Types and Applications of heavy copper pcb

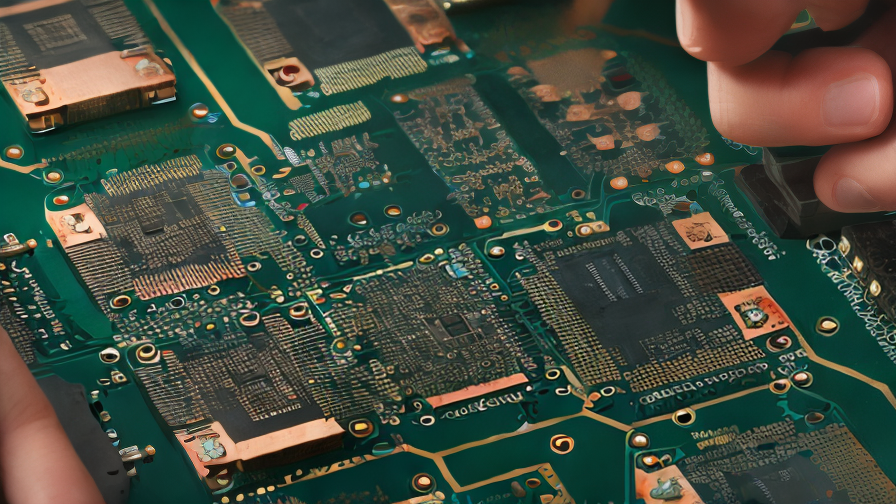

Heavy copper PCB, also known as thick copper PCB, is a type of printed circuit board that has copper thickness between 3 oz/ft2 and 20 oz/ft2. These PCBs are commonly used in high-power electronic systems and applications that require high current capacity, ruggedness, and reliability.

There are several types of heavy copper PCBs available, including single-sided, double-sided, and multi-layered. The choice of PCB type depends on the specific application and requirements.

Some of the typical applications where heavy copper PCBs are used include power supplies, automotive applications, industrial controls, inverters, and motor drives. Heavy copper PCBs provide the necessary electrical conductivity, heat dissipation, and mechanical strength required in such applications.

Heavy copper PCBs can be used in LED lighting applications, where they provide a robust and reliable electrical circuit that can handle high power loads and operate in harsh environments. Additionally, they are used in aerospace applications, where they provide reliable and stable connections between the electronic systems.

In summary, heavy copper PCBs are ideal for applications that require high power and withstand mechanical stress. They offer various benefits over traditional PCBs, including better current carrying capacity, thermal conductivity, and reliability. Their applications are diverse, including automotive, power supplies, aerospace, and industrial control systems, among others.

Benefits and Feature of Utilizing heavy copper pcb

Heavy copper PCBs refer to printed circuit boards that feature copper conductors with thicker weights. These circuit boards offer several benefits, including:

1. High Heat Dissipation: Heavy copper PCBs can dissipate heat much better than standard PCBs, reducing the risk of overheating and damage caused by excessive temperatures.

2. Strong Mechanical Stability: Heavy copper PCBs are much stronger and more durable than regular PCBs, making them an ideal choice for electronic products that require significant mechanical stability.

3. Improved Power Distribution: With thicker copper layers, heavy copper PCBs can handle higher currents, enabling better power distribution throughout the board.

4. High Reliability: Heavy copper PCBs are more reliable than typical PCBs, thanks to their sturdiness and ability to bear heavy stress and load.

5. Enhanced Signal Integrity: Heavy copper PCBs improve signal integrity, which is significant for achieving high-speed, high-frequency signal transmission.

6. Cost-Effective: Heavy copper PCBs are cost-effective since they reduce the need for costly and bulky power supplies.

In summary, the benefits of utilizing heavy copper PCBs include excellent heat dissipation, strong mechanical stability, improved power distribution, higher reliability, enhanced signal integrity, and cost-effectiveness. These advantages make heavy copper PCBs suitable for a variety of applications, including power electronics, automotive, industrial control, and aerospace industries.

