Benefits of Hand Hay Baler

A hand hay baler is a small, compact machine that is used to make small hay bales primarily used by small farmers. This machine has numerous benefits that have made it a popular tool for farmers, especially those with small farms.

First, the hand hay baler is a cost-effective investment. Unlike large hay balers that require high capital outlay, hand hay balers are affordable. They are easy to maintain and do not require many replacement parts, which reduces the overall operating cost.

Second, this machine requires little physical effort to operate. A single person can handle the entire process of baling the hay. The machine’s design, with a long lever, makes it easy to compress the hay into compact bales.

Third, hand hay balers are eco-friendly. They are manual machines and do not require any electricity, fuel, or other energy sources to operate. Hence, they do not produce any carbon footprint, making them an environmentally friendly option.

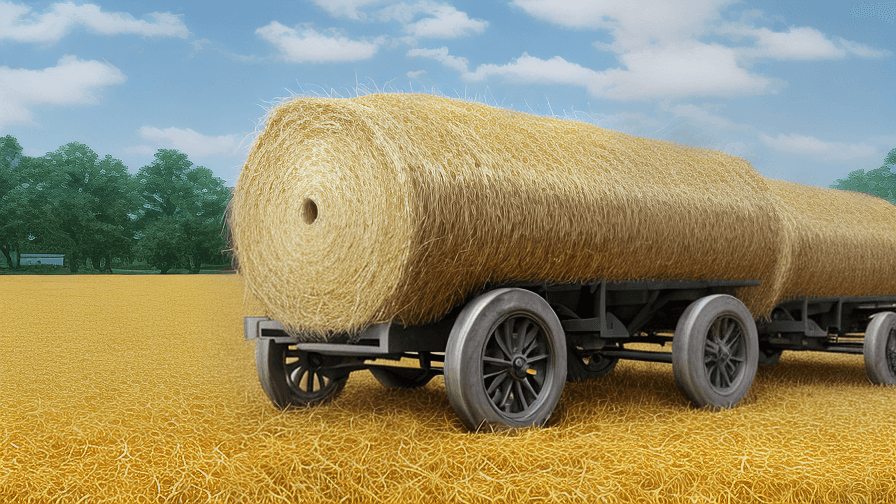

Fourth, hand hay balers provide better quality hay bales. The machine produces uniform and dense bales that are easy to stack and transport. High-density bales reduce transportation costs and make it easier to handle and store the hay.

Finally, using a hand hay baler saves time. Small farmers do not need to hire labor or wait for a large baler to become available to complete their hay baling process. Instead, they can complete the process themselves at their convenience.

In conclusion, hand hay balers offer many benefits to small farmers, including cost-effectiveness, ease of use, eco-friendliness, better quality hay bales, and time savings. They are an essential tool for small-scale hay baling operations and have proven to be reliable for many years.

Features of Hand Hay Baler

A hand hay baler is a simple machine that is used in small-scale hay production processes. This tool provides a feasible, economical and practical solution for farmers who want to save labor and resources, and reduce their dependence on traditional techniques of harvesting hay.

One of the main features of a hand hay baler is its simplicity. This machine is designed to be operated by a single person. It requires minimal training to handle and can be used effectively by farmers of all skill levels. Furthermore, it is lightweight and compact, making it easy to store and transport.

Another important feature of a hand hay baler is its efficiency. This tool can help farmers save money by reducing labor costs. It is capable of baling hay faster than traditional hand baling methods, which helps to optimize the overall productivity of the farm.

In addition, a hand hay baler is an environmentally friendly machine. It does not emit any harmful gases or particulates, and it does not produce any waste or pollution. This makes it a practical and sustainable solution for farmers who are concerned about conserving natural resources and protecting the environment.

Finally, a hand hay baler is durable and reliable. It is made from high-quality materials that are designed to withstand harsh outdoor conditions, and it requires minimal maintenance. This means that farmers can rely on their baler to perform consistently over time and to provide a high-quality end product.

In conclusion, the hand hay baler is a simple, efficient, practical and environmentally friendly machine that can help farmers to optimize their hay baling process. Its durability and reliability make it a valuable investment for small-scale farmers who are looking to increase productivity, save labor and reduce costs.

Various Types of Hand Hay Baler

Hand hay balers are an essential tool for any farmer who wants to save time and effort when baling hay. These machines come in various types, and each one serves a specific purpose. Here, we’ll explore different types of hand hay balers that are commonly used in farms.

The first type of hand hay baler is the vertical baler. This machine is used to compress and bind hay into small, tight bales that are easy to store and transport. Vertical balers are ideal for small-scale farmers who need to store hay for personal use or feed livestock.

