Introduce about injection plastics guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

Injection plastics guide provides information on the process of injecting molten plastic into a mold to create various products. It covers the steps involved in the process, from design to production, to ensure high-quality results. Quality is crucial in injection plastics as it affects the durability and functionality of the final products. Factors like material selection, mold design, and production process all contribute to the overall quality.

Cost is another significant aspect to consider when it comes to injection plastics. Factors like material cost, tooling costs, and production volume impact the overall cost of manufacturing plastic components. It’s essential to find a reliable supplier who can provide high-quality injection plastics at a competitive price.

Certification is essential in the injection plastics industry as it ensures that products meet industry standards and regulations. Look for suppliers who have certifications like ISO 9001 to ensure quality and consistency.

The market for injection plastics is vast and diverse, with applications in various industries like automotive, electronics, and healthcare. Understanding market trends and demands can help in making informed decisions about production and distribution.

Tips for successful injection plastics manufacturing include proper design and mold considerations, material selection, and regular maintenance of equipment. Frequently asked questions about injection plastics cover topics like material selection, production processes, and cost considerations.

Overall, having a good understanding of injection plastics guide can help in producing high-quality plastic components at a competitive cost, ensuring success in the market.

Types of injection plastics

Injection molding is a widely used manufacturing process for producing plastic parts in large volumes. Depending on the desired properties and applications of the final product, different types of injection plastics can be used. Here are some common types:

1. Polyethylene (PE): This is the most commonly used plastic worldwide. It has excellent chemical resistance, low cost, and good impact strength. PE is available in different grades, such as high-density (HDPE) and low-density (LDPE), which offer various levels of stiffness and flexibility.

2. Polypropylene (PP): PP is known for its high heat resistance, chemical resistance, and good dimensional stability. It is widely used in automotive, consumer goods, and packaging industries due to its high strength and lightweight properties.

3. Acrylonitrile Butadiene Styrene (ABS): ABS is a versatile and commonly used plastic. It has good impact resistance, high strength, and good surface finish. ABS is extensively used in automotive parts, household appliances, and electronic enclosures.

4. Polystyrene (PS): This plastic is available in two main forms: general-purpose (GPPS) and high-impact (HIPS). GPPS is rigid and transparent, commonly used in food packaging and disposable products. HIPS has better impact resistance and is used in applications where more durability is required.

5. Polyvinyl Chloride (PVC): PVC is known for its excellent chemical resistance and good weatherability. It is widely used in construction, electrical insulation, and healthcare industries. PVC can be rigid or flexible, depending on the plasticizers used.

6. Polyethylene Terephthalate (PET): PET is a popular plastic for producing bottles and containers. It has good clarity, strength, and barrier properties against moisture and gases. PET is also recyclable, making it an environmentally friendly option.

7. Polycarbonate (PC): PC is a strong and transparent plastic with high impact resistance, making it suitable for applications where safety is critical. It is used in automotive components, safety glasses, and electronic devices.

These are just a few examples of the many types of plastics used in injection molding. Each plastic has its own unique properties, allowing manufacturers to choose the most suitable material for their specific application.

Pros and Cons of Using injection plastics

Injection plastics have become an essential material in various industries due to their versatility, durability, and cost-effectiveness. However, there are also some drawbacks to consider when using injection plastics.

Pros:

1. Versatility: Injection plastics can be easily molded into various shapes and sizes, making them suitable for a wide range of applications across different industries.

2. Durability: Injection plastics are known for their durability and long-lasting performance. They are resistant to corrosion, wear, and tear, making them ideal for long-term use.

3. Cost-effectiveness: Injection plastics are relatively inexpensive compared to other materials such as metal or wood. This makes them a cost-effective option for mass production and large-scale manufacturing.

Cons:

1. Environmental impact: Injection plastics are made from petrochemicals, which are non-renewable resources and can have a negative impact on the environment. Their disposal and recycling can also contribute to pollution and waste.

2. Limited heat resistance: Some injection plastics have limited heat resistance, which can be a disadvantage in high-temperature applications. They may deform or melt under extreme heat conditions.

3. Limited strength: While injection plastics are durable, they may not be as strong as other materials such as metal. This can be a limitation in applications that require high tensile strength or toughness.