The Process of heavy copper pcb

Heavy copper PCBs are defined as boards with copper thickness greater than 3oz on the outer layers, and more than 10oz on the internal layers. The process involved in manufacturing these PCBs is similar to that of standard PCBs, but with additional steps.

The first step in the process is to prepare a board blank with the desired dimensions. This can be done by cutting a larger board to size, or by ordering a pre-cut board. The board should be made from a suitable high-temperature material, such as FR4 or polyimide.

Next, a layer of copper foil is laminated onto the board. In the case of heavy copper PCBs, this foil is thicker than that used in standard PCBs, typically 3oz or more. The foil is bonded to the board using heat and pressure, and then excess copper is removed using a chemical etching process.

The next step is to drill the holes for vias and through-holes. These holes are plated with copper to form a conductive path from one side of the board to the other. For heavy copper PCBs, the plating is typically thicker than that used in standard PCBs, to ensure good conductivity.

After drilling, the layers of the board are stacked and bonded using heat and pressure. This creates a multilayer board with the necessary connectivity between layers.

The final step in the process is to apply a soldermask and silkscreen to the board. These layers help to protect the copper traces and provide visual identification of components and connections.

In summary, the process of manufacturing heavy copper PCBs involves laminating thick copper foil onto the board, drilling and plating vias and through-holes, stacking and bonding layers, and applying a soldermask and silkscreen. These additional steps are necessary to ensure the necessary conductivity and durability of the board, and to support the high-current and high-temperature applications for which heavy copper PCBs are used.

How to use heavy copper pcb

Heavy copper PCB is a type of printed circuit board that has high copper weight in its internal and external layers. It is used when the electronics require high currents or when high-powered applications are used. Heavy copper PCB can be used in power supplies, converters, motor controllers, and other devices that require high electrical conductivity, mechanical strength, and durability.

The design of heavy copper PCBs varies depending on the specific requirements of the application. The designer must consider the maximum operating temperature, input power, voltage, current density, and the type of circuit being used. Heavy copper PCBs can be single-layer, double-layer or multi-layered.

The manufacturing process for heavy copper PCBs is different from the standard PCB manufacturing process. The standard process involves laminating layers of a substrate with copper-clad layers. In contrast, the heavy copper PCB involves multiple cycles of lamination and bonding.

The advantages of using heavy copper PCB include better thermal management, better reliability, better efficiency, and lower operating costs. Heavy copper PCBs can also withstand harsh environments, vibrations, and mechanical stress.

In conclusion, the use of heavy copper PCB is desirable in applications that require high electrical conductivity, mechanical strength, and reliability. The design and manufacturing process must be carefully considered to ensure that the PCB meets the specific requirements of the application. Additionally, using a heavy copper PCB can lead to better thermal management, reliability, and cost savings.

heavy copper pcb Manufacturer,Supplier and Wholesale

As a leading heavy copper PCB manufacturer, supplier, and wholesaler, we provide businesses with high-quality printed circuit boards that meet even the most demanding applications. Our heavy copper PCBs, also known as thick copper PCBs, are designed for applications where high power and durability are critical. We specialize in providing customized heavy copper PCB solutions that deliver precise performance, ruggedness, and unparalleled reliability for various industries.

Our heavy copper PCBs are made using advanced technologies and high-quality materials to ensure superior product performance and longevity. The thicker copper traces and heavier copper layers allow for greater thermal dissipation, which enhances the stability, safety, and longevity of the PCB. Moreover, our heavy copper PCBs are ideal for high power and current-carrying applications and can handle up to 20 oz. copper thicknesses.

We strive to provide our customers with cost-effective solutions that meet their specific needs and requirements. Our experienced engineers work with customers to design PCBs that meet their specific requirements while offering critical guidance on materials and manufacturing options to optimize functionality and minimize costs.

