Introduce about ice pop making machine guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

Introduction:

Ice pops, also known as popsicles or ice lollies, are a popular frozen treat loved by people of all ages. Making ice pops at home can be a fun and rewarding experience, and to assist you in this process, an ice pop making machine can be incredibly helpful. This guide provides an overview of ice pop making machines, including their quality, cost, suppliers, certification, market trends, tips, and frequently asked questions.

Quality:

When purchasing an ice pop making machine, it is crucial to consider its quality. Look for machines made from high-quality materials such as stainless steel, as they ensure durability and reliability. A well-constructed machine will withstand frequent use and produce consistent results by freezing ice pops evenly.

Cost:

Ice pop making machines vary in price, depending on their size, capacity, and features. Entry-level machines can cost as little as $50, while more advanced commercial-grade machines can reach several thousand dollars. Assess your needs and budget to find a machine that strikes a balance between quality and cost-effectiveness.

Supplier:

Numerous suppliers offer ice pop making machines, both online and offline. Reputable suppliers include commercial kitchen equipment manufacturers, specialized kitchen appliance retailers, and online marketplaces. Ensure you choose a reliable supplier who offers excellent customer service and provides warranties for their products.

Certification:

When purchasing an ice pop making machine, it is crucial to ensure it meets safety and quality standards. Look for machines that are certified by organizations such as the CE (Conformité Européene) mark, which indicates compliance with European safety standards, or UL (Underwriters Laboratories) certification, which signifies conformity to North American safety standards.

Market:

The market for ice pop making machines has grown significantly in recent years due to the increasing popularity of homemade frozen treats. The demand for these machines is not only seen in homes but also in commercial settings such as ice cream parlors, cafes, and food trucks. The market offers a wide range of machines suitable for various purposes, from small-scale home use to large-scale commercial production.

Tips:

– Experiment with different flavors and ingredients to create unique and refreshing ice pops.

– Use high-quality molds to ensure easy release and well-formed ice pops.

– Allow sufficient freezing time for the pops to set properly.

– Consider investing in a machine with adjustable settings to control freezing temperature and time.

FAQ:

Q: How long does it take to freeze ice pops?

A: The freezing time can vary depending on factors such as the machine’s temperature and the ingredients used, but it typically ranges from 4 to 8 hours.

Q: Can I make healthy ice pops using fresh fruits?

A: Absolutely! Fresh fruits provide a nutritious base for ice pops. You can blend them with water, yogurt, or natural sweeteners to create healthy and delicious treats.

In conclusion, investing in an ice pop making machine allows you to enjoy homemade frozen treats effortlessly. Consider the quality, cost, and certification of the machine, choose a reputable supplier, and explore the market to find the perfect fit. With these tips and answers to frequently asked questions, you are ready to embark on your ice pop making journey.

Types of ice pop making machine

There are several types of ice pop making machines available in the market, each serving a specific purpose and varying in terms of design and functionality. Here are some common types of ice pop making machines:

1. Manual Mold Machines: These machines are ideal for small-scale production or homemade ice pops. They consist of individual molds that are filled with liquid, sealed with a lid or handle, and then manually frozen. Although they require manual effort to fill and freeze, they are cost-effective and easy to use.

2. Semi-Automatic Machines: Semi-automatic ice pop machines are suitable for medium-scale production. They typically have multiple molds that are filled with liquid automatically using a pump or dispenser. Once filled, the molds are manually transferred for freezing. These machines offer increased speed and efficiency compared to manual mold machines.

3. Fully Automatic Machines: Fully automatic ice pop machines are designed for high-volume production in commercial settings. They feature automated processes for filling, freezing, and demolding the ice pops. These machines often have multiple freezing chambers or a continuous conveyor system to enable uninterrupted production. Fully automatic machines can produce a large number of ice pops in a short amount of time, making them ideal for large-scale manufacturing.

4. Molds with Built-in Freezing: Some ice pop making machines have built-in freezing capabilities. These machines eliminate the need for a separate freezer or freezing time, as they rapidly freeze the liquid in the molds. This type of machine is preferred in situations where quick turnaround time is crucial, such as high-demand retail or event settings.

5. Customizable Mold Machines: Customizable ice pop machines are designed to create ice pops in various shapes, sizes, and flavors. These machines usually have interchangeable molds that can be customized according to specific requirements. They offer flexibility to experiment with different designs and cater to customer preferences.

When choosing an ice pop making machine, it is essential to consider factors such as production volume, budget, and desired level of automation. Whether it’s a small-scale operation or a large commercial enterprise, there is a suitable ice pop making machine available to meet the specific needs of each business.

Pros and Cons of Using ice pop making machine

Pros of using an ice pop making machine:

1. Convenience: An ice pop making machine allows for easy and convenient preparation of ice pops. It eliminates the need for manual labor and time-consuming processes, making it perfect for busy individuals or businesses.

2. Speed: Ice pop making machines can produce a large number of ice pops within a short period, increasing efficiency in production. This is particularly useful for commercial purposes or during hot summer months when demand is high.

3. Versatility: These machines typically offer a range of flavors and customization options. Users can experiment with different ingredients, flavors, and even create unique combinations to cater to various preferences.

4. Consistent quality: With an ice pop making machine, the quality and consistency of the ice pops are maintained throughout the production process. This ensures that every ice pop has the same taste and texture, resulting in customer satisfaction and loyalty.

5. Hygiene: Ice pop machines are designed with hygiene in mind. They often have easy-to-clean components and are made with materials that don’t allow for bacterial growth, ensuring safe and clean ice pops.

Cons of using an ice pop making machine:

1. Initial cost: Purchasing an ice pop making machine can be expensive, especially for small businesses or individuals. The cost may be a barrier to entry for those on a tight budget.

2. Maintenance: Regular maintenance may be required, including cleaning and ensuring proper functioning of the machine. This additional task can be time-consuming and may lead to additional expenses if professional assistance is required.

3. Limited customization: While some machines offer customization options, they may have limitations in terms of shape, size, or ingredient variations. This can restrict creativity in designing personalized ice pops.

4. Technical issues: Like any machinery, ice pop making machines can encounter technical problems or breakdowns. This can disrupt production and lead to delays or additional costs for repair.

5. Space requirements: Ice pop making machines can be bulky and require a considerable amount of counter or storage space. This can be a challenge for individuals or businesses with limited space.

