Introduce about hollow brick making machine guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

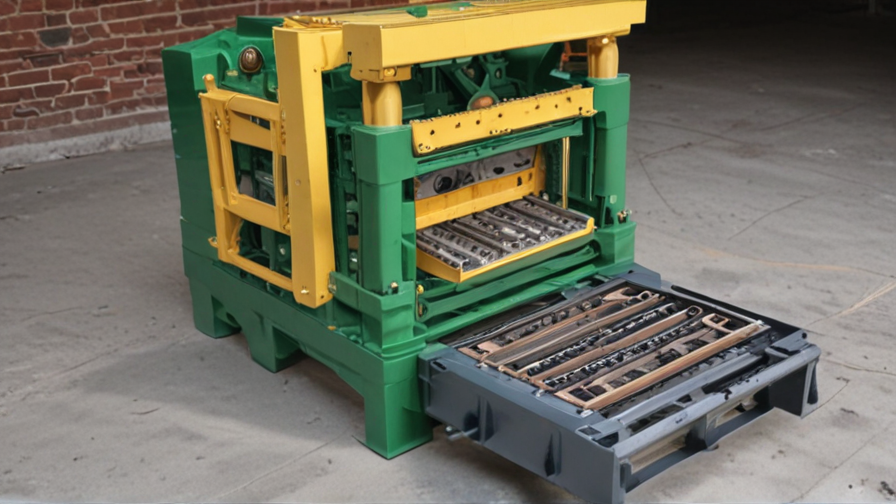

Hollow brick making machines are essential equipment in the construction industry for producing hollow bricks, which are widely used in building houses, roads, and other structures. This guide aims to provide a comprehensive overview of hollow brick making machines, including quality, cost, suppliers, certification, market, tips, and frequently asked questions (FAQ).

Quality is a crucial factor when selecting a hollow brick making machine. The machine should be made of high-quality materials, durable, and capable of producing consistent and precise bricks. It is essential to choose a reliable manufacturer or supplier with a proven track record in producing top-notch machines.

When considering the cost of a hollow brick making machine, various factors come into play. These include the machine’s capacity, speed, automation level, power source, and additional features. Investing in a high-quality machine might result in a higher upfront cost, but it usually guarantees long-term reliability and efficiency.

Finding a reputable supplier is vital to ensure the quality and reliability of the hollow brick making machine. It is recommended to research and compare different suppliers, considering factors such as their experience, customer reviews, and technical support. Also, it is advisable to check if the supplier offers after-sales services, including maintenance and spare parts availability.

Certification is an essential aspect when choosing a hollow brick making machine. Look for machines that comply with international quality standards, such as ISO certifications, CE marking, or other relevant certifications. These certifications ensure that the machine meets the necessary safety and quality requirements.

The market for hollow brick making machines is vast, with various manufacturers and suppliers catering to different customer needs. Researching the market and understanding the available options will help in making an informed decision. Consider factors such as machine performance, price, and customer feedback, to select the best fit for your requirements.

Here are some tips for operating a hollow brick making machine effectively:

1. Follow the manufacturer’s guidelines and machine-specific instructions.

2. Regularly maintain and service the machine to ensure optimal performance.

3. Use high-quality raw materials to produce durable and high-strength bricks.

4. Train operators on proper machine handling and safety precautions.

5. Implement quality control measures to monitor and maintain consistent brick quality.

FAQ:

1. What is the production capacity of a hollow brick making machine?

The production capacity varies depending on the machine’s specifications and can range from a few thousand bricks per day to tens of thousands.

2. Can hollow brick making machines be customized?

Yes, many manufacturers offer customization options to meet specific requirements and preferences.

3. Are hollow bricks eco-friendly?

Yes, hollow bricks are eco-friendly as they use less material and provide better insulation, resulting in energy savings.

In conclusion, hollow brick making machines play a vital role in the construction industry. Choosing a high-quality machine from a reputable supplier, considering certification, and understanding the market will ensure a successful investment. Following the provided tips and addressing common FAQs will help in operating the machine effectively and producing top-quality hollow bricks.

Types of hollow brick making machine

There are several types of hollow brick making machines available in the market, each designed for specific purposes and production capacities. Here are some common types:

1. Manual Hollow Brick Making Machine: This is the simplest type of hollow brick making machine and is operated manually. It requires human effort to mold and shape the bricks. Although it has limited production capacity, it is suitable for small-scale projects or areas with a limited supply of electricity.

2. Semi-Automatic Hollow Brick Making Machine: This type of machine partially automates the brick-making process. It involves manual loading of raw materials into the machine, while the machine takes care of the compaction and molding process. It offers higher production capacity than manual machines and is suitable for small to medium-sized projects.

3. Fully Automatic Hollow Brick Making Machine: This is the most advanced type of hollow brick making machine. It requires minimal human intervention as it can perform all the steps of brick production automatically, including raw material feeding, compaction, molding, and brick stacking. It offers the highest production capacity and is suitable for large-scale productions.

4. Hydraulic Hollow Brick Making Machine: This type of machine uses hydraulic pressure to mold and compress the raw materials. It offers consistent quality control and higher strength of hollow bricks. Hydraulic machines can be either manual, semi-automatic, or fully automatic, depending on the level of automation required.

5. Fly Ash Hollow Brick Making Machine: This machine is specifically designed to utilize fly ash, a waste material generated by coal-fired power plants, as one of the main raw materials. These machines help in reducing environmental pollution by utilizing fly ash effectively.

6. Cement Hollow Brick Making Machine: This machine is designed to produce hollow bricks using cement as the primary raw material. It can be used for both small-scale and large-scale productions, depending on the model and capacity.

7. Clay Hollow Brick Making Machine: This type of machine is ideal for areas where clay is abundantly available. It utilizes clay as the main raw material for hollow brick production.

In summary, there are various types of hollow brick making machines available, including manual, semi-automatic, fully automatic, hydraulic, fly ash, cement, and clay machines. Each type has its own features, benefits, and production capacities, catering to the specific needs and requirements of different projects or areas.

Pros and Cons of Using hollow brick making machine

Using a hollow brick making machine has its own set of pros and cons. Below are some of the main advantages and disadvantages:

Pros:

1. Increased Production Capacity: Hollow brick making machines are designed to produce a large number of bricks at a time. This helps to increase productivity and meet the demand for bricks in a shorter period.

2. Cost-Effective: The use of hollow brick making machines reduces labor costs significantly. With automation, the machine can produce bricks with minimal human intervention, resulting in reduced labor expenses.

3. Versatility: These machines can produce different types and sizes of bricks, including hollow bricks, solid bricks, interlocking bricks, and more. This versatility allows for flexibility in meeting specific construction requirements.

4. Consistent Quality: Hollow brick making machines are designed to produce bricks with consistent quality. The use of automation ensures that every brick is manufactured with precision, resulting in uniformity in size, shape, and strength.