In conclusion, the use of injection plastics has many benefits, such as versatility, durability, and cost-effectiveness. However, it is essential to consider the potential drawbacks, including their environmental impact, limited heat resistance, and strength. Overall, injection plastics can be a valuable material when used appropriately and responsibly in production and manufacturing processes.

injection plastics Reference Specifications (varies for different product)

Injection plastics refer to a manufacturing process where melted plastic is injected into a mold to create various products. The reference specifications for injection plastics can vary depending on the specific product being manufactured. However, there are several key considerations that apply to most injection plastics processes.

Firstly, the type of plastic material used in injection molding greatly impacts the final product’s characteristics. Common plastic materials utilized in injection molding include polyethylene, polypropylene, polystyrene, and polyvinyl chloride. Each material offers unique properties such as strength, flexibility, heat resistance, and chemical compatibility, which need to be considered during the production process.

The specifications also encompass the design of the injection mold. The mold design must be precisely engineered to ensure the desired shape, size, and functionality of the finished product. Factors such as part complexity, mold material, ejection system, cooling channels, and gate design are taken into account to fulfill the requirements of the injection plastics process.

Furthermore, the injection molding machine itself should meet specific specifications. The machine’s capacity, clamping force, injection pressure, and melt temperature parameters need to be adjusted to ensure proper plastic flow, filling, and cooling within the mold. These settings ensure the integrity and quality of the final product.

Other crucial considerations include cycle time, which refers to the time taken for a complete molding cycle (injection, cooling, ejection) and influences production efficiency. The part’s dimensional tolerances or allowable variations in size and shape play a significant role in meeting product requirements. Surface finish requirements must be defined to determine the level of smoothness or texture on the product’s surface.

In summary, injection plastics reference specifications vary across different products. They typically include the choice of plastic material, mold design, injection molding machine parameters, cycle time, dimensional tolerances, and surface finish requirements. These specifications are crucial to ensure the successful production of high-quality injection plastic products.

Applications of injection plastics

Injection plastics have revolutionized various industries with their versatility, cost-effectiveness, durability, and ease of production. They find a wide range of applications in several sectors, including automotive, medical, packaging, electronics, construction, and consumer goods. Here are some key applications:

1. Automotive Industry: Injection plastics are extensively used in the automotive sector for producing components like car interiors, dashboards, bumpers, door panels, and electrical connectors. These plastics offer lightweight, impact resistance, and lower costs compared to traditional materials like metal.

2. Medical Devices: Injection plastics play a crucial role in the medical field, producing devices such as syringes, IV components, dental equipment, implantable devices, surgical instruments, and diagnostic equipment. Their biocompatibility, sterilizability, and ability to maintain dimensional stability make them ideal for medical applications.

3. Packaging: Injection plastics are widely used in the packaging industry, producing bottles, caps, containers, lids, and films. These plastics offer excellent barrier properties, preventing spoilage, contamination, and preserving product freshness. They are also lightweight and cost-effective, making them a popular choice for consumer products.

4. Electronics: The electronics industry extensively uses injection plastics for producing components such as casings, connectors, switches, and cable insulation. These plastics offer excellent electrical insulation, flame resistance, and the ability to withstand harsh environmental conditions.

5. Construction: Injection plastics are used in the construction industry for producing pipes, fittings, insulation materials, window frames, flooring, and roofing materials. These plastics are lightweight, durable, and resistant to chemicals, making them suitable for various construction applications.

6. Consumer Goods: Injection plastics find applications in the creation of a wide range of consumer goods, including toys, household appliances, furniture, sporting goods, and kitchenware. They offer design flexibility, durability, and cost-effectiveness compared to other materials.

7. Aerospace: Injection plastics are utilized in the aerospace industry for manufacturing lightweight components, reducing fuel consumption and increasing efficiency. Examples include aircraft interiors, seating components, ventilation systems, and electrical connectors.

In conclusion, injection plastics have diverse and significant applications across many industries, demonstrating their importance and relevance in the modern world. Their versatility and ability to meet specific requirements make them a preferred choice for various applications, enhancing functionality, reducing costs, and driving innovation.

The Work Process and how to use injection plastics

The work process of injection plastics involves several steps that are necessary for creating plastic parts or products. Here is an overview of the process and how it can be used effectively:

1. Design: The first step in the process is designing the plastic part or product using computer-aided design (CAD) software. This step involves creating a 3D model of the desired plastic item.

