Introduce about hydraulic pump parts guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

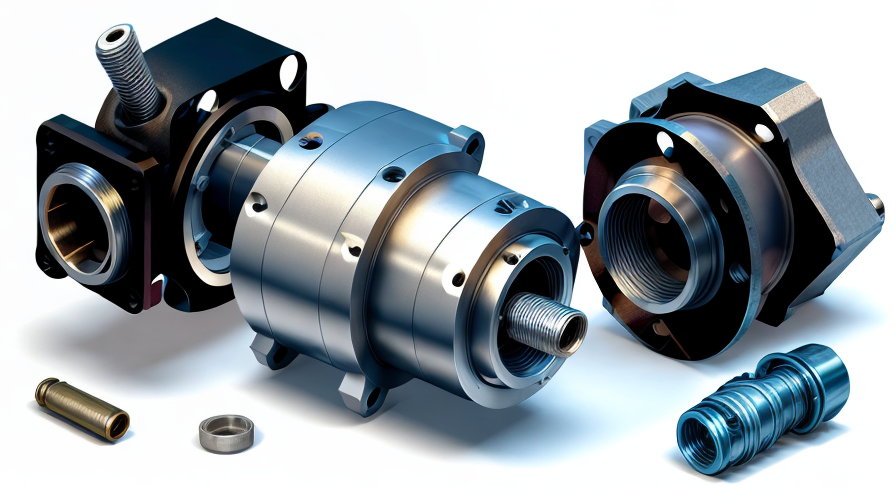

A hydraulic pump plays a crucial role in converting mechanical power into hydraulic energy, which powers various hydraulic systems. Understanding the different parts of a hydraulic pump is essential for maintenance and troubleshooting. Common parts include the housing, rotor, vanes, and seals.

When it comes to quality, it is important to source parts from reputable suppliers to ensure optimal performance and longevity of the pump. While quality parts may come at a higher cost initially, they can help prevent costly breakdowns and repairs in the long run.

Suppliers of hydraulic pump parts should ideally have the necessary certifications and adhere to industry standards to guarantee the quality and reliability of their products. Market demand for hydraulic pump parts continues to grow, driven by the increasing use of hydraulic systems in various industries.

Here are some tips for buying hydraulic pump parts:

1. Ensure compatibility with your specific pump model

2. Choose parts made from high-quality materials

3. Consider the reputation and track record of the supplier

4. Get recommendations from industry experts or colleagues

FAQs about hydraulic pump parts may include inquiries about compatibility, installation, maintenance, troubleshooting, and warranty. By familiarizing yourself with the parts guide and following best practices, you can ensure the efficient operation of your hydraulic pump system.

Types of hydraulic pump parts

Some common types of hydraulic pump parts include:

1. Pump housing: The metal casing that contains all of the internal components of the pump, such as the gears or pistons.

2. Gears or pistons: These are the components inside the pump that actually create the fluid flow by moving back and forth or rotating.

3. Bearings: These parts help support the rotating components inside the pump and prevent excessive wear.

4. Seals and gaskets: These are used to prevent fluid leakage and maintain pressure within the pump.

5. Valves: These regulate the flow of fluid through the pump and control the direction of the fluid flow.

6. Hydraulic fluid reservoir: This part holds the hydraulic fluid that is necessary for the operation of the pump.

7. Filters: These are used to remove contaminants from the hydraulic fluid and help to prolong the life of the pump.

8. Pressure relief valve: This is a safety feature that prevents the pump from building up too much pressure and potentially causing damage.

9. Suction and discharge ports: These are the openings that allow fluid to enter and exit the pump.

Overall, these are just a few of the many parts that make up a hydraulic pump. Each part plays a crucial role in the functioning of the pump and helps to ensure that it operates efficiently and effectively. Regular maintenance and replacement of worn parts are essential to keep a hydraulic pump running smoothly.

Pros and Cons of Using hydraulic pump parts

Hydraulic pump parts play a crucial role in various industries that rely on hydraulic systems, including construction, automotive, agricultural, and manufacturing. Despite their importance, it is essential to consider the pros and cons of using hydraulic pump parts before making a decision.

Pros:

1. Efficiency: Hydraulic systems are known for their high efficiency and power density. The use of hydraulic pump parts ensures that the system can generate a significant amount of force with relatively small components.

2. Versatility: Hydraulic pump parts can be used in a wide range of applications, such as lifting heavy loads, controlling machinery movements, and powering tools. They can adapt to different operating conditions and provide a flexible solution for various tasks.

3. Durability: Hydraulic pump parts are designed to withstand high pressures and extreme temperatures, making them highly durable. The robust construction and materials used ensure that the parts can withstand heavy-duty applications without frequent maintenance or replacements.

4. Precise Control: Hydraulic systems offer precise control over force, speed, and motion. By using hydraulic pump parts, operators can fine-tune the system to achieve accurate and repeatable results, enhancing safety and productivity.

Cons:

1. Complexity: Hydraulic systems can be complex to design, install, and maintain. The use of hydraulic pump parts necessitates a thorough understanding of the system’s mechanics, including valves, actuators, and other components. This complexity may increase the cost and sophistication of the system.

2. Potential for Leakage: One of the primary challenges with hydraulic systems is the potential for leakage. Hydraulic pump parts need proper sealing and installation to prevent leaks, which can lead to system inefficiency, contamination, and safety hazards.

3. High Maintenance: Although hydraulic pump parts are durable, regular maintenance is crucial to ensure optimal system performance. This maintenance may include monitoring fluid levels, replacing filters, inspecting seals, and conducting periodic checks for any wear or damage.

4. Environmental Impact: Hydraulic systems require hydraulic fluid, which can pose environmental challenges if not handled correctly. Fluid leaks or spills can contaminate soil and water sources, potentially harming the ecosystem. Proper disposal and containment practices are necessary to mitigate this risk.