5. Energy Efficiency: Many modern hollow brick making machines are designed with energy-efficient features. These machines consume less power during the manufacturing process, leading to reduced energy costs and a smaller carbon footprint.

Cons:

1. Initial Investment: Purchasing a hollow brick making machine requires a significant upfront investment. These machines are heavy-duty and complex, which contributes to their higher cost. However, this initial expense can be justified by the long-term benefits and increased productivity.

2. Specialized Skills: Operating a hollow brick making machine requires technical knowledge and training. Operators need to be familiar with the operating procedures, settings, and maintenance requirements to ensure the machine operates efficiently and effectively.

3. Space Requirements: Hollow brick making machines are generally large and require adequate space for installation. This may pose a challenge, especially in smaller production facilities or construction sites with limited space availability.

4. Maintenance and Repairs: Like any mechanical equipment, hollow brick making machines require regular maintenance to ensure optimal performance. This includes routine inspections, lubrication, and potential repairs, which may cause downtime if not properly managed.

5. Dependence on Power Supply: Hollow brick making machines heavily rely on a stable and reliable power supply. In some regions or construction sites with frequent power outages or limited access to electricity, the machine’s operating efficiency may be compromised.

In conclusion, using a hollow brick making machine offers several advantages, including increased production capacity, cost-effectiveness, versatility, consistent quality, and energy efficiency. However, it also has some drawbacks, such as the initial investment, the need for specialized skills, space requirements, maintenance responsibilities, and reliance on a stable power supply. Despite these cons, the long-term benefits of using a hollow brick making machine often outweigh the challenges, making it a preferable choice for brick production in many construction projects.

hollow brick making machine Reference Specifications (varies for different product)

The hollow brick making machine is a versatile equipment used to manufacture hollow bricks, also known as concrete blocks or cement bricks. These bricks have a hollow core, which provides better insulation and reduces the overall weight of the brick.

The reference specifications of the hollow brick making machine may vary depending on the specific product and manufacturer. However, most machines generally share certain key features and capabilities.

Firstly, the machine is typically designed to work with various raw materials like cement, sand, fly ash, and stone dust. These materials are mixed together with water to form a high-quality concrete mixture. The machine is equipped with a robust mixing system that ensures thorough and even mixing of the ingredients.

The brick making machine is also equipped with a mould that shapes the wet concrete mixture into desired hollow brick shapes. The mould can be customized to produce bricks of different sizes and dimensions, according to the specific requirements of the project. The machine has a hydraulic system that applies pressure to the wet concrete mixture in the mould, ensuring the bricks have a uniform shape and strength.

The hollow brick making machine operates in an automated or semi-automated manner, depending on the model. It may incorporate a computerized control system that enables easy and convenient operation, reducing human effort and ensuring consistent production.

In terms of production capacity, the machine can typically produce a large number of hollow bricks within a short time. This capacity can vary depending on the machine size and design, but it can often range from a few hundred to thousands of bricks per hour.

Overall, the hollow brick making machine is a durable and efficient piece of equipment used in the construction industry. It offers a reliable and cost-effective solution for producing high-quality hollow bricks, meeting the diverse needs of construction projects worldwide.

Applications of hollow brick making machine

The hollow brick making machine is a vital component in the construction industry as it helps in the manufacturing of high-quality and durable hollow bricks. These bricks have cavities in their structure, which significantly reduces their weight without compromising their strength. There are numerous applications for hollow bricks, making the hollow brick making machine highly beneficial for the industry.

Firstly, hollow bricks are widely used in the construction of residential buildings. Their lightweight nature makes them easier to handle and transport, reducing overall construction time and costs. Additionally, hollow bricks provide excellent insulation properties, retaining heat during colder seasons and keeping the indoors cool during hot summer days.

Secondly, hollow bricks are frequently utilized in the construction of commercial buildings such as offices, schools, and hospitals. These structures require strong and durable walls and partitions to withstand heavy occupancy and constant usage. Hollow bricks’ structural integrity ensures they can endure high loads and maintain the necessary fire safety standards.

Thirdly, hollow bricks find applications in the construction of road infrastructure. They are commonly used to build retaining walls, embankments, and drainage systems, due to their ability to carry heavy loads and resist erosion. The cavities in the bricks serve as conduits for water, preventing excess moisture buildup that can damage the infrastructure.

Furthermore, hollow bricks are often used in the creation of decorative structures like garden walls, fences, and landscaping features. These bricks can be easily shaped, making them ideal for various architectural designs. Their distinctive appearance can enhance the aesthetic appeal of the surroundings while providing stability and durability.

In conclusion, the hollow brick making machine plays a significant role in the construction industry by manufacturing hollow bricks. These bricks have various applications, including residential and commercial buildings, road infrastructure, and decorative structures. The lightweight nature, insulation properties, and structural integrity of hollow bricks make them highly advantageous in the construction process.

The Work Process and how to use hollow brick making machine

The work process of a hollow brick making machine involves several steps. Firstly, raw materials such as cement, sand, and water are mixed together in a concrete mixer to form a consistent mixture. This mixture is then transferred to the hollow brick making machine.

Next, the machine molds the mixture into hollow bricks using moulds of various sizes and shapes. The moulds are filled with the mixture and compressed to ensure proper compaction. The excess material is trimmed off, and the bricks are allowed to cure for a specific period of time.

After the curing process, the bricks are removed from the moulds and arranged in a specific pattern. Finally, the bricks are sent for drying in a drying chamber or under the sun to further strengthen and solidify them.

To use a hollow brick making machine effectively, it is important to follow some guidelines. Firstly, the machine should be set up on a levelled surface for stability. The raw materials should be measured accurately to maintain the proper ratio for the mixture.

It is crucial to clean the machine regularly to avoid any blockages or malfunctions. The moulds should also be cleaned after each use to ensure smooth operation. Additionally, proper maintenance and lubrication of the machine’s moving parts should be done periodically.

Furthermore, the cured bricks should be handled carefully during the removal and drying process to avoid any damages. It is recommended to follow the manufacturer’s instructions for the specific machine being used.

In conclusion, the work process of a hollow brick making machine involves mixing the raw materials, molding the mixture into bricks, curing, and drying. Following the guidelines mentioned above will help in effectively utilizing the machine and producing high-quality hollow bricks.

Quality Testing Methods for hollow brick making machine and how to control the quality

When it comes to quality testing methods for hollow brick making machines, there are several crucial steps that can be undertaken to control the quality. Here are some key methods:

1. Raw Material Testing: The first step is to test the quality of the raw materials used in the brick making process. This includes the testing of clay, cement, sand, and other additives. By conducting tests on these materials, one can ensure that they meet the required specifications for making high-quality hollow bricks.

2. Mixing Proportions: Accurate mixing proportions of the raw materials play a vital role in determining the brick’s strength and durability. Regular testing of the mixing process to achieve the appropriate proportions is necessary to maintain consistent quality.