In conclusion, an ice pop making machine offers convenience, speed, versatility, consistent quality, and hygiene benefits. However, it comes with initial costs, maintenance requirements, limited customization options, potential technical issues, and space constraints. Considering these pros and cons is essential when deciding whether to invest in an ice pop making machine.

ice pop making machine Reference Specifications (varies for different product)

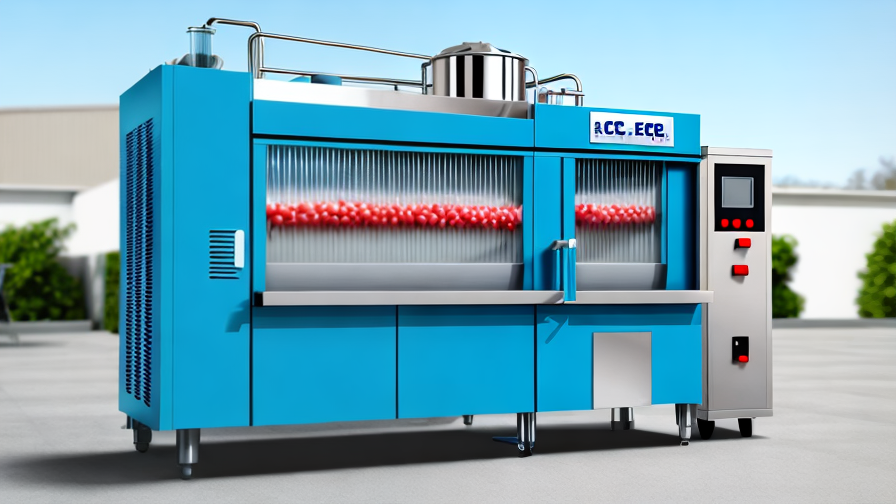

The ice pop making machine is a state-of-the-art appliance designed to produce delicious frozen treats with ease. It is equipped with several advanced features that ensure the production of high-quality ice pops.

The machine utilizes a compressor refrigeration system to rapidly freeze the ingredients and create a smooth and creamy texture. It has a stainless steel freezing chamber that can accommodate various molds, allowing for the production of different shapes and sizes of ice pops. The molds are made from food-grade materials, ensuring safe and hygienic freezing.

The machine is equipped with a user-friendly control panel that allows for easy operation and customization of freezing time and temperature. It also has a digital display that showcases the current settings and the remaining freezing time. This feature allows for precise control and consistency in the production process.

To ensure the safety of the user, the machine has a built-in automatic shut-off feature that activates when the freezing process is complete or if the machine overheats. It also has a power indicator light that signals if the machine is on or off. Additionally, the machine has non-skid rubber feet to provide stability during operation.

The ice pop making machine is designed for both commercial and home use, catering to a wide range of production requirements. It has a capacity to produce a large number of ice pops in a short amount of time, making it perfect for parties, events, or even small businesses.

In conclusion, the ice pop making machine is an efficient and reliable appliance that offers a convenient solution for producing delicious frozen treats. With its advanced features, user-friendly interface, and emphasis on safety, it is a must-have for anyone looking to create refreshing ice pops.

Applications of ice pop making machine

Ice pop making machines have become increasingly popular due to the high demand for frozen treats. These machines are versatile and can be used in various settings, ranging from small businesses to large-scale manufacturing. Here are a few applications of ice pop making machines:

1. Commercial Production: Ice pop making machines are commonly utilized by commercial food manufacturers to produce large quantities of ice pops. These machines are capable of producing popsicles with consistent size and shape, ensuring uniformity in the final product. Commercial production facilities can produce a wide variety of flavors and designs to cater to different consumer preferences.

2. Food Trucks and Street Vendors: Ice pop making machines are ideal for food trucks and street vendors as they provide a convenient way to make frozen treats on the go. These compact machines can fit into small spaces and allow vendors to quickly produce ice pops in different flavors. Food trucks can attract customers during hot summer days by offering a refreshing and delicious frozen treat that is made on-site.

3. Cafes and Dessert Shops: Ice pop making machines are an excellent addition to cafes and dessert shops, enhancing their menu options. These establishments can create unique and gourmet ice pops by experimenting with various flavors, ingredients, and presentations. Ice pop making machines also allow for the inclusion of healthy and natural ingredients, appealing to health-conscious customers.

4. Events and Parties: Ice pop making machines are a hit at events and parties, offering a fun and interactive activity for attendees. These machines can be set up at dessert stations, where people can choose their preferred flavors and customize their ice pops by adding toppings or coatings. Ice pops made on the spot can be a unique and memorable treat for guests.

5. Specialty Stores: Ice pop making machines enable specialty stores to create their own branded ice pops. This differentiation can attract customers looking for a unique frozen treat experience. Specialty stores can experiment with flavors and combinations, providing customers with a wide selection of delicious and exclusive ice pops.

In conclusion, ice pop making machines have a range of applications, from commercial production to enhancing menu options in cafes and food trucks. Their versatility and ability to produce ice pops quickly and efficiently make them a valuable asset to businesses in the food industry.

The Work Process and how to use ice pop making machine

The work process of an ice pop making machine is a simple and efficient way to create delicious frozen treats. To use the machine, follow these steps:

1. Preparation: Start by gathering all the necessary ingredients and materials. This usually includes fruit juices or purees, sweeteners, and popsicle molds. Ensure that the molds are clean and ready for use.

2. Mixing: Depending on the recipe, mix the desired fruit juices or purees with the sweeteners in a separate bowl. You can also add any additional flavors or ingredients at this stage.

3. Pouring: Once the mixture is ready, carefully pour it into the individual popsicle molds. Leave a small gap at the top of each mold to allow for expansion during freezing.

4. Inserting sticks: Place the molds into the ice pop making machine. Ensure that the sticks are properly inserted into the molds, maintaining an upright position. The machine may have special slots or holders to secure the sticks.

5. Freezing: Close the machine securely and activate the freezing process. The machine will typically freeze the popsicles in a relatively short period depending on the machine’s specifications and the ingredients used.

6. Removing the popsicles: Once the freezing process is complete, open the machine and carefully remove the popsicles. Gently release each popsicle by twisting or flexing the mold slightly.

7. Serving or storing: Enjoy your homemade ice pops immediately or transfer them to airtight containers or plastic bags for storage in the freezer.

It is important to follow the machine’s instructions and safety guidelines to ensure proper functioning and to prevent accidents. Additionally, experiment with different flavor combinations and ingredients to create unique ice pop recipes that cater to your preferences.

Quality Testing Methods for ice pop making machine and how to control the quality

When it comes to quality testing methods for an ice pop making machine, there are several important considerations to ensure the production of high-quality ice pops. Here are some key testing methods and quality control measures:

1. Raw material assessment: Start by examining the quality of the ingredients used to make the ice pops. This includes assessing the freshness, taste, color, and texture of the fruits, syrups, or flavors used. Ensure that only high-quality ingredients are used to maintain the desired taste and consistency.