The second type of hand hay baler is the horizontal baler. Horizontally compressed bales are heavier and more durable than vertically compressed ones, making them suitable for longer-term storage. Horizontal balers, however, require more manual labor and are less suitable for small-scale farmers.

The third type of hand hay baler is the tractor-mounted baler. These machines are attached to a tractor, and they automate the baling process, making it much faster and more efficient. Tractor-mounted balers come in both horizontal and vertical designs and are most suited to larger farms with a substantial hay baling operation.

The fourth type of baler is the mini hay baler. This machine is smaller than other balers and is perfect for farmers with small fields or low volumes of hay. Mini hay balers are easy to operate and are often manually powered, making them less expensive.

In conclusion, there are various types of hand hay balers available on the market, each designed to suit different needs. Whether you’re a small-scale farmer looking for a simple, affordable solution or a large-scale producer seeking efficiency and speed, there is sure to be a hay baler that meets your needs.

Applications of Hand Hay Baler

A hand hay baler is a device used to compress loose hay into bales. This manual device was commonly used in the past when machines for baling were not readily available and it’s still being used nowadays. Today, the applications of hand hay balers are wide-reaching and diverse.

One of the most important applications of hand hay balers is in small-scale farming. Farmers who produce a small amount of hay for feeding their livestock often use hand hay balers to compress their hay into bales. This reduces labor costs and ensures that the hay is stored properly. These balers are also relatively inexpensive, making them an affordable option for small scale farmers.

Hand hay balers are also used in remote areas where machinery is not available. This can be in areas where farmland is located in rough terrains that make it almost impossible for cars or tractors to access. In some parts of Africa, farmers use these balers to compress grasses completely dried before stocking them in open areas for feeding livestock.

Another application of hand hay balers is in areas where machines are too big or too expensive. For example, smallhold farmers in developing countries may struggle to afford expensive baling machinery, or the cost of transporting such large machines may be prohibitively high. Therefore, a hand hay baler is a practical solution because it is small, lightweight, and affordable.

Finally, hand hay balers have an important role in the sustainability of agriculture. They require no fuel or electricity to operate, reducing carbon emissions thereby promoting a sustainable, environmentally friendly practice. Additionally, they are easy to maintain and repair, meaning they can give many years of useful service.

In conclusion, the applications of hand hay balers are diverse and far-reaching. They have a crucial role to play in small-scale farming, remote areas, developing countries, and sustainable agriculture. As a low-cost and sustainable tool, the hand hay baler remains an essential piece of equipment for many farming communities around the world.

The Process of Hand Hay Baler

Hand hay balers have been used throughout history to compact hay into manageable sizes for storage and transportation. The process of hand hay baling involves a few simple steps, but requires physical strength and manual labor.

Firstly, the hay must be raked into rows and fluffed up to ensure a more even and efficient bale. Then, the hay is gathered and compressed into a rectangular shape using the hand-held baler. This manual baling machine consists of two wooden blocks attached with metal brackets. One block acts as the base, while the other acts as the compressing lever.

The hay is placed between the two blocks, and the operator uses physical force to press down on the lever to compress the hay. Typically, a hand hay baler produces bales that are around 18 inches wide, 14 inches tall, and 30 inches long.

Once the hay has been fully compressed, the operator ties off the bale with twine or wire to secure the hay within the bale. The bale is then lifted and stacked for storage. Historically, hay bales were often stored in barns or silos, but in modern times, they may be stored in covered or uncovered fields.

The process of hand hay baling is physically taxing and time-consuming, and therefore, has largely been replaced by mechanized hay balers. These machines can perform the same task much more quickly and efficiently, with less physical labor involved.

However, for those who enjoy the manual, traditional approach to hay baling, hand hay balers are still used today. They offer a nostalgic connection to the past and a sense of pride, knowing that they were able to produce their own bales of hay from start to finish.

How to use Hand Hay Baler

Hand hay balers are an effective way to bale hay for small- and medium-sized farms. As the name suggests, they are operated manually. Hay balers come in different shapes and sizes, but most are simple and easy to use. Here are the steps to using a hand hay baler:

Step 1: Set up the hay baler

Start by attaching the baler to the baler arm or handle. Then, connect the baler arm or handle to the tractor’s hydraulic system. Ensure that the baler is level and that all the moving parts are lubricated and working correctly.

Step 2: Load the hay onto the baler

Take small piles of hay and feed them into the baler. Try to keep the hay level, so it is compacted evenly.

Step 3: Close the baler

Once the hay is loaded, close the baler’s tailgate. This will trap the hay inside the chamber and prepare it for compression.