3. Compression Strength Testing: The strength of a hollow brick is a crucial characteristic to evaluate its quality. Compression strength tests are conducted on the bricks, where they are subjected to compressive forces until failure. The bricks need to meet the desired strength requirements to ensure their longevity and structural stability.

4. Dimensional Tests: Hollow bricks should have standardized dimensions to ensure proper fitting during construction. Regular checks on dimensions such as length, width, and height are essential to control the quality. Any significant deviations from the standard should be addressed promptly.

5. Water Absorption Testing: The water absorption rate of hollow bricks is an indicator of their quality. The lower the water absorption rate, the better the brick’s resistance to weathering and moisture-related issues. Water absorption tests help ensure that the bricks do not absorb excessive moisture.

6. Visual Inspection: Regular visual inspections allow for the detection of any defects or irregularities in the bricks, such as cracks, surface blemishes, or uneven texture. Any faulty bricks should be identified and rejected to uphold quality standards.

To control the quality throughout the manufacturing process of hollow bricks, it is essential to maintain proper documentation of test results, monitor machinery performance, and provide regular training to operators. Additionally, conducting periodic audits and seeking feedback from customers can aid in continuous improvement efforts. By following these quality testing methods and implementing effective control measures, one can ensure the production of high-quality hollow bricks with consistent standards.

hollow brick making machine Sample Policy and Post-Purchase Considerations for hollow brick making machine from China

Sample Policy:

When purchasing a hollow brick making machine from China, it is important to consider the sample policy to ensure the quality and suitability of the machine. Most suppliers offer sample machines for customers to evaluate and test before making a purchase. The sample policy usually includes the following aspects:

1. Availability of samples: Suppliers should clarify whether samples are available and provide details on how to request them.

2. Cost of samples: Suppliers may charge for the samples, including the machine cost, shipping fee, and any additional charges related to customization or other specifications.

3. Sample delivery time: Suppliers should clearly state the estimated delivery time for the samples, allowing customers to plan accordingly.

4. Sample quality: Suppliers should ensure that the samples provided accurately represent the quality and performance of the hollow brick making machine.

5. Return policy: In case the customer is not satisfied with the sample, suppliers should clarify their return policy, including any applicable charges or requirements.

Post-Purchase Considerations:

After purchasing a hollow brick making machine from China, there are several important considerations to keep in mind:

1. Installation and training: Check if the supplier provides installation and training services to ensure that the machine is properly set up and operated. This is especially crucial if the customer is unfamiliar with the machines’ operation.

2. Warranty and after-sales support: Clarify the warranty period and what it covers, including any costs for replacement parts or repairs. Suppliers should offer reliable after-sales support, including technical assistance and spare parts availability.

3. Quality certification: Ensure that the machine meets the required quality standards, such as ISO certification or other relevant industry certifications.

4. Transportation and logistics: Discuss with the supplier the transportation and logistics arrangements, including shipping costs, delivery time, and any necessary customs documentation.

5. Payment terms: Agree on the payment terms, including the initial deposit, milestone payments, and final payment upon machine delivery.

6. Communication and language: Clarify the preferred communication channels and language to avoid any misunderstandings during the purchasing process or in case of future support needs.

Overall, thorough consideration of the sample policy and post-purchase considerations is essential when purchasing a hollow brick making machine from China to ensure a smooth and successful transaction.

Sourcing hollow brick making machine from China: Opportunities, Risks, and Key Players

Sourcing hollow brick making machines from China presents both opportunities and risks for buyers. China is known for its advanced machinery manufacturing capabilities, and many reputable manufacturers offer high-quality hollow brick making machines at competitive prices. Chinese machines are often sought after by buyers worldwide due to their efficiency, durability, and cost-effectiveness.

One significant opportunity of sourcing from China is the wide range of options available. Chinese manufacturers offer a variety of hollow brick making machines with different specifications, capacities, and automation levels. This allows buyers to choose the most suitable machine that best fits their production requirements.

Another advantage is the cost advantage. Chinese manufacturers generally offer hollow brick making machines at lower prices compared to their counterparts in other countries. This cost advantage is primarily due to China’s well-developed manufacturing infrastructure, large-scale production capabilities, and competitive labor costs.

However, there are also risks associated with sourcing from China. One major concern is product quality. While many Chinese manufacturers offer high-quality machines, there are also those who may compromise on quality to reduce costs. It is crucial for buyers to conduct thorough research and due diligence to identify reputable manufacturers with a proven track record of producing reliable hollow brick making machines.

Another risk is potential language and communication barriers. Chinese manufacturers primarily operate in Mandarin, and language differences can lead to misunderstandings or miscommunications during the sourcing process. Overcoming these barriers may require hiring translators or using reliable intermediaries that can bridge the communication gap effectively.

Key players in the hollow brick making machine market in China include well-established manufacturers such as Zhengzhou Yingfeng Machinery Co., Ltd., Quanzhou City Sanlian Machinery Manufacture Co., Ltd., and Wuhan Bandao Brick Machine Equipment Co., Ltd. These companies have gained a strong reputation for producing high-quality machines and providing excellent customer service.

In conclusion, sourcing hollow brick making machines from China offers significant opportunities in terms of cost, quality, and variety. However, it is essential for buyers to carefully assess the risks, conduct thorough research, and select reputable manufacturers to ensure a successful sourcing experience.

How to find and select reliable hollow brick making machine manufacturers in China,use google search manufacturers and suppliers

When looking for reliable hollow brick making machine manufacturers in China, it is essential to streamline the search process efficiently. Here are a few steps to find and select trustworthy manufacturers using Google search:

1. Begin with a focused search query: Start by using specific keywords such as “reliable hollow brick making machine manufacturers in China.” This targeted search will help narrow down the results to appropriate suppliers.

2. Scan through the first few pages of results: Generally, the most reliable and established manufacturers are more likely to appear on the initial pages of the search results. Scan through the first few pages to gather a list of potential manufacturers.

3. Filter by company credibility: Once you have identified a few manufacturers, assess their credibility. Look for information such as the number of years the company has been in business, their company size, and customer reviews or feedback. This data can provide insights into their reliability and customer satisfaction levels.

4. Verify product quality: It is crucial to ensure that the manufacturer produces high-quality hollow brick making machines. Look for product information like specifications, certifications, and production processes. Additionally, consider requesting samples or arranging visits to their factories to check the machine’s quality firsthand.

5. Assess production capacity and customization: Evaluate the manufacturer’s production capacity to ensure they can meet your demands. If you require customized machines, check if the manufacturer offers such services and inquire about their capabilities in meeting specific requirements.

6. Seek references or recommendations: Customer reviews and testimonials can provide valuable insights into a manufacturer’s reliability. Additionally, consider seeking recommendations from industry experts, colleagues, or peers who have prior experience with hollow brick making machine manufacturers in China.

7. Contact multiple manufacturers: Shortlist a few potential manufacturers and get in touch with them. Communicate your requirements, ask for quotations, and clarify any doubts or concerns you may have. Prompt and professional responses can indicate the manufacturer’s reliability.

