.

The manufacturing process starts with mixing ingredients like sugar, corn syrup, gelatin, and water in large vats. These ingredients are heated and stirred until they form a syrup-like consistency. Then, flavorings and food colorings are added to the mixture.

The next step is to create the actual gummy shape. The hot liquid mixture is poured into molds that have been sprayed with a non-stick coating. These molds can be any shape, from animals to fruits to letters, depending on the manufacturer’s design.

To create different colors and flavors, the manufacturing process uses several molds at once. The molds are placed on a conveyor belt and sent into a cooling tunnel where the gummies solidify.

Once the gummies are cooled and hardened, they are removed from the molds and packaged for distribution. This packaging process can include individual packaging or bulk packaging for wholesale distribution.

One of the most critical processes during gummy manufacturing is quality control. Quality control ensures that each batch of gummies is consistent in shape, flavor, and texture. Regular testing is done to ensure that the gummies meet the required safety and health regulations.

In conclusion, gummy manufacturing is a multi-step process that requires precision and attention to detail. From mixing and molding to packaging and quality control, every step is crucial in creating the perfect gummy candy. So, the next time you enjoy a sweet and chewy gummy, you will have a better appreciation of the complex process behind this delicious treat.

How to use Gummy Manufacturing

Gummy manufacturing is a popular and effective way to produce gummy vitamins, weed gummies, and other types of gummies. If you’re interested in creating your own gummies, here are some basic steps to get started with gummy manufacturing.

First, you’ll need to gather your ingredients. You’ll need gelatin, corn syrup, water, and flavoring or oil. You can also add colors, sugar, or other ingredients to create your desired texture, taste, and appearance.

Next, you’ll need to heat the ingredients together in a large pot. Stir the mixture constantly until all the ingredients have dissolved and the mixture is smooth. Once the mixture is smooth, you can add any additional ingredients you want to use to create your desired taste and texture.

The next step in gummy manufacturing is to pour the mixture into molds. This can be done by using a dropper or other tool to carefully fill each mold. Once the molds are filled, the gummies will need to be left to cool and solidify. This can take anywhere from a few hours to overnight, depending on the temperature and humidity of your environment.

Once the gummies have solidified, they can be removed from the molds and packaged. You can package them individually or in bulk, depending on your needs. Be sure to label your gummies with any important information, such as ingredients, dosages, and expiration dates.

When it comes to gummy manufacturing, there are a few tips to keep in mind. First, be sure to follow the recipe carefully and measure your ingredients accurately. This will help ensure that your gummies turn out correctly. Additionally, be sure to use high-quality ingredients to achieve the best taste and texture.

Overall, gummy manufacturing can be a fun, rewarding, and profitable hobby or business endeavor. With the right ingredients, tools, and techniques, you can create your own customized gummies that are perfect for your needs.

Selecting the Ideal Manufacturer Gummy Manufacturing

When it comes to gummy manufacturing, selecting the ideal manufacturer is essential for creating a successful product. With so many options available, it can be challenging to determine which company is the right fit for your needs. Here are some key factors to consider when selecting an ideal manufacturer:

1. Quality: The quality of the products is crucial to ensure the customers’ satisfaction. The ideal gummy manufacturer should have a strong commitment to quality control at every stage of the process, from raw materials to finished product.

2. Expertise: The manufacturer must have in-depth knowledge of making gummies. They should have a team of experienced professionals who understand the process and can help you create the desired flavor, texture, and appearance of your product.

3. Flexibility: The manufacturer should be flexible enough to adjust to your needs and produce gummies tailored to your brand’s specifications. They should have a wide range of options available and be willing to work with you to achieve your goals.

4. Regulatory compliance: The manufacturer should be compliant with all necessary regulations and certifications. They should be transparent about their processes and the ingredients they use.

5. Cost: While cost isn’t the only factor, it is important to consider. The ideal manufacturer should be able to provide you with a quote that suits your budget and offers value for money.

6. Communication: It’s essential to have good communication with the manufacturer regarding timelines, updates, and any potential issues that may arise. They should be responsive and transparent throughout the process.

