Knowledge about Hydraulic Cutting Machine

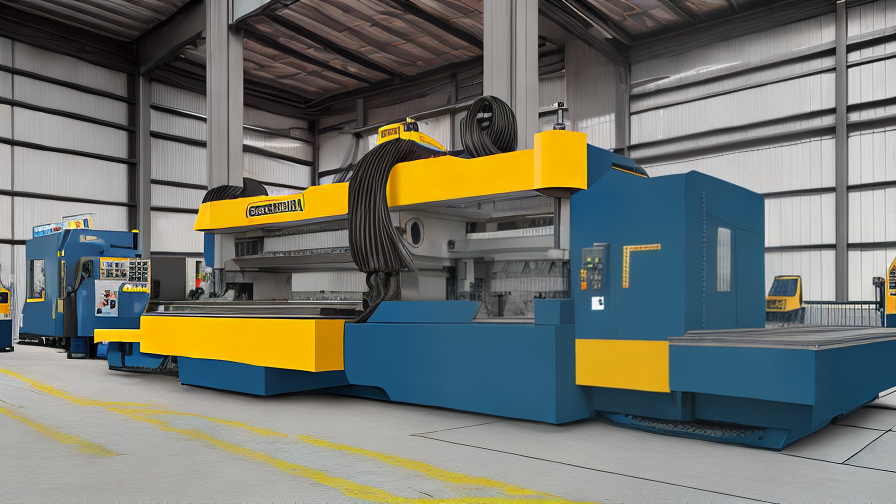

Hydraulic cutting machines are a type of machinery used in factories and workshops for cutting materials such as metal, leather, and even rubber. It uses hydraulic power to operate its cutting blades, allowing for efficient and precise cuts.

These machines come in various sizes and models, and the choice of the appropriate machine depends on the intended use and size of the materials being cut. They also come with various features such as the ability to adjust the cutting depth, feed speed, and pressure settings.

To operate the hydraulic cutting machine, one must first ensure proper safety measures such as wearing protective gear and verifying that the machine is functioning correctly. The materials being cut must also be secured properly to prevent accidents.

Maintaining the machine and its blades is vital to ensure that it operates smoothly and efficiently. Proper lubrication and cleaning of the machine after each use help prolong the lifespan of the machine and its parts.

It is essential to take note of the power requirements of the machine and to ensure that it is correctly plugged in and wired before use. It’s safer to have a professional set up the machine and conduct regular safety checks to avoid accidents.

In conclusion, knowledge about hydraulic cutting machines is essential for operators and individuals responsible for maintaining them. Understanding safety measures, proper maintenance practices, and how to operate the machine correctly can prevent accidents and prolong the machine’s lifespan.

Various Types of Hydraulic Cutting Machine

Hydraulic cutting machine is a versatile tool that is used in various industries like metalworking, automotive, textiles, and packaging. These machines are used to cut materials like metal sheets, leather, fabrics, paper, and plastics with precision and accuracy.

There are various types of hydraulic cutting machines available in the market that are used for different purposes. One of the most common types is the swing beam hydraulic cutting machine, which is used for cutting metals and plastics. It uses a hydraulic system to apply pressure on the material being cut, and a swing beam ensures uniform and accurate cutting.

Another type is the traveling head hydraulic cutting machine, which is used for cutting leather, rubber, and plastics. It has a head that moves forward and backward to cut the material, and the cutting pressure can be adjusted based on the thickness of the material.

The beam press hydraulic cutting machine is used for cutting multiple layers of materials like textiles, foam, and carpets. It uses a hydraulic-powered beam to press down on the material, and the cutting blade is mounted on the beam to ensure uniform cutting.

The CNC hydraulic cutting machine is a computer-controlled machine that is used for cutting complex shapes and patterns. It uses a hydraulic system to apply pressure and a computer to control the cutting process, making it ideal for cutting materials like metal plates and alloys.

Finally, the die-cutting hydraulic cutting machine is used for cutting materials like paper and cardboard. It uses a hydraulic-powered die to cut the material into shapes and patterns, and it is commonly used in the packaging and stationery industries.

In conclusion, hydraulic cutting machines are essential tools in various industries, and there are several types available to suit different requirements. These machines offer efficient, accurate, and precise cutting, making them a valuable investment for businesses looking to improve their productivity and workflow.