8. Evaluate after-sales service and support: Adequate after-sales support is crucial for long-term satisfaction with your purchase. Inquire about the manufacturer’s warranty policies, availability of spare parts, and technical assistance. Prompt and comprehensive after-sales service is a positive sign of a reliable manufacturer.

By following these steps, you can efficiently find and select reliable hollow brick making machine manufacturers in China through Google search. However, always exercise due diligence, conduct thorough research, and consider other credibility-checking techniques to ensure a successful and satisfactory business partnership.

How to check hollow brick making machine manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To determine the reliability of a hollow brick making machine manufacturer’s website, you can utilize Google Chrome’s SEOquake extension, which allows you to check its ranking within the top 10 million websites. Here is a step-by-step guide on how to assess the reliability of the manufacturer’s website using SEOquake and some additional tips:

1. Install SEOquake Extension: Open Google Chrome browser and search for SEOquake extension. Click on the official link and add the extension to your browser.

2. Enable SEOquake: After installation, look for the SEOquake toolbar at the top-right corner of your browser. You can toggle it on or off by clicking on the SEOquake icon.

3. Visit the Manufacturer’s Website: Enter the website address of the hollow brick making machine manufacturer in the Chrome address bar and press Enter.

4. Use SEOquake: Once the website loads, activate SEOquake by clicking on its toolbar icon. A new section will appear displaying various SEO metrics.

5. Check Website Ranking: Look for the “Alexa Rank” metric within the SEOquake section. If the website’s ranking falls within the top 10 million, it indicates decent online visibility and generally suggests reliability.

Additional Tips:

– Consider User Experience: Besides ranking, pay attention to the website’s design, navigation, and overall user experience. A well-designed and user-friendly site often indicates professionalism and reliability.

– Verify Contact Details: Ensure that the website provides comprehensive contact information such as phone numbers, email addresses, and physical addresses. Legitimate manufacturers usually make their contact details readily available.

– Check for Testimonials: Look for customer reviews or testimonials on the website, as they can provide insights into the manufacturer’s reputation and product quality.

– Research Beyond Website: Conduct additional research about the manufacturer, such as reading reviews on external platforms or checking their presence on social media. This will help you gather a more comprehensive understanding of their reliability and credibility.

Remember, while the ranking and other factors mentioned above can indicate the manufacturer’s website’s reliability, it is essential to consider multiple sources and conduct thorough due diligence before making any purchasing decisions.

Top 10 hollow brick making machine manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Qinhuangdao Mevmachine Industry and Trade Co., Ltd. specializes in the manufacturing of hollow brick making machines. Their machines are designed to produce high-quality hollow bricks with precise dimensions and excellent durability. Equipped with advanced technology, their machines have high production efficiency and low energy consumption, making them an ideal choice for large-scale brick production.

2. Beijing Zhongcai Jianke Institute of Science and Technology for Building Materials manufactures a wide range of hollow brick making machines. Their machines are equipped with hydraulic systems, ensuring precise control over brick production. Advanced PLC control systems and high-quality components guarantee stable performance and durability. Their machines are also highly adaptable and can produce various types of hollow bricks to meet different construction requirements.

3. Quanzhou Xing Xin Machinery Manufacturing Co., Ltd. specializes in the production of automatic hollow brick making machines. Their machines are designed to eliminate manual labor and improve efficiency. With advanced technology, their machines can produce high-quality hollow bricks with excellent strength and resistance. Their machines are also user-friendly, with easy maintenance and operation.

4. Xiamen Sunlight Xin Mechanic Equipment Co., Ltd. offers a diverse range of hollow brick making machines. Their machines are built with precision and can produce hollow bricks with accurate dimensions. Equipped with powerful motors and hydraulic systems, their machines have high production efficiency and can operate continuously for long periods. Their machines are also known for their durability and low maintenance requirements.

5. Fujian HGM Machinery Co., Ltd. is a leading manufacturer of hollow brick making machines. Their machines are designed to produce hollow bricks with high strength and thermal insulation properties. With advanced vibration technology, their machines can efficiently compact the concrete mixture, ensuring optimum brick quality. Their machines are also versatile, capable of producing various sizes and shapes of hollow bricks.

6. Linyi Brick Mate Machinery Co., Ltd. specializes in the manufacturing of hydraulic hollow brick making machines. Their machines are equipped with hydraulic systems that provide precise control over the brick production process. With high-quality components, their machines have excellent durability and require minimal maintenance. Their machines are also energy-efficient, reducing overall production costs.

7. Quanzhou Yixin Machinery Technology Co., Ltd. offers a wide range of hollow brick making machines. Their machines are designed to produce hollow bricks with precise dimensions and consistent quality. Equipped with advanced PLC control systems, their machines are easy to operate and maintain. Their machines also have high production efficiency and can meet the demands of large-scale brick production.

8. Ningbo Haishu Nuoya Cement Block Machine Factory manufactures high-quality hollow brick making machines. Their machines utilize advanced vibration technology to ensure proper compaction of the concrete mixture, resulting in superior brick quality. With user-friendly designs, their machines are easy to operate and maintain. Their machines are also energy-efficient, reducing both production costs and environmental impact.

9. ZCJK Intelligent Machinery Wuhan Co., Ltd. specializes in the production of intelligent hollow brick making machines. Their machines are equipped with advanced control systems that provide precise control over the brick production process. With high-quality components, their machines have excellent durability and can withstand heavy-duty operations. Their machines are also known for their high production efficiency and low energy consumption.

10. Shandong Dongfengshuanglong Machinery Co., Ltd. offers a range of hollow brick making machines suitable for different construction needs. Their machines are designed with robust structures and high-quality components to ensure long-lasting performance. Equipped with advanced control systems, their machines can produce hollow bricks with precise dimensions. Their machines are also user-friendly, with simplified operation and maintenance procedures.

| Manufacturer | Product Range | Technology | Production Efficiency | Durability | Automation |

|——————————————|———————|———————————————————-|———————–|————|—————————|

| Qinhuangdao Mevmachine Industry and Trade | High-quality bricks | Advanced technology with high production efficiency | High | Excellent | Manual labor reduction |

| Beijing Zhongcai Jianke Institute | Diverse | Hydraulic systems and high-quality components | Stable | Durable | Multiple brick production |

| Quanzhou Xing Xin Machinery Manufacturing | Automatic | Advanced technology with high-quality output | High | User-friendly | Minimal manual intervention |

| Xiamen Sunlight Xin Mechanic Equipment | Diverse range | Powerful motors and hydraulic systems | Continuous operation | Durable | Low maintenance |

| Fujian HGM Machinery | Thermal insulation | Advanced vibration technology for improved brick quality | Efficient compaction | Reliable | Versatile |

| Linyi Brick Mate Machinery | Hydraulic systems | High-quality components for extended durability | Minimal maintenance | Energy-efficient | User-friendly operations |

| Quanzhou Yixin Machinery Technology | Precise dimensions | Advanced PLC control systems for easy operation and maintenance | Large-scale production | Durable | High productivity |

| Ningbo Haishu Nuoya Cement Block Machine | High-quality bricks | Advanced vibration technology for superior brick quality | User-friendly | Energy-efficient | Lower production costs |

| ZCJK Intelligent Machinery Wuhan | Intelligent design | Advanced control systems for precise brick production | High | Durable | Reduced manual labor |

| Shandong Dongfengshuanglong Machinery | Diverse | Robust structure and high-quality components | Long-lasting performance | Precise dimensions | Simplified operation and maintenance |

Background Research for hollow brick making machine manufacturers Companies in China, use qcc.com archive.org importyeti.com

When searching for hollow brick making machine manufacturers in China, several reliable sources can be utilized, such as qcc.com, archive.org, and importyeti.com. These platforms provide valuable information about companies, including their background, products, and manufacturing capabilities.