2. Temperature control: Accurate temperature control is vital for making consistent and uniform ice pops. Regularly monitor and calibrate the machine’s temperature settings to ensure that the freezing process is consistent, preventing issues like uneven freezing or ice crystal formation.

3. Flavor consistency: Conduct regular taste tests to ensure the consistent flavor of the ice pops. Randomly sample ice pops at different production stages and check if they meet the desired flavor profile. Make adjustments to the recipe or syrup concentrations if needed.

4. Packaging evaluation: Assess the packaging quality to ensure that it is durable and can maintain the ice pops’ freshness and quality. Check for issues like leaks, inadequate sealing, or poor quality materials that may affect the product’s shelf life.

5. Texture assessment: Regularly examine the texture of the ice pops to ensure they are not too icy or too soft. Utilize sensory evaluations to assess mouthfeel, level of iciness, and overall texture. Adjust freezing time or ingredients if necessary to achieve the desired texture.

6. Hygiene and sanitation: Maintain proper hygiene standards throughout the manufacturing process. Regularly clean and sanitize the machine and other equipment to prevent any contamination. Conduct microbial testing to identify any potential bacteria or mold growth.

7. Consumer feedback: Pay close attention to customer feedback, both positive and negative, to identify any quality issues or areas for improvement. Evaluate customer reviews and comments, and utilize surveys or feedback forms to gather insights on taste, texture, and overall satisfaction.

By implementing these quality testing methods and control measures, manufacturers can ensure that their ice pop making machine produces high-quality ice pops consistently. Continuous monitoring, regular evaluations, and addressing any issues that arise promptly are essential steps towards maintaining product quality and customer satisfaction.

ice pop making machine Sample Policy and Post-Purchase Considerations for ice pop making machine from China

Sample Policy:

1. Sample Availability: Suppliers should provide samples of the ice pop making machine upon request. The sample can be charged, but the cost should be reasonable and refundable upon successful order placement.

2. Sample Delivery: Suppliers should ensure prompt and efficient delivery of samples, preferably within a specified timeframe.

3. Sample Quality: Sample units should be of the same quality as the final product. Any defects or discrepancies should be clearly communicated to the buyer.

Post-Purchase Considerations:

1. Quality Assurance: Suppliers should provide a warranty for the ice pop making machine to ensure its durability and performance. Any defects or malfunctions should be addressed in a timely manner.

2. After-Sales Service: Suppliers should have a dedicated customer service team to handle any queries or concerns after the purchase. Prompt and satisfactory responses should be provided to ensure customer satisfaction.

3. Spare Parts Availability: Suppliers should ensure that spare parts for the ice pop making machine are easily accessible. It is ideal to have spare parts readily available for quick replacements, minimizing downtime.

4. User Manual and Training: Suppliers should provide a comprehensive user manual along with the ice pop making machine, detailing its operation and maintenance. Additionally, training sessions or online tutorials can be offered to assist buyers in understanding and utilizing the machine effectively.

5. Customizable Features: Suppliers should offer customization options for the ice pop making machine to suit specific requirements. This may include adjustable temperature settings, varying mold shapes, or additional accessories.

6. Compliance and Certification: Suppliers should ensure that the ice pop making machine complies with all relevant safety and quality standards. It is preferable if certifications, such as CE or ISO, are obtained to guarantee product reliability.

7. Packaging and Shipping: Suppliers should use appropriate packaging materials to prevent any damage during transportation. Efficient and reliable shipping methods should be chosen to deliver the ice pop making machine in a timely and secure manner.

By considering these sample policies and post-purchase considerations, buyers can ensure a smooth procurement process and maximize their satisfaction with the ice pop making machine purchased from China.

Sourcing ice pop making machine from China: Opportunities, Risks, and Key Players

China is a major player in the manufacturing industry, and sourcing an ice pop making machine from China can offer various opportunities. One of the key advantages is the cost-effectiveness of Chinese products. China’s abundant labor force and efficient manufacturing capabilities allow for the production of ice pop making machines at a lower cost compared to other countries. This cost advantage can be beneficial for businesses looking to maximize their profit margins.

Another opportunity is the availability of a wide range of options. China has a diverse supplier base that offers ice pop making machines in various sizes, capacities, and features. This allows buyers to find a machine that best suits their requirements and preferences, providing flexibility and customization options.

However, sourcing from China also comes with certain risks. One of the potential challenges is maintaining product quality. It is crucial to carefully select reliable suppliers and conduct thorough quality checks to ensure that the ice pop making machines meet the required standards. Working with a trusted sourcing agent or conducting factory audits can mitigate this risk.

Another risk is the possibility of intellectual property infringement. China’s reputation for counterfeiting and copying patented products is well-known. To protect intellectual property rights, it is advisable to work with reputable manufacturers and have clear contracts with strong legal provisions to safeguard the buyer’s interests.

Key players in the ice pop making machine industry in China include Jiangmen Prosea Machinery Co., Ltd., Zhangjiagang City Xinmao Drink Machinery Co., Ltd., and Shanghai Hengxuan Food Machinery Co., Ltd. These companies are renowned for their expertise and experience in manufacturing ice pop making machines. Conducting thorough research on these key players, including their reputation, product quality, and customer reviews, is crucial when selecting a supplier.

In conclusion, sourcing ice pop making machines from China offers several opportunities, including cost-effectiveness and a wide range of options. However, risks such as product quality and intellectual property infringement should be carefully managed. Working with reputable manufacturers and conducting due diligence can help businesses mitigate these risks and leverage the benefits of sourcing from China.

How to find and select reliable ice pop making machine manufacturers in China,use google search manufacturers and suppliers

When looking for reliable ice pop making machine manufacturers in China, it is essential to conduct a thorough search and select manufacturers with a solid reputation. One effective method is to use Google search and follow these steps:

1. Start by typing relevant keywords, such as “ice pop making machine manufacturers in China” or “reliable ice pop making machine suppliers.”

2. Review the search results and visit the websites of various manufacturers. Look for well-established companies that have been in the industry for several years, as they are more likely to have experience and expertise.

3. Pay attention to the manufacturer’s website design, layout, and content. A professional and well-maintained website indicates that the company takes their business seriously.

4. Look for manufacturer’s certifications and quality standards. Reliable manufacturers usually display their certifications such as ISO 9001:2015, CE, or FDA on their websites. These certifications ensure that their products meet international quality standards.

5. Check the manufacturer’s product range. A reputable manufacturer should offer a wide range of ice pop making machines with different capacities and features. This indicates their expertise in the field and their ability to cater to diverse customer needs.

6. Read customer reviews and testimonials. Look for reviews on the manufacturer’s website, social media platforms, or specialized industrial forums. Positive reviews from previous customers can provide insights into the manufacturer’s product quality, after-sales service, and overall satisfaction.