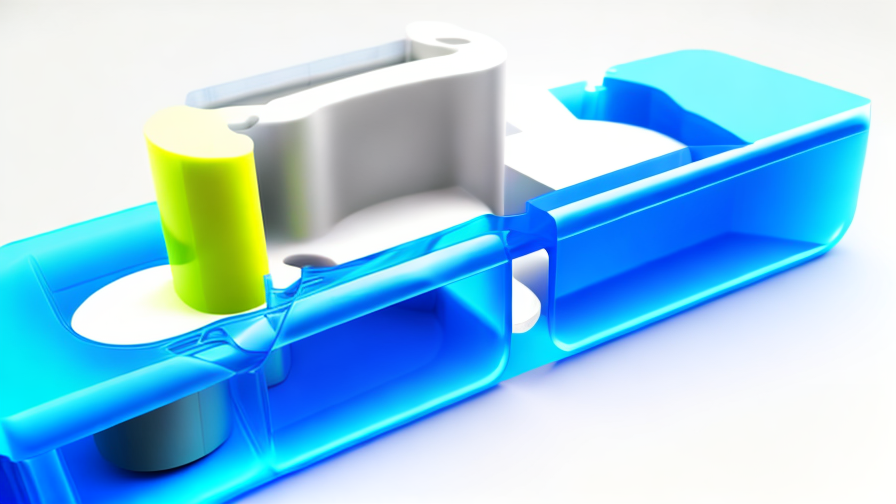

2. Mold creation: Once the design is finalized, a mold is created for injection molding. The mold is typically made from metal and consists of two halves, the cavity and the core. The mold design should take into account factors such as wall thickness, draft angles, and parting lines.

3. Material selection: The next step is selecting the appropriate plastic material for the injection molding process. Factors such as desired properties, cost, and required volume play a role in material selection. Common plastics used in injection molding include polypropylene, polystyrene, and polyethylene.

4. Injection molding: In this step, the selected plastic material is melted and injected into the mold cavity under high pressure. The molten plastic fills the entire cavity and takes the shape of the mold. Injection molding machines are used to perform this process. Once the plastic solidifies, the mold is opened, and the part or product is ejected.

5. Post-processing: After the plastic part is ejected from the mold, it may require some post-processing operations. This can include removing any excess material or using additional processes like trimming, welding, or assembling.

Injection plastics can be used in a wide range of industries and applications due to their versatility and cost-effectiveness. It is commonly used for manufacturing consumer products, automotive parts, medical devices, and electronic components.

To use injection plastics effectively, it is important to consider the following:

1. Design for manufacturability: Design the plastic part keeping in mind the capabilities and limitations of injection molding. Consider factors like wall thickness, draft angles, and use of ribs or gussets to enhance structural integrity.

2. Material selection: Choose a plastic material that meets the required properties for the part or product. Consider factors like mechanical strength, temperature resistance, chemical resistance, and cost.

3. Mold design: Design the mold to ensure proper filling, cooling, and ejection of the plastic part. Adequate venting, cooling channels, and ejection mechanisms should be incorporated in the mold design.

4. Quality control: Implementing strict quality control measures is crucial to ensure the consistency and reliability of the injection molded parts. Regular inspection, testing, and monitoring of the process parameters are essential to maintain high-quality standards.

By following these steps and considerations, injection plastics can be effectively used to create high-quality plastic parts and products efficiently.

Quality Testing Methods for injection plastics and how to control the quality

Quality testing methods for injection plastics involve various techniques to ensure the reliability, durability, and overall quality of plastic products. Here are some commonly used testing methods:

1. Dimensional Analysis: This involves checking the dimensions of the injection-molded parts to ensure they meet the design specifications. Calipers, coordinate measuring machines (CMM), or vision systems are used for accurate measurements.

2. Visual Inspection: This is a basic method to detect any visible defects like surface imperfections, scratches, or flow marks on the plastic parts.

3. Mechanical Testing: Various mechanical properties such as tensile strength, flexural strength, and impact resistance are tested to evaluate the strength and performance of the plastic material. Universal testing machines or impact testers are utilized for such tests.