Qcc.com is a reputable Chinese business information website that offers comprehensive company profiles and business data. It provides details such as the company’s registration information, legal status, production capacity, and certification. This platform is widely used by businesses and individuals for conducting background research on potential suppliers.

Archive.org is a digital library that archives web pages, allowing users to access past versions of websites. Checking the archived pages of brick making machine manufacturers can provide insights into the company’s history, including changes in their products, website, and overall development over time. This information can be helpful in assessing the company’s experience and track record.

Importyeti.com is a platform that specializes in facilitating global trade. It provides valuable data on import and export activities, including shipment details and trade records. By searching for specific keywords related to hollow brick making machines or relevant product codes, users can find information regarding the manufacturers, their export history, production volume, and target markets. This gives a clearer picture of the company’s market reach and export capabilities.

Through these platforms, researchers can gain a wealth of information about hollow brick making machine manufacturers in China, including their company background, history, production capacity, and export activities. This data will aid in evaluating potential suppliers and making an informed decision based on the specific requirements of the project.

Leveraging Trade Shows and Expos for hollow brick making machine Sourcing in China

Trade shows and expos are excellent platforms for sourcing hollow brick making machines in China. These events provide opportunities to connect with manufacturers, explore new products, and establish business relationships. Here is how businesses can leverage trade shows and expos for hollow brick making machine sourcing in China:

1. Research and select relevant trade shows: Conduct thorough research to identify trade shows and expos that focus on machinery and construction equipment. China International Building Materials Exhibition (CIBME), China International Building and Construction Trade Fair (CBCTF), and Canton Fair are some prominent examples. These events attract a wide range of manufacturers, suppliers, and buyers, offering a comprehensive platform for sourcing hollow brick making machines.

2. Pre-show preparation: Before attending a trade show or expo, businesses should define their requirements, such as specific machine specifications, budget, and quality standards. Research and identify potential exhibitors in advance, and schedule appointments or meetings with them. This preparation ensures efficient use of time and resources during the event.

3. On-site evaluation: During the trade show or expo, visit the booths of shortlisted manufacturers and suppliers. Take the opportunity to examine their hollow brick making machines, inquire about their production capabilities, and discuss customization options. Assess the quality, features, and pricing of different machines from various vendors.

4. Networking and relationship-building: Trade shows and expos provide a platform to network with industry professionals, including manufacturers, distributors, and experts. Engage in conversations, exchange business cards, and share contact information for future collaborations. Building relationships with industry stakeholders can be beneficial for future sourcing needs and gaining valuable insights.

5. Factory visits and negotiations: After identifying potential suppliers at trade shows, arrange visits to their factories for a more detailed evaluation of their facilities, product quality, and manufacturing processes. This allows businesses to make informed decisions based on firsthand knowledge. During factory visits, negotiate pricing, terms, and conditions with the aim of securing the best deal.

In conclusion, trade shows and expos offer businesses an ideal opportunity to source hollow brick making machines in China. By conducting thorough research, preparing in advance, and actively engaging with manufacturers at these events, businesses can establish fruitful relationships and fulfill their sourcing needs effectively.

The Role of Agents and Sourcing Companies in Facilitating hollow brick making machine Purchases from China

Agents and sourcing companies play a crucial role in facilitating the purchase of hollow brick making machines from China. These intermediaries act as a bridge between buyers and manufacturers, streamlining the sourcing process and ensuring a smooth transaction. Here is an overview of their role:

1. Supplier identification: Agents and sourcing companies have a deep understanding of the Chinese market and its manufacturing capabilities. They help buyers identify reliable and reputable manufacturers who specialize in hollow brick making machines. This saves buyers from the extensive research and verification process, as agents already have up-to-date information on manufacturers’ credentials.

2. Negotiation and price optimization: Agents and sourcing companies negotiate with the manufacturers on behalf of the buyers to secure the most favorable pricing and terms. Their understanding of the local market gives them the leverage to negotiate better deals, resulting in cost savings for the buyers.

3. Quality assurance: Ensuring the quality of the purchased machine is critical. Agents and sourcing companies conduct on-site inspections at the manufacturing facilities to assess the production process, quality control measures, and overall manufacturing standards. They also arrange for sample testing and quality certifications, giving buyers confidence in the product’s reliability and durability.

4. Order coordination and logistics: Agents and sourcing companies handle all order coordination activities, including documentation, payment processing, and shipping logistics. They ensure that all necessary documentation, such as contracts, product specifications, and certificates, are in order. They also coordinate with freight forwarders and customs clearance agents to ensure timely shipping and hassle-free delivery to the buyer’s destination.

5. After-sales support and dispute resolution: In case of any issues or disputes, agents and sourcing companies represent the buyer’s interest and work towards a satisfactory resolution. They can negotiate warranty terms, arrange for repairs or replacements, and mediate between the buyer and the manufacturer to resolve any conflicts.

In summary, agents and sourcing companies streamline the purchase process of hollow brick making machines from China by identifying reliable suppliers, negotiating favorable prices, ensuring quality control, coordinating logistics, and providing after-sales support. Their expertise and local presence in China greatly benefit buyers, saving them time, money, and potential risks associated with international trade.

Price Cost Research for hollow brick making machine manufacturers Companies in China, use temu.com and 1688.com

When it comes to finding hollow brick making machine manufacturers in China, two popular platforms for research are temu.com and 1688.com. These websites provide a wide range of products from various manufacturers, making it easier for potential buyers to explore options and compare prices.

Temu.com is an online B2B platform that connects buyers with verified suppliers. It offers a comprehensive range of machinery, including hollow brick making machines. Users can search for manufacturers, browse their product catalogs, and contact them directly for further inquiries. The platform also provides detailed information about each supplier, such as company profile, product range, certifications, and customer reviews. With the help of temu.com, buyers can easily shortlist manufacturers and request price quotations to compare.