FAQ sourcing Hydraulic Cutting Machine manufacturer from China

FAQ sourcing Hydraulic Cutting Machine manufacturer from China with multiple answers

Hydraulic Cutting Machine is widely used in various industries for cutting different materials such as plastic, leather, and metal. China is known for its industrial manufacturing capabilities and is home to several Hydraulic Cutting Machine manufacturers. However, finding a reliable and suitable manufacturer can be a daunting task. Here are some frequently asked questions about sourcing Hydraulic Cutting Machine manufacturer from China.

Q: What should I consider when sourcing a Hydraulic Cutting Machine manufacturer in China?

A: When sourcing a manufacturer, it is pertinent to consider manufacturer’s reputation, production capacity, quality control, certification, and after-sales service.

Q: How do I know if a manufacturer is reputable?

A: You can check the manufacturer’s reputation by researching their company profile, reviews from previous customers, and their trading history.

Q: What is the production capacity of a typical Hydraulic Cutting Machine manufacturer in China?

A: The production capacity varies depending on the manufacturer size and their equipment capability. It is advisable to select a manufacturer that can meet your required production capacity.

Q: What is quality control?

A: Quality control refers to the measures taken by the manufacturer to ensure the quality of their products. It includes product inspection, testing, and certification.

Q: What is the importance of certification?

A: Certification is important because it ensures that the manufacturer’s product meets the required standards and regulations.

Q: Is after-sales service crucial when selecting a manufacturer?

A: Yes, after-sales service is crucial as it ensures that the manufacturer can provide technical support, training, and maintenance services to their customers.

In conclusion, sourcing a Hydraulic Cutting Machine manufacturer from China requires careful consideration of several factors. By conducting diligent research and asking the right questions, businesses can select a reliable and suitable manufacturer that will meet their production needs.

Applications of Hydraulic Cutting Machine

The hydraulic cutting machine is a device that uses hydraulic fluid to operate and is commonly used in a variety of industries. One of the most popular applications for the hydraulic cutting machine is in the manufacturing industry, where it is used for cutting a wide range of materials including metal, plastic, and even wood.

Another application of hydraulic cutting machines is in the construction industry. The hydraulic cutting machine can be used to cut through concrete and other tough materials, making it an essential tool in the construction of buildings and other structures.

In the automotive industry, the hydraulic cutting machine is used for cutting and shaping metal parts. It is also used in the production of car body panels, which require precise cuts and shapes.

The hydraulic cutting machine is also widely used in the packaging industry. It is used to cut various types of packaging materials such as cardboard, plastic, and paper. This application is especially important for industries that require precise cutting for packaging purposes, such as the food industry.

In the textile industry, hydraulic cutting machines are used to cut fabrics into various shapes and sizes. This is a crucial process as it allows manufacturers to create tailored clothing and other textile products.

Finally, the hydraulic cutting machine is also used in the woodworking industry, where it is used to cut and shape wood. This application is essential for creating unique wooden designs and furniture pieces.

In conclusion, the hydraulic cutting machine has a wide range of applications across various industries. Its ability to cut through various materials with precision and control makes it an essential tool for many manufacturing, construction, automotive, and packaging businesses.

Manufactured Products made of Hydraulic Cutting Machine

Hydraulic cutting machines are a powerful tool in the manufacturing industry, capable of cutting and shaping a variety of materials with speed and precision. The products made of this machine are wide-ranging and widespread, from auto parts to construction materials, and even household appliances.

One industry that heavily relies on hydraulic cutting machines is the automotive industry, where the machines can cut and shape metal sheets for car bodies, engine parts, and other components. The precision of hydraulic cutting machines ensures that each part produced is uniform in size and shape, reducing defects and increasing safety.

The construction industry also makes use of hydraulic cutting machines for producing building materials such as concrete slabs, tiles, and bricks. These machines can cut and shape materials with exceptional accuracy, resulting in precise and efficient manufacturing processes. Additionally, hydraulic cutting machines can be used to shape materials like PVC and polymers, creating plumbing fixtures and other construction-related products.