4. Thermal Analysis: This testing method is used to assess the behavior of the plastic material under different temperature conditions. Techniques like differential scanning calorimetry (DSC) or thermogravimetric analysis (TGA) help understand the thermal stability and melting behavior of the plastic.

5. Chemical Testing: This involves analyzing the chemical composition and properties of the plastic material. Tests like Fourier-transform infrared spectroscopy (FTIR) or gas chromatography-mass spectrometry (GC-MS) help identify any impurities or additives in the plastic.

To control the quality during injection plastic manufacturing, several strategies can be implemented:

1. Robust Process Design: Develop a well-defined manufacturing process with optimized parameters to ensure consistent product quality.

2. Proper Material Selection: Select suitable plastic materials that meet the specific requirements of the product, considering factors like mechanical properties, chemical resistance, and environmental conditions.

3. Regular Maintenance of Equipment: Conduct routine maintenance and calibration of injection molding machines, molds, and other equipment to ensure accurate and consistent production.

4. Statistical Process Control (SPC): Use statistical techniques to monitor the process during production and detect any variations or defects early on. This includes techniques like control charts, capability studies, and process capability indices.

5. Effective Quality Assurance: Implement a comprehensive quality management system that includes supplier evaluation, incoming material inspection, in-process monitoring, and final product inspection.

By following these quality testing methods and control measures, manufacturers can ensure that injection plastic products meet the desired quality standards, resulting in customer satisfaction and product reliability.

injection plastics Sample Policy and Post-Purchase Considerations for injection plastics from China

Sample Policy: When purchasing injection plastics from China, it is important to have a clear understanding of the supplier’s policies. Ensure that the supplier provides a detailed written agreement outlining specifications, quality standards, delivery timelines, and payment terms. It is recommended to request for samples before placing a bulk order to verify the quality and performance of the plastics. Additionally, discuss the supplier’s return policy in case of any defects or discrepancies in the products received.

Post-Purchase Considerations: After receiving the injection plastics from China, it is important to inspect the products thoroughly to ensure they meet the agreed specifications and quality standards. Communicate with the supplier promptly if there are any issues or concerns with the products. It is advisable to maintain a good relationship with the supplier for any future orders or warranty claims. Keep records of all transactions and communications with the supplier for reference in case of disputes or follow-up orders. Conduct regular quality checks on the injection plastics to ensure they are meeting your specific requirements and standards. Consider providing feedback to the supplier on the performance of the products to help improve future orders.

Sourcing injection plastics from China: Opportunities, Risks, and Key Players

China is renowned for its extensive experience and expertise in injection plastics manufacturing. Both opportunities and risks can be identified when sourcing injection plastics from China, and there are key players in the industry to consider.

Opportunities:

1. Cost Advantage: China offers a significant cost advantage in injection plastics manufacturing due to its low labor and production costs. This enables businesses to reduce their overall production expenses and increase competitiveness in the global market.

2. Technical Expertise: Chinese manufacturers have acquired substantial technical knowledge and expertise in injection plastics manufacturing. They possess the capability to produce complex and high-quality plastic components, fulfilling diverse customer requirements.

3. Manufacturing Scale: China has developed an impressive infrastructure to support large-scale manufacturing. The country has efficient supply chains and extensive production capacities, ensuring timely delivery and scalability of injection plastics production.

Risks:

1. Quality Control: Maintaining quality control can be a significant challenge when sourcing from China. Despite advancements in manufacturing standards, some manufacturers may not adhere to the required quality benchmarks. It is vital to thoroughly vet potential suppliers and establish stringent quality assurance processes.

2. Intellectual Property Protection: Intellectual property theft remains a concern in China. Companies need to carefully evaluate the chosen manufacturer’s commitment to intellectual property protection to avoid potential counterfeiting or unauthorized duplication of their products.

3. Language and Cultural Barriers: Communication and cultural differences can present challenges when sourcing from China. Effective communication and regular dialogue are essential to avoid misunderstandings and ensure that the requirements are properly understood and met.

Key Players:

Several key players dominate the injection plastics industry in China. Some prominent companies include:

1. Foxconn Technology Group: Known for manufacturing electronic products, Foxconn also specializes in injection plastics production.

2. Flex: As a global leader in electronics manufacturing services, Flex has extended its operations to include injection plastics manufacturing.

