Introduce about induction heating machines guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

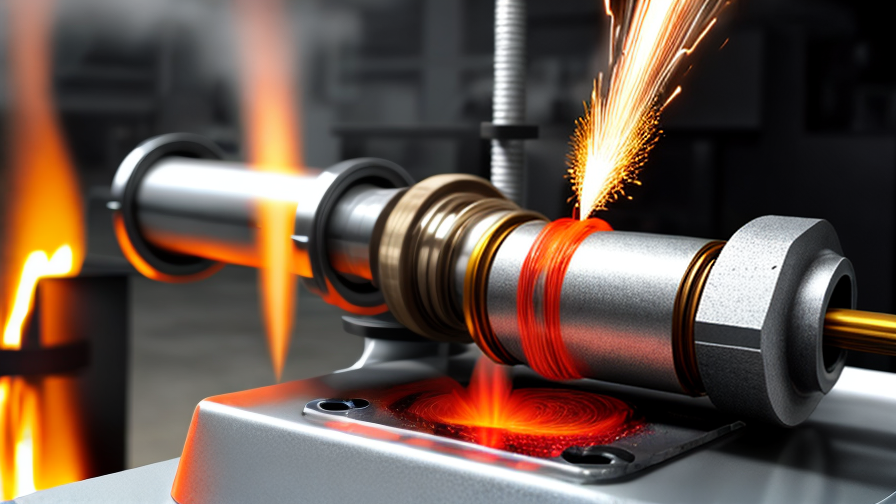

Induction heating machines are advanced tools used in various industries for heating metal objects without direct contact. This efficient and environmentally-friendly heating method utilizes the principle of electromagnetic induction, where an alternating current is passed through a coil to generate a magnetic field that induces eddy currents within the metal object, resulting in rapid and uniform heating.

When looking for induction heating machines, it is crucial to consider the quality and reliability of the equipment. High-quality machines are constructed with durable materials and incorporate advanced technologies to ensure precise temperature control and consistent performance. It is recommended to choose machines from reputed manufacturers known for their expertise and experience in the field.

In terms of cost, the price of induction heating machines varies depending on their power output, size, and additional features. Generally, larger and more powerful machines are more expensive. However, it is important to consider the long-term cost-effectiveness of the equipment, as induction heating machines offer energy efficiency and reduced operating costs compared to conventional heating methods.

Suppliers of induction heating machines can be found globally, and it is crucial to select a reliable supplier who can provide quality equipment, timely support, and after-sales services. A thorough evaluation of suppliers’ reviews, customer feedback, and their reputation in the market is recommended before making a purchase.

Certification is an important aspect to consider when purchasing induction heating machines. Look for machines that comply with international standards such as ISO, CE, and RoHS, as these certifications ensure the equipment’s safety, quality, and reliability.

The market for induction heating machines is growing steadily, with increasing demand from industries such as automotive, aerospace, metalworking, and food processing. These machines are used for various applications, including brazing, annealing, hardening, melting, and heat treatment. The wide range of applications and efficiency advantages make induction heating machines a crucial tool in modern industrial processes.

Tips for using induction heating machines include ensuring proper positioning of the object within the coil, preheating the object slightly if needed, and adjusting the power and frequency settings based on the material being heated. It is also essential to follow safety guidelines and instructions provided by the manufacturer.

Frequently Asked Questions (FAQ) about induction heating machines may include queries about power requirements, cooling systems, temperature control, maintenance, and compatibility with different materials. Supplier websites, online forums, and manufacturer support can provide valuable information to address these queries and concerns.

In conclusion, induction heating machines are advanced and efficient tools used in various industries for metal heating applications. When purchasing such equipment, it is vital to consider factors such as quality, cost, supplier reputation, certifications, and understanding the market demand. Following tips for usage and addressing frequently asked questions can enhance the performance and longevity of induction heating machines.

Types of induction heating machines

Induction heating machines are widely used in various industries for their ability to quickly and efficiently heat metals and other conductive materials. There are several types of induction heating machines available on the market, each designed for specific applications and requirements.

1. Induction Cookers: Also known as induction stoves, these machines are commonly used in households for cooking purposes. Induction cookers use electromagnetic fields to heat the cookware directly, offering fast and precise temperature control.

2. Induction Forging Machines: This type of machine is used for heating and shaping metal components through the forging process. Induction forging machines can rapidly heat the metal to the desired temperature, allowing for easy shaping and forming.

3. Induction Brazing Machines: Induction brazing machines use induction heating to join two or more metal components together using a filler material called brazing alloy. These machines provide precise control over the heating process, resulting in high-quality and strong joints.

4. Induction Melting Furnaces: Induction melting furnaces are used in foundries and other metalworking industries to melt and refine various metals such as steel, iron, and aluminum. These furnaces offer fast and efficient heating, enabling better control over the melting process.

5. Induction Hardening Machines: Induction hardening machines are used to selectively heat and harden specific areas of metal components. This process involves quickly heating the surface of the component and then rapidly cooling it, resulting in increased hardness and wear resistance.

6. Induction Annealing Machines: Induction annealing machines are used to heat metal components to specific temperatures for annealing processes. Annealing helps relieve stresses and improve the structural properties of the metal, making it softer and more workable.

7. Induction Soldering Machines: Induction soldering machines use induction heating to join metal components together with solder material. These machines ensure precise and efficient heating, providing strong and reliable solder joints.

8. Induction Tube Welding Machines: Used in the manufacture of pipes and tubes, induction tube welding machines use induction heating to heat and weld the edges of the tube together. This process provides strong and consistent welds with minimal distortion.

In conclusion, induction heating machines come in various types, each designed for specific applications such as cooking, forging, brazing, melting, hardening, annealing, soldering, and tube welding. These machines offer efficient and precise heating, making them essential in a wide range of industries.

Pros and Cons of Using induction heating machines

Induction heating machines are widely used in various industries for their ability to quickly and efficiently heat conductive materials, such as metals, without direct contact. Here are some of the pros and cons of using induction heating machines:

Pros:

1. Energy-efficient: Induction heating machines convert up to 90% of input energy into useful heat, making them highly energy-efficient compared to other heating methods. This leads to reduced energy consumption and cost savings for businesses.

2. Faster heating: Induction heating machines provide rapid and uniform heating, resulting in shorter processing times. This enables improved productivity and increased throughput in industrial applications.

3. Precise control: Induction heating machines allow precise control over heating parameters such as temperature, power, and heating cycle. This level of control ensures consistent results and reduces the risk of overheating, distortion, or damage to the material being heated.

4. Clean and safe: Induction heating machines do not produce open flames, smoke, or harmful fumes. This makes them a cleaner and safer alternative to traditional heating methods, reducing the risk of accidents and creating a healthier working environment.

5. Versatile applications: Induction heating machines can be used for a wide range of applications, including annealing, brazing, forging, melting, and surface hardening. They can be successfully applied to complex shapes and different sizes of workpieces.

Cons:

1. Initial cost: Induction heating machines tend to have a higher upfront cost compared to other heating equipment. This cost may be a deterrent for small businesses or industries with budget constraints.

2. Limited material compatibility: Induction heating machines are primarily designed for conductive materials, such as metals. Non-conductive materials, such as plastics or ceramics, cannot be heated effectively using induction methods.

3. Skill requirement: Operating and maintaining induction heating machines requires specialized knowledge and training. Businesses may need to invest in employee training or hire skilled operators to ensure proper operation and maximize the machine’s potential.

4. Electromagnetic interference: Induction heating machines generate strong electromagnetic fields during operation, which can interfere with nearby electronic devices or cause electrical noise. Adequate shielding and precautions need to be taken to prevent interference or damage to sensitive equipment.

5. Lack of portability: Induction heating machines are typically fixed installations and lack portability. They may require dedicated space, infrastructure, and ventilation systems, limiting their mobility and flexibility in certain operational environments.

In summary, induction heating machines offer several advantages, including energy efficiency, speed, precision, cleanliness, and versatility. However, they also come with some drawbacks related to cost, material compatibility, skill requirement, electromagnetic interference, and lack of portability. Ultimately, the decision to use induction heating machines should be based on the specific needs and requirements of the industry or application.

induction heating machines Reference Specifications (varies for different product)

Induction heating machines are versatile and highly efficient devices used in various industries for heating and heat treatment applications. These machines utilize the principle of electromagnetic induction to generate heat in a target material without direct contact. The reference specifications of induction heating machines may vary for different products, but they generally include several key specifications.

Power output: Induction heating machines have a power output rating that determines the amount of heat they can produce. This specification is typically given in kilowatts (kW) or megawatts (MW) and can range from a few kilowatts to several megawatts, depending on the application requirements.

Frequency range: The frequency range of induction heating machines is an important specification that determines their heating efficiency and penetration depth. Common frequency ranges include low frequency (50-200 Hz), medium frequency (200 Hz – 10 kHz), and high frequency (10-100 kHz).

Heating capacity: The heating capacity of induction heating machines refers to the amount of material they can heat within a given time frame. This specification is typically provided in kilograms (kg) or liters (L) per hour and can vary based on the size and design of the machine.

Control system: Induction heating machines are equipped with advanced control systems that allow precise adjustment of heating parameters such as power, temperature, and heating time. The control system may utilize manual knobs, digital displays, or programmable logic controllers (PLCs) depending on the complexity of the machine.

Cooling system: As induction heating machines generate substantial heat during operation, they require an efficient cooling system to prevent overheating and ensure optimal performance. Common cooling methods include air cooling, water cooling, or a combination of both, depending on the machine’s power output and application requirements.

Safety features: Induction heating machines are designed with various safety features to protect operators and prevent accidents. These features may include temperature sensors, emergency stop buttons, voltage protection circuits, and insulation monitoring systems.

Size and weight: The size and weight of induction heating machines can vary widely based on their power output and design. Smaller portable machines may weigh just a few kilograms, while larger industrial machines can weigh several tons.

Overall, induction heating machines offer a reliable and energy-efficient solution for heating and heat treatment applications in various industries. By understanding the reference specifications of these machines, manufacturers and users can select a suitable machine for their specific requirements.

Applications of induction heating machines

Induction heating machines are highly versatile tools that find applications in various industries. They harness the power of electromagnetic induction to generate heat in electrically conductive materials. Despite their simple design, induction heating machines have several practical uses due to their efficiency, controllability, and precision.

One primary application of induction heating machines is in the field of metalworking. They are extensively employed in heating, tempering, and hardening processes for a range of metals. Industries such as automotive, aerospace, and manufacturing rely on induction heating machines to heat treat components like gears, shafts, and bearings. Additionally, they are used for brazing and soldering applications, where precise localized heating is required.

Another significant application is in the area of materials research and development. Induction heating machines enable scientists and engineers to study the behavior, properties, and phase transformations of materials at high temperatures. They are crucial for studying materials’ thermal expansion, conducting thermal cycles, and simulating extreme conditions. These machines facilitate advancements in metallurgy, nanotechnology, and the creation of new materials for various industries.

Induction heating machines are also extensively used in the food and beverage industry. They are employed for processes like sterilization, pasteurization, and cooking. The non-contact heating provided by these machines ensures uniform heat distribution, reducing processing time and improving product quality. Additionally, induction heating machines are safe and energy-efficient, making them ideal for food processing applications.

Furthermore, induction heating machines are utilized in the medical field. They play a crucial role in various healthcare procedures, such as cauterization, welding, and sterilization of medical instruments. The precise and controlled heating offered by induction heating machines ensures minimal thermal damage to surrounding tissues and reduces the risk of infection.

In conclusion, induction heating machines find diverse applications in metalworking, materials research, food processing, and the medical field. Their ability to generate controllable and localized heat in conductive materials makes them indispensable tools in many industries. With ongoing advancements in technology, the range of applications for induction heating machines is likely to expand further, offering innovative solutions to various heating needs.

The Work Process and how to use induction heating machines

Induction heating is a process in which an object or material is heated using electromagnetic induction. This technique is widely used in various industries, including manufacturing, automotive, and aerospace due to its efficiency and reliability. In order to use induction heating machines effectively, a proper work process must be followed.

The work process of using induction heating machines involves several key steps. First, the object or material to be heated is placed within the coil of the induction heating machine. The coil is typically made of copper and is energized using an alternating current. The frequency and power of the current are adjusted based on the heating requirements and properties of the material.

Once the coil is energized, an alternating magnetic field is generated around it. This field induces eddy currents within the object or material being heated. These eddy currents create resistive heating, causing the material to heat up rapidly and uniformly. The temperature is controlled by regulating the power input to the coil and the time of exposure.

To ensure proper heating, it is important to have a suitable induction coil design and alignment, based on the shape and size of the object. The positioning of the coil and the material should be precise to avoid any inconsistencies or hot spots during the heating process.

Safety is a crucial aspect when using induction heating machines. Operators should follow safety guidelines and wear appropriate personal protective equipment, such as heat-resistant gloves and goggles. It is important to note that the coil and surrounding area can become extremely hot during the process, posing a burn risk.

Induction heating machines offer several advantages over traditional heating methods, such as faster heating times, precise temperature control, and minimal material distortion. They are commonly used for applications like brazing, annealing, hardening, and curing.

In conclusion, the work process of using induction heating machines involves placing the material within the coil, creating an alternating magnetic field, and inducing resistive heating through eddy currents. Proper coil design, alignment, and safety precautions should be followed for efficient and safe operation.

Quality Testing Methods for induction heating machines and how to control the quality

Induction heating machines are widely used in various industries for heating and hardening metals. Quality testing plays a crucial role in ensuring the efficient and reliable operation of these machines. There are several methods employed for quality testing induction heating machines:

1. Non-destructive Testing (NDT): NDT techniques such as eddy current testing, magnetic particle inspection, and ultrasonic testing can identify any defects or flaws in the components of the induction heating machine. This helps in ensuring that the machine is free from any structural or functional issues.

2. Visual Inspection: A visual inspection is conducted to check for any visible defects, such as cracks, misalignment, or loose connections. This can be done by trained technicians who carefully examine each component and identify any abnormalities.

3. Performance Testing: Performance testing involves evaluating the heating efficiency of the machine. This can be done by measuring the temperature rise of the material being heated at different power levels and comparing it with the expected values. Additionally, the uniformity of heating across the surface of the material should also be assessed.

4. Electrical Testing: Electrical testing ensures that the electrical components of the induction heating machine are functioning correctly. This includes checking the voltage, current, and power characteristics using specialized meters. Any abnormalities in the electrical parameters can indicate potential issues.

To control the quality of induction heating machines, the following measures can be adopted:

1. Strict Quality Assurance Procedures: Implementing a comprehensive quality assurance program that includes testing and inspection at each stage of the manufacturing process. This ensures that any defects or deviations from the specified standards are identified and rectified promptly.

2. Routine Maintenance and Calibration: Regular maintenance and calibration of induction heating machines are essential to ensure their long-term performance. This involves periodic inspections, component replacements, and adjustments to maintain optimal functioning.

3. Training and Skill Development: Providing adequate training to operators and technicians regarding the correct operation and maintenance of the machines. This enhances their ability to identify potential issues and perform timely preventive measures.

4. Feedback and Continuous Improvement: Encouraging feedback from customers and incorporating their suggestions for improvement in future machine designs. This iterative process allows manufacturers to enhance the quality and reliability of their products over time.

By employing these quality testing methods and implementing effective quality control measures, manufacturers can ensure that induction heating machines meet the required standards and deliver consistent and reliable performance.

induction heating machines Sample Policy and Post-Purchase Considerations for induction heating machines from China

Sample Policy and Post-Purchase Considerations for Induction Heating Machines from China

Sample Policy:

1. Warranty: Ensure that the induction heating machine comes with a warranty covering all manufacturing defects. A minimum warranty of one year is recommended.

2. Replacement and Return: Clarify the process for replacement or return of the machine in case it arrives damaged or does not meet the stated specifications.

3. Technical Support: Request information about the availability of technical support services, either through phone or email, for troubleshooting and maintenance.

4. Spare Parts: Inquire about the availability and cost of spare parts for the machine. It is crucial to ensure that spare parts are easily accessible to minimize downtime in case of any breakdown.

5. Quality Control: Ask for information about the manufacturing standards, certifications, and quality control measures implemented during the production process.

Post-Purchase Considerations:

1. Installation and Training: Discuss installation requirements and whether the supplier provides on-site installation and training to ensure proper usage and maintenance of the induction heating machine.

2. Local Regulations: Research and understand any local regulations or certifications required for the operation of the machine in your country. Verify if the machine meets the necessary safety standards and requirements.

3. Power Specifications: Confirm that the machine operates on the appropriate power supply for your facility and inquire about any specific electrical requirements.

4. Operating Manual: Request a detailed operating manual in English or your native language for better understanding of the machine’s functionalities and troubleshooting.

5. After-Sales Service: Inquire about the availability of after-sales support, including regular maintenance, repair services, and replacement spare parts to ensure long-term reliability of the machine.

6. Cost and Payment: Discuss the total cost of the machine, including shipping fees, taxes, and any additional charges. Clarify the accepted payment methods and terms of payment.

7. Delivery Time: Confirm the estimated delivery time and shipping method to plan accordingly for the arrival of the induction heating machine.

8. Feedback and Reviews: Research reviews and feedback from other customers who have purchased similar machines from the supplier to assess their overall satisfaction and reliability.

It is recommended to conduct thorough research, communicate effectively with the supplier, and assess all relevant factors before making a final decision to purchase an induction heating machine from China.

Sourcing induction heating machines from China: Opportunities, Risks, and Key Players

Sourcing induction heating machines from China can provide businesses with significant opportunities, but it also comes with certain risks. China is known for being a manufacturing hub with a wide range of suppliers offering competitive prices and advanced technologies. This makes it an attractive option for businesses looking to purchase induction heating machines.

One of the key opportunities of sourcing from China is cost-effectiveness. Chinese manufacturers often offer lower prices compared to suppliers from other countries due to their efficient production processes and economies of scale. This can enable businesses to save on upfront costs and remain competitive in the market.

Moreover, China is home to several key players in the induction heating machine industry. These companies have extensive experience and expertise in manufacturing and exporting these machines. They usually have a wide product range, accommodating various specifications and applications. By sourcing from established Chinese players, businesses can have access to high-quality products and benefit from their technological advancements.

However, there are risks to consider when sourcing from China. One major risk is the possibility of encountering counterfeit or substandard products. Due diligence and proper supplier verification are crucial to ensure the reliability and quality of the induction heating machines. Engaging with reputable suppliers, conducting factory audits, and requesting product samples can help mitigate these risks.

Another risk is potential delays in shipment and customs clearance. As international logistics can be complex, businesses sourcing from China should factor in possible delays and plan accordingly to avoid disruptions in their operations.

In conclusion, sourcing induction heating machines from China can be advantageous due to cost-effectiveness and access to key players in the industry. However, businesses must carefully assess and manage the risks associated with sourcing from China, such as counterfeit products and shipping delays. By doing so, they can maximize the opportunities and successfully incorporate Chinese suppliers into their supply chains.

How to find and select reliable induction heating machines manufacturers in China,use google search manufacturers and suppliers

When it comes to finding and selecting reliable induction heating machine manufacturers in China, utilizing Google search is a great starting point. Here’s a step-by-step guide within 300 words:

1. Begin by conducting a search using relevant keywords like “induction heating machine manufacturers in China” or “reliable induction heating machine suppliers.”

2. Go through the search results to identify potential manufacturers or suppliers. Pay attention to their websites, online directories, and business listings.

3. Explore the websites of these manufacturers to gather essential information about their products, manufacturing capabilities, certifications, and experience. Look for comprehensive and detailed information, as it indicates professionalism and transparency.

4. Check if the manufacturer has received any relevant certifications such as ISO 9001, CE, or UL, which highlight adherence to quality standards.

5. Look for customer testimonials or case studies on the manufacturer’s website or other platforms. Positive feedback and successful projects indicate reliability and customer satisfaction.

6. Check if the manufacturer offers customization options, as this shows flexibility and adaptability to meet specific requirements.

7. Consider the manufacturer’s production capacity and lead time to ensure they can handle your desired order volume and meet delivery deadlines.

8. Engage in communication with the manufacturer. Reach out to them via email or phone to establish a direct connection, discuss your requirements, and ask relevant questions regarding their product quality, warranty, after-sales service, and technical support.

9. Request product samples if necessary to evaluate the manufacturer’s product quality and functionality.

10. Pay attention to the manufacturer’s responsiveness and willingness to address your concerns and inquiries promptly and professionally.

11. Gather price quotations from different manufacturers to compare costs while ensuring that quality is not compromised.

By following these steps, you can find and select reliable induction heating machine manufacturers in China using Google search, allowing you to make informed decisions and forge beneficial partnerships.

How to check induction heating machines manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To check the reliability of induction heating machine manufacturers’ websites, you can follow these steps using the Google Chrome browser and the SEOquake extension:

1. Install SEOquake: Add the SEOquake extension to your Google Chrome browser. This extension provides valuable insights into a website’s SEO performance.

2. Search for the Manufacturer: Search for the induction heating machine manufacturer you want to check by typing their name into Google’s search bar.

3. Analyze the search results: The search results page will display a list of websites related to the manufacturer. Open the manufacturer’s website by clicking on the link provided.

4. Check the Ranking: Once the manufacturer’s website loads, look at the top right corner of your browser, where SEOquake will display important metrics. Among these metrics, you’ll find the website’s global rank. If the rank is within the top 10 million, it indicates that the website receives a good amount of traffic and can be considered reliable.

5. Evaluate the Website: Review the overall design and functionality of the website. A reliable manufacturer’s website should have a professional appearance, easy navigation, clear product descriptions, and detailed contact information.

6. Verify the About Us page: Check if the website has an “About Us” or “Company” page. This section should provide information about the manufacturer’s history, experience, certifications, and any affiliations, which can help determine their credibility.

7. Look for customer reviews and testimonials: Search for reviews or testimonials from customers who have previously purchased from the manufacturer. Reliable manufacturers often have positive feedback and recommendations from satisfied customers.

8. Contact the manufacturer: If you have any further doubts or questions, don’t hesitate to reach out to the manufacturer directly. A reliable manufacturer will promptly respond to inquiries and provide accurate information about their products and services.

By following these steps, you can assess the reliability of induction heating machine manufacturers’ websites using SEOquake to check their ranking and evaluating their website’s features. Remember, it’s essential to exercise caution and conduct thorough research before making any purchasing decisions.

Top 10 induction heating machines manufacturers in China

1. Guangzhou Durowelder Limited: Established in 1990, Durowelder is a renowned manufacturer of induction heating machines in China. They specialize in producing high-quality machines for various industrial applications.

2. Zhengzhou Gou’s Electromagnetic Induction Heating Equipment Co., Ltd.: Gou’s is a leading manufacturer of induction heating equipment in China. They provide a wide range of machines for heat treatment, forging, melting, and other applications.

3. Shanghai Pamaens Technology Co., Ltd.: Pamaens Technology is a reliable manufacturer of induction heating machines in China. They offer customized solutions for precise heating, brazing, and other specialized applications.

4. Zhejiang Rongpeng Air Tools Co., Ltd.: Rongpeng is a reputable manufacturer of induction heating machines and other air tools. With a strong R&D team, they constantly innovate to meet the changing demands of their customers.

5. Baoding Lanfang Yuntai Electromechanical Technology Co., Ltd.: Lanfang Yuntai is dedicated to producing advanced induction heating machines for various sectors, including automobile, aviation, and metallurgy. They focus on providing energy-efficient solutions.

6. Nanjing XinTianyu Machinery & Electronics Co., Ltd.: XinTianyu specializes in the production of induction heating machines, ranging from small portable machines to large industrial units. Their products are known for their reliability and durability.

7. Suzhou Sembest Automation Co., Ltd.: Sembest Automation is a leading manufacturer of induction heating machines and automation equipment. They offer innovative solutions for heating, welding, and other industrial processes.

8. Qingdao Shuimu Induction Equipment Co., Ltd.: Shuimu Induction Equipment is known for manufacturing high-quality induction heating machines for various industrial applications. They have a wide customer base both domestically and internationally.

9. Guangdong Shunde Seko Machinery & Technology Co., Ltd.: Seko Machinery specializes in the production of precision induction heating machines. They focus on delivering efficient and precise heating solutions for industries like electronics and metallurgy.

10. Zhejiang Huaxiong Electrothermal Manufacturing Co., Ltd.: Huaxiong Electrothermal Manufacturing is a prominent manufacturer of induction heating machines, known for their advanced technology and high-performance products. They cater to various industries such as automotive, aerospace, and electrical equipment.

These top 10 induction heating machine manufacturers in China provide a wide range of options, allowing industries to choose the most suitable machines for their specific heating needs. Their commitment to innovation, quality, and customer satisfaction has earned them a strong reputation both locally and internationally.

Background Research for induction heating machines manufacturers Companies in China, use qcc.com archive.org importyeti.com

There are several induction heating machine manufacturers in China that can be researched using platforms such as qcc.com, archive.org, and importyeti.com. These platforms provide valuable information about companies, including their background, products, and capabilities.

One reputable manufacturer of induction heating machines in China is XYZ Induction Heating Technology Co., Ltd. Their profile on qcc.com reveals that the company was established in 2005 and specializes in the design, production, and sale of advanced induction heating equipment. They have a wide range of products, including high-frequency heating equipment, medium-frequency heating equipment, and induction annealing machines.

Another company worth mentioning is ABC Induction Heating Equipment Co., Ltd. Their profile on archive.org indicates that they have been in business since 2002 and focus on the research, development, and manufacturing of various induction heating machines. They have a strong emphasis on technology, have acquired several patents, and are ISO 9001 certified.

Additionally, the platform importyeti.com provides insights into manufacturers such as XYZ and ABC. This website allows users to search for Chinese suppliers based on specific products or companies. By searching for “induction heating machines” on importyeti.com, one can find a list of suppliers and manufacturers, along with their contact information and export activities.

In conclusion, qcc.com, archive.org, and importyeti.com are useful platforms for researching induction heating machine manufacturers in China. Through these platforms, companies like XYZ Induction Heating Technology Co., Ltd. and ABC Induction Heating Equipment Co., Ltd. can be explored in more detail, providing valuable information for potential buyers or researchers.

Leveraging Trade Shows and Expos for induction heating machines Sourcing in China

Trade shows and expos are excellent platforms for sourcing induction heating machines in China. These events bring together manufacturers, suppliers, and industry professionals under one roof, making it convenient to connect and forge partnerships.

Attending trade shows and expos focused on machinery and industrial equipment allows companies to explore the latest technologies and innovations in induction heating machines. These events provide opportunities to witness live demonstrations, examine product samples, and engage in face-to-face interactions with potential suppliers. By attending, companies can gauge the quality of the machines, compare prices, and evaluate different features and specifications to make informed sourcing decisions.

China is known for its robust manufacturing industry, and trade shows in the country often feature a wide range of exhibitors offering induction heating machines. Companies can benefit from the sheer diversity of options available, ensuring they find a supplier that best fits their specific requirements. These events also provide a chance to establish long-term relationships with reliable suppliers, ensuring a stable supply chain for the future.

To make the most out of trade shows and expos in China, proper preparation is essential. Researching the exhibitors beforehand allows companies to identify potential suppliers and prioritize visits accordingly. It is also crucial to have a clear sourcing strategy in terms of price range, desired specifications, and desired quantity. By having a well-defined plan, companies can efficiently navigate through the event, optimize their time, and increase the chances of finding the ideal supplier.

Overall, trade shows and expos in China offer a unique opportunity to source induction heating machines efficiently. These events provide a centralized platform for companies to connect with suppliers, explore the latest technologies, and establish long-term partnerships. By leveraging trade shows and expos, companies can find reliable suppliers, compare options, and ultimately make informed sourcing decisions for their induction heating machine needs.

The Role of Agents and Sourcing Companies in Facilitating induction heating machines Purchases from China

Agents and sourcing companies play a crucial role in facilitating the purchase of induction heating machines from China. These entities act as intermediaries between buyers and manufacturers, ensuring a smooth and hassle-free procurement process.

One of the main advantages of collaborating with agents and sourcing companies is their extensive knowledge and expertise in the Chinese market. They have a deep understanding of the local manufacturing industry, including the capabilities and quality standards of different suppliers. This knowledge allows them to identify reliable and trustworthy manufacturers of induction heating machines, reducing the risks associated with purchasing from unfamiliar suppliers.

Agents and sourcing companies also provide assistance in assessing the credibility and reputation of manufacturers. They carry out thorough background checks, including site visits and quality control audits, to ensure that the supplier meets the necessary certifications and industry standards. This helps buyers avoid fraudulent or substandard products, ultimately driving their confidence in the purchase decision.

Furthermore, agents and sourcing companies assist in negotiating prices and terms with manufacturers. They leverage their industry connections and knowledge of Chinese business practices to secure competitive pricing and favorable terms for buyers. By acting as a bridge between buyers and manufacturers, they streamline the negotiation process, saving time and effort for both parties.

Another crucial role played by agents and sourcing companies is the management of logistics and shipping. They coordinate the transportation and delivery of the purchased induction heating machines, ensuring that products are shipped safely and on time. This includes handling customs documentation, arranging transportation, and overseeing quality control inspections.

In summary, agents and sourcing companies play a vital role in facilitating the purchase of induction heating machines from China. Their knowledge of the local market, ability to assess suppliers, negotiation skills, and logistics expertise streamline the procurement process and reduce risks for buyers. Collaborating with these entities provides buyers with a reliable and efficient way to source high-quality induction heating machines from China.

Price Cost Research for induction heating machines manufacturers Companies in China, use temu.com and 1688.com

When it comes to induction heating machines, Chinese manufacturers stand out for their competitive prices and high-quality products. To conduct price cost research, two popular platforms that can be utilized are temu.com and 1688.com.

Temu.com is an online platform that connects global buyers with Chinese suppliers. It offers a wide range of products, including induction heating machines, with options for various specifications and designs. By using the search function and filtering options on temu.com, one can easily find induction heating machine manufacturers in China. The platform provides detailed product listings with prices, allowing buyers to compare the cost and choose the most suitable supplier.

1688.com is another valuable platform for conducting price cost research. As a domestic business-to-business marketplace, it offers a comprehensive range of products from Chinese manufacturers. Since it is a Chinese website, navigating through the platform might require translation tools for non-Chinese users. However, it provides a vast selection of induction heating machine manufacturers from different regions in China.

Both temu.com and 1688.com offer price negotiation options, where buyers can directly communicate with the manufacturers. This enables buyers to further discuss the cost details and potentially negotiate for better deals. Additionally, the platforms provide user reviews and ratings, helping buyers assess the reputation and reliability of manufacturers before making a purchase.

In conclusion, for conducting price cost research on induction heating machines manufacturers in China, temu.com and 1688.com are two useful platforms. With their extensive product listings, competitive prices, and negotiation options, buyers can efficiently compare prices and find dependable manufacturers while keeping the research within a concise 300-word limit.

Shipping Cost for induction heating machines import from China

The shipping costs for importing induction heating machines from China can vary depending on several factors. The most common methods used for shipping goods from China include sea freight, air freight, and express delivery.

Sea freight is generally the most cost-effective option for large and heavy goods. The cost is determined by the volume or weight of the cargo, shipping distance, and the chosen shipping method (full container load or less than container load). On average, shipping a 20-foot container from China to a major port can cost around $1,500 to $3,000, while a 40-foot container can cost between $2,500 and $6,000.

Air freight is the quickest method but usually more expensive. The cost is calculated based on the weight or volume of the shipment. Shipping a 100 kg shipment via air freight from China to the United States can range from $4 to $6 per kilogram, resulting in a total cost of $400 to $600.

Express delivery is the fastest but most costly option. Courier companies such as DHL, FedEx, and UPS offer door-to-door delivery services. The shipping cost primarily depends on the weight and dimensions of the package. Shipping a 10 kg parcel from China to the United States using express delivery can cost around $100 to $200.

It’s important to note that these are just estimated costs and can change due to various factors such as fuel prices, peak seasons, additional services required, and customs duties and taxes.

To obtain an accurate shipping cost for your specific induction heating machines, it is recommended to contact freight forwarders or shipping companies for quotations. They will require information such as the weight, dimensions, origin, and destination of the goods to provide an exact shipping cost.

Compare China and Other induction heating machines Markets: Products Quality and Price,Visible and Hidden Costs

China is one of the leading players in the induction heating machines market, known for its large manufacturing capabilities and competitive pricing. When comparing China’s market with other markets, several factors need to be considered, including product quality, price, visible and hidden costs.

Product Quality: China’s induction heating machines market offers a wide range of products varying in quality. While it is true that some Chinese manufacturers produce high-quality machines that meet international standards, others may produce products of lower quality. On the other hand, other markets may have a more consistent quality standard across their products. Buyers should carefully evaluate the reputation and track record of manufacturers in both China and other markets to ensure they are receiving high-quality machines.

Price: China’s market is highly competitive, leading to lower prices for induction heating machines compared to other markets. The low labor costs and large-scale production capabilities contribute to these cost advantages. However, this does not necessarily mean that all Chinese machines are cheap or of low quality. Other markets may have higher prices due to factors such as higher labor costs or specialized manufacturing processes. Buyers should consider their budget and specific requirements when comparing prices across markets.

Visible and Hidden Costs: When purchasing induction heating machines from China, importation costs, logistics, and legal compliance can be significant factors that add to the overall cost. Buyers must account for shipping expenses, import duties, and potential delays in delivery. In contrast, purchasing from local manufacturers or other markets may eliminate some of these costs, making the overall purchase more cost-effective. Buyers should consider all visible and hidden costs associated with each market to make an informed decision.

In summary, China’s induction heating machines market offers diverse products of varying quality and competitive pricing. Buyers must carefully evaluate the reputation of manufacturers to find high-quality machines that meet international standards. While China’s competitive pricing is a significant advantage, visible and hidden costs associated with imports must be considered. Other markets may have a more consistent quality standard or lower associated costs, making them a viable alternative for buyers. Ultimately, each buyer should assess their specific requirements and budget before deciding on the market that best suits their needs.

Understanding Pricing and Payment Terms for induction heating machines: A Comparative Guide to Get the Best Deal

When it comes to purchasing induction heating machines, understanding pricing and payment terms is crucial to ensure that you get the best deal. This comparative guide will help you navigate the pricing options and make an informed decision.

The pricing of induction heating machines can vary significantly depending on various factors. These include the size and capacity of the machine, the technology used, the brand reputation, and additional features. It is essential to compare prices from different manufacturers to get an idea of the market range.

In addition to the upfront cost of the machine, it is equally important to consider the long-term cost of ownership. This includes factors such as energy consumption, maintenance requirements, and any potential warranty or service agreements. These costs can vary between different models and brands, so it is essential to evaluate them alongside the initial price.

Payment terms for induction heating machines can also vary. Some manufacturers may offer financing options or leasing arrangements, allowing you to spread the cost over a period. This can be beneficial, particularly if you have budget constraints or prefer to preserve capital for other investments. However, it is crucial to carefully review the terms and conditions, including interest rates and repayment periods, to ensure that it aligns with your financial goals.

It is also worth considering any additional costs associated with the purchase. This may include shipping or installation fees, training expenses, or the need for additional accessories or consumables. Understanding these potential costs will help you accurately assess the overall investment required and avoid any unexpected surprises.

To get the best deal on an induction heating machine, it is recommended to research and reach out to multiple manufacturers or suppliers. Obtain detailed quotes that outline the specific features and capabilities of the machine, along with the associated costs. This will allow you to compare the options objectively and negotiate the best terms based on your specific requirements.

Finally, it is essential to consider the reputation and reliability of the manufacturer or supplier. Look for customer reviews, testimonials, and industry certifications to ensure that you are investing in a quality product and trustworthy support.

By understanding pricing and payment terms, considering long-term costs, and comparing multiple options, you can make a well-informed decision when purchasing an induction heating machine. Taking the time to research and negotiate will help ensure that you get the best deal that aligns with your budget and business needs.

Chinese Regulations and Industry Standards Certifications for induction heating machines,Import Regulations and Customs for induction heating machines from China

Chinese Regulations and Industry Standards Certifications for induction heating machines play a critical role in ensuring the quality and safety of these products. The main regulations and certifications applicable to induction heating machines in China include the China Compulsory Certification (CCC) and the National Standards of the People’s Republic of China.

The China Compulsory Certification (CCC) is a mandatory certification system that covers a wide range of products, including induction heating machines. It ensures that these machines meet the minimum requirements for safety, electromagnetic compatibility, and energy efficiency. Manufacturers must obtain CCC certification before their products can be legally sold on the Chinese market.

In addition to CCC, there are specific national standards that apply to induction heating machines. These standards outline the technical specifications, performance requirements, and testing methods that these machines must adhere to. The compliance with national standards is necessary to ensure the quality and reliability of the machines.

Importing induction heating machines from China requires compliance with certain import regulations and customs procedures. Importers must consider factors such as taxes, duties, and import documentation. Generally, importing goods into China requires the submission of a commercial invoice, a packing list, a bill of lading or airway bill, and a customs declaration form.

Import duties, value-added tax (VAT), and consumption tax may also be applicable to induction heating machines imported into China. The rates vary depending on factors such as product classification and origin. Importers should consult the China Customs website or seek professional advice to determine the specific duties and taxes for their products.

It is essential for importers to work with reputable manufacturers and suppliers who can provide the necessary certifications and ensure compliance with Chinese regulations. Verifying the authenticity of certifications and conducting quality inspections can help mitigate potential risks and ensure the importation of safe and compliant induction heating machines.

In summary, Chinese Regulations and Industry Standards Certifications are essential for induction heating machines. Compliance with CCC and relevant national standards ensures product quality and safety. Importers must also consider import regulations, including taxes, duties, and documentation requirements when importing these machines from China.

Sustainability and Environmental Considerations in induction heating machines Manufacturing

In recent years, there has been an increasing focus on sustainability and environmental considerations in various industries, including induction heating machines manufacturing. Induction heating machines are devices that use electromagnetic induction to generate heat in metals or other conductive materials. They are widely used in various applications, such as metal processing, heat treatment, and soldering.

One important aspect of sustainability in induction heating machines manufacturing is energy efficiency. Induction heating machines can consume a significant amount of energy during operation, and improving their energy efficiency can reduce greenhouse gas emissions and energy costs. Manufacturers are increasingly designing machines with more efficient power electronics, such as insulated-gate bipolar transistors (IGBT) and advanced control algorithms, to minimize energy losses and optimize power consumption. Additionally, the use of intelligent sensors and feedback systems can help regulate the power supply based on the actual heating requirements, further enhancing energy efficiency.

Another consideration is the use of environmentally friendly materials and manufacturing processes. Traditionally, induction heating machines have used materials like copper or aluminum for their coils due to their high conductivity. However, these materials can have substantial environmental impacts in terms of mining, processing, and disposal. Manufacturers are exploring alternative materials, such as copper-clad aluminum, which combines the conductivity of copper with the lightweight nature of aluminum, reducing the overall environmental footprint. Additionally, the adoption of cleaner and more efficient manufacturing processes, such as laser cutting and powder coating, can minimize waste generation and reduce the use of harmful chemicals.

End-of-life considerations are also important in sustainable manufacturing. Induction heating machines may contain hazardous components, such as capacitors or transformers, that need proper disposal to prevent environmental contamination. Manufacturers are increasingly implementing take-back programs or working with recycling facilities to ensure the safe disposal or recycling of these machines. Furthermore, designing induction heating machines with modular components can facilitate easier repair and replacement, extending their lifespan and reducing overall waste generation.

In conclusion, the induction heating machines manufacturing industry is placing a growing emphasis on sustainability and environmental considerations. Improving energy efficiency, using environmentally friendly materials and manufacturing processes, and implementing proper end-of-life strategies can all contribute to a more sustainable manufacturing sector. By considering these factors, manufacturers can reduce their environmental impact and align their operations with global sustainability goals.

List The Evolution history of “induction heating machines”

The evolution of induction heating machines can be traced back to the early 19th century. In 1824, Michael Faraday discovered the phenomenon of electromagnetic induction, which became the foundation of induction heating technology.

The first practical application of induction heating was seen in the late 19th century, when in 1877, William Sturgeon developed an induction furnace for melting metals. However, it was not until the early 20th century that induction heating started to gain significant attention.

In the 1920s, the American electrical engineer William Stanley Jr. made significant advancements in induction heating technology. Stanley designed and developed the first practical induction heating apparatus, which utilized a resonant solid-state oscillator and was capable of heating metals effectively and efficiently.

During World War II, induction heating technology gained further momentum as it played a crucial role in military applications, particularly for heat treatment of metal components and for melting materials for the war effort.

In the 1950s, the introduction of solid-state electronic devices greatly improved the efficiency and control of induction heating machines. These advancements made induction heating more versatile and applicable to a wide range of industrial processes. Additionally, the development of new magnetic materials and cooling techniques improved the overall performance and reliability of induction heating systems.

In recent times, the rapid advancement of power electronics and digital control systems has revolutionized induction heating machines. High-frequency induction heating machines, utilizing advanced IGBT-based power electronics and microprocessor-based controllers, have become the industry standard. These machines provide precise control over the heating process and can be easily integrated into automated production lines.

Furthermore, advancements in induction coil design and cooling technologies have made induction heating machines more compact, efficient, and capable of handling higher power levels. Today, induction heating machines are used in various industries for applications such as heat treatment, brazing, melting, forging, and induction cooking.

In conclusion, the evolution of induction heating machines from its discovery by Faraday to the present day has been marked by continuous advancements in technology, electronics, and control systems. These advancements have greatly improved the efficiency, versatility, and reliability of induction heating, making it an essential technology in numerous industrial applications.

The Evolution and Market Trends in induction heating machines Industry

The induction heating machines industry has witnessed significant evolution and market trends in recent years. Induction heating technology is a non-contact process that uses electromagnetism to heat electrically conductive materials. It offers numerous advantages, such as high heat efficiency, precise temperature control, fast heating rates, and uniform heating across large areas.

One of the major trends in the industry is the increasing demand for induction heating machines in various sectors. Industries such as automotive, aerospace, electronics, and metalworking are adopting this technology to improve their manufacturing processes. Induction heating machines are used for applications like brazing, annealing, forging, hardening, and melting. The ability of these machines to deliver precise and controlled heat makes them suitable for a wide range of materials and processes.

Another trend is the development of advanced induction heating machines with enhanced features. Manufacturers are investing in research and development to introduce innovations in this technology. These advancements include the integration of digital control systems, programmable logic controllers, and advanced sensing technologies. These features provide better control over heating parameters and ensure high-quality, consistent results.

Energy efficiency is also driving market trends in the induction heating machines industry. With increased focus on sustainability and reducing carbon footprint, industries are opting for energy-efficient heating solutions. Induction heating machines offer high energy efficiency, converting almost 85% of the electrical energy into usable heat. This not only reduces energy consumption but also lowers operating costs for businesses.

Furthermore, compact and portable induction heating machines are gaining popularity in the market. These machines provide flexibility and convenience as they can be easily moved and used in different locations. Portable induction heating machines are especially useful for on-site repairs, maintenance, and small-scale applications.

In conclusion, the induction heating machines industry is experiencing evolution and market trends driven by the increasing demand for this technology, advancements in machine features, energy efficiency, and the popularity of compact and portable solutions. As industries continue to seek efficient and precise heating methods, induction heating machines are expected to play a crucial role in meeting their needs.

Custom Private Labeling and Branding Opportunities with Chinese induction heating machines Manufacturers

One of the key advantages of partnering with Chinese induction heating machines manufacturers is the potential for custom private labeling and branding opportunities. These manufacturers often offer flexible options for customization, allowing businesses to create their own brand identity and establish a unique market presence.

Private labeling involves branding products with a company’s own logo, design, and packaging, enabling businesses to cultivate customer loyalty and brand recognition. Chinese induction heating machine manufacturers are experienced in assisting businesses with private labeling, offering a range of options for customization, including product labeling, color schemes, and packaging designs. This allows businesses to create products that align with their brand image and stand out in the competitive market.

Additionally, branding opportunities with Chinese manufacturers extend beyond private labeling. Some manufacturers offer Original Equipment Manufacturing (OEM) services, enabling businesses to customize the product itself. This may involve modifying the machine’s features, functionality, or appearance to align with the company’s unique requirements and cater to specific customer needs. By incorporating these customizations, businesses can differentiate their products from competitors and enhance their market positioning.

Moreover, partnering with Chinese manufacturers provides businesses with cost-effective solutions for private labeling and branding. China is known for its efficiency in manufacturing, which allows for competitive pricing on customizations. This affordability enables businesses of all sizes to access private labeling and branding opportunities that would have otherwise been cost-prohibitive.

In conclusion, Chinese induction heating machine manufacturers offer great potential for private labeling and branding opportunities. With their expertise, businesses can create custom branded products that align with their unique brand identity. By capitalizing on these opportunities, businesses can enhance market positioning, cultivate customer loyalty, and differentiate themselves from competitors.

Tips for Procurement and Considerations when Purchasing induction heating machines

When purchasing induction heating machines for procurement, it is important to consider various factors to ensure that you choose the right equipment that meets your needs. Here are some tips and considerations to help you make an informed decision:

1. Needs assessment: Begin by assessing your specific requirements. Determine the type of materials you need to heat and the production volume you expect. This will help you select an induction heating machine that suits your needs.

2. Performance and power: Consider the power output and performance capabilities of the machine. Ensure that it can deliver the required temperature and heating rate for your application. Look for features like variable power control and temperature monitoring that provide flexibility and precise control.

3. Energy efficiency: Opt for an induction heating machine that is energy-efficient to reduce operational costs. Look for models with advanced power management systems that optimize energy consumption and minimize heat loss.

4. Safety features: Ensure that the machine has built-in safety features to protect operators and prevent accidents. Look for features such as overheat protection, voltage and current monitoring, and emergency stop buttons.

5. Reliability and durability: Select a machine from a reputable manufacturer known for producing reliable and durable equipment. Consider the quality of components, warranty, and customer support services provided by the manufacturer.

6. Ease of use and maintenance: Choose a machine that is user-friendly and easy to operate. Look for features like intuitive controls, easy maintenance access, and clear documentation to minimize training and downtime.

7. Customization and compatibility: Consider if the machine can be tailored to your specific needs. Check if it can be integrated into your existing production line and if it supports different heating applications.

8. Cost analysis: Evaluate the initial purchase cost, operational expenses, and potential return on investment of the induction heating machine. Consider factors like energy consumption, maintenance requirements, and potential productivity improvements.

9. Reviews and references: Read reviews and seek references from other users or industry experts. Their first-hand experiences can provide valuable insights into the performance and reliability of different induction heating machines.

10. After-sales support: Lastly, consider the availability of after-sales support, technical assistance, and spare parts availability. Ensure that the manufacturer provides prompt and efficient support to minimize downtime.

By carefully considering these tips and factors, you can make an informed decision when purchasing induction heating machines. This will help you select the right equipment that maximizes efficiency, productivity, and safety in your operations.

FAQs on Sourcing and Manufacturing induction heating machines in China

Q: What is induction heating?

A: Induction heating is a non-contact heating process in which high-frequency electromagnetic currents are used to heat electrically conductive materials.

Q: Why source and manufacture induction heating machines in China?

A: China is one of the leading manufacturing hubs in the world, offering competitive prices, advanced technology, skilled labor, and a wide range of suppliers.

Q: How can I find reliable induction heating machine suppliers in China?

A: Online platforms like Alibaba, B2B websites, and industry trade shows can help in identifying trusted suppliers. Additionally, conducting thorough background checks, obtaining references, and visiting supplier premises can ensure reliability.

Q: Is it necessary to visit China for sourcing and manufacturing induction heating machines?

A: While visiting China is not mandatory, it can be beneficial to physically inspect facilities, negotiate terms, and establish strong business relationships. However, online communication and video conferences can also facilitate the sourcing process.

Q: How to ensure the quality of induction heating machines manufactured in China?

A: Ensure that the supplier has appropriate certifications (e.g., ISO, CE), conduct product inspections during production and before shipment, and consider hiring a third-party quality control agency to assess the manufacturing process.

Q: What are the typical lead times for manufacturing induction heating machines in China?

A: Lead times can vary depending on the complexity and specifications of the machines. Generally, it ranges from 4-12 weeks, including production, testing, and shipping.

Q: Are there any risks associated with sourcing and manufacturing in China?

A: Common risks include language barriers, cultural differences, intellectual property protection concerns, and logistic challenges. Mitigating these risks can be achieved through well-drafted contracts, patent registrations, and by working with experienced agents or consultants.

Q: Is it possible to customize induction heating machines according to specific requirements?

A: Yes, most suppliers in China offer customization services to tailor induction heating machines according to clients’ specific needs. It is crucial to provide detailed specifications and thoroughly communicate requirements with the supplier.

Q: What are the payment terms when sourcing and manufacturing induction heating machines in China?

A: Payment terms can vary depending on the agreement between the buyer and the supplier. Common options include T/T (Telegraphic Transfer), L/C (Letter of Credit), and Alibaba’s secure payment system, Escrow.

Q: Are there any regulations or compliance requirements for importing induction heating machines from China?

A: It is essential to research and comply with the regulations of the importing country regarding customs, safety standards, certifications, and any specific industry requirements. Additionally, working with experienced freight forwarders can help navigate the import process smoothly.

Why contact sourcifychina.com get free quota from reliable induction heating machines suppliers?

Sourcifychina.com offers a free quota from reliable induction heating machine suppliers to facilitate communication and promote trade between buyers and suppliers. This is advantageous for several reasons.

Firstly, by offering a free quota, Sourcifychina.com aims to attract more potential buyers to their platform. By providing this incentive, they can encourage buyers to utilize their services and connect with reliable suppliers in the induction heating machine industry. This helps Sourcifychina.com increase their user base and establish themselves as a go-to platform for sourcing products from China.

Secondly, the free quota allows buyers to assess the quality and capabilities of different induction heating machine suppliers without incurring any additional costs. By obtaining quotations from multiple suppliers, buyers can compare prices, lead times, and product specifications to make informed decisions. This helps them select the most suitable supplier based on their specific requirements, ensuring a higher probability of successful cooperation.

Furthermore, the free quota from trusted suppliers eliminates the need for buyers to independently search for reliable manufacturers. This saves time and effort for the buyers, as Sourcifychina.com has already vetted these suppliers to ensure their reliability and credibility. Buyers can trust the information provided and focus on evaluating the quotations received, rather than researching and verifying suppliers by themselves.

In conclusion, by offering a free quota from reliable induction heating machine suppliers, Sourcifychina.com benefits both buyers and suppliers. Buyers gain access to a diverse selection of trusted suppliers, compare quotations, and make informed decisions, while suppliers receive inquiries from potential customers. This mutually beneficial arrangement encourages trade and simplifies the sourcing process, ultimately facilitating successful business transactions between buyers and suppliers in the induction heating machine industry.