Another area where hydraulic cutting machines excel is in the production of household goods. These machines can cut and shape materials such as foam and textiles, producing products like furniture cushions, upholstered goods, and even clothing. The precision of the machine results in goods that are perfectly sized, making them ready for use in household items.

In conclusion, hydraulic cutting machines have become an indispensable tool for many industries ranging from automotive to household goods. The products made from hydraulic cutting machines are wide-ranging, covering everything from car parts to building materials and much more. With their high speed and accuracy, hydraulic cutting machines continually revolutionize the manufacturing industry, enabling the creation of more efficient and precise products.

The Evolution history of Hydraulic Cutting Machine

Hydraulic cutting machines have come a long way since the early 20th century. Initially used for cutting leather and fabric, the machines have evolved to cut through a variety of materials, including metal and plastic.

The first hydraulic cutting machines were manual, requiring a worker to manually operate the levers and blades. However, with the advent of electric power, the machines became motorized, reducing the need for manual labor.

In the 1950s, computer-controlled hydraulic cutting machines were introduced. These machines were able to cut complex shapes with high precision, making them ideal for use in the automobile and aerospace industries.

As technology developed, hydraulic cutting machines became more versatile, allowing for the cutting of thicker materials and the use of multiple cutting heads at once. Additionally, the introduction of laser cutting technology has made it possible to cut through even harder materials like titanium and steel.

Today, hydraulic cutting machines are used in a variety of industries, including construction, manufacturing, and transportation. They are used for cutting materials ranging from paper and plastic to metal and stone.

In conclusion, the evolution of hydraulic cutting machines has been crucial to the advancement of many industries. From manual to motorized, from computer-controlled to laser-assisted, hydraulic cutting machines have continued to prove their worth as vital tools for cutting through a wide range of materials quickly and accurately.

The Process of Hydraulic Cutting Machine

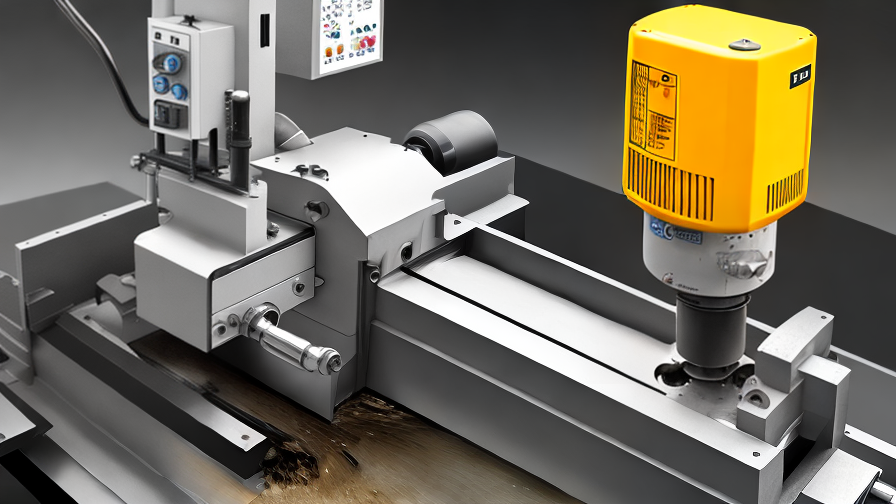

Hydraulic cutting machines are an essential tool in many industries, including manufacturing, construction, and metalworking. The process of hydraulic cutting involves using pressurized fluid to power a cutting tool that can slice through a wide range of materials.

The first step in the process of hydraulic cutting is to select the proper tool for the job. This may include a variety of blades or cutters designed to work with specific materials, including metal, plastic, and wood. Once the proper tool has been selected, it is attached to the hydraulic cutting machine.

Next, the machine is powered on and the material to be cut is secured in place. The hydraulic system is then activated, which pressurizes the fluid and powers the cutting tool. As the tool moves across the material, it creates a clean and precise cut, leaving smooth edges that require no further finishing.

One key advantage of hydraulic cutting machines is their versatility. They can be used for a variety of cutting tasks, from slicing through metal pipes to trimming insulation materials. Additionally, hydraulic cutting machines require minimal operator input, as they are designed to be easy to use and highly efficient.

Overall, the process of hydraulic cutting is a highly effective and efficient method for slicing through a variety of materials. Whether you are a manufacturer, a construction professional, or a metalworking enthusiast, hydraulic cutting machines can help you achieve your goals quickly and easily. With their ability to deliver precise, clean cuts every time, these machines are a must-have tool for anyone looking to streamline their cutting processes and achieve superior results.

Benefits Advantages of Utilizing Hydraulic Cutting Machine

Hydraulic cutting machine is a versatile and efficient tool that converts hydraulic pressure into mechanical energy to cut and shape different materials. This machine has gained popularity in industrial applications due to its numerous benefits. In this article, we will discuss the advantages of utilizing hydraulic cutting machines.

Firstly, the hydraulic cutting machine is highly efficient and faster compared to manual cutting methods. It can handle heavy cutting tasks and deliver precise and accurate cuts in a short time. This feature makes it an essential tool in industries that require high-speed production such as automotive, aerospace, and construction.

Secondly, the hydraulic cutting machine is highly versatile, and it can cut through various materials such as metals, plastics, and composites. This feature makes it a cost-effective tool, as it eliminates the need to purchase several different cutting machines to handle each material.

Thirdly, hydraulic cutting machines are highly reliable and easy to operate. They require minimal maintenance and can run continuously for extended periods, reducing downtime and production costs.

Fourthly, hydraulic cutting machines offer excellent cutting precision and accuracy. This feature makes them ideal for creating intricate designs and shapes for various products, including automotive parts, aircraft components, and architectural designs.

Finally, hydraulic cutting machines offer high-level safety features. They feature emergency stop buttons and safety guards that protect operators from potential hazards, reducing the risk of injuries and accidents in the workplace.

In conclusion, hydraulic cutting machines offer numerous advantages that make them essential tools in various industries. They are highly efficient, versatile, reliable, easy to operate, precise, and offer excellent safety features. Their ability to handle heavy-duty cutting tasks and deliver precise cuts in a short time makes them highly cost-effective tools for industrial use.

Disadvantages Hydraulic Cutting Machine

Hydraulic cutting machines have become a popular choice for many industries due to their precision and ease of use. However, they also come with their own set of disadvantages that manufacturers and users need to consider. Here are some of the disadvantages of hydraulic cutting machines.

First and foremost, hydraulic cutting machines are often more expensive than their mechanical counterparts. The cost of the hydraulic system used in these machines adds a significant premium to the price. This can be a limiting factor for small businesses and startups that are looking to minimize their initial investment.

Another disadvantage of hydraulic cutting machines is their dependence on hydraulic fluid. Leaks or spills of hydraulic fluid can cause damage to the environment and even pose health risks to workers. Such spills can be challenging to clean up, and the cost of disposing of the contaminated fluid can add up.

Furthermore, hydraulic cutting machines also require a high level of maintenance to ensure they are running at optimal performance. This maintenance can be both costly and time-consuming, especially if parts need to be replaced or repaired. Failure to maintain hydraulic machines can result in unscheduled downtime and costly repairs.

Finally, hydraulic cutting machines can also be a safety concern as they operate using high-pressure hydraulic fluid. Any malfunction or mishandling can lead to serious injuries, and the risk of injury can be further increased if operators are not adequately trained.

In conclusion, while hydraulic cutting machines offer convenience and precision, they also come with their own set of disadvantages. These include high upfront costs, reliance on hydraulic fluid, high maintenance requirements, and safety concerns. Businesses considering hydraulic cutting machines must weigh these factors against the benefits of such machines before making a final decision.

Selecting the Ideal Manufacturer Hydraulic Cutting Machine

When selecting a hydraulic cutting machine, there are several factors to consider to ensure you choose the ideal manufacturer. Here are some of the key things to consider when making your decision.

Firstly, you should consider the reputation of the manufacturer. Look for companies that have been in the business for several years and have a proven track record of producing quality machines. Reading customer reviews can also help you get an idea of the company’s history of customer service and satisfaction.

Secondly, consider the specific requirements of your business. You need to choose a hydraulic cutting machine that is suited to your particular application. Look for manufacturers that offer a variety of machines with different functionalities and specifications, so you can choose the one that best fits your needs.

Another important consideration is after-sales support. Make sure the manufacturer provides adequate support and maintenance services, as this will help ensure your machine keeps running smoothly and avoid costly repair bills down the line.

Finally, cost is always a crucial factor when purchasing any machinery. Do not always be tempted by the cheapest option, as it may not always be the most cost-effective in the long run. A more expensive machine may be more durable and require less maintenance, which can save you money in the long-term.

In conclusion, selecting the ideal manufacturer hydraulic cutting machine requires careful consideration of factors such as reputation, specific business requirements, after-sales support, and cost. By taking these factors into account, you can be confident that you are purchasing a high-quality hydraulic cutting machine that will serve your business for years to come.

Things to Consider When Purchasing Hydraulic Cutting Machine

Hydraulic cutting machines have become an essential industrial tool for many industries. They are capable of cutting a wide range of materials like plastic, metal, foam, and others. With the help of hydraulic cutting machines, manufacturers can increase their production capacity, precision and efficiency. However, with so many options available, it can be overwhelming to choose the right one. Here are some things to consider when purchasing a hydraulic cutting machine.

Cutting Capacity: It is essential to consider the cutting capacity of the machine before purchasing it. The machine’s cutting capacity should match the size and thickness of the material you plan to cut. This will ensure that you get the desired results and won’t damage the machine.

Accuracy: Accuracy is another factor that you should consider when purchasing a hydraulic cutting machine. A good machine should offer precise cutting and ensure that the cuts are uniform throughout the material. The machine should also have adjustable cutting width to cater to different materials.

Ease of Use: The hydraulic cutting machine should be easy to operate, even for operators with little experience. It should have clearly labeled controls and be intuitive to use. Some machines may require special training, which could increase training costs and operator fatigue.

Safety: Safety should be a top priority when purchasing a hydraulic cutting machine. The machine should have safety features like emergency stop buttons and safety guards. Additionally, the machine’s safety features should be easy to identify and operate.

Price: Last but not least, you should consider the price of the hydraulic cutting machine. The machine should fit within your budget and offer good value for money. Good machines may cost more but offer better quality and longevity.

In summary, consider the cutting capacity, accuracy, ease of use, safety features and price when purchasing a hydraulic cutting machine. These factors will help you choose a machine that suits your needs and assures longevity.

Properties of Hydraulic Cutting Machine

A hydraulic cutting machine is a device that uses hydraulic power to cut various materials such as wood, plastic, metal, and others. The machine is equipped with a hydraulic system that provides power to the cutting blade, which gives it the ability to cut through the toughest materials.

Some notable properties of hydraulic cutting machines include:

1. High precision: Hydraulic cutting machines are known for their precision cuts. The hydraulic system provides a constant and steady force to the blade, which ensures that the cut is consistent and accurate.

2. Speed: Hydraulic cutting machines are also known for their high cutting speed. The machine’s ability to provide a constant force to the blade enables it to cut through materials quickly, which can save time and increase productivity.

3. Safety: Compared to other cutting machines, hydraulic cutting machines are generally considered to be safer. The hydraulic system provides a more controlled and stable cutting force, which reduces the risk of accidents or injuries.

4. Durability: The hydraulic cutting machine is designed to be robust and long-lasting. The hydraulic system is built to withstand heavy loads and constant use, which makes the machine ideal for industrial applications.

5. Flexibility: The hydraulic cutting machine can cut through a variety of materials, including wood, plastic, metal, and others. The machine’s blade can also be adjusted to different angles and heights, which makes it more versatile for different cutting needs.

In conclusion, the hydraulic cutting machine is a reliable device that can make cutting tough materials easier and more efficient. Its properties of precision, speed, safety, durability, and flexibility make it a valuable investment for businesses that require consistent and accurate cutting.

How to use Hydraulic Cutting Machine

Hydraulic cutting machines are an essential tool for cutting various types of materials. They are commonly used in machining, metalworking, and fabrication industries. Proper use of a hydraulic cutting machine is crucial in ensuring safety and achieving precise cuts.

Before operating the hydraulic cutting machine, it is imperative to conduct a safety check to ensure that all the components are in good working condition. The operator should ensure that the machine is appropriately grounded, and there are no flammable substances nearby.

Once the safety check is complete, the operator should insert the material to be cut into the machine. The hydraulic cutting machine applies a significant amount of force to cut through the material, and it is essential to ensure that the material is securely held in place.

The operator should then adjust the cutting speed and pressure to suit the material being cut. The cutting speed and pressure can be adjusted using the machine’s control panel. It is essential to use the correct settings to achieve precise cuts and prevent damage to the machine.

During the cutting process, the operator should keep a safe distance from the machine and avoid placing their hands near the cutting area. The machine’s safety guard should always be engaged to prevent debris from flying out during the cutting process.

Once the material is cut, the operator should switch off the machine and remove the cut piece. It is essential to clean the machine after use and ensure that it is stored in a dry and secure place.

When using a hydraulic cutting machine, safety is a top priority. Always wear appropriate safety gear, such as gloves and safety glasses, and follow the manufacturer’s instructions for safe operation. With proper use, a hydraulic cutting machine can be a versatile and reliable tool for cutting various materials accurately and efficiently.

Glossary Terminology Terms for Hydraulic Cutting Machine

A hydraulic cutting machine is a piece of equipment that uses hydraulic pressure to cut materials, such as metal, plastic, and rubber. It is commonly used in manufacturing and fabrication industries for precision cutting. To understand the terminology used in hydraulic cutting machines, here is a glossary of terms:

1. Hydraulic pump: a device that converts mechanical energy into hydraulic energy, which is used to power the hydraulic cutting machine.

2. Hydraulic cylinder: a mechanical actuator that converts hydraulic energy into mechanical force to move the cutting blade.

3. Cutting blade: a sharp tool attached to the hydraulic cylinder that cuts through the material being processed.

4. Cutting force: the amount of force applied by the cutting blade to the material being cut.

5. Control valve: a device that controls the flow of hydraulic fluid to the hydraulic cylinder.

6. Hydraulic fluid: a liquid used to transmit power in hydraulic systems.

7. Pressure gauge: a device that measures the pressure of the hydraulic fluid from the hydraulic pump.

8. Cutting capacity: the thickness and type of material that a hydraulic cutting machine can cut.

9. Feed rate: the speed at which the cutting blade moves through the material being processed.

10. Back gauge: a mechanical stop that positions the material being cut to a specific length.

11. Foot pedal: a device that activates the hydraulic cutting machine when pressed.

12. Blade clearance: the distance between the cutting blade and the material being cut.

13. Stroke limit: the maximum distance that the hydraulic cylinder can move the cutting blade.

14. Manual override: a feature that allows the operator to manually control the hydraulic cutting machine in case of a malfunction.

Understanding the terminology used in hydraulic cutting machines is essential to ensure safe and efficient operation. By familiarizing oneself with these terms, it simplifies communication between the manufacturer, operator, and maintenance personnel for troubleshooting and maintenance purposes.

Hydraulic Cutting Machine Price

Hydraulic cutting machine, also known as hydraulic press cutting machines, is widely used in various industries for precise cutting of different materials such as steel, plastics, rubber, and even fabric. The price of a hydraulic cutting machine is crucial when purchasing one.

Various factors can influence the hydraulic cutting machine price, such as the cutting capacity, precision, and speed. Therefore, one must opt for a hydraulic cutting machine that meets specific requirements and features, including the cutting length and thickness, tonnage, motor power, and cutting force.

The prices of hydraulic cutting machines range from $1000 to $50,000 or more, depending on the factors mentioned above. The most basic models available in the market can cost around $1000 to $5000, while industrial hydraulic cutting machines with more features and capabilities start from $10,000 and exceeding up to $50,000.

When buying a hydraulic cutting machine, it is crucial to consider its quality and reliability in the long run, to avoid significant maintenance expenses. The price is not everything, and one should not compromise on quality and durability for a cheaper hydraulic cutting machine.

Furthermore, additional costs, such as various customizations, after-sale service, and warranty, can also affect the total cost of a hydraulic cutting machine.

To make an informed decision when purchasing a hydraulic cutting machine, one should research and compare different brands and models available in the market. This will help find the best value for money hydraulic cutting machine, that meets specific requirements and performance expectations.

In conclusion, the price of hydraulic cutting machines can vary depending on the features and capabilities. One should always consider the quality, durability, and additional costs when making a purchase. A wise investment in a high-quality hydraulic cutting machine can offer significant benefits in the long run.