3. BYD Company Limited: BYD is a leading manufacturer of automobiles, batteries, and electronic products, with a strong presence in injection plastics manufacturing.

4. Midea Group: Midea is one of the world’s largest home appliance manufacturers, offering a wide range of products that are extensively produced using injection plastics.

It is essential to thoroughly research and evaluate potential suppliers based on their expertise, reputation, and experience in injection plastics manufacturing before engaging in business partnerships.

How to find and select reliable injection plastics manufacturers in China,use google search manufacturers and suppliers

When searching for reliable injection plastics manufacturers in China, Google search can be an effective tool. Here are some steps to help you find and select trustworthy manufacturers and suppliers:

1. Conduct a targeted search: Use specific search terms like “injection plastics manufacturers in China” or “reliable plastic injection molding companies in China.” This will yield more relevant results.

2. Evaluate company websites: Look for well-designed and professional websites that showcase their capabilities, facilities, and certifications. Pay attention to the quality of their content, product/service descriptions, and contact information.

3. Check experience and specialization: Look for manufacturers with extensive experience in the industry. Consider their specialization and whether it aligns with your specific requirements. A manufacturer specializing in your desired plastic material or product category is likely to offer better quality.

4. Assess production capabilities: Check if the manufacturer has sufficient production capacity to meet your demand. Look for information on their machinery, processes, and production scale. A well-equipped facility with modern technology indicates a professional manufacturer.

5. Review quality control systems: Reliable manufacturers have effective quality control measures in place. Look for ISO certification or other industry-specific quality certifications. Assess whether they follow international production standards, perform rigorous testing, and have quality control checks at different stages of production.

6. Analyze customer reviews and testimonials: Search for reviews or testimonials from previous clients. Look for feedback on the manufacturer’s communication, responsiveness, on-time delivery, and product quality. This can give you insights into their reliability and customer satisfaction.

7. Request samples or visit their factory: If possible, request product samples to assess the quality first-hand. Alternatively, consider visiting their factory to see their production process, facilities, and meet their team. Both approaches can help you gauge their capabilities and commitment to quality.

8. Seek multiple quotes: Contact multiple manufacturers and request quotes for your desired project. Compare pricing, lead times, and service offerings. However, keep in mind that the lowest price is not always the best option – prioritize reliability and quality over cost.

Ultimately, thorough research, analysis, and due diligence are crucial in selecting reliable injection plastics manufacturers in China. Using Google search and following the steps outlined above will help you find dependable suppliers that meet your specific requirements.

How to check injection plastics manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

When checking the reliability of an injection plastics manufacturer’s website, one way is to use Google Chrome’s SEOquake extension which can provide insights into the website’s search engine ranking. By checking if the website ranks in the top 10 million on Google search results, you can gauge the website’s visibility and credibility.

Additionally, you can look for specific indicators of reliability on the website itself. Check for a professional design, clear contact information, and transparency about the company’s background and manufacturing process. Look for customer reviews and testimonials to get an idea of the company’s reputation and quality of products.

It’s also important to verify the company’s credentials and certifications, such as ISO standards or industry affiliations. A trustworthy company will likely display these credentials on their website.

Overall, conducting thorough research and checks on the company’s website can help you determine the reliability of an injection plastics manufacturer. If in doubt, you can also contact the company directly to ask any questions or request more information.

Top 10 injection plastics manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. **Formlabs**

Formlabs specializes in SLA 3D printing technology, offering a range of advanced resins for various industries such as engineering, healthcare, and education. Their high-resolution printers produce detailed prototypes and end-use parts.

2. **Proto Labs**

Proto Labs provides rapid injection molding services with short lead times and low volumes. They offer a variety of thermoplastic materials to choose from, ensuring high-quality and cost-effective production for a wide range of industries.

3. **Rutland Plastics**

Rutland Plastics specializes in custom injection molding for automotive, medical, and consumer goods applications. Their expertise in tooling and design ensures precision and efficiency in manufacturing complex parts.

4. **Ningbo Haishu Will Win**

Will Win is a leading injection molding manufacturer in China, offering a wide range of plastic products for industries such as automotive, electronics, and household appliances. They are known for their high-quality finishes and strict quality control standards.