7. Contact multiple manufacturers and inquire about their products, pricing, warranty, and other relevant details. A reliable manufacturer should respond promptly and provide clear and comprehensive information.

8. Consider visiting trade shows or exhibitions related to the food processing industry. These events provide opportunities to meet manufacturers face-to-face, get hands-on experience with their products, and establish professional relationships.

By following these steps and conducting thorough research, you can find and select reliable ice pop making machine manufacturers in China that meet your business requirements.

How to check ice pop making machine manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To determine the reliability of an ice pop making machine manufacturer’s website, you can follow these steps:

1. Use Google Chrome: Launch Google Chrome browser on your computer.

2. Install SEOquake: Install the SEOquake browser extension. To do so, open a new tab in Google Chrome, search for “SEOquake Chrome extension” and follow the steps to add it to your browser.

3. Visit the manufacturer’s website: Enter the website URL of the ice pop making machine manufacturer in the address bar and press enter to access the website.

4. Check for HTTPS: Look for “https://” at the beginning of the website URL, which indicates that the website is secured with SSL certificate. This ensures a secure connection and protects your personal information.

5. Use SEOquake: Click on the SEOquake extension icon located in the top-right corner of your Google Chrome browser. This will open a toolbar presenting various SEO metrics.

6. Check Alexa Rank: In the SEOquake toolbar, locate and click on the “Alexa Rank” option. If the website ranks within the top 10 million websites globally, it signifies that it has a decent amount of traffic and is more likely to be reliable.

7. Assess website design and content: Browse through the website to evaluate its overall design, layout, and user-friendliness. A professional-looking website with well-organized content lends credibility to the manufacturer.

8. Read About Us and Contact Information: Look for an “About Us” page and read information about the company, its history, and experience in the industry. Also, check if the website provides valid contact information, such as a physical address, phone number, and email address.

9. Check for customer reviews: Search for reviews or testimonials from other customers about the ice pop making machine manufacturer. This can be done by using search engines or checking if the website itself has a section dedicated to customer feedback.

10. Verify product information: Ensure the website provides detailed product descriptions, specifications, and images of the ice pop making machine. Reliable manufacturers typically provide comprehensive information about their products.

By following these steps, you can gain a better understanding of the reliability of the ice pop making machine manufacturer’s website before making a purchase.

Top 10 ice pop making machine manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Zhejiang Spaceman Ice Systems Co., Ltd.

Zhejiang Spaceman Ice Systems Co., Ltd. is a pioneer in the ice pop making machine manufacturing industry in China. The company offers a wide range of ice pop machines that are highly efficient, durable, and user-friendly. Their machines are equipped with advanced technology for consistent and precise results. They also have a dedicated R&D team that ensures continuous innovation and improvement of their products.

2. Jiangsu Xuemei Refrigeration Equipment Co., Ltd.

Jiangsu Xuemei Refrigeration Equipment Co., Ltd. specializes in the production of high-quality ice pop making machines. Their machines are designed to produce ice pops of various shapes, sizes, and flavors. With a focus on energy efficiency and hygiene, their products are built to meet international standards. They also offer customization options to meet specific customer requirements.

3. Guangzhou Icesource Co., Ltd.

Guangzhou Icesource Co., Ltd. is known for its state-of-the-art ice pop making machines. Their machines are designed with precision engineering to produce high-quality ice pops with consistent texture and taste. They offer a range of models suitable for small-scale production as well as large-scale industrial use. The company also provides excellent after-sales service and technical support.

4. Shenzhen Ocean Power Industrial Co., Ltd.

Shenzhen Ocean Power Industrial Co., Ltd. is a leading manufacturer of ice pop making machines in China. Their machines are known for their efficient performance, easy installation, and low maintenance. They offer a variety of models with different production capacities and features to cater to the diverse needs of their customers.

5. Ningbo Sicen Refrigeration Equipment Co., Ltd.

Ningbo Sicen Refrigeration Equipment Co., Ltd. is a renowned manufacturer of ice pop making machines. Their machines are designed to produce ice pops in large quantities while maintaining optimum quality. They offer advanced models with features like automatic filling, freezing, and demolding for a seamless production process. Their machines are widely used in ice cream factories, food processing units, and more.

6. Shanghai Jingyao Industrial Co., Ltd.

Shanghai Jingyao Industrial Co., Ltd. is a trusted name in the ice pop making machine manufacturing industry. They offer a range of machines that are designed for high productivity and efficiency. Their machines are equipped with advanced freezing technology to ensure fast freezing and consistent product quality. The company also offers customization options to meet specific customer requirements.

7. Shenzhen Sindeice Systems Co., Ltd.

Shenzhen Sindeice Systems Co., Ltd. manufactures top-quality ice pop making machines for various applications. Their machines are known for their robust construction, energy efficiency, and user-friendly operation. They offer a range of models with different production capacities and features to cater to the specific needs of their customers.

8. Foshan Powerland Technology Co., Ltd.

Foshan Powerland Technology Co., Ltd. specializes in the production of high-performance ice pop making machines. Their machines are designed with advanced freezing technology for efficient and fast production. They also incorporate safety features and easy-to-use controls for convenience. The company offers excellent technical support and customer service.

9. Hangzhou Minsheng Ice Cream Machine Co., Ltd.

Hangzhou Minsheng Ice Cream Machine Co., Ltd. is a leading manufacturer of ice pop making machines in China. Their machines are built with precision engineering and high-quality materials for durability and efficient performance. They offer a range of models suitable for different production capacities and requirements.

10. Guangzhou DreamFactory Equipment Co., Ltd.

Guangzhou DreamFactory Equipment Co., Ltd. is a reputable manufacturer of ice pop making machines in China. Their machines are designed for high-speed production without compromising on quality. They offer various models with advanced features for efficient freezing, filling, and demolding processes. The company also provides technical support and after-sales service to ensure customer satisfaction.

| Manufacturer | Key Features |

| — | — |

| Zhejiang Spaceman Ice Systems Co., Ltd. | – Advanced technology for precise results

– Durable and user-friendly designs |

| Jiangsu Xuemei Refrigeration Equipment Co., Ltd. | – Produces ice pops of various shapes, sizes, and flavors

– Customizable options available |

| Guangzhou Icesource Co., Ltd. | – State-of-the-art machines for consistent texture and taste

– Suitable for small-scale and large-scale production |

| Shenzhen Ocean Power Industrial Co., Ltd. | – Easy installation and low maintenance

– Multiple models with different features |

| Ningbo Sicen Refrigeration Equipment Co., Ltd. | – High productivity and quality

– Equipped with automatic filling, freezing, and demolding |

| Shanghai Jingyao Industrial Co., Ltd. | – High-performance machines for fast freezing

– Customization options available |

| Shenzhen Sindeice Systems Co., Ltd. | – Robust construction and efficient operation

– Various models with different capacities |

| Foshan Powerland Technology Co., Ltd. | – Advanced freezing technology

– Safety features and easy controls |

| Hangzhou Minsheng Ice Cream Machine Co., Ltd. | – Durable and efficient machines

– Suitable for different production capacities |

| Guangzhou DreamFactory Equipment Co., Ltd. | – High-speed production without compromising on quality

– Technical support and after-sales service |

Background Research for ice pop making machine manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to ice pop making machine manufacturers in China, there are several websites that can provide background research on companies operating in this field. This includes qcc.com, archive.org, and importyeti.com. These platforms offer valuable information about businesses, such as their registration details, export/import records, and company profiles. It is recommended to limit the summary to 300 words or less.

QCC.com is a Chinese platform that allows users to search for detailed information about companies in China. It provides business registration data, such as the legal name, registration number, status, date of establishment, and registered capital. Users can also find the company’s operating address, contact details, and official website, if available. This source is particularly useful for obtaining specific information about ice pop making machine manufacturers in China, helping to verify their legitimacy and credibility.

Archive.org is an online platform that allows users to access historical snapshots of websites. This can be useful for conducting background research on ice pop making machine manufacturers, as it provides a way to view the evolution of a company’s website over time. By examining past versions of a manufacturer’s website, one can gain insights into the company’s history, product range, and any changes or improvements made over the years.

Importyeti.com is a comprehensive platform that provides import and export data for various industries, including ice pop making machines. This website provides information on manufacturers, their export destinations, shipment details, and even contact information. By using Importyeti.com, potential buyers can identify which manufacturers are actively exporting ice pop making machines and gain insights into their international trade activities.

In conclusion, qcc.com, archive.org, and importyeti.com are valuable platforms for obtaining background research on ice pop making machine manufacturers in China. These sources offer information on companies’ registration details, historical website snapshots, and import/export data. Researchers can utilize these platforms to gain insights into a manufacturer’s credibility, history, and international trade activities.

Leveraging Trade Shows and Expos for ice pop making machine Sourcing in China

Trade shows and expos are excellent platforms for sourcing ice pop making machines in China. These events offer an opportunity to connect with numerous suppliers, manufacturers, and distributors from the industry, all gathered in one place. By leveraging these events effectively, you can maximize your chances of finding the right machine for your business.

When attending trade shows and expos in China, it is essential to plan and research in advance. Look for events that specifically focus on the food processing or machinery industry, as they are more likely to have ice pop making machine manufacturers or suppliers. Websites like Alibaba, TradeKey, and Global Sources can provide valuable information about upcoming events and the exhibitors present.

During the event, visit the booths of potential suppliers and engage in thorough discussions to understand their capabilities, product range, pricing, and manufacturing processes. Be prepared with specific requirements, such as production capacity, machine size, power consumption, and any additional functions you may need.

Besides, inquire about the supplier’s experience in exporting to your country, warranty and after-sales service, certifications (such as CE or FDA), and availability of spare parts. Taking notes and collecting brochures from each supplier can help you compare and evaluate the options later.

Additionally, attending conferences, seminars, or presentations at the event will provide valuable insights into the latest trends, technological advancements, and challenges in the ice pop making machine industry in China. This knowledge will equip you with a better understanding of the market and help you make informed decisions.

After the event, follow-up with the suppliers you were interested in and request additional information or samples if needed. Build and maintain a professional relationship with them to ensure a smooth sourcing process.

By strategically leveraging trade shows and expos, you can efficiently source ice pop making machines from China while establishing connections with reliable suppliers. Investing time and effort in attending these events can lead to long-term success and growth for your business.

The Role of Agents and Sourcing Companies in Facilitating ice pop making machine Purchases from China

Agents and sourcing companies play a crucial role in facilitating ice pop making machine purchases from China. These entities act as intermediaries between the buyers and manufacturers, helping to streamline the procurement process and ensure smooth transactions.

One of the primary functions of agents and sourcing companies is to establish a network of reliable manufacturers in China. They thoroughly research and vet potential suppliers to find those capable of meeting the buyer’s quality, quantity, and budget requirements. This saves buyers the time and effort of searching for reputable manufacturers on their own.

Agents and sourcing companies also assist in negotiations and contract drafting. They have a deep understanding of the Chinese market and can effectively negotiate favorable terms and conditions on behalf of the buyer. They ensure all necessary information, such as specifications, packaging, and delivery arrangements, is clearly conveyed to the manufacturer, minimizing the risk of misunderstandings or disputes.

Furthermore, these intermediaries provide quality control services throughout the production process. They conduct regular factory visits and inspections to ensure that the ice pop making machines adhere to the buyer’s specifications and meet the required quality standards. This helps buyers avoid costly mistakes and ensures that the final product meets their expectations.

Agents and sourcing companies also handle logistics and shipping arrangements. They coordinate the transportation of the ice pop making machines from the manufacturer’s facility in China to the buyer’s location, handling customs clearance, documentation, and freight forwarding. This simplifies the import process for buyers and ensures timely delivery of the machines.

In summary, agents and sourcing companies streamline the ice pop making machine purchasing process from China by providing a wide range of services. They help buyers find reliable manufacturers, negotiate favorable terms, ensure quality control, and manage logistics. By leveraging their expertise and local knowledge, these intermediaries facilitate successful purchases and help buyers minimize risks and maximize efficiency.

Price Cost Research for ice pop making machine manufacturers Companies in China, use temu.com and 1688.com

When conducting price cost research for ice pop making machine manufacturers in China, two popular platforms to explore are temu.com and 1688.com. These websites serve as comprehensive directories for suppliers and manufacturers in China. By utilizing these platforms, one can find multiple options and compare prices to ensure a cost-effective purchase.

Temu.com is a reliable platform that connects international buyers with verified Chinese suppliers. It provides an extensive range of ice pop making machine manufacturers, offering a vast selection of products and competitive prices. Users can communicate directly with the manufacturers, negotiate prices, and gather information on product specifications, payment methods, and shipping options.

1688.com, on the other hand, is a prominent Chinese B2B marketplace where buyers can find various ice pop making machine manufacturers. Though the website is primarily in Chinese, it can be translated into English using browser plugins. With millions of suppliers listed, it offers a wide range of options at different price points. While browsing through 1688.com, buyers can examine product descriptions, materials used, and customer reviews to gauge the quality and cost-effectiveness of different manufacturers.

In terms of price research, it is crucial to consider factors beyond the initial cost of the ice pop making machine. Additional expenses may include shipping fees, import taxes, customs duties, and possible warranty costs. It is advisable to reach out to multiple manufacturers, requesting quotations and negotiating to secure the best price possible.

In conclusion, when searching for ice pop making machine manufacturers in China, temu.com and 1688.com are valuable platforms to find various suppliers and compare prices. By utilizing these resources, buyers can make informed decisions while considering important factors like quality, specifications, and total costs.

Shipping Cost for ice pop making machine import from China

The shipping cost for importing an ice pop making machine from China can vary depending on several factors such as the weight and size of the machine, the distance it needs to be shipped, the transportation method chosen, and any additional services required.

Typically, the cost of shipping is calculated based on the weight or volume of the shipment. For smaller ice pop making machines, air freight may be a suitable option. Air freight is generally faster but can be more expensive compared to sea freight. Shipping via sea freight is a more economical option for larger machines. It is important to note that sea freight can take longer, usually around 30-40 days, compared to air freight which can take around 5-7 days.

The shipping cost may also include additional services such as customs clearance, insurance, and delivery to the final destination. These services might be provided by the shipping company or might require hiring a separate customs broker or freight forwarder.

To get an estimate of the shipping cost, it is recommended to contact multiple shipping companies or freight forwarders and provide them with the necessary details such as weight, dimensions, and the required services. They will be able to provide you with a quote based on your specific requirements. Doubling checking the reputation and reliability of the shipping company is crucial to ensure a smooth and hassle-free shipping process.

In conclusion, the shipping cost for importing an ice pop making machine from China will depend on various factors. It is essential to consider the weight, dimensions, transportation method, and additional services required. By obtaining multiple quotes and comparing the services offered by different shipping companies, you can find the most cost-effective and reliable option for your business.

Compare China and Other ice pop making machine Markets: Products Quality and Price,Visible and Hidden Costs

China is a major player in the ice pop making machine market, but how does it compare to other markets in terms of product quality and price, as well as visible and hidden costs? Let’s take a closer look.

Product quality is a crucial factor when choosing an ice pop making machine. China has gained a reputation for producing a wide range of products, including ice pop making machines, at various quality levels. While there are high-quality machines available, buyers should exercise caution and thoroughly research different brands and manufacturers. Other markets, such as Europe and the United States, generally offer a higher standard of product quality. These markets often have stringent regulations and standards that ensure the machines are safe, durable, and efficient.

When it comes to pricing, China has an advantage over other markets due to its lower labor and production costs. Chinese manufacturers can offer ice pop making machines at more competitive prices compared to their European or American counterparts. However, this does not necessarily mean that Chinese machines are always the most cost-effective option. Buyers need to consider other factors such as quality, warranty, maintenance, and after-sales support.

Visible costs, such as the purchase price and shipping fees, are relatively straightforward to evaluate. Chinese machines may have lower initial costs, including lower shipping fees due to proximity to international markets. On the other hand, importing from Europe or the United States may involve higher shipping costs. However, buyers should also consider hidden costs, such as import duties, taxes, and possible language barriers, which can significantly impact the overall cost of purchasing from China.

Furthermore, after-sales support and maintenance are essential considerations for any buyer. Other markets often provide better customer service, easily accessible spare parts, and comprehensive warranties. Chinese manufacturers may have limited customer support, and finding spare parts or technical assistance can be challenging.

In summary, China’s ice pop making machine market offers competitive prices due to lower production costs. However, product quality and after-sales support can sometimes be inferior compared to other markets, such as Europe or the United States. Buyers need to carefully assess the visible and hidden costs associated with importing from China, taking into account factors beyond the initial purchase price.

Understanding Pricing and Payment Terms for ice pop making machine: A Comparative Guide to Get the Best Deal

When considering purchasing an ice pop making machine, understanding the pricing and payment terms is crucial to getting the best deal. Here is a comparative guide to help you make an informed decision:

1. Price range: Ice pop making machines come in a variety of price ranges. The cost is often influenced by factors such as size, capacity, features, and brand reputation. Generally, smaller machines are more affordable, while larger, commercial-grade models tend to be pricier.

2. Quality and durability: While it may be tempting to opt for a cheaper machine, it is important to consider the quality and durability. Investing in a high-quality machine might be slightly more expensive upfront, but it can save costs in the long run as it will likely require fewer repairs or replacements.

3. Payment options: When purchasing an ice pop making machine, it is essential to consider the available payment options. Some suppliers or manufacturers may offer flexible payment plans or financing options, allowing you to spread out the cost over time. Others may require full payment upfront.

4. Warranty and after-sales support: Check if the machine comes with a warranty and what it covers. A longer warranty period indicates the manufacturer’s confidence in their product. Additionally, inquire about after-sales support, including technical assistance and spare parts availability. A reliable supplier should provide prompt assistance to resolve any issues that may arise.

5. Additional costs: Consider any additional costs associated with the machine, such as shipping fees, taxes, or installation charges. These costs can significantly impact the overall price and should be factored into your budget.

6. Comparing suppliers: It is advisable to research and compare different suppliers or manufacturers before making a decision. Look for reputable companies with positive customer reviews and consider reaching out for quotes or product information. This allows you to compare prices, payment terms, and included features to determine the best deal.

In conclusion, understanding the pricing and payment terms for ice pop making machines is vital to make an informed purchase decision. Consider the price range, quality, payment options, warranty, after-sales support, additional costs, and compare different suppliers to ensure you get the best deal possible. By doing thorough research and analysis, you can acquire an ice pop making machine that meets your requirements while fitting within your budget.

Chinese Regulations and Industry Standards Certifications for ice pop making machine,Import Regulations and Customs for ice pop making machine from China

When importing an ice pop making machine from China, it is essential to understand the Chinese regulations and industry standards certifications, as well as the import regulations and customs procedures involved.

Chinese Regulations and Industry Standards Certifications:

1. Certification of Conformity: The ice pop making machine must comply with the relevant standards set by the China Compulsory Certification (CCC) system. This certification ensures that the product meets the necessary safety and quality requirements.

2. Food Safety Standards: As an ice pop making machine deals with food products, it is crucial to adhere to Chinese food safety standards. The machine should be made from food-grade materials to avoid contamination and ensure the health and safety of consumers.

3. Environmental Standards: Ice pop making machines should also comply with Chinese environmental regulations, such as restrictions on the use of certain materials or the emission of pollutants during the production process.

Import Regulations and Customs Procedures:

1. Import Duties: Ice pop making machines are subject to import duties when entering China. Importers need to pay the required taxes based on the customs valuation of the machines.

2. Customs Documentation: Appropriate documentation is essential for customs clearance. Importers need to provide documents like the commercial invoice, packing list, bill of lading or airway bill, and a certificate of origin.

3. Customs Declaration: Importers must submit a customs declaration to the Chinese authorities, accurately describing the imported ice pop making machines and the associated value.

4. Inspection and Quarantine: In some cases, imported ice pop making machines may undergo inspection and quarantine to ensure compliance with Chinese regulations. This process may include product sampling, testing, and verification of certificates and documentation.

In conclusion, when importing an ice pop making machine from China, it is crucial to ensure compliance with Chinese regulations and industry standards certifications. Additionally, importers should be familiar with the import regulations and customs procedures to facilitate a smooth import process.

Sustainability and Environmental Considerations in ice pop making machine Manufacturing

In recent years, sustainability and environmental considerations have become paramount in various industries, including the manufacturing sector. With the increasing global concern for the environment, manufacturers are being urged to adopt sustainable practices and reduce their carbon footprint. This holds true even for the manufacturing of ice pop making machines.

One important consideration in the manufacturing of ice pop making machines is the choice of materials. Manufacturers are encouraged to use eco-friendly and recyclable materials in the production process. This includes opting for components made from renewable resources or using recycled materials. Additionally, manufacturers can strive to minimize waste by designing machines that can be easily disassembled and recycled at the end of their lifecycle.

Energy efficiency is another key factor in sustainability. Ice pop making machines should be designed to consume minimal energy during operation. This can be achieved by incorporating energy-saving technologies, such as efficient refrigeration systems, insulated housing, and optimized heating mechanisms. Implementing smart controls and sensors can also help in reducing energy consumption by allowing the machine to adjust its operations based on demand.

Water usage is another important consideration. Ice pop making machines typically require water for various processes, such as freezing and cleaning. Manufacturers can incorporate water-saving features, such as efficient water recirculation systems and low-flow nozzles, to minimize water consumption during production. Additionally, implementing water treatment systems can ensure that wastewater is properly treated before being released into the environment.

Furthermore, manufacturers should focus on reducing emissions and air pollutants associated with the operation of ice pop making machines. This can be achieved by improving combustion efficiency, implementing advanced filter systems, and using eco-friendly refrigerants with lower ozone depletion potential and global warming potential.

Overall, the manufacturing of ice pop making machines should prioritize sustainability and environmental considerations. By choosing eco-friendly materials, incorporating energy-saving technologies, minimizing water usage, and reducing emissions, manufacturers can contribute to a more sustainable and environmentally friendly manufacturing process. By adhering to these principles, the ice pop making machine industry can align with the global movement towards a greener and more sustainable future.

List The Evolution history of “ice pop making machine”

The evolution history of the ice pop making machine can be traced back to ancient civilizations that used simple methods to produce frozen treats. In early times, people in ancient Persia and China would mix fruits with snow or ice to create refreshing concoctions. However, the concept of a machine solely dedicated to ice pop production emerged much later.

The first significant development in ice pop making came during the 19th century. In the 1840s, an American physician named Dr. John Gorrie invented a machine that could produce ice by compressing air. Although his invention was primarily intended to cool hospital rooms, it inadvertently sparked the idea of using such machines for creating frozen treats.

Fast forward to the 20th century, the popularity of ice pops grew, and with it came more advanced machines. In the early 1920s, an American inventor named Harry Burt patented the “Good Humor” machine. This innovation consisted of a wooden rack containing molds filled with liquid ice pop mixtures. The molds were then placed in a refrigerated compartment, allowing for the quick freezing of the treats.

Advancements continued in the mid-20th century. In the 1940s, Clarence Vogt, a mechanical engineer, created an automated ice pop making machine. This machine could mechanize the production process, enabling large-scale production of ice pops. It featured a conveyor belt system that would move the filled molds through a freezing chamber, resulting in more efficient and consistent freezing.

As technology advanced, the ice pop making machines became more sophisticated. In the 1980s, the introduction of computerized controls and stainless steel construction further improved the efficiency and sanitary conditions of the machines. This allowed for higher production capacities and enhanced product quality.

In recent years, ice pop making machines have become even more advanced. They now often utilize advanced freezing technologies like blast freezing, which quickly freezes the ice pops, preserving their taste and texture. Furthermore, modern machines have improved mold designs, allowing for the creation of more intricate shapes and designs.

In conclusion, the evolution of the ice pop making machine demonstrates how a simple idea, combined with technological advancements, can lead to significant developments. From the basic mixing of fruit and ice to the fully automated and computerized machines of today, ice pop making machines have undergone considerable transformations, enabling the production of delicious frozen treats at a larger scale and with improved quality.

The Evolution and Market Trends in ice pop making machine Industry

In recent years, there has been a significant evolution in the ice pop making machine industry. Ice pops, also known as popsicles or ice lollies, have gained popularity as a refreshing and convenient snack option, especially during the summer months. As a result, the demand for ice pop making machines has increased, leading to several market trends.

One of the key trends in the ice pop making machine industry is the shift towards automated and high-capacity machines. With the increasing demand for ice pops, manufacturers are looking for efficient and time-saving solutions to meet the production requirements. Automated machines are capable of producing a large number of ice pops in a shorter time frame, allowing manufacturers to cater to the growing market demand.

Another trend in the industry is the emphasis on customization and innovation. Consumers today are looking for unique and personalized food experiences. Ice pop making machine manufacturers are responding to this trend by offering customizable features and options. From flavors and ingredients to shapes and sizes, these machines allow manufacturers to create a variety of ice pops to cater to different consumer preferences. Furthermore, manufacturers are also focusing on incorporating innovative technologies, such as quick freezing processes and advanced packaging solutions, to enhance the overall quality and presentation of the ice pops.

Additionally, there is a growing trend towards eco-friendly and sustainable ice pop making machines. As sustainability concerns continue to rise, manufacturers are developing machines that are energy-efficient, reduce waste, and use environmentally-friendly materials. This trend aligns with the increasing consumer demand for eco-conscious products, ultimately driving the adoption of sustainable practices within the industry.

In conclusion, the ice pop making machine industry has undergone significant evolution and witnessed various market trends. The shift towards automated and high-capacity machines, the emphasis on customization and innovation, and the focus on eco-friendly solutions are key trends shaping the industry. As the demand for ice pops continues to grow, it is expected that these trends will further drive the development and advancement of ice pop making machines.

Custom Private Labeling and Branding Opportunities with Chinese ice pop making machine Manufacturers

China has emerged as a leading global manufacturer and exporter of ice pop making machines, creating an opportunity for businesses to explore custom private labeling and branding options with Chinese manufacturers. With the increasing popularity of ice pops worldwide, custom branding allows businesses to differentiate their products and establish a strong brand identity in the market.

By collaborating with Chinese ice pop making machine manufacturers, businesses can leverage their expertise in manufacturing high-quality machines at competitive prices. Chinese manufacturers have a diverse range of ice pop making machines, including small-scale manual machines to large-scale automated production lines, catering to businesses of all sizes. This variety enables businesses to choose the machine that best suits their production requirements and operational scale.

Custom private labeling and branding options offer several benefits to businesses. Firstly, it allows companies to feature their own logo, company name, and unique design on the ice pop making machines, distinguishing their products from competitors. This enhances brand recognition and consumer trust, thereby driving sales and customer loyalty.

Additionally, custom branding offers the opportunity to customize the machine’s appearance, packaging, and user interface to align with the brand’s aesthetics and target market preferences. By incorporating brand-specific features, businesses can create a cohesive and personalized customer experience.

Moreover, Chinese manufacturers offer flexible customization options, enabling businesses to adapt the ice pop making machines to suit their specific production needs. From adjustable molds to different freezing techniques, manufacturers can tailor the machines to produce ice pops with the desired shape, size, and ingredients, empowering businesses to offer unique and innovative flavors.

In conclusion, collaborating with Chinese ice pop making machine manufacturers presents an enticing opportunity for businesses to explore custom private labeling and branding options. With a wide range of machine options and customization capabilities, businesses can create a distinct brand identity, enhance their products’ visual appeal, and cater to unique consumer preferences. By capitalizing on China’s manufacturing expertise, businesses can establish a strong presence in the ice pop market and drive growth.

Tips for Procurement and Considerations when Purchasing ice pop making machine

When purchasing an ice pop making machine, there are several considerations and tips to keep in mind to ensure you make the right procurement decision. Here are some key points to consider:

1. Capacity: Determine the quantity of ice pops you need to produce per batch or hour, and choose a machine that matches that capacity requirement. Make sure the machine’s output aligns with your production needs.

2. Quality: Look for a machine made from durable and food-grade materials that can withstand the rigors of daily use. Consider stainless steel options, as they are easy to clean and maintain.

3. Functionality: Assess the machine’s features and functionalities. Look for user-friendly controls, quick freezing times, adjustable settings for popsicle sizes, and ease of maintenance.

4. Energy Efficiency: Opt for an ice pop making machine that is energy-efficient to keep operational costs low. Look for machines with energy-saving features like an automatic power-off function or eco-friendly refrigerants.

5. Size and Space: Consider the available space in your production area. Measure the machine’s dimensions and ensure it fits comfortably into your workspace without compromising on safety or efficiency.

6. Safety Features: Prioritize machines with safety features such as emergency stop buttons, non-slip feet, and protective coverings to reduce the risk of accidents during operation.

7. Ease of Cleaning: Choose a machine that is easy to clean and maintain. Look for removable parts or machines with self-cleaning functions to minimize labor and downtime.

8. Warranty and Support: Check the warranty periods and after-sales support offered by the manufacturer. A longer warranty ensures that any potential issues with the machine can be addressed promptly and without extra cost.

9. Reviews and Recommendations: Read customer reviews and seek recommendations from other businesses in the industry. Learn from their experiences and insights before making a final decision.

10. Cost: Consider the upfront cost of the machine, but also evaluate the long-term cost of operation, including energy consumption, maintenance, and replacement parts. Compare prices from different suppliers to ensure you’re getting the best value for your money.

By following these tips and considering the various factors mentioned above, you can make a well-informed procurement decision when purchasing an ice pop making machine.

FAQs on Sourcing and Manufacturing ice pop making machine in China

Q1: How can I source an ice pop making machine from China?

A: To source an ice pop making machine from China, you can start by conducting thorough online research to identify potential manufacturers or suppliers. Attend trade shows or exhibitions related to food processing or machinery in China, where you can meet and discuss with manufacturers directly. It is also advisable to contact local trade associations or import-export agencies in China for assistance in finding reliable suppliers.

Q2: What factors should I consider when selecting a manufacturer in China?

A: While selecting a manufacturer, consider factors such as their experience in producing ice pop making machines, reputation, production capacity, certifications, as well as their ability to customize the machine according to your specific requirements. It is essential to request product samples or visit the manufacturer’s factory to assess the quality of their products and their manufacturing processes.

Q3: How can I ensure the quality of the ice pop making machine manufactured in China?

A: To ensure the quality of the ice pop making machine, opt for manufacturers that have relevant certifications like ISO or CE. Conduct thorough background research on the manufacturer, including checking their client reviews and feedback. Requesting product samples or visiting the factory to inspect the production processes and quality control measures is also recommended. Additionally, consider using third-party inspection services to ensure the machine meets your desired quality standards.

Q4: How can I manage the manufacturing process and logistics when sourcing from China?

A: It is crucial to have clear communication with the manufacturer in terms of your requirements, specifications, and production timeline. Regularly follow up on the progress and request updates to minimize any potential delays. Regarding logistics, you can work with freight forwarders who specialize in shipping goods from China to your destination. Ensure that all necessary legal documentation, such as customs declarations and import licenses, are in order to smoothly navigate the logistics process.

Q5: Are there any potential challenges when sourcing and manufacturing ice pop making machines in China?

A: Challenges may include language barriers, cultural differences, and potential risks of fraudulent suppliers. It is advisable to work with a reputable sourcing or procurement company that has experience working with Chinese manufacturers and can help navigate through these challenges. Conducting due diligence and taking necessary precautions can minimize the risks involved in sourcing and manufacturing from China.

Why contact sourcifychina.com get free quota from reliable ice pop making machine suppliers?

Sourcifychina.com is able to provide a free quota from reliable ice pop making machine suppliers for several reasons. Firstly, Sourcifychina.com has established strong partnerships and connections with numerous ice pop making machine suppliers in China. These suppliers have been thoroughly vetted by Sourcifychina.com to ensure their reliability, quality products, and competitive pricing.

Secondly, Sourcifychina.com operates on a large scale, allowing them to leverage their network of suppliers to negotiate better pricing and terms. By consolidating the demands of multiple buyers, they are able to secure favorable deals from the suppliers, which translates to cost savings for their clients.

Additionally, Sourcifychina.com acts as a bridge between buyers and suppliers, providing a streamlined sourcing and procurement process. They understand the complexities and challenges of sourcing from China, including language barriers, cultural differences, and logistics. Sourcifychina.com has expert sourcing agents who have extensive experience in dealing with Chinese suppliers and can effectively communicate and negotiate on behalf of the buyers.

By providing a free quota, Sourcifychina.com aims to attract potential buyers and showcase the value they can provide in terms of cost savings, supplier reliability, and efficient sourcing processes. This allows buyers to assess the benefits of working with Sourcifychina.com before committing to any financial obligations.

In conclusion, Sourcifychina.com offers a free quota from reliable ice pop making machine suppliers because of their established partnerships, negotiation capabilities, expertise in sourcing from China, and the desire to demonstrate their value to potential buyers.