Selecting the ideal gummy manufacturer requires thorough research and due diligence. Consider these factors when making your decision to ensure you get a quality product that meets your brand’s needs.

list FAQ with answer about Gummy Manufacturing

Gummy manufacturing is the process of creating various types of gummies, including those that are consumed as a candy or as supplements. As a popular form of confectionery, gummy manufacturing has become increasingly popular. Here are some frequently asked questions and their answers regarding gummy manufacturing.

1. What is the process of gummy manufacturing?

Gummy manufacturing involves many steps such as preparation, mixing, cooking, cooling, forming, and packaging. The process begins by preparing the ingredients, which are mixed and cooked in a specialized vessel at high temperatures. Then, the mixture is cooled and poured into molds to form the desired shapes. The gummies are then dried, coated with sugar, and packaged.

2. What are the ingredients used in gummy manufacturing?

The ingredients used in gummy manufacturing vary depending on the desired gummy product. Generally, the main ingredients include sugar, gelatin or other gelling agents, flavorings, and colorings. In many cases, gummies also contain additional vitamins and minerals, which may be added to create dietary supplements.

3. What are the types of gummy molds available?

There are several types of gummy molds, including silicone, plastic, and metal molds. Silicone molds offer the most flexibility and are ideal for complex shapes, while metal molds are used for commercial gummy manufacturing because they allow for high-volume production.

4. What are the best storage conditions for gummies?

To maintain the quality and freshness of gummies, they should be stored at room temperature in a dry place, away from direct sunlight or heat. Gummies may also be stored in an airtight container to prevent moisture from affecting their texture.

5. Can gummies be made using natural ingredients?

Yes, gummies can be made with natural ingredients. Some gummy manufacturers specialize in using natural and organic ingredients to create healthier alternative gummies. These may include fruit concentrates, natural sweeteners, and plant-based gelling agents.

In conclusion, gummy manufacturing involves several steps and a variety of ingredients to create the desired product. With proper storage and quality ingredients, gummies can be a tasty treat or a healthful supplement.

Things to Consider When Purchasing Gummy Manufacturing

Gummy manufacturing is a profitable business that can be very rewarding, but before you jump in, there are things you need to consider before making a purchase. Here are some things to consider:

1. Production Capacity: The production capacity of the gummy manufacturing machine is essential. Choose a machine that can produce a sufficient number of gummies to satisfy your daily needs. Keep the market demand in mind and choose accordingly.

2. Quality of Gummy: The quality of gummies plays a crucial role in deciding the success of a product. The gummy manufacturing machine should be able to produce gummies of consistent size, taste, and texture. Quality control measures should be in place to ensure standardization of the products.

3. Reliability: Look for machines from reputable manufacturers or brands. Spare parts and service should be available readily. And with the advancement of technology, you need to choose a machine with modern features like automated and computer-controlled units for precision and accuracy.

4. Cost: The cost of the machine is an essential factor to consider. Buying the most expensive machine doesn’t always guarantee quality or sustainability of the business. However, you must also understand that lower-priced machines may produce lower quality and poorly made gummies. Determine your budget and choose the machine within the budget.

5. Maintenance: Maintenance of the gummy manufacturing machine is crucial as it can affect the quality of the gummies produced, and it may cause unwanted downtime. Choose a machine that can be easily maintained with minimal expenses.

Finally, before making a purchase, make sure that you do your research on different machines to choose the one that suits your needs best. Ask for recommendations from those with experience in the industry, and don’t forget to consider factors like warranty, customer service and training provided by the manufacturer. By considering these things, you can be sure that you’re purchasing a gummy manufacturing machine that will serve you for years to come.

Properties of Gummy Manufacturing

Gummy manufacturing is a complex process that requires careful attention to detail to ensure quality and consistency. There are several properties that play an essential role in the manufacturing of gummies, including texture, appearance, flavor, and shelf-life.