5. **Suzhou Get Plastic Technology**

Get Plastic Technology is an injection molding company in China that specializes in precision molds and plastic parts for industries such as automotive, electronics, and medical devices. They provide customizable solutions for various applications.

| Manufacturer | Specialization | Industries Served | Quality Control |

|—————————|———————–|———————–|——————|

| Formlabs | SLA 3D printing | Engineering, Healthcare, Education | High-resolution printing |

| Proto Labs | Injection molding | Various | Rapid production |

| Rutland Plastics | Custom molding | Automotive, Medical, Consumer goods | Tooling expertise |

| Ningbo Haishu Will Win | Injection molding | Automotive, Electronics, Appliances | High-quality finishes |

| Suzhou Get Plastic Tech | Precision molds, parts | Automotive, Electronics, Medical devices | Customizable solutions |

Background Research for injection plastics manufacturers Companies in China, use qcc.com archive.org importyeti.com

Injection plastics manufacturers in China are a key part of the country’s manufacturing industry, providing components for a wide range of products. Companies such as Sun Yingsha Plastics Co., Ltd. and Shenzhen Abery Mold & Plastics Co., Ltd. are leading players in this sector.

Sun Yingsha Plastics Co., Ltd. specializes in the production of injection molded plastic parts for industries such as automotive, electronics, and medical equipment. The company has a strong reputation for quality and reliability, with a focus on using advanced technology and equipment to ensure precision and consistency in their products.

Shenzhen Abery Mold & Plastics Co., Ltd. is another major player in the injection plastics manufacturing industry in China. The company offers a wide range of services, including product design, mold making, injection molding, and assembly. It serves clients in various industries, including electronics, telecommunications, and automotive.

These companies can be found on platforms such as qcc.com, archive.org, and importyeti.com, where potential customers can access information about their products and services. By utilizing these platforms, businesses can easily connect with injection plastics manufacturers in China and explore potential partnerships for their manufacturing needs.

Leveraging Trade Shows and Expos for injection plastics Sourcing in China

Trade shows and expos can be valuable resources for sourcing injection plastics in China. These events provide a platform for connecting with suppliers, gaining industry insights, and exploring new products and technologies. Here are some tips for leveraging trade shows and expos for injection plastics sourcing in China:

1. Research and Plan: Before attending a trade show or expo, do some research on the exhibitors and products that will be featured. Identify the suppliers that specialize in injection plastics and make a plan to visit their booths.

2. Network: Trade shows and expos are great opportunities to network with industry professionals and build relationships with potential suppliers. Take the time to introduce yourself, exchange contact information, and learn more about their capabilities.

3. Attend Seminars and Workshops: Many trade shows and expos offer informative seminars and workshops on topics related to injection plastics sourcing. Take advantage of these educational opportunities to stay current on industry trends and best practices.

4. Request Samples and Catalogs: When visiting suppliers at trade shows and expos, don’t hesitate to request samples and catalogs of their injection plastics products. This will give you a better sense of their quality, pricing, and range of offerings.

5. Compare Options: Take the time to compare different suppliers and their products before making a decision. Consider factors such as pricing, lead times, quality standards, and customer service.

By leveraging trade shows and expos for injection plastics sourcing in China, you can expand your network, discover new suppliers, and stay competitive in the industry. With careful planning and research, these events can be a valuable resource for finding the right partners for your injection plastics sourcing needs.

The Role of Agents and Sourcing Companies in Facilitating injection plastics Purchases from China

Agents and sourcing companies play a crucial role in facilitating injection plastics purchases from China by acting as intermediaries between buyers and manufacturers. These entities have a deep understanding of the Chinese market, regulatory framework, and the complexities involved in sourcing high-quality injection plastics products.

Agents and sourcing companies help buyers navigate language and cultural barriers, as well as provide insights into the local business practices, ensuring a smooth and efficient procurement process. They assist in identifying reputable manufacturers, conducting supplier audits, negotiating prices, and managing the entire sourcing process from product development to shipping.

Moreover, agents and sourcing companies leverage their network of contacts and relationships with manufacturers to secure better pricing, quality control, and on-time delivery. They also help with logistics, customs clearance, and compliance with import regulations, saving buyers time and effort in dealing with these complexities.