Step 4: Start compressing the hay

Activate the baler’s hydraulic system to start compressing the hay. You will feel resistance as the hydraulic system pushes the hay into a compacted bundle.

Step 5: Tie the bale

Once the hay has been compacted, tie it using twine or wire. Ensure that the tie is tight enough to hold the bale together but not so tight that it tears or distorts the bale shape.

Step 6: Remove the bale

Open the tailgate and remove the completed bale. Move it to a safe location or store it for transportation or use.

In conclusion, using a hand hay baler can be simple and easy. By following these steps, you can produce quality bales of hay for your farm or business.

Selecting the Ideal Manufacturer Hand Hay Baler

Selecting the ideal manufacturer hand hay baler is crucial for those looking to efficiently bale hay without the use of heavy machinery. When selecting a manufacturer, it is important to consider their reputation, experience, and product quality.

First and foremost, it is essential to choose a manufacturer with a solid reputation. Look for reviews and ratings of their products online as well as ask for recommendations from others in the farming community. A manufacturer that consistently produces high-quality products and provides excellent customer service is paramount.

Experience is also an important factor to consider. Choose a manufacturer that has been in the industry for a significant amount of time and has a proven track record of producing hand hay balers that are durable and efficient. An experienced manufacturer will have a better understanding of the unique needs and challenges of the farming community.

Lastly, product quality is critical. Look for a manufacturer that uses high-quality materials to construct their hand hay balers. Consider the structural design of the baler, as it is essential for functionality, durability, and ease of use. Additionally, select a manufacturer that offers a warranty or guarantee on their products.

Overall, selecting the ideal manufacturer hand hay baler requires thorough research and careful consideration. Choose a manufacturer with a solid reputation, extensive experience, and produces high-quality products. By selecting the right manufacturer, farmers can efficiently bale hay without the use of heavy machinery and improve their overall productivity.

list FAQ with answer about Hand Hay Baler

Hand hay balers are great tools for small-scale haymakers. They are easy to use and affordable, making them great options for those who do not have access to large-scale baling equipment. To help you better understand hand hay balers, we have compiled a list of frequently asked questions with answers.

What is a hand hay baler?

A hand hay baler is a manual device used for baling hay. It allows you to easily create small bales of hay without the need for heavy machinery.

What kind of hay can be baled using a hand hay baler?

Hand hay balers can be used to bale a variety of hay, including alfalfa, grass, and clover. However, it is important to remember that hand hay balers work best with fine stem hay.

How much hay can be baled at once using a hand hay baler?

The amount of hay that can be baled using a hand hay baler depends on the size of the baler. However, most hand hay balers can create bales that weigh between 40 to 100 pounds.

What kind of maintenance does a hand hay baler require?

Hand hay balers require minimal maintenance. However, it is important to keep the baler free of debris and to lubricate the moving parts regularly.

How long does it take to create a bale using a hand hay baler?

The time it takes to create a bale using a hand hay baler varies depending on the user’s experience and the size of the baler. However, it usually takes between 10-30 minutes to create a bale.

What is the cost of a hand hay baler?

The cost of a hand hay baler varies depending on the manufacturer and size of the baler. However, on average, a hand hay baler costs between $250 to $500.

Can a hand hay baler be used to bale straw?

Yes, hand hay balers can be used to bale straw. However, it is important to note that they work best with fine stem straw.

In conclusion, hand hay balers are great tools for small-scale haymakers. They are easy to use, affordable, and can help you create small bales of hay without the need for large machinery. By understanding the answers to these frequently asked questions, you can better determine if a hand hay baler is right for you.

Things to Consider When Purchasing Hand Hay Baler

For those who are passionate about farming and agriculture, purchasing a hand hay baler can be an essential investment. However, it is important to consider a few factors before making the purchase.

Firstly, it is important to determine the amount of hay you need to bale. Hand hay balers come in different sizes and capacities, so it’s necessary to choose one that can handle the amount of hay you plan to bale. Small hay balers with lower capacities can be ideal for those who have small farms or backyards.

Another factor to consider is the type of hay you plan to bale. Different types of hay can require different types of hay balers. For example, some hay balers are well suited for straw harvesting, while others are best suited for grass hay. If you are unsure about the right machine for your needs, seek advice from experts in the agriculture industry.

When purchasing a hand hay baler, look out for the baler’s durability. Choose a machine that is made from high-quality materials and a robust design. Avoid going for a cheap machine, which may be prone to breakages and costly in the long run.

Before making the purchase, consider how much you are willing to spend on the baler. Determine your budget, and choose a machine that falls within your price range. Also, consider the cost of maintenance, as some balers require more maintenance than others.

In conclusion, purchasing a hand hay baler can be a wise investment for those who are passionate about agriculture. It is necessary to consider the size and capacity of the baler, the type of hay you plan to bale, the durability of the baler, your budget, and the cost of maintenance. By considering these factors, you can ensure that you invest in a quality hand hay baler that meets your needs.

Properties of Hand Hay Baler

Hand hay balers are essential tools for farmers that operate in small scale farms. These balers are relatively simple machines that consist of a hollow rectangular shaped wooden or metal frame and a compressing mechanism that squeezes and compacts the hay into rectangular bales. Despite being a very basic tool, hand hay balers are highly effective and have numerous properties that make them indispensable. In this article, we shall explore some of these properties.

Firstly, hand hay balers are highly affordable. Compared to motorized balers, which are expensive and require regular maintenance, hand hay balers are an economical alternative that can save farmers a lot of money. Moreover, the simplicity of these tools means that farmers can easily build them using available materials and do not need to buy them.

Secondly, hand hay balers are very portable. These tools are generally compact and lightweight, making them ideal for farmers who need to move their hay bales from one location to another. Additionally, their size makes them easy to store in small sheds or barns, thus reducing clutter on a farm.

Thirdly, hand hay balers are incredibly efficient. These tools can compress a large amount of hay into compact bales in just a few minutes. This makes the hay easier to handle and transport, and reduces wastage that can occur when hay is lost in the field.

Fourthly, hand hay balers require minimal maintenance. Since these tools have very few moving parts, there is little that can go wrong with them. In the event that repairs are needed, it is typically easy and inexpensive to fix them.

Finally, hand hay balers are eco-friendly. These tools do not require any fuel or electricity to operate, making them very environmentally friendly. Furthermore, they create minimal waste as most of the materials used in the baling process can be reused or recycled.

In conclusion, hand hay balers are simple yet highly effective tools that are favored by small scale farmers. Their affordability, portability, efficiency, minimal maintenance needs, and eco-friendliness are properties that make them an indispensable tool in farming.

Technical Parameters Terms for Hand Hay Baler

As with any piece of technical equipment, understanding the technical parameters terms for a hand hay baler is crucial for optimal performance and safety. The following are some of the most important technical parameters terms to be familiar with when using a hand hay baler.

1. Bale weight capacity: The maximum weight capacity of the baler determines the size of the bale that it can produce. It is important to not exceed the weight limit, as this can cause damage to the equipment and create a safety hazard.

2. Baling chamber dimensions: The dimensions of the baling chamber determine the size and shape of the bales that can be produced, as well as the amount of hay that can be loaded at one time.

3. Stroke length: The stroke length refers to the distance the plunger travels during each cycle of the baler. A longer stroke length can result in a more compact bale, but may require more effort to operate.

4. Compression force: The compression force is the amount of pressure applied to the hay during the baling process. A higher compression force can result in denser bales, but may also require more effort to operate.

5. Operating pressure: The operating pressure refers to the amount of hydraulic pressure required to operate the baler. It is important to ensure that the operating pressure is within the manufacturer’s recommended range to prevent damage to the equipment and ensure safe operation.

6. Bale tying mechanism: The bale tying mechanism determines how the bale is secured once it has been compressed. Different types of balers may use different methods, such as twine, wire, or netting.

By understanding these technical parameters terms for a hand hay baler, farmers and ranchers can ensure that they are using their equipment properly and safely, and producing high-quality bales of hay.

Hand Hay Baler Price

A hand hay baler is a tool used to compress hay into bales for easier transportation and storage. These devices have been used for many years, and they remain popular with small-scale farmers and hobbyists. Those interested in purchasing a hand hay baler need to consider the price of the equipment.

The price of a hand hay baler can vary depending on several factors. The most significant factor is the quality of the equipment. A high-quality hand hay baler will be more expensive than a cheaper model. Hand hay balers are made from materials such as metal, wood, and plastic, and the materials used will have an impact on the price.

Another factor that affects the price of a hand hay baler is its capacity. Some hand hay balers can only produce small bales, while others can create larger bales. The size of the bales will impact the price of the hand hay baler.

Additional features can also impact the price of a hand hay baler. For example, some hand hay balers come with a built-in twine holder that simplifies the baling process. Other hand hay balers may have more durable components that increase their lifespan.

Pricing for hand hay balers can vary from under $100 to over $1,000, depending on the model and quality. It is important to consider factors such as the frequency of usage, the size of the operation, and budget when selecting a hand hay baler.

In conclusion, buyers should be careful in choosing the right hand hay baler for their needs. There are many different options on the market, each with varying prices and capabilities. By taking the time to research different models, buyers can identify the right hand hay baler for their operation.