1688.com, on the other hand, is a popular Chinese wholesale website owned by Alibaba Group. This platform targets domestic buyers and offers a vast selection of products, including hollow brick making machines. Although primarily in Chinese language, with the help of online translation tools, international buyers can still navigate and search for relevant manufacturers. One advantage of 1688.com is the potential for finding more cost-effective options than on other platforms, as it connects buyers directly with manufacturers or wholesalers in China.

To conduct research on pricing, buyers can utilize the search filters on both platforms to specify their requirements, such as machine specifications, production capacity, and quality standards. By gathering information on multiple manufacturers and their respective prices, buyers can compare and negotiate for the best possible deal.

In summary, temu.com and 1688.com are valuable platforms for researching hollow brick making machine manufacturers in China. While temu.com provides a more English-friendly interface and verified suppliers, 1688.com offers a wider range of manufacturers and potentially more cost-effective options. By utilizing these platforms and comparing prices, buyers can make well-informed decisions and find the most suitable hollow brick making machine manufacturer for their needs.

Shipping Cost for hollow brick making machine import from China

Importing a hollow brick making machine from China involves several factors that determine the shipping cost. These factors include the weight and dimensions of the machine, the shipping method chosen, and any additional services required.

The weight and dimensions of the hollow brick making machine are significant in determining the shipping cost. Generally, heavier and more substantial machines will incur higher shipping costs. This is because transportation charges are usually calculated based on weight and size. To reduce costs, it is advisable to choose a machine that is as lightweight and compact as possible while still meeting your production needs.

The shipping method selected also affects the cost. There are several options available, including air freight, sea freight, and express delivery. Air freight is the fastest but most expensive option, while sea freight is more affordable but slower. Express delivery services like DHL or FedEx are often the most expensive but do offer the benefit of faster delivery times.

Additionally, special services required for shipping the machine can impact the cost. These may include packaging, customs clearance, and insurance. Properly packaging the machine ensures that it arrives intact and undamaged. Customs clearance fees depend on the regulations and requirements of the importing country. Insurance provides financial protection in case of any unforeseen events during transit.

To estimate the shipping cost, it is necessary to provide the weight and dimensions of the machine to potential shipping companies. They will then provide a quote based on the chosen shipping method and any additional services required. To try to minimize shipping costs, it is essential to compare quotes from multiple shipping companies and negotiate the best terms possible.

In conclusion, shipping costs for importing a hollow brick making machine from China depend on factors such as weight and dimensions, shipping method, and additional services required. Researching and comparing different shipping options will help in finding the most cost-effective solution while ensuring smooth transportation of the machine.

Compare China and Other hollow brick making machine Markets: Products Quality and Price,Visible and Hidden Costs

China is one of the largest markets for hollow brick making machines, and comparisons with other markets can provide insights into product quality and price as well as visible and hidden costs.

In terms of product quality, China has a diverse array of manufacturers producing hollow brick making machines, ranging from low-end to high-end options. While the quality can vary, many Chinese manufacturers have invested heavily in technology and innovation, resulting in products that are reliable and durable. However, it is essential to carefully research and choose a reputable manufacturer to ensure the quality meets the required standards.

Price is another significant factor when comparing China with other markets. Chinese manufacturers have a competitive advantage due to their lower labor and production costs. As a result, hollow brick making machines from China tend to be more affordable compared to those from other markets, such as Europe or the United States. This lower price gives Chinese machines a strong advantage in terms of cost-effectiveness.

Visible costs, such as the purchase price, are relatively straightforward to evaluate. Chinese manufacturers often provide detailed pricing information, making it easier for buyers to compare prices. However, other markets may have higher visible costs due to higher labor and production expenses. Hence, purchasing a hollow brick making machine from China can lead to significant cost savings.

Hidden costs, on the other hand, can be more challenging to identify. These costs include factors like shipping, customs duties, and after-sales service. While Chinese manufacturers often offer competitive shipping rates due to their proximity to major ports, buyers must consider potential customs duties and taxes imposed by their respective countries. Additionally, after-sales service may vary across markets, and it is crucial to consider the availability of spare parts and technical support when purchasing a hollow brick making machine.

In conclusion, when comparing China with other hollow brick making machine markets, it is essential to carefully evaluate the product quality and price, as well as visible and hidden costs. China’s diverse manufacturing landscape offers a range of product quality, while its lower labor and production costs result in more affordable machines. However, buyers must consider factors like shipping, customs duties, and after-sales service to accurately assess the overall cost-effectiveness.

Understanding Pricing and Payment Terms for hollow brick making machine: A Comparative Guide to Get the Best Deal

When it comes to purchasing a hollow brick making machine, understanding pricing and payment terms is essential to ensure that you get the best deal. In this comparative guide, we will provide you with the necessary information to make an informed decision while adhering to the word limit of 300 words.

Pricing of hollow brick making machines can vary significantly depending on various factors such as the brand, capacity, and features. It is advisable to compare prices from different suppliers to get an idea of the average market price. However, keep in mind that the cheapest option may not always be the best in terms of quality and durability. Therefore, it is essential to strike a balance between price and machine performance.

Payment terms play a crucial role in finalizing a deal. Most suppliers offer flexible payment options, including full upfront payment, installment plans, or letters of credit. Full upfront payments provide the advantage of quicker delivery and sometimes even discounts. However, it is important to do thorough research on the supplier’s reputation and credibility before making such a payment.

Installment plans allow buyers to spread the cost over a certain period, making it more manageable for those with limited budgets. It is advisable to negotiate the terms and conditions of the installment plan, including the interest rate, duration, and down payment. This ensures that you receive favorable terms and are not burdened financially.

Letters of credit provide security for both the buyer and the supplier. It assures the supplier that they will receive payment upon fulfilling the agreed-upon terms and conditions, while also protecting the buyer’s interests.

Additionally, it is imperative to consider other costs associated with the purchase, such as shipping, installation, and after-sales services. Some suppliers include these costs within the machine’s price, while others charge them separately. Understanding these additional expenses will help you determine the total cost and make accurate comparisons between different suppliers.

In conclusion, understanding pricing and payment terms is crucial when purchasing a hollow brick making machine. It is advisable to conduct thorough research and compare prices from various suppliers. Additionally, evaluating payment options and considering other associated costs will help you negotiate the best deal that suits your budget and requirements.

Chinese Regulations and Industry Standards Certifications for hollow brick making machine,Import Regulations and Customs for hollow brick making machine from China

In China, the production and sale of hollow brick making machines are subject to various regulations and industry standards certifications. These regulations ensure the quality, safety, and compliance of the machines in the market.

One of the primary regulations is the National Standards for Construction Machinery. This standard sets the technical requirements for hollow brick making machines, including the specifications, performance, and safety features. Manufacturers need to meet these standards and obtain the relevant certifications before their products can be sold in the market.

Additionally, the China Compulsory Certification (CCC) is also required for hollow brick making machines. This certification is a mandatory requirement for products that may impact the safety of human life, property, or the environment. It ensures that the machines meet specific quality and safety standards and comply with the necessary technical requirements.

When importing hollow brick making machines from China, it is essential to comply with import regulations and customs procedures. Importers need to ensure that the machines meet the specific standards and certifications required by their country of import. They should consult with local authorities or seek the assistance of a customs broker to understand the specific requirements and procedures for the importation of construction machinery.

For customs clearance, importers need to provide relevant documents such as commercial invoices, packing lists, and bills of lading. They may also need to pay import duties, taxes, and other fees levied by their country’s customs regulations.

In summary, hollow brick making machines in China need to comply with national standards and obtain certifications such as CCC to ensure quality and safety. Importers should be aware of the import regulations and customs procedures in their country to facilitate a smooth importation process.

Sustainability and Environmental Considerations in hollow brick making machine Manufacturing

In recent years, there has been an increasing global concern about sustainability and environmental considerations in various industries, including the manufacturing sector. The hollow brick making machine manufacturing industry is no exception, and it is crucial for manufacturers to adopt sustainable practices to minimize their impact on the environment.

Efficient energy consumption is one of the key aspects of sustainability in hollow brick making machine manufacturing. Manufacturers can invest in energy-efficient equipment and optimize their production processes to minimize energy waste. This can be achieved by adopting advanced technologies, such as using energy-efficient motors, optimizing heating and cooling systems, and implementing smart control systems to regulate energy usage.

Another important consideration is the responsible management of waste and emissions. Manufacturers should implement proper waste management systems to reduce, reuse, and recycle production waste. This can be achieved through the adoption of circular economy principles, where waste materials are used as inputs for other processes. Additionally, implementing effective emission control measures, such as using filters and proper ventilation systems, can significantly reduce air pollution and contribute to a cleaner environment.

Water conservation is another crucial element of sustainability in hollow brick making machine manufacturing. Manufacturers should aim to reduce water usage by implementing water-efficient processes and recycling or treating wastewater. This can be achieved through the use of closed-loop water systems and the adoption of water-efficient technologies, such as low-flow fixtures and water-saving equipment.

Furthermore, sustainable sourcing of raw materials is essential in promoting environmental considerations in hollow brick making machine manufacturing. Manufacturers should evaluate their supply chains and prioritize suppliers that adhere to sustainable practices. This may involve sourcing raw materials from local or certified sustainable sources and ensuring responsible extraction and processing methods.

Lastly, manufacturers should prioritize product durability and longevity to reduce overall environmental impact. By producing high-quality and long-lasting hollow brick making machines, manufacturers can minimize the need for frequent replacements and thus reduce the environmental footprint associated with production and disposal.

In conclusion, sustainability and environmental considerations play a vital role in hollow brick making machine manufacturing. Through the adoption of energy-efficient practices, responsible waste management, water conservation, sustainable sourcing, and ensuring product durability, manufacturers can significantly reduce their environmental impact and contribute to a more sustainable future.

List The Evolution history of “hollow brick making machine”

The evolution history of the “hollow brick making machine” can be traced back to ancient times when humans first started constructing brick structures. Initially, bricks were handmade using molds or by manually shaping clay and then sun-drying or firing them. This primitive method was labor-intensive and time-consuming.

The first notable advancement in brick-making technology was the invention of the manual brick press in the 19th century. This press allowed for the production of bricks in a more standardized and efficient manner. However, it still required significant human effort.

In the early 20th century, the first mechanical brick press machines were developed. These machines utilized hydraulic pressure to compress the clay and produce bricks with enhanced strength and uniformity. The use of hydraulics significantly increased the speed and productivity of brick-making.

As the demand for bricks grew with urbanization and industrialization, there was a need for even more efficient brick-making machinery. In the mid-20th century, the fully automatic brick-making machine was introduced. These machines incorporated conveyor belts, automated clay feeding systems, and hydraulic presses with high production capacities. They greatly reduced the need for manual labor while increasing output.

In recent years, the evolution of hollow brick making machines has focused on enhancing energy efficiency, versatility, and automation. Modern machines are often equipped with computerized controls and sensors to optimize brick production and reduce material wastage. The introduction of robotics and artificial intelligence has also improved the precision and quality of hollow brick production.

Additionally, sustainable practices have been integrated into the design of brick-making machines. Some advanced models now have features like water recycling systems and energy-efficient motors, reducing the environmental impact of the manufacturing process.

Overall, the evolution of hollow brick making machines has been driven by the need for efficiency, productivity, and sustainability. From manual labor to automated processes, these machines continue to play a vital role in the construction industry, enabling the production of high-quality hollow bricks for various applications.

The Evolution and Market Trends in hollow brick making machine Industry

The hollow brick making machine industry has witnessed significant evolution and market trends in recent years. These developments can be attributed to various factors, including advancements in technology, changing market demands, and increasing focus on sustainability.

One major evolution in the industry is the introduction of automatic hollow brick making machines. These machines have greatly enhanced productivity and efficiency by automating various processes, such as raw material feeding, brick molding, and brick stacking. Automatic machines not only save labor costs but also ensure consistent quality and reduced human errors. Manufacturers are increasingly investing in these advanced machines to stay competitive in the market.

Another important trend in the hollow brick making machine industry is the growing demand for eco-friendly and sustainable manufacturing practices. With increasing environmental concerns, there is a shift towards using alternative materials in brick making, such as fly ash, slag, and recycled aggregates. This has led to the development of hollow brick making machines that are specifically designed to handle these materials. Additionally, manufacturers are incorporating energy-efficient technologies into their machines to reduce energy consumption and carbon emissions.

Market trends also indicate a rising demand for hollow bricks that offer superior thermal insulation and acoustic properties. These bricks are considered essential in constructing energy-efficient buildings that comply with stringent environmental regulations. As a result, manufacturers are focusing on developing hollow brick making machines that can produce bricks with precise dimensions and consistent quality, ensuring excellent insulation properties.

Furthermore, the market is witnessing increased customization and innovation in hollow brick making machines. Manufacturers are offering machines with modular designs that can be easily modified to produce different sizes, shapes, and patterns of bricks. This enables the production of unique and aesthetically appealing bricks, catering to the diverse needs of the construction industry.

In conclusion, the hollow brick making machine industry has undergone significant evolution driven by technology advancements, changing market demands, and environmental concerns. The introduction of automatic machines, the focus on sustainability, the demand for superior thermal insulation and acoustic properties, and the emphasis on customization and innovation are key trends shaping the industry. As the construction industry continues to evolve, the hollow brick making machine industry must adapt and innovate to meet the ever-changing demands of the market.

Custom Private Labeling and Branding Opportunities with Chinese hollow brick making machine Manufacturers

Chinese hollow brick making machine manufacturers offer a range of opportunities for custom private labeling and branding. These manufacturers are known for producing high-quality machines at competitive prices, making them an attractive option for businesses looking to expand their product line or start a new venture.