Overall, agents and sourcing companies play a vital role in bridging the gap between buyers and manufacturers in China, facilitating seamless communication, efficient procurement, and ensuring a successful injection plastics purchase process. Their expertise and support are invaluable in meeting buyers’ needs while navigating the challenges of sourcing from overseas markets.

Price Cost Research for injection plastics manufacturers Companies in China, use temu.com and 1688.com

When it comes to injection plastics manufacturers, China is known for its competitive pricing and quality products. For conducting price cost research, two widely-used online platforms in China are temu.com and 1688.com.

temu.com is a popular sourcing platform that allows users to find reliable manufacturers and suppliers. It provides a wide range of products, including injection plastics, and allows buyers to directly communicate with suppliers. To conduct price cost research on temu.com, users can search for injection plastics manufacturers and compare the prices and cost details provided by different suppliers. This helps in getting an idea of the average price range and understanding the cost components involved in producing injection plastics in China.

Another platform commonly used for price cost research in China is 1688.com. It is a prominent wholesale marketplace that offers a vast range of products, including injection plastics. 1688.com allows users to search for specific products and view the price details provided by different manufacturers and suppliers. Users can also communicate directly with suppliers on the platform to inquire about the cost breakdown and negotiate prices.

When conducting price cost research on these platforms, it is crucial to keep the following points in mind:

1. Compare prices from multiple suppliers to get a better understanding of the average price range.

2. Pay attention to the cost breakdown provided by suppliers to understand the components contributing to the overall price.

3. Consider other factors such as quality, certifications, and manufacturing capabilities while evaluating suppliers.

In conclusion, temu.com and 1688.com are valuable platforms for conducting price cost research for injection plastics manufacturers in China. By utilizing these platforms, users can compare prices, understand the cost components, and make informed decisions about their sourcing needs.

Shipping Cost for injection plastics import from China

The shipping cost for importing injection plastics from China will depend on several factors such as the size and weight of the shipment, the shipping method chosen, and the distance between the supplier in China and the destination country.

Typically, the most common shipping methods for importing goods from China are sea freight and air freight. Sea freight is usually more cost-effective for larger shipments as it allows for economies of scale, while air freight is faster but more expensive.

For a shipment of injection plastics, sea freight would likely be the more economical choice. The cost of sea freight can range from $3,000 to $7,000 for a full container load (FCL) depending on the size and weight of the shipment, as well as the specific port of departure and destination.

If the shipment is smaller, less than a full container load (LCL), the cost will be based on the volume of the goods being shipped. This can range from $500 to $2,000 for a smaller shipment of injection plastics.

Keep in mind that additional costs such as customs duties, taxes, and import tariffs will also need to be factored into the overall cost of importing injection plastics from China. It is recommended to work with a reputable freight forwarder or shipping company to assist with the logistics of importing goods from China to ensure a smooth and cost-effective process.

Compare China and Other injection plastics Markets: Products Quality and Price,Visible and Hidden Costs

China is known for being the global manufacturing hub, exporting a wide range of products, including injection plastics, to various countries worldwide. When comparing China’s injection plastics market with other markets, several factors come into play, including product quality, price, visible and hidden costs.

In terms of product quality, China has made significant strides over the years. Many manufacturers in China now adhere to international quality standards, meeting the requirements and specifications set by customers. However, it is important to note that there is still a wide range in terms of quality among Chinese manufacturers. Some offer high-quality injection plastics that are on par with products from other markets, while others may produce lower-quality items. It is crucial for buyers to carefully vet manufacturers and perform stringent quality checks before making a purchase.

Price is another important factor when comparing China’s injection plastics market with other markets. China’s manufacturing capabilities and abundant labor force often result in lower production costs, which in turn leads to competitive pricing. Buyers can often find injection plastics at a lower cost from Chinese manufacturers compared to other markets. However, pricing can vary depending on factors such as product complexity, customization, and quantity ordered. Additionally, transportation costs should also be considered when comparing prices, as these can significantly impact the overall cost of the product.

Visible and hidden costs need to be taken into consideration when evaluating the overall cost of sourcing injection plastics from China or other markets. Visible costs include manufacturing costs, transportation, import duties, and taxes. China’s relatively low labor costs can be a major advantage when it comes to visible costs. However, hidden costs need to be carefully assessed as well. These may include quality control measures, intellectual property protection, product customization, and potential delays in production or delivery. Hidden costs can vary depending on the specific requirements of the buyer and should be thoroughly evaluated to get an accurate cost analysis.