Some of the industries that benefit from our heavy copper PCB products include aerospace, medical, military, and industrial automation. We deliver high-quality products that meet all regulatory compliance requirements and offer our clients peace of mind and the high level of service that they expect.

In conclusion, our extensive experience in heavy copper PCB production, manufacturing processes, and quality management systems allows us to provide best-in-class PCB products that meet the most challenging applications. With us, you’re sure to get superior quality and cost-effective solutions that meet your specific requirements and exceed your expectations. Contact us today to experience the difference that quality and commitment can make for your business.

heavy copper pcb Price

Heavy copper PCBs are printed circuit boards that have copper conductors with a thickness greater than 3 oz/ft2. The heavy copper PCBs are used where high power and high-temperature control are required. These PCBs are usually used in industrial applications such as power electronics, automotive, and military applications where superior conductivity is required.

The price of heavy copper PCBs can vary depending on the size and complexity of the PCB. The cost can also increase with the thickness of the copper. Generally, the price of 1 oz copper thickness PCB is around $5 per square inch, and for 2 oz copper thickness PCB, the price ranges from $5 to $7 per square inch. The price of 3 oz copper thickness PCB starts from $7 to $12 per square inch.

However, the price of heavy copper PCB is worth it due to its beneficial properties. Heavy copper PCBs have unique benefits such as increased current carrying capacity, reduced board sizes, better thermal management, and improved mechanical strength. Due to these valuable benefits, heavy copper PCBs are often used in applications that require high reliability and durability.

In conclusion, heavy copper PCBs are essential in today’s technology-driven world due to their incredible properties and benefits. The cost of these PCBs might be higher when compared to conventional PCBs, but it is worth the investment. Heavy copper PCBs offer superior conductivity and are typically used in high power and high-temperature control applications.

FAQ sourcing heavy copper pcb manufacturer from China with multiple answers

Q: How do I source a heavy copper PCB manufacturer in China?

A: There are several ways to source a heavy copper PCB manufacturer in China. One way is to search online directories, such as Alibaba or Made in China. Another way is to attend trade shows and exhibitions, such as the China International Industry Fair or the Global Sources Electronics show. Additionally, you can get referrals from colleagues or suppliers who have worked with heavy copper PCB manufacturers in China.

Q: What should I look for in a heavy copper PCB manufacturer in China?

A: When sourcing a heavy copper PCB manufacturer in China, it is important to look for a supplier with experience in manufacturing these types of boards. You should also check the supplier’s certifications, such as ISO 9001 or UL certifications, to ensure they meet international standards for quality and safety. Additionally, you should verify their production capabilities and delivery lead times, as well as their communication and customer service.

Q: How do I ensure quality control when sourcing a heavy copper PCB manufacturer in China?

A: Quality control is crucial when sourcing a heavy copper PCB manufacturer in China. You should look for suppliers who have strict quality control processes in place, such as inspection and testing, and who have a track record for producing high-quality products. Additionally, you should consider visiting the supplier’s facilities to see their production lines and quality control measures firsthand.

Q: How much does it cost to source a heavy copper PCB manufacturer in China?

A: The cost of sourcing a heavy copper PCB manufacturer in China can vary depending on several factors, such as the complexity of the board design, the quantity required, and the supplier’s pricing structure. It is important to request quotes from multiple suppliers and compare their pricing and terms before making a decision. However, it is important to balance price with quality and reliability, as choosing the cheapest supplier may result in inferior products or delivery delays.

Q: How do I ensure intellectual property protection when sourcing a heavy copper PCB manufacturer in China?

A: Protecting intellectual property is important when sourcing a heavy copper PCB manufacturer in China. You should look for suppliers who have strict intellectual property protection policies in place and who are willing to sign non-disclosure agreements. Additionally, you should conduct thorough due diligence and legal research before entering into any contracts or partnerships to ensure your intellectual property is safe.