Benefits of Hydraulic Press Cylinder

Hydraulic press cylinders are mechanisms that use hydraulic pressure to create force in order to move and compress materials. They have numerous benefits that make them a popular choice in various industries.

First and foremost, hydraulic press cylinders are extremely versatile. They can be used in a wide range of applications, from industrial manufacturing to car repair. They can be used to compress and shape materials, lift heavy weights and move large objects. They are also used in the construction of industrial machines, such as hydraulic presses and excavators.

Hydraulic press cylinders are also highly efficient. They can generate a high amount of pressure using a relatively small amount of force, which makes them ideal for applications that require a lot of power. They are also energy-efficient, as they do not require much electricity or fuel to run.

Another benefit of hydraulic press cylinders is their durability. They are designed to withstand high levels of pressure and wear and tear, which means they require less maintenance and can last for many years. This is especially important in industrial applications, where machinery needs to be reliable and efficient to maintain productivity.

Hydraulic press cylinders also offer precise control and accuracy. They can be easily controlled and adjusted to achieve the desired level of force and pressure. This makes them ideal for applications that require precise positioning and pressure control.

Finally, hydraulic press cylinders are safe to use. They have built-in safety features, such as pressure relief valves, that prevent them from exceeding their capacity and causing accidents. They are also designed to minimize the risk of fluid leaks and other hazards.

In conclusion, hydraulic press cylinders offer numerous benefits that make them a popular choice in various industries. They are versatile, efficient, durable, precise, and safe to use. With their ability to generate high levels of force with minimal effort, they are a must-have for any manufacturing or construction application.

Features of Hydraulic Press Cylinder

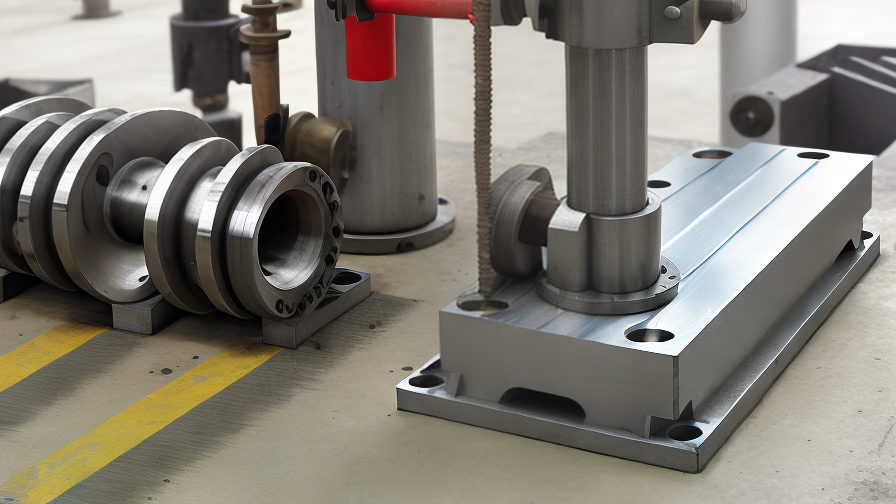

Hydraulic press cylinders are an integral component of hydraulic presses, and they play a crucial role in press operations. The cylinder’s structure can vary depending on the job requirements, but they must have a sturdy design to withstand the high pressures involved in hydraulic press operations. In this article, we will discuss the significant features of hydraulic press cylinders.

Pressure Capacity: The cylinders are designed to handle high pressures. They can create a compression force of up to 10,000 psi, allowing them to press thick and heavy plates smoothly. The pressure cap can vary depending on the cylinder’s size, but in general, they can handle a broad range of pressure requirements.

Construction: The hydraulic cylinders are designed with high-grade materials, such as sturdy steel alloys, to ensure strength and durability. To prevent corrosion, rust, and wear, the cylinders are coated with substances that are resistant to friction and oxidation.

Size and Shape: The design of hydraulic press cylinders varies according to the intended use. Depending on the needs of the industry, the cylinders come in a range of shapes, sizes, and pressures.

Stroke Length: The stroke length refers to the distance the piston can travel. The stroke length of a hydraulic press cylinder varies depending on the application. The stroke can be extended or shortened for different projects to provide the necessary range to get the job done.

Ease of Installation: One of the important features of hydraulic press cylinders is that they are simple to install. They can be easily bolted onto the work station, so you can quickly install and remove them to complete a project.

Conclusion:

Hydraulic press cylinders play a crucial role in hydraulic press operations, and their features are what make them reliable and versatile. The pressure capacity, construction, size and shape, stroke length, and ease of installation are some of the most significant features of hydraulic press cylinders. Because hydraulic press cylinders are essential components in the hydraulic press, they must be reliable, robust, and designed to endure extreme pressure, and the features discussed in this article provide these qualities.

Various Types of Hydraulic Press Cylinder

Hydraulic press cylinders are essential components of hydraulic press machines that generate substantial force when they operate. There are several types of hydraulic press cylinders that users can choose from, depending on the intended use and specific requirements of the application.

One of the most popular types of hydraulic press cylinders is the single-acting cylinder, which uses hydraulic pressure to extend in one direction and relies on an external force, such as gravity, to retract. This type of cylinder is used in applications that require a high force output in one direction, such as in stamping and punching machines.

Another popular hydraulic press cylinder is the double-acting cylinder, which uses hydraulic pressure to extend and retract in both directions. This type of cylinder is used in applications that require a high force output in both directions, such as in metal-forming machines and forging presses.

Telescopic cylinders are another type of hydraulic press cylinder that is commonly used in long-range applications, such as in dump trucks and cranes. These cylinders have a series of nested barrels that can extend and retract to different lengths to achieve the desired range.

Heavy-duty hydraulic press cylinders, on the other hand, are designed to handle extreme loads and are commonly used in mining, construction, and other heavy industries. These cylinders have a larger diameter and thicker walls to withstand the high pressures and force outputs required in these applications.

Finally, there are custom hydraulic press cylinders, which are designed and built to meet specific requirements and unique applications. These cylinders may have customized dimensions, pressure capacities, and force outputs to suit the specific needs of the user.

In conclusion, hydraulic press cylinders come in various types and designs, each with its own unique features and applications. By understanding the specific requirements of a particular application, users can choose the appropriate type of cylinder to ensure optimal performance and reliability of hydraulic press machines.

Applications of Hydraulic Press Cylinder

Hydraulic press cylinders are an essential component of hydraulic press machines. With the help of hydraulic press cylinders, the hydraulic press machines can generate tremendous force required for various applications. Hydraulic press cylinders are made of high-quality materials like steel, aluminum, and cast iron, which makes them durable and long-lasting.

Applications of hydraulic press cylinders are numerous. Here are a few examples:

1. Sheet Metal Stamping: The hydraulic press cylinders are used to stamp and form sheet metal into various shapes and sizes. The machine generates high-pressure force, which helps to shape and cut the metal sheets.

2. Rubber Vulcanization: Rubber vulcanization is a process of heating up the rubber to make it more durable and elastic. Hydraulic press cylinders press the rubber sheets tightly and apply heat to the rubber to create a durable and robust end product.

3. Plastic Molding: Hydraulic press cylinders play a critical role in the plastic molding process. The machine uses high-pressure force to mold and shape the plastic material into different structures, including water bottles, car parts, and other plastic-based materials.

4. Baling: Hydraulic press cylinders are used in baling machines to compact and compress waste material. The machines use high-pressure force to make large blocks of waste material, which can then be transported to waste management facilities.

5. Forging: Forging is a process of shaping the metal by hammering it under high pressure. Hydraulic press cylinders provide the required force to shape the metal and create the desired shape and structure.

Conclusion:

Hydraulic press cylinders are versatile machines used in various industrial applications. They are an essential component of hydraulic press machines as they provide the required force to shape and form materials. From sheet metal stamping to plastic molding and rubber vulcanization, hydraulic press cylinders are used in various applications to create durable and long-lasting end products.

The Process of Hydraulic Press Cylinder

Hydraulic press cylinders are widely used in various industries for performing heavy operations such as compression, forming, and punching. The process of a hydraulic press cylinder is quite simple yet effective. It works on the principle of Pascal’s Law. The force applied to a liquid (in this case, hydraulic oil) in a closed container gets distributed uniformly in all directions.

In the hydraulic press cylinder, a piston is placed inside a cylinder that is filled with hydraulic oil. The cylinder has an inlet port and an outlet port fitted with valves. The inlet port is connected to a hydraulic pump, while the outlet port is connected to a hydraulic motor. When the pump starts, it creates pressure and sends hydraulic oil through the inlet port, which pushes the piston down.

Due to Pascal’s Law, the force applied to the hydraulic oil gets distributed to the piston surface area, causing it to move downward with great force. The hydraulic oil then flows back through the outlet port to the hydraulic motor, completing the cycle.

The pressure and force exerted by the hydraulic press cylinder can be controlled by adjusting the pump flow rate and the valve settings. This allows for precise control over the speed of operation and the force applied.

To ensure the smooth operation and long life of a hydraulic press cylinder, it should be made of high-quality materials that are resistant to wear and tear. Additionally, regular maintenance and inspections should be carried out to identify any wear and tear, leaks or defects, and address them promptly.

In conclusion, the process of a hydraulic press cylinder is a simple yet effective way to perform heavy operations. It is widely used in industries such as manufacturing, construction, and automotive. Proper maintenance, high-quality materials, and precise control ensure efficient operation and long life.

How to use Hydraulic Press Cylinder

A hydraulic press cylinder is a powerful device that can generate a significant amount of pressure to perform various tasks. It works by converting the energy from hydraulic fluid into mechanical force to perform tasks such as pressing, stamping, punching, and bending. Here are some tips on how to use a hydraulic press cylinder effectively and safely.

Step 1: Preparation

Before using the hydraulic press cylinder, you should ensure that it is in good working condition. Check for any damage or leaks in the hydraulic system, hoses, and seals. Make sure the pressure gauge and relief valve are working correctly before operating the machine.

Step 2: Adjusting the Pressure

To use the hydraulic press cylinder, you should first adjust the pressure of the hydraulic fluid to the desired level. Ensure that the pressure does not exceed the maximum pressure capacity of the machine. You can adjust the pressure using the pressure control valve or the pressure relief valve.

Step 3: Placing the Object to be Pressed

Carefully place the object you want to press onto the bed of the hydraulic press cylinder. You should ensure that the object is centrally aligned with the cylinder to prevent accidents. Make sure that the object is secured in place and cannot move during the pressing process.

Step 4: Pressing the Object

When you are ready to start pressing the object, you should turn on the machine and slowly pump the hydraulic fluid into the cylinder. As the pressure increases, you will see the object start to compress. Monitor the pressure gauge to ensure that you do not exceed the maximum pressure limit.

Step 5: Releasing the Pressure

After pressing the object, you should slowly release the pressure by opening the release valve. This will allow the hydraulic fluid to flow back into the reservoir, and the press bed will move back into its original position. You can then remove the compressed object from the bed.

In conclusion, hydraulic press cylinders are powerful tools that can be used for various applications. However, it is important to follow the manufacturer’s instructions carefully to ensure that you use the machine safely and effectively. Always check the machine’s maintenance schedule, wear personal protective equipment (PPE), and stay alert while operating the machine.

Selecting the Ideal Manufacturer Hydraulic Press Cylinder

When it comes to selecting the ideal manufacturer hydraulic press cylinder, the key is to choose a company that has a proven track record for quality, reliability, and expert craftsmanship. With so many manufacturers offering hydraulic press cylinders on the market today, it can be overwhelming to choose the right one for your needs. Here are a few things to keep in mind when selecting a manufacturer for your hydraulic press cylinder:

Firstly, ensure that the manufacturer has a solid reputation in the industry. Do your research, read customer reviews, and ask for references. A reliable manufacturer will be happy to provide you with past client testimonials and references to show that they can deliver quality hydraulic press cylinders that meet your needs and requirements.

Secondly, choose a manufacturer that has a strong understanding of hydraulic press technology. Hydraulic press cylinders can vary widely in design and construction, so it’s important to work with a manufacturer that has experience and knowledge in the industry. The manufacturer should be able to provide you with expert advice and recommendations on the best hydraulic press cylinder for your specific application.

Thirdly, look for a manufacturer that offers customization options. Every hydraulic press application is unique, and a one-size-fits-all approach may not be the best solution. A good hydraulic press cylinder manufacturer should be able to provide you with customizable options and features that meet your specific requirements.

Lastly, make sure the manufacturer offers excellent customer service and support. Hydraulic press cylinders are complex machines, and you’ll need a manufacturer that can provide you with ongoing support, maintenance, and repair services if needed. The manufacturer should be responsive, knowledgeable, and willing to help you address any issues or concerns that arise.

In conclusion, selecting the ideal manufacturer hydraulic press cylinder requires careful consideration and research. By doing your due diligence and working with a reliable, experienced manufacturer, you can ensure that you get a high-quality hydraulic press cylinder that meets your precise specifications and delivers reliable performance long-term.

list FAQ with answer about Hydraulic Press Cylinder

A hydraulic press cylinder is an essential component in many industrial and commercial processes. It is designed to convert fluid power into linear mechanical force. If you have questions about this component, this article will provide you with answers to the most frequently asked questions.

1. How does a hydraulic press cylinder work?

A hydraulic press cylinder works by converting hydraulic pressure into mechanical force. When fluid is applied to one end of the cylinder, it pushes a piston, which moves a load on the other end.

2. What are the types of hydraulic press cylinders?

Hydraulic press cylinders come in three types: single-acting, double-acting, and telescopic. Single-acting cylinders have one port, while double-acting cylinders have two ports. Telescopic cylinders are used when a long stroke is required.

3. How do I choose the right hydraulic press cylinder?

Choosing the right hydraulic press cylinder depends on the application. The key factors to consider include the size and weight of the load, the required force, and the speed of the operation.

4. What are the maintenance requirements for hydraulic press cylinders?

Maintenance requirements for hydraulic press cylinders include regular cleaning and lubrication. Additionally, ensure that the hydraulic fluid is clean and topped up to prevent damage to the cylinder.

5. What are the safety precautions I should take when using hydraulic press cylinders?

When using hydraulic press cylinders, it is essential to follow safety precautions, including wearing protective gear, ensuring that the load is stable, and avoiding overloading the cylinder. Regular inspection and maintenance are also crucial for safety.

In conclusion, hydraulic press cylinders are essential components in many industrial applications. Understanding how they work, choosing the right type, and maintaining them properly can ensure that they perform efficiently and safely.

Things to Consider When Purchasing Hydraulic Press Cylinder

Hydraulic press cylinders are essential for a range of industrial applications that require high precision. When purchasing a hydraulic press cylinder, there are several things to consider to ensure that the equipment meets your needs effectively.

First, you need to determine the application of the hydraulic cylinder to determine the type, size, and specifications. Factors such as pressure range, stroke length, and bore diameter are essential to match the equipment’s requirements to the machine’s expectations.

Second, consider the quality and durability of the hydraulic press cylinder you are planning to purchase. A high-quality hydraulic press cylinder is built to withstand the pressures required for your application, is reliable, and has a long lifespan.

Third, consider the cost of the hydraulic press cylinder as well as any additional equipment that may be required, such as a pump, motor, hoses, and fittings. Always ensure that you get the best value for your money without sacrificing quality.

Fourth, consider the brand and reputation of the manufacturer of the hydraulic press cylinder. Select a manufacturer with a solid reputation for manufacturing durable and high-quality hydraulic cylinders.

Fifth, consider the type of hydraulic fluid that the press cylinder requires. Ensure that you use the recommended hydraulic fluid and oil that meets the manufacturer’s specifications for optimal performance.

Sixth, consider the safety features associated with the hydraulic press cylinder. Ensure that it has safety features such as pressure relief valves or overpressure protection that prevent accidents or damage to the equipment.

In conclusion, purchasing the right hydraulic press cylinder is essential to ensure the efficiency, safety, and longevity of your industrial operations. Always consider the type, quality, cost, manufacturer, hydraulic fluid, and safety features before making your purchase decision.

Properties of Hydraulic Press Cylinder

A hydraulic press cylinder is a crucial component in any hydraulic press system. It is responsible for converting the hydraulic pressure generated by the system’s hydraulic fluid into mechanical force. There are several crucial properties of hydraulic press cylinders that make them suitable for various applications.

Firstly, hydraulic press cylinders are highly durable and resistant to wear and tear, thanks to their strong construction. They are typically made of high-strength materials such as steel or alloy, which can resist the high pressure and forces generated by the hydraulic system.

Secondly, hydraulic press cylinders are highly efficient at converting hydraulic pressure into mechanical force. This efficiency is due to their design, which allows for the transfer of pressure from the hydraulic fluid to a piston, which in turn generates a mechanical force.

Thirdly, hydraulic press cylinders are highly versatile and can be used in a wide range of applications. They come in various sizes, shapes, and configurations, making them suitable for applications like metal stamping, forging, drawing, and many more. Besides, they can be easily customized to meet specific operational requirements.

Fourthly, hydraulic press cylinders are highly reliable and require minimal maintenance. They can operate for prolonged periods without the need for frequent checks or repairs. This is because they are designed to withstand the high forces and stringent conditions of the hydraulic press system.

Lastly, hydraulic press cylinders are highly safe to use. They come with safety features such as limit switches, pressure relief valves, and locking mechanisms, which reduce the risk of accidents and injuries while operating the hydraulic press system.

Conclusion

Overall, hydraulic press cylinders are essential components in any hydraulic press system. Their properties of durability, efficiency, versatility, reliability, and safety make them highly suitable for various applications. Therefore, it is crucial to consider these properties when selecting a hydraulic press cylinder for a particular use.

Technical Parameters Terms for Hydraulic Press Cylinder

Hydraulic press cylinders are used to generate and apply force in various industrial applications. Technical parameters are used to specify the characteristics of hydraulic press cylinders. These parameters are crucial as they help in selecting the right type of cylinder for the intended application.

One of the most important technical parameters for a hydraulic press cylinder is its bore. Bore describes the diameter of the cylinder’s inner surface. The bore size influences the amount of force the cylinder can produce as well as the speed at which the cylinder can move.

Another important technical parameter is stroke length. Stroke length refers to the distance the cylinder’s piston is capable of moving up and down. This parameter is crucial as it determines the amount of work the cylinder can perform in a single cycle.

The next parameter is operating pressure, which is the maximum pressure that the cylinder can sustain without damage. This parameter is crucial in specifying the right cylinder as it can vary depending on the intended application.

Additionally, the piston diameter is another important parameter that specifies the size of the piston in the hydraulic press cylinder. It is essential to choose the correct piston diameter, as it directly affects the force and the speed of the cylinder’s operation.

The type of mounting, thread size, and port size are other parameters that need to be considered when selecting a hydraulic press cylinder. These parameters ensure proper fitting of the cylinder within the equipment or machinery.

Finally, the materials used to build the cylinder are also important technical parameters. Cylinder materials should be strong, durable, and able to handle the operating pressures required for the intended application.

In conclusion, selecting the right hydraulic press cylinder for a specific application is critical for success. Understanding the different technical parameters and their importance is crucial for making an informed decision. By considering these parameters and selecting the right hydraulic press cylinder, better performance, reliability, and durability can be achieved.

Hydraulic Press Cylinder Price

A hydraulic press is a machine tool used in heavy industries that requires great force to be applied to compress or compress materials. Its operation involves the use of hydraulic cylinders that generate the necessary force to accomplish the tasks. Hydraulic cylinders are key components of hydraulic presses as they transform the hydraulic energy from pressurized fluids into mechanical energy through linear motion.

The price of hydraulic press cylinders may vary depending on the brand, material, size, and other specifications. On average, hydraulic press cylinders range from $500 to over $10,000. The cost of hydraulic press cylinder directly correlates with the performance and durability of the tool. As a result, it is important to carefully select the right cylinder that can withstand the rigors of industrial work demands and provide long-lasting service.

One important factor to consider when purchasing hydraulic press cylinders is their material. The most common types of materials are steel and aluminum, each having its own advantages and disadvantages. Steel hydraulic press cylinders have a higher overall strength and can withstand high temperatures, but they are susceptible to corrosion. Aluminum hydraulic press cylinders are lightweight, resist corrosion, and offer better heat dissipation, but are prone to deformation.

Size is another crucial factor that affects the price of hydraulic press cylinders. Larger cylinders tend to be more expensive than smaller ones because of the robustness required to generate higher forces. A larger cylinder requires a larger bore and piston, which increases the cost of the material used and overall manufacturing.

In conclusion, hydraulic press cylinders play an essential role in the operations of a hydraulic press. When purchasing them, it is important to consider factors such as material, size, and price to ensure that the best quality cylinders are obtained. While the cost may be a key factor, investing in high-quality, durable hydraulic cylinders will prove to be a wise decision in the long run as it reduces maintenance costs and increases productivity.