One opportunity is the ability to customize the machines with private labels and branding. This allows businesses to establish their own unique identity in the market and differentiate themselves from competitors. Chinese manufacturers can provide a variety of options for customizing the machines, such as adding the company logo, colors, and design elements. This helps businesses create a strong brand image and build customer loyalty.

Moreover, Chinese manufacturers often offer OEM (Original Equipment Manufacturer) services, allowing businesses to customize the machines based on their specific requirements. This includes making modifications to the machine’s functionalities, size, and capabilities to meet the unique needs of the business. By doing so, manufacturers can help businesses develop a unique product that caters to their target market.

In addition to private labeling and customization, Chinese hollow brick making machine manufacturers can also assist businesses in designing and developing their branding strategies. They can provide expert guidance and advice on branding elements such as packaging, marketing materials, and positioning in the market. This ensures that businesses can effectively communicate their value proposition and connect with their target audience.

Overall, partnering with Chinese hollow brick making machine manufacturers offers businesses an opportunity to customize their products, establish their own brand identity, and access high-quality machines at competitive prices. With their expertise and flexibility, these manufacturers can help businesses create a successful and unique product line in the hollow brick making industry.

Tips for Procurement and Considerations when Purchasing hollow brick making machine

When purchasing a hollow brick making machine, there are several considerations and tips that can help ensure a successful procurement process. Here are some important points to keep in mind:

1. Quality: Ensure that the machine is of high quality and built to last. Look for machines made from durable materials that can withstand the rigors of continuous brick production.

2. Capacity: Determine the required production capacity based on your needs. Consider factors such as the size of your project, the volume of bricks required, and the available space for installation.

3. Automation: Evaluate the level of automation offered by the machine. Fully automated machines can increase production efficiency and reduce labor costs.

4. Energy efficiency: Look for machines that are energy-efficient to minimize operational costs and contribute to sustainability efforts.

5. Maintenance and support: Consider the availability of spare parts, after-sales services, and technical support to ensure smooth operation and minimal downtime.

6. Cost-effectiveness: Compare prices from different suppliers and evaluate the value for money offered by each machine. Consider not only the upfront cost but also the long-term benefits and potential savings.

7. Reputation and reviews: Research the reputation of the supplier and read customer reviews to gauge their reliability and customer satisfaction.

8. Customization options: If specific brick sizes or shapes are required for your project, check if the machine can be customized to meet your specifications.

9. Training and operation: Ensure that the supplier provides adequate training for machine operation and maintenance to maximize productivity and minimize the risk of accidents or damage.

10. Safety features: Ensure that the machine is equipped with necessary safety features to protect operators during operation.

By considering these tips and taking into account the specific requirements and considerations mentioned above, you can make an informed decision when purchasing a hollow brick making machine.

FAQs on Sourcing and Manufacturing hollow brick making machine in China

Q: Can I source a hollow brick making machine in China?

A: Yes, China is a major manufacturing hub and offers a wide range of options for sourcing and manufacturing hollow brick making machines.

Q: What are the advantages of sourcing a hollow brick making machine from China?

A: Sourcing from China can provide cost-effective solutions as manufacturers often offer competitive prices due to low labor costs and economies of scale. China also has a vast supplier network, ensuring a wide selection of machines to choose from.

Q: How do I find a reliable manufacturer in China?

A: To find a reliable manufacturer, thorough research and due diligence are essential. Utilize online platforms, trade directories, and industry exhibitions to identify potential manufacturers. Verify their credentials, reputation, and quality control processes. It is also advisable to request samples for quality assessment before finalizing any transaction.

Q: Are there any risks associated with sourcing from China?

A: While sourcing from China can be advantageous, there are some risks to consider. These may include communication challenges due to language barriers, intellectual property concerns, and potential delays in production or shipping. Establishing clear contractual agreements, conducting quality inspections, and working with reputable third-party logistics providers can help mitigate these risks.

Q: Can I customize the hollow brick making machine according to my specific requirements?

A: Yes, many manufacturers in China offer customization options to meet individual requirements. However, it is important to communicate your specifications clearly and ensure that the manufacturer has the capability to fulfill them.

Q: What is the typical lead time for manufacturing a hollow brick making machine in China?

A: Lead times can vary depending on factors such as machine complexity, order quantity, and the manufacturer’s production schedule. It is advisable to discuss and agree on specific lead times with the manufacturer in advance.

Q: How can I ensure the quality of the hollow brick making machine?

A: Inspecting the manufacturer’s production facilities, requesting product samples, and conducting on-site quality inspections are effective ways to ensure the quality of the machine. Additionally, it is advisable to work with manufacturers who have relevant certifications and adhere to international quality standards.

Q: What are the payment terms for purchasing a hollow brick making machine from China?

A: Payment terms can vary depending on the manufacturer. Common options include a percentage deposit upon order confirmation, with the remaining balance payable before shipment. It is advisable to discuss and agree on payment terms, including any milestones or guarantees, with the manufacturer to ensure a mutually beneficial arrangement.

Q: Are there import duties or taxes to consider when importing a hollow brick making machine from China?

A: Import duties and taxes vary by country and should be researched and considered during the sourcing process. Consulting with a customs broker or import specialist can help navigate the applicable fees and regulations for your specific location.

Why contact sourcifychina.com get free quota from reliable hollow brick making machine suppliers?

Sourcifychina.com, as an online platform connecting international buyers with Chinese suppliers, offers sourcing and procurement services in various industries, including the hollow brick making machine industry. They may have obtained a free quota from reliable suppliers in order to attract potential customers and build trust among buyers.

There are several reasons why suppliers might offer a free quota to sourcifychina.com. Firstly, by partnering with a reputable platform like Sourcifychina.com, suppliers can gain exposure to a wider range of potential customers from around the world. This can contribute to increased market share, customer base, and ultimately, revenue. Offering a free quota enables suppliers to showcase their products to a larger audience and increase their chances of securing future business deals.

Secondly, the hollow brick making machine industry in China is highly competitive. There are numerous manufacturers and suppliers offering similar products, making it challenging for buyers to identify reliable and trustworthy suppliers. By providing a free quota, suppliers can establish themselves as credible and dependable partners, ensuring that buyers are more likely to consider their products for purchase.

Furthermore, by offering a free quota to sourcifychina.com, suppliers can gain insights into the global market demand and customer preferences. This information can help suppliers refine their products, enhance their production processes, and stay ahead of the competition. Suppliers can also use this opportunity to collect feedback and reviews from buyers, which can be valuable for improving their products and services.

In conclusion, sourcifychina.com may have received a free quota from reputable hollow brick making machine suppliers as a result of their established platform, which attracts international buyers. The incentives for suppliers to provide such quotas include increased exposure, market share, and customer base, as well as gaining insights into the global market and customer preferences. This mutually beneficial relationship allows buyers on sourcifychina.com to access reliable suppliers, while suppliers can expand their business globally.