In conclusion, the use of hydraulic pump parts offers several advantages such as efficiency, versatility, durability, and precise control. However, it is important to consider the complexity, potential for leakage, high maintenance requirements, and the environmental impact they may have on a project or operation. Therefore, careful evaluation and regular maintenance are essential to ensure the successful use of hydraulic pump parts in various industries.

hydraulic pump parts Reference Specifications (varies for different product)

Hydraulic pump parts are critical components that play a crucial role in the functioning of hydraulic pumps. These parts vary depending on the specific product and application requirements. The reference specifications for hydraulic pump parts outline the important characteristics, dimensions, and features that a particular part should possess. These specifications ensure that the parts are compatible with the pump and can effectively perform their intended function.

Some common hydraulic pump parts include:

1. Pistons: Pistons are cylindrical components that move back and forth inside the pump’s cylinder block. They are typically made of high-strength materials to withstand the hydraulic pressures exerted on them. The reference specifications for pistons usually include dimensions such as diameter and length, as well as any special features like coatings or sealing arrangements.

2. Cylinder Block: The cylinder block houses the pistons and guides their movement. It is an essential component that must be precisely machined to ensure a proper fit with the pistons. Reference specifications for cylinder blocks may include bore dimensions, surface finish requirements, and tolerance limits.

3. Valve Plates: Valve plates control the flow of hydraulic fluid within the pump. They feature various channels, ports, and openings that enable the pump to regulate pressure and direction. Reference specifications for valve plates specify the number and size of ports, required flatness, and any additional features like anti-cavitation measures or specialized coatings.

4. Bearings: Bearings provide support and reduce friction between moving parts. They are crucial for improving the efficiency and lifespan of the hydraulic pump. Reference specifications for bearings usually include dimensions, load-bearing capacity, tolerances, and lubrication requirements.

5. Seals: Seals prevent internal leakage and maintain the hydraulic fluid’s pressure within the pump. They help improve the overall performance and efficiency of the pump. Reference specifications for seals outline the material type, dimensions, hardness, and working temperature range.

Additionally, other hydraulic pump parts like shafts, housings, gears, and filters have their own reference specifications, ensuring proper functioning and compatibility with the hydraulic system.

In conclusion, reference specifications for hydraulic pump parts are essential guidelines that ensure the proper design, quality, and compatibility of these crucial components. By adhering to these specifications, manufacturers can ensure that their hydraulic pumps perform optimally, increasing productivity and reliability in various industries and applications.

Applications of hydraulic pump parts

Hydraulic pump parts play a critical role in various applications where hydraulic power is required. These parts are essential for the smooth functioning and operation of hydraulic systems. Here are some common applications where hydraulic pump parts are utilized:

1. Construction Machinery: Hydraulic systems are extensively used in construction machinery such as excavators, loaders, bulldozers, and cranes. Hydraulic pump parts, such as pistons, cylinders, valves, and seals, are integral components in these machines, enabling them to perform heavy-duty tasks like lifting, digging, and hauling.

2. Agricultural Equipment: Hydraulic pump parts are extensively used in agricultural machinery, including tractors, harvesters, sprayers, and irrigation systems. These parts help in powering hydraulic systems that control various operations, such as steering, lifting, and manipulating attachment tools.

3. Automotive Industry: Hydraulic pump parts are crucial in automotive applications, especially in heavy-duty vehicles like trucks and buses. They are responsible for powering systems like power steering, transmission, and braking. These parts enable seamless control and maneuverability of the vehicles.

4. Industrial Machinery: In industrial settings, hydraulic pump parts are used in various types of machinery, including manufacturing equipment, presses, machine tools, and hydraulic lifts. These parts are vital for providing the required force and motion control necessary for efficient production processes.

5. Aerospace Industry: Hydraulic systems are employed in aircraft for functions like landing gear operation, wing flaps deployment, and control surface movements. Hydraulic pump parts, along with other components, enable these critical operations, ensuring safe and reliable flight.

6. Marine Applications: Hydraulic pump parts find significant usage in marine applications, including ship steering systems, crane operations, winches, and offshore platforms. These parts facilitate the precise control and movement of heavy equipment, enhancing maritime operation efficiency.

7. Material Handling Equipment: Forklifts, pallet jacks, and material handling conveyors rely on hydraulic systems to lift, move, and transport heavy loads. Hydraulic pump parts ensure the smooth functioning of these systems, enabling effortless material handling operations.

8. Oil and Gas Industry: In the oil and gas sector, hydraulic pump parts are utilized in drilling rigs, wellhead control units, and hydraulic power packs. These parts enable safe and efficient operations by providing the necessary force to carry out drilling and extraction processes.

In conclusion, hydraulic pump parts find widespread applications across various industries, contributing to the efficient working of machinery and systems. Their reliability, durability, and ability to generate substantial force make them crucial components in enhancing productivity and safety in numerous industrial sectors.

The Work Process and how to use hydraulic pump parts

The work process of a hydraulic pump involves the conversion of mechanical power into hydraulic energy through the use of hydraulic pump parts. These parts include a reservoir, pump, valves, filters, hoses, and fittings.

To begin the work process, the hydraulic pump draws oil from the reservoir through a suction line. The pump then pressurizes the oil and sends it through a series of valves to control the flow of hydraulic fluid. The fluid is then directed to the hydraulic cylinder or motor to perform the intended work.

When using hydraulic pump parts, it is important to ensure that they are properly maintained and in good working condition. Regular inspections should be conducted to check for any leaks, worn out parts, or deteriorating seals. Any damaged parts should be promptly replaced to prevent potential breakdowns or accidents.

To effectively use hydraulic pump parts, it is essential to follow the manufacturer’s guidelines and specifications. This includes using the correct type and size of pump for the intended application, proper installation, and regular maintenance. Additionally, it is important to monitor the pressure levels and temperature of the hydraulic fluid to prevent overheating and system failure.

In conclusion, the work process of a hydraulic pump involves the conversion of mechanical power into hydraulic energy with the use of various parts. To ensure optimal performance and longevity of hydraulic pump parts, it is crucial to follow proper maintenance practices and adhere to manufacturer specifications.

Quality Testing Methods for hydraulic pump parts and how to control the quality

There are several quality testing methods for hydraulic pump parts, including visual inspection, dimensional measurements, material testing, functional testing, and performance testing. Visual inspection involves visually examining the part for any defects, such as cracks, dents, or surface irregularities. Dimensional measurements involve measuring the part’s dimensions using various tools, such as calipers or micrometers, to ensure it meets the specifications.

Material testing involves analyzing the composition of the material used to make the part, such as metal alloy or rubber, to ensure it is of the correct grade and quality. Functional testing involves testing the part in a hydraulic system to ensure it functions properly and does not leak or malfunction. Performance testing involves subjecting the part to various operating conditions to determine its performance under different circumstances.

To control the quality of hydraulic pump parts, it is important to establish clear quality standards and specifications for the parts. This includes defining acceptable tolerances for dimensions, materials, and performance criteria. Regular quality checks should be conducted during the manufacturing process to ensure that the parts meet these standards. If any defects or deviations are found, corrective actions should be taken to address them.

Furthermore, implementing a quality management system, such as ISO 9001, can help improve the overall quality control processes and ensure that consistent quality standards are maintained. By using these quality testing methods and implementing effective quality control measures, manufacturers can ensure that their hydraulic pump parts meet the highest standards of quality and performance.

hydraulic pump parts Sample Policy and Post-Purchase Considerations for hydraulic pump parts from China

When purchasing hydraulic pump parts from China, it is important to consider the following post-purchase considerations and sample policy:

1. Sample Policy: When ordering hydraulic pump parts from China, it is advisable to request samples before placing a bulk order. This will allow you to assess the quality and compatibility of the parts with your equipment. Additionally, ensure that the supplier provides detailed information about the samples, such as specifications, materials used, and compatibility with your machinery.

2. Warranty and Return Policy: Before finalizing the purchase, review the supplier’s warranty and return policy for the hydraulic pump parts. Ensure that the policy covers any possible defects or damages to the parts and provides clear guidelines for return or replacement.

3. Quality Control: Choose a supplier that implements strict quality control measures to ensure the reliability and performance of the hydraulic pump parts. Request information about the supplier’s quality assurance processes, certifications, and inspections to guarantee the parts meet industry standards.

4. Shipping and Delivery: Consider the shipping and delivery options offered by the supplier. Ensure that they provide efficient and reliable shipping services to deliver the hydraulic pump parts safely to your location. Discuss lead times and delivery schedules to avoid any delays in receiving the parts.

5. Communication and Support: Establish clear communication channels with the supplier to address any inquiries or concerns regarding the hydraulic pump parts. Ensure that the supplier offers timely and responsive customer support to assist you throughout the procurement process.

By following these post-purchase considerations and sample policy, you can ensure a smooth and successful purchase of hydraulic pump parts from China. Remember to conduct thorough research and due diligence before selecting a reputable supplier to obtain high-quality and reliable parts for your machinery.

Sourcing hydraulic pump parts from China: Opportunities, Risks, and Key Players

China offers a wide range of opportunities for sourcing hydraulic pump parts due to its large manufacturing base and competitive prices. The country has a robust infrastructure and skilled workforce, making it a preferred destination for businesses looking to procure hydraulic pump parts.

However, there are also risks associated with sourcing from China. These include quality control issues, intellectual property concerns, and potential delays in delivery times. It is important for businesses to conduct thorough due diligence and establish strong relationships with suppliers to mitigate these risks.

Key players in the hydraulic pump parts industry in China include companies like Bosch Rexroth, Eaton, Parker Hannifin, and Yuken. These companies have a solid reputation for producing high-quality hydraulic pump parts and have a strong presence in the global market.

Overall, sourcing hydraulic pump parts from China can be a cost-effective and efficient option for businesses looking to expand their supply chain. However, it is important for companies to carefully evaluate the risks and potential challenges associated with sourcing from China and take necessary precautions to ensure a successful sourcing process.

How to find and select reliable hydraulic pump parts manufacturers in China,use google search manufacturers and suppliers

When searching for reliable hydraulic pump parts manufacturers in China, it is important to use Google as a starting point. By typing in keywords such as “hydraulic pump parts manufacturers in China” or “reliable hydraulic pump parts suppliers in China,” you can easily find a list of potential companies to consider.

To narrow down your search, consider looking for manufacturers with a solid reputation, positive reviews, and a history of providing high-quality products. You can also look for manufacturers that have certifications or partnerships with reputable organizations in the industry.

Once you have a list of potential manufacturers, it is important to reach out to them for more information. Ask about their manufacturing processes, quality control measures, lead times, pricing, and any other relevant details. You may also want to request samples or visit their facilities to assess their capabilities firsthand.

In addition, consider looking for manufacturers that offer customization options and have a strong customer service team. This can help ensure that you receive the exact hydraulic pump parts that you need and that any issues or concerns can be addressed promptly.

Overall, finding a reliable hydraulic pump parts manufacturer in China requires thorough research and due diligence. By using Google search and carefully evaluating your options, you can select a reputable manufacturer that meets your specific requirements.

How to check hydraulic pump parts manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To check the reliability of a hydraulic pump parts manufacturer’s website, you can follow these steps:

1. Use Google Chrome: Open the manufacturer’s website using the Google Chrome browser. Chrome offers various useful extensions that can help evaluate the website’s reliability.

2. Install SEOquake: Install the SEOquake extension for Chrome, which provides valuable insights about a website’s SEO performance. It is a free tool that can be easily found and installed from the Chrome Web Store.

3. Check the website’s ranking: Once SEOquake is installed, it will appear as a toolbar on your browser. Click on the SEOquake icon and select “Show SERP overlay.” This feature allows you to see the website’s ranking in the search engine results page (SERP). If the website is ranked among the top 10 million websites, it indicates a decent level of online presence.

4. Review other factors: While the SERP ranking is a good starting point, it is also essential to assess other factors to determine the website’s reliability. Consider the website’s overall design, user-friendliness, and professional appearance. A reputable manufacturer will invest in creating a user-friendly and visually appealing website.

5. Validate the information: Verify the authenticity of the information provided on the website. Look for contact information, including a physical address, phone number, and customer support email. Check if the website mentions the manufacturer’s history, experience, certifications, and quality control processes. Additionally, ensure that the website contains detailed product descriptions, specifications, and images.

6. Read customer reviews or testimonials: Look for customer reviews or testimonials on the website to gain insights into other customers’ experiences. Genuine reviews often indicate the manufacturer’s reliability and customer satisfaction.

7. Verify SSL certificate: Check if the website has an SSL certificate, indicated by a small padlock icon in the address bar. This ensures that the website has a secure connection, protecting users’ data during transactions or information sharing.

Remember to trust your instincts and conduct additional research if you have any doubts about a hydraulic pump parts manufacturer’s website.

Top 10 hydraulic pump parts manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. **Bosch Rexroth**

– Bosch Rexroth is a leading manufacturer of hydraulic pump parts in China, offering a wide range of products such as piston pumps, vane pumps, and gear pumps. Their products are known for their high quality and reliability, making them a popular choice among customers.

2. **Parker Hannifin**

– Parker Hannifin specializes in hydraulic pump parts for various industries, including construction, agriculture, and mining. Their products are designed to withstand harsh operating conditions and deliver consistent performance.

3. **Eaton**

– Eaton is a trusted supplier of hydraulic pump parts in China, offering a diverse range of products such as axial piston pumps, bent axis pumps, and external gear pumps. Their products are known for their efficiency and durability.

4. **Kawasaki**

– Kawasaki is a leading manufacturer of hydraulic pump parts in China, offering a wide range of products such as radial piston pumps, axial piston pumps, and bent axis pumps. Their products are known for their precision engineering and performance.

5. **Yuken**

– Yuken is a reputable manufacturer of hydraulic pump parts in China, specializing in products such as vane pumps, piston pumps, and gear pumps. Their products are designed to deliver high performance and reliability in various applications.

6. **Sauer Danfoss**

– Sauer Danfoss is a well-known manufacturer of hydraulic pump parts in China, offering a diverse range of products such as variable displacement pumps, fixed displacement pumps, and open circuit pumps. Their products are known for their innovative design and efficiency.

7. **Poclain Hydraulics**

– Poclain Hydraulics is a leading supplier of hydraulic pump parts in China, offering a wide range of products such as radial piston pumps, gear pumps, and vane pumps. Their products are designed to deliver superior performance and reliability.

8. **Daikin**

– Daikin is a reputable manufacturer of hydraulic pump parts in China, offering a diverse range of products such as piston pumps, vane pumps, and gear pumps. Their products are known for their high efficiency and durability.

9. **Rexroth**

– Rexroth is a trusted manufacturer of hydraulic pump parts in China, offering a wide range of products such as radial piston pumps, axial piston pumps, and vane pumps. Their products are known for their precision engineering and high performance.

10. **Bucher Hydraulics**

– Bucher Hydraulics is a leading manufacturer of hydraulic pump parts in China, offering a diverse range of products such as bent axis pumps, gear pumps, and piston pumps. Their products are known for their reliability and efficiency.

| Manufacturer | Products |

|——————–|————————————————————————————————————|

| Bosch Rexroth | Piston pumps, vane pumps, gear pumps |

| Parker Hannifin | Hydraulic pump parts for construction, agriculture, and mining industries |

| Eaton | Axial piston pumps, bent axis pumps, external gear pumps |

| Kawasaki | Radial piston pumps, axial piston pumps, bent axis pumps |

| Yuken | Vane pumps, piston pumps, gear pumps |

| Sauer Danfoss | Variable displacement pumps, fixed displacement pumps, open circuit pumps |

| Poclain Hydraulics | Radial piston pumps, gear pumps, vane pumps |

| Daikin | Piston pumps, vane pumps, gear pumps |

| Rexroth | Radial piston pumps, axial piston pumps, vane pumps |

| Bucher Hydraulics | Bent axis pumps, gear pumps, piston pumps |

Background Research for hydraulic pump parts manufacturers Companies in China, use qcc.com archive.org importyeti.com

When looking for hydraulic pump parts manufacturers in China, Qcc.com provides a comprehensive database of companies that specialize in producing a wide range of hydraulic pump parts. This platform allows users to search for manufacturers based on location, product type, and company size.

Archive.org is a valuable resource for researching the history and background of hydraulic pump parts manufacturers in China. By accessing archived websites and pages, users can track the growth and development of specific companies over time.

Importyeti.com is a useful tool for identifying popular and reliable hydraulic pump parts manufacturers in China. This platform offers insights into the import and export activities of different companies, allowing users to gauge their credibility and reputation in the industry.

By utilizing these resources, buyers can gather relevant information about hydraulic pump parts manufacturers in China, such as company profiles, product catalogs, certifications, and customer reviews. This research can help buyers make informed decisions when selecting a manufacturer that meets their quality and pricing requirements.

Leveraging Trade Shows and Expos for hydraulic pump parts Sourcing in China

Trade shows and expos can be valuable tools for sourcing hydraulic pump parts in China. These events provide an opportunity to connect with suppliers, compare products, and establish business relationships. By leveraging trade shows and expos, businesses can potentially find reliable and competitively priced suppliers for hydraulic pump parts.

Attending trade shows and expos in China allows businesses to directly interact with suppliers and manufacturers. These events gather numerous companies and industries under one roof, providing a convenient platform for face-to-face communication. This allows businesses to ask questions, evaluate the quality of products, and negotiate pricing and lead times directly with potential suppliers.

In addition to direct interactions, trade shows and expos also offer a chance to observe the latest technologies and trends in hydraulic pump parts. Manufacturers often display their latest products and innovations during these events, giving businesses valuable insight into the market. By staying up to date with the latest advancements, businesses can make more informed decisions when selecting suppliers and products.

Furthermore, trade shows and expos provide an opportunity to network with industry professionals and peers. Engaging in conversations and exchanging information can help businesses gain insights and recommendations for reliable suppliers. Building a network of contacts within the industry can prove invaluable for future sourcing endeavors.

To make the most of trade shows and expos, businesses should plan ahead. Researching the event, its exhibitors, and the specific hydraulic pump parts suppliers present can help prioritize which booths to visit. Preparing a list of questions and specifications can also ensure efficient and productive discussions with potential suppliers.

Overall, leveraging trade shows and expos in China can be an effective strategy for hydraulic pump parts sourcing. These events facilitate direct interactions with suppliers, provide market insights, and foster networking opportunities. By being strategic and proactive, businesses can find reliable and competitively priced suppliers for their hydraulic pump parts needs.

The Role of Agents and Sourcing Companies in Facilitating hydraulic pump parts Purchases from China

Agents and sourcing companies play a crucial role in facilitating hydraulic pump parts purchases from China by bridging the gap between buyers and suppliers. These intermediaries have a deep understanding of the Chinese market, suppliers, and regulatory environment, which helps in streamlining the sourcing process.

Agents and sourcing companies act as the liaison between buyers and suppliers, ensuring effective communication, negotiation, and coordination throughout the purchasing process. They help buyers identify reliable and reputable suppliers, negotiate favorable terms, and ensure timely delivery of products.

Additionally, agents and sourcing companies provide valuable insights and guidance on market trends, pricing, quality standards, and regulatory requirements, helping buyers make informed decisions. They also assist in quality control, inspection, and logistics, ensuring that the purchased hydraulic pump parts meet the required specifications and are delivered efficiently.

Overall, agents and sourcing companies play a pivotal role in simplifying the sourcing process, reducing risks, and achieving cost-effective procurement of hydraulic pump parts from China. Their expertise and network in the Chinese market enable buyers to access a wide range of suppliers and products, ultimately facilitating a smooth and successful purchasing experience.

Price Cost Research for hydraulic pump parts manufacturers Companies in China, use temu.com and 1688.com

When researching hydraulic pump parts manufacturers in China, two popular platforms to consider are Temu.com and 1688.com. These platforms provide a wide range of suppliers, making it easier for customers to find suitable options for their needs. Conducting price cost research on these platforms can help buyers make informed decisions and find competitive deals.

Temu.com is an online global sourcing platform that offers a vast array of suppliers for various products, including hydraulic pump parts. It enables buyers to connect with verified manufacturers and obtain competitive quotes. Temu.com simplifies the procurement process by providing a transparent platform where buyers can compare prices, negotiate deals, and manage orders efficiently.

1688.com, on the other hand, is a popular B2B e-commerce website in China. It is owned by Alibaba Group and offers a comprehensive range of suppliers. Although the platform is primarily designed for the Chinese market, it can still be used by international buyers with the help of translation tools. 1688.com allows users to directly contact suppliers, negotiate prices, and place orders.

When conducting price cost research on these platforms, it is important to consider certain factors. Firstly, thoroughly analyzing the product specifications and quality standards provided by the manufacturer is crucial. Secondly, paying attention to the supplier’s background, reputation, and credibility is necessary for a secure and reliable transaction. Additionally, comparing prices from different suppliers can help identify the most competitive offers in terms of both cost and quality.

By using Temu.com and 1688.com, customers can access a wide pool of hydraulic pump parts manufacturers in China. These platforms simplify the sourcing process, making it easier for customers to find the most suitable suppliers. However, it is essential for buyers to thoroughly evaluate the products, suppliers, and prices in order to make well-informed purchasing decisions.

Shipping Cost for hydraulic pump parts import from China

The shipping cost for hydraulic pump parts imported from China can vary depending on several factors such as weight, volume, shipping method, and destination. Generally, there are two main shipping methods: air freight and ocean freight.

If the hydraulic pump parts are relatively small and lightweight, air freight might be the most suitable option. Air freight is usually faster but more expensive compared to ocean freight. The cost for air freight is calculated based on the weight or volume, whichever is greater. It is recommended to obtain quotes from different freight forwarders to compare prices and services. On average, the shipping cost for air freight can range from $3 to $10 per kilogram.

For larger shipments, ocean freight is a more cost-effective choice. Ocean freight rates depend on the shipment’s volume, weight, and destination port. Freight forwarders usually offer different options, such as Full Container Load (FCL) or Less than Container Load (LCL). The cost for ocean freight can range from $1000 to $5000 per container, depending on various factors. It is crucial to consider additional charges like customs duties, taxes, and import fees that may apply at the destination country.

It is essential to work with a reliable freight forwarder or shipping agent who can provide accurate quotes and handle the documentation and customs clearance process smoothly. They can guide you with the necessary paperwork, including the bill of lading, commercial invoice, packing list, and any other required documents.

To minimize shipping costs, it is advisable to consolidate multiple orders or negotiate shipping rates with the freight forwarder. Additionally, optimizing packaging and stacking can help reduce volume and, consequently, shipping costs.

In conclusion, the shipping cost for hydraulic pump parts imported from China can vary depending on factors like weight, volume, shipping method, and destination. Obtaining quotes from different freight forwarders, comparing prices, and considering additional fees is essential to make an informed decision. Collaboration with a reliable shipping agent can ensure a smooth shipping process reducing the overall costs.

Compare China and Other hydraulic pump parts Markets: Products Quality and Price,Visible and Hidden Costs

China is known as one of the largest manufacturers and exporters of hydraulic pump parts in the world. When comparing the Chinese market with others, several factors should be considered, such as products quality and price, visible and hidden costs.

In terms of products quality, China has made significant progress over the years. The country has invested heavily in research and development, leading to improvements in the manufacturing process and product standards. However, the quality of Chinese hydraulic pump parts can vary greatly. While some Chinese manufacturers produce high-quality products that meet international standards, others may offer lower-quality products at a lower price. Other hydraulic pump parts markets, such as those in Europe and the United States, generally have a reputation for producing higher-quality products. Buyers may have to pay a premium for these products, but they can be assured of their reliability and durability.

Price is another important factor to consider when comparing markets. China has the advantage of low labor and production costs, allowing manufacturers to offer their products at a competitive price. This has made Chinese hydraulic pump parts popular in the global market, especially for cost-conscious buyers. However, it is essential to consider not only the upfront price but also visible and hidden costs. Visible costs include shipping, import duties, and taxes, which can significantly impact the overall price. Hidden costs, such as potential product defects or delays in delivery, should also be considered when evaluating the true cost of purchasing from China.

While China offers competitive prices, there can be hidden costs associated with quality issues. Buyers may face additional expenses for repairs, replacements, or even complete failures if the quality of the purchased products is insufficient. The cost of warranty claims, customer dissatisfaction, and the risk of lower productivity due to equipment failure should be taken into account. In comparison, other markets may provide higher-quality products that result in fewer hidden costs over time.

In conclusion, the Chinese market for hydraulic pump parts has made strides in terms of product quality and offers competitive pricing due to low labor and production costs. However, the quality of Chinese products can vary, and buyers need to factor in visible and hidden costs when making purchasing decisions. Other markets, such as Europe and the United States, generally have a reputation for producing higher-quality products, but at a higher cost.

Understanding Pricing and Payment Terms for hydraulic pump parts: A Comparative Guide to Get the Best Deal

Pricing and payment terms for hydraulic pump parts can vary significantly depending on several factors, including the manufacturer, the type of part, the quality, and the quantity needed. To ensure you get the best deal, it is essential to compare different suppliers and consider the following factors:

1. Price Comparison: Gather quotes from multiple suppliers to compare the prices of hydraulic pump parts. Take into account not only the initial cost but also any additional charges, such as shipping fees or taxes. Keep in mind that the lowest price might not always offer the best value, as quality and reliability should also be considered.

2. Quality Assessment: Carefully evaluate the quality of the hydraulic pump parts offered by different suppliers. Consider factors such as durability, performance, and the reputation of the brand or manufacturer. Investing in high-quality parts might cost more upfront but can save you from frequent repairs or replacements in the long run.

3. Payment Terms: Understand the payment terms offered by each supplier. Some may require full payment upfront, while others offer flexible options such as partial payments or payment upon delivery. Choose a payment arrangement that aligns with your budget and cash flow situation.

4. Discounts and Special Offers: Inquire about any available discounts or special offers that can potentially reduce the overall cost. Some suppliers may offer volume discounts for bulk orders, while others may have promotions or loyalty programs that can help you get a better deal.

5. Delivery Time: Consider the delivery time offered by each supplier, especially if you require the hydraulic pump parts urgently. While quick delivery is favorable, ensure it is not at the expense of quality or reliability.

6. Warranty and After-Sales Support: Check if the hydraulic pump parts come with a warranty and inquire about the supplier’s after-sales support. A supplier that provides reliable warranty coverage and efficient customer service can help you address any issues that may arise after the purchase.

By considering these factors and carefully comparing different suppliers, you can ensure that you get the best deal for hydraulic pump parts while maintaining quality and reliability. Remember to prioritize the long-term benefits and value instead of solely focusing on the initial price.

Chinese Regulations and Industry Standards Certifications for hydraulic pump parts,Import Regulations and Customs for hydraulic pump parts from China

When importing hydraulic pump parts from China, it is important to ensure that the products meet Chinese regulations and industry standards certifications. In China, hydraulic pump parts are subject to various regulations and standards set by the government and industry organizations. The most common certifications for hydraulic pump parts include China Compulsory Certification (CCC), China Energy Label (CEL), and China RoHS.

In addition to ensuring compliance with Chinese regulations and standards, importers must also be aware of the import regulations and customs procedures for hydraulic pump parts from China. It is important to obtain the necessary import licenses and permits, as well as provide accurate and complete documentation to customs authorities. Import duties and taxes may also apply, so importers should be prepared to pay these fees.

To streamline the importing process and avoid any issues with customs, importers can work with a reputable freight forwarder or customs broker who is familiar with the regulations and procedures for importing hydraulic pump parts from China. By following the necessary steps and ensuring compliance with regulations and standards, importers can successfully import hydraulic pump parts from China for use in various industries.

Sustainability and Environmental Considerations in hydraulic pump parts Manufacturing

Sustainability and environmental considerations are crucial aspects of hydraulic pump parts manufacturing. With growing concerns about climate change and environmental degradation, manufacturers must prioritize sustainable practices to minimize their impact on the planet.

One key aspect of sustainability in manufacturing is reducing energy consumption. Hydraulic pump parts manufacturers should aim to optimize their energy usage through various means, such as implementing more efficient production processes and investing in energy-saving equipment. By reducing energy consumption, manufacturers not only contribute to a more sustainable future but also benefit from cost savings in the long run.

Another vital factor in sustainable manufacturing is the responsible use of materials. Manufacturers should strive to minimize waste generation by employing efficient material handling and recycling techniques. Additionally, using environmentally friendly materials, such as recycled or biodegradable alternatives, can further enhance sustainability efforts. Manufacturers must also ensure proper disposal of hazardous materials and pollutants to prevent them from entering ecosystems and causing harm.

Water usage is another critical consideration in hydraulic pump parts manufacturing. As water scarcity becomes a global concern, manufacturers should strive to minimize water consumption and ensure responsible water management practices. Implementing closed-loop cooling systems and water recycling techniques can significantly reduce water usage in the manufacturing process.

Furthermore, manufacturers should prioritize reducing carbon emissions. By implementing measures such as energy-efficient transportation, choosing eco-friendly packaging materials, and promoting remote working options, companies can minimize their carbon footprint and contribute to climate change mitigation efforts.

Lastly, manufacturers should prioritize sustainability throughout their supply chains. By selecting suppliers who adhere to sustainable practices and promoting ethical sourcing, companies can ensure that sustainability considerations extend beyond their own manufacturing processes.

In conclusion, sustainability and environmental considerations are vital in hydraulic pump parts manufacturing. By focusing on energy efficiency, responsible material usage, water management, carbon emissions reduction, and sustainable supply chain practices, manufacturers can contribute to a more sustainable and environmentally conscious future.

List The Evolution history of “hydraulic pump parts”

Hydraulic pump parts have evolved significantly over the years to meet the ever-increasing demands of various industries. Initially, hydraulic pumps were simple devices with basic components like pistons, cylinders, and valves. These early pumps were mainly used for lifting heavy objects and performing basic tasks.

As technology advanced, hydraulic pump parts became more sophisticated and durable. Manufacturers started using high-quality materials like steel and aluminum to improve the pumps’ performance and longevity. The addition of seals and gaskets helped to prevent leaks and ensure smooth operation.

In recent years, the evolution of hydraulic pump parts has been driven by the need for efficiency and environmental sustainability. Manufacturers have introduced innovative designs and technologies like variable displacement pumps and energy-efficient motors to reduce power consumption and emissions.

Furthermore, advancements in materials science have led to the development of lightweight, corrosion-resistant components that can withstand harsh operating conditions. Electronic controls and sensors have also been integrated into hydraulic pump systems to enhance precision and monitoring capabilities.

Overall, the evolution of hydraulic pump parts has been characterized by a continuous quest for improved performance, reliability, and efficiency. As industries continue to demand more from their hydraulic systems, we can expect further innovations and advancements in the design and functionality of hydraulic pump parts in the future.

The Evolution and Market Trends in hydraulic pump parts Industry

The hydraulic pump parts industry has undergone significant evolution and witnessed several market trends over the years. Rapid advancements in technology, increasing demand for efficient and reliable hydraulic systems, and growing industrialization have played a crucial role in shaping the industry.

One of the major evolution in the hydraulic pump parts industry is the transition from traditional to modern hydraulic systems. In the past, hydraulic systems were bulky, cumbersome, and had high maintenance requirements. However, with the introduction of advanced materials, improved design techniques, and technological innovations, hydraulic systems have become more compact, lightweight, and durable. This evolution has led to increased efficiency, reduced operational costs, and improved overall performance.

Moreover, the market has experienced a shift towards the use of sustainable and eco-friendly hydraulic pump parts. As the focus on environmental conservation and energy efficiency grows, manufacturers are developing hydraulic pump parts that are more energy-efficient, consume less power, and produce minimal carbon emissions. This market trend is driven by strict regulations imposed by governments and organizations to reduce the environmental impact of industrial processes.

Another emerging market trend in the hydraulic pump parts industry is the increasing adoption of automation and digitization. The integration of sensors, IoT (Internet of Things) technology, and data analytics has allowed for remote monitoring, predictive maintenance, and real-time performance analysis of hydraulic systems. This advancement has enabled proactive maintenance, reduced downtime, and improved productivity, making it a popular choice among industries.

Furthermore, the growing demand for customization and personalized solutions has influenced the market trends in the hydraulic pump parts industry. Manufacturers are now focusing on offering a wide range of options, including different sizes, configurations, and materials, to cater to the diverse needs of customers. This trend is driven by the varying requirements of industries such as construction, agriculture, and manufacturing.

In conclusion, the hydraulic pump parts industry has evolved significantly due to advancements in technology, increased focus on sustainability, adoption of automation, and demand for customized solutions. These market trends have transformed the industry by improving efficiency, reducing environmental impact, and providing enhanced performance capabilities. As the industry continues to evolve, it is expected that further innovations and market trends will shape its future.

Custom Private Labeling and Branding Opportunities with Chinese hydraulic pump parts Manufacturers

Chinese hydraulic pump parts manufacturers offer various opportunities for custom private labeling and branding. With their expertise in manufacturing high-quality components, they provide businesses the chance to create their own unique brand identity in the hydraulic industry.

One possible opportunity for private labeling is to customize the packaging. Manufacturers can design packaging materials such as boxes, labels, and stickers with a business’s logo and brand name. This allows companies to enhance their brand visibility and create a lasting impression on their customers.

Another option for branding is to engrave or print the business’s logo on the hydraulic pump parts themselves. This distinct marking not only serves as a branding element but also facilitates easy identification and credibility of the components, promoting trust in the product quality.

Additionally, Chinese manufacturers can offer custom specifications and designs. Businesses can collaborate with them to develop unique hydraulic pump parts that meet their specific requirements. Through this partnership, companies can differentiate themselves from competitors and establish their brand as a provider of innovative and exceptional products.

Furthermore, Chinese manufacturers often have the capability to customize the performance and functionality of hydraulic pump parts. By tailoring the components to suit a business’s unique applications, companies can differentiate their products in the market and build a reputation for providing specialized solutions.

In conclusion, Chinese hydraulic pump parts manufacturers offer various opportunities for custom private labeling and branding. From customized packaging and distinct markings to tailoring specifications and designs, companies can create a unique brand identity in the hydraulic industry, enhancing their visibility and credibility in the market.

Tips for Procurement and Considerations when Purchasing hydraulic pump parts

When purchasing hydraulic pump parts, it is important to consider several key factors to ensure you get the right parts for your needs. Here are some tips and considerations to help you make an informed procurement decision:

1. Identify your requirements: Before purchasing hydraulic pump parts, determine the specific needs of your system. This includes understanding the flow rate, pressure requirements, and compatibility with existing components.

2. Quality and reliability: It is crucial to choose high-quality parts to ensure the long-term performance and reliability of your hydraulic pump. Look for reputable suppliers with a proven track record in manufacturing reliable and durable parts.

3. OEM vs. aftermarket parts: Original Equipment Manufacturer (OEM) parts are specifically designed for a particular brand and model of hydraulic pump. While they guarantee compatibility, they can be more expensive. Alternatively, aftermarket parts are manufactured by third-party companies and may offer cost savings, but it’s essential to ensure they meet quality standards.

4. Supplier reliability: Choose a reliable supplier who can provide genuine, certified hydraulic pump parts. Check for customer reviews and testimonials before making a purchase.

5. Availability and lead time: Consider the availability of the required hydraulic pump parts, as well as lead times for delivery. Opt for suppliers who have a good stock level to avoid project delays.

6. Price and warranty: Compare prices from different suppliers, but make sure not to compromise on quality. Additionally, inquire about warranty terms to protect yourself against defective or low-quality parts.

7. Consider maintenance and service requirements: Find out if the purchased hydraulic pump parts require any specific maintenance or service procedures. This will help you plan maintenance schedules and ensure the longevity of your hydraulic system.

8. Support and technical expertise: Choose a supplier who can provide technical assistance and support in case you encounter any issues with the hydraulic pump parts. They should be able to guide you through troubleshooting and offer reliable solutions.

By considering these factors and following these tips, you can ensure a successful procurement process while purchasing hydraulic pump parts.

FAQs on Sourcing and Manufacturing hydraulic pump parts in China

Q: Why should I consider sourcing hydraulic pump parts from China?

A: China is known for its vast manufacturing capabilities and competitive pricing. Many companies choose to source their hydraulic pump parts from China due to the availability of a wide range of products, cost-savings opportunities, and quality control measures implemented by reputable manufacturers.

Q: Are Chinese manufacturers reliable in terms of producing high-quality hydraulic pump parts?

A: While it is true that there have been instances of low-quality products from some Chinese manufacturers, there are also reputable companies that prioritize quality control. By conducting thorough research and choosing experienced manufacturers with good track records, you can ensure the production of high-quality hydraulic pump parts in China.

Q: Are there any advantages to sourcing hydraulic pump parts from China?

A: Yes, there are several advantages. Firstly, China offers competitive pricing due to its low labor costs. This can result in significant cost savings for businesses. Additionally, Chinese manufacturers often have extensive experience in producing hydraulic pump parts, ensuring a wide variety of options for customers. Furthermore, China’s efficient supply chain and logistics infrastructure enable timely delivery of products.

Q: How do I find reliable manufacturers for hydraulic pump parts in China?

A: It is essential to conduct thorough due diligence and research before selecting a manufacturer. Utilize online platforms, such as Alibaba or Global Sources, to find potential suppliers. Verify their certifications, quality control processes, and manufacturing capabilities. Obtaining samples and closely inspecting them can also help evaluate the manufacturer’s quality standards.

Q: Can I have customized hydraulic pump parts manufactured in China?

A: Yes, many Chinese manufacturers offer customization options for hydraulic pump parts. Engage in clear and detailed communication regarding your specific requirements with the chosen manufacturer. This will help ensure that the final products meet your desired specifications.

Q: What about intellectual property protection when sourcing hydraulic pump parts from China?

A: While intellectual property protection can be a concern, it is important to establish legal agreements such as non-disclosure agreements (NDAs) and intellectual property rights agreements with the chosen manufacturers. Engaging with reputable manufacturers with established protocols for intellectual property protection can help mitigate the risk.

In conclusion, sourcing hydraulic pump parts from China offers several advantages such as cost savings, a wide range of options, and efficient supply chains. However, it is crucial to conduct thorough research, choose reputable manufacturers, and establish legal agreements to ensure quality and protect intellectual property.

Why contact sourcifychina.com get free quota from reliable hydraulic pump parts suppliers?

Sourcifychina.com, being a sourcing platform, offers a free quota to connect buyers with reliable hydraulic pump parts suppliers. There are several reasons why this service is provided:

1. Access to a vast network: Sourcifychina.com has built a strong network of reputable hydraulic pump parts suppliers in China. By offering a free quota, it allows buyers to tap into this network and connect with reliable suppliers that have been vetted by Sourcifychina.com.

2. Quality assurance: The suppliers recommended by Sourcifychina.com are carefully selected based on their track record of producing high-quality hydraulic pump parts. This ensures that buyers receive products that meet their expectations, reducing the risk of receiving subpar or counterfeit parts.

3. Cost-effective sourcing: Sourcing hydraulic pump parts from China can be a cost-effective option for many buyers. By providing a free quota, Sourcifychina.com enables buyers to explore this option without any upfront payment or commitment. This can help businesses save money on sourcing costs and potentially increase their profit margins.

4. Time-saving solution: Searching for reliable suppliers on one’s own can be a time-consuming process. By using Sourcifychina.com’s free quota, buyers can expedite the supplier selection process. Sourcifychina.com’s team of experts can assist in identifying and connecting buyers with the most suitable suppliers, saving them valuable time and effort.

5. Customer satisfaction: Sourcifychina.com aims to ensure the satisfaction of its customers by offering a free quota. This demonstrates their commitment to providing a valuable service and assisting buyers in finding reliable hydraulic pump parts suppliers.

In conclusion, Sourcifychina.com offers a free quota to connect buyers with reliable hydraulic pump parts suppliers in order to provide access to a vast network, assure quality, offer cost-effective sourcing, save time, and ensure customer satisfaction. This service enables buyers to streamline their sourcing process and connect with trustworthy suppliers in China.