One of the most important properties of gummy manufacturing is texture. Gummies must have a soft and chewy consistency that is enjoyable to eat. Achieving the perfect texture requires precise measurements of the ingredients, including gelatin, sugar, and flavorings. Overheating or overmixing can result in a hard or tough texture that is not desirable.

Another critical property of gummy manufacturing is appearance. Consumers are drawn to colorful and visually appealing gummies, so manufacturers must pay close attention to the appearance of their products. This includes ensuring that the gummies are uniform in size and shape and that the colors are vibrant and eye-catching.

Flavor is also a crucial property of gummy manufacturing. Gummy manufacturers must choose flavorings that are both tasty and appealing to their target market. This can be challenging because different consumers have different preferences when it comes to flavor. Manufacturers may conduct market research to determine the most popular flavors among their target audience.

Finally, shelf-life is an essential property of gummy manufacturing. Consumers expect their gummies to remain fresh and chewy for an extended period, so manufacturers must employ techniques that extend the shelf-life of their products. This can include adding preservatives or packaging the gummies in a way that prevents moisture and air from entering the package.

In conclusion, gummy manufacturing requires a careful balance of several important properties to achieve quality and consistency in the final product. Texture, appearance, flavor, and shelf-life are all critical considerations that must be carefully managed to produce gummies that meet consumers’ expectations.

Technical Parameters Terms for Gummy Manufacturing

When it comes to gummy manufacturing, there are a variety of technical parameters that must be understood and taken into consideration. These parameters impact everything from the consistency and texture of the gummies to their taste and shelf life. Below are some of the most important technical parameters and terms for gummy manufacturing.

1. Gel Strength: This refers to the rigidity of the gelatin that is used in the gummy recipe. The higher the gel strength, the firmer the gummy will be.

2. Bloom Value: This is another measure of the quality of the gelatin. It measures the viscosity of the gelatin solution after it has been dissolved and then allowed to cool.

3. Rheology: This refers to the flow properties of the gummy mixture. It is important to have the right viscosity and flow behavior to ensure that the gummy is properly formed and molded.

4. Moisture Content: This is the amount of water that is present in the gummy. If the moisture content is too high, it can cause the gummies to become sticky or to spoil more quickly.

5. pH: The pH level of the gummy mixture can affect the taste and texture of the gummies. Higher pH levels can lead to gummies that are more chewy, while lower pH levels can result in softer gummies.

6. Flavor: The flavorings used in the gummy recipe can impact the overall taste of the gummies. It is important to use high-quality flavorings that are consistent from batch to batch.

7. Gelatinization Temperature: This is the temperature at which the gelatin fully dissolves and forms a gel. It is important to maintain a consistent gelatinization temperature throughout the manufacturing process to ensure consistent results.

By understanding and controlling these technical parameters, gummy manufacturers can create high-quality products that meet consumer expectations in terms of taste, texture, and appearance.

Gummy Manufacturing Price

Gummy candies have become increasingly popular over the years, with a variety of shapes, sizes, and flavors available on the market. The manufacturing price of gummy candies varies depending on the quality of ingredients, production volume, and labor costs.

One of the most critical factors that influence the cost of manufacturing gummy candies is the quality of ingredients used. High-quality ingredients, such as natural fruit extracts, can be expensive, while artificial flavorings and preservatives can be cheaper. Additionally, the price of gelatin, the primary ingredient used to make gummy candies, can fluctuate based on market demand.

Production volume is another factor that impacts the manufacturing price of gummy candies. Large-scale production allows for the use of cost-saving measures such as automation, which can increase efficiency and lower labor costs. However, smaller factories that produce lower volumes may need to pay more for labor and equipment, resulting in higher production costs.

Labor costs are another factor that affects the manufacturing price of gummy candies. The production process of gummy candies involves several stages such as mixing, cooking, forming, and packaging. Depending on the production volume, companies may need a significant number of workers to ensure efficient production processes.

In conclusion, the manufacturing price of gummy candies varies depending on several factors such as the quality of ingredients, production volume, and labor costs. Nevertheless, gummy candy remains a popular treat worldwide, and manufacturers continue to find innovative ways to produce affordable yet tasty gummy candies.