In conclusion, China’s injection plastics market offers a competitive combination of both quality and price. While product quality has improved, it is important for buyers to carefully assess and select reputable manufacturers. China’s manufacturing capabilities often result in lower production costs, providing cost advantages. However, visible and hidden costs need to be considered to ensure a comprehensive understanding of the overall cost implications when compared to other markets.

Understanding Pricing and Payment Terms for injection plastics: A Comparative Guide to Get the Best Deal

When it comes to the pricing and payment terms for injection plastics, understanding the key factors and comparing different options can help you secure the best deal. Here is a comparative guide to help you navigate this process.

1. Price per Unit: Comparing the price per unit is crucial. It allows you to evaluate the cost-effectiveness of different suppliers. Consider not only the initial price but also the quality and specifications provided by each supplier.

2. Volume Discounts: Inquire about volume discounts. If you have a large order, suppliers may offer discounts to incentivize bulk purchases. Understanding the discount thresholds can help you estimate potential savings.

3. Tooling Costs: Injection molding requires specific tooling, which can be expensive. Some suppliers may charge tooling costs separately, while others may include them in the unit price. Clarify whether tooling costs are a one-time fee or if they are spread across the production order.

4. Mold Ownership: Determine who will own the injection molding molds. Some suppliers offer to cover the mold costs but retain ownership, while others may require you to bear the expenses but grant you ownership. Considering long-term manufacturing plans and ownership rights is essential.

5. Payment Terms: Review the payment terms offered by different suppliers. This includes understanding the payment schedule, acceptable methods of payment, and any potential fees or penalties for late payments. Negotiating favorable payment terms can provide better cash flow management.

6. Lead Time: Evaluate the lead time for production and delivery. Shorter lead times are advantageous, but keep in mind that rushing production may affect quality. Balancing production time with quality requirements is crucial.

7. Quality Assurance: Inquire about the supplier’s quality control process. Ensure that they have established measures to deliver consistent quality products. Request samples or visit their facilities to assess their production capabilities and quality standards.

8. Warranty or Returns Policy: Understand the supplier’s warranty or returns policy. Clarify their stance on product defects, replacements, or refunds. A supplier with favorable warranty terms demonstrates confidence in their product quality.

9. Additional Services: Some suppliers might offer additional services, such as packaging, shipping, or post-production support. Evaluate the costs and benefits of outsourcing these services versus managing them in-house.

10. Supplier Reputation: Research and assess the reputation and track record of potential suppliers. Read customer reviews, request references, and consider their experience in the injection plastics industry. A reliable and reputable supplier can ensure a smoother production process and higher customer satisfaction.

In conclusion, understanding pricing and payment terms for injection plastics involves comparing factors such as price per unit, volume discounts, tooling costs, payment terms, lead time, quality assurance, warranty, additional services, and supplier reputation. Careful evaluation and negotiation can help you secure the best deal while maintaining quality standards for your injection plastics needs.

Chinese Regulations and Industry Standards Certifications for injection plastics,Import Regulations and Customs for injection plastics from China

China has a well-established system of regulations and industry standards certifications for injection plastics. These requirements ensure the quality and safety of plastic products manufactured in China, both for domestic consumption and export.

One of the key certifications is the China Compulsory Certification (CCC) mark. This certification is mandatory for many products, including injection plastics, that enter the Chinese market. The CCC mark indicates that the product complies with the established safety and quality standards. Manufacturers must obtain the CCC mark before they can sell their products in China.

In addition to the CCC mark, there are several industry-specific certification standards for injection plastics, such as the ISO 9001 quality management system certification and the ISO 14001 environmental management system certification. These certifications demonstrate that the manufacturer follows internationally recognized best practices in terms of quality control and environmental sustainability.

When importing injection plastics from China, it is important to be familiar with the regulations and customs procedures. Importers should ensure that the products they import comply with the relevant Chinese regulations and certifications. Failure to do so may result in customs clearance issues or even the confiscation of the goods.

Importing injection plastics from China requires the completion of customs paperwork, including a commercial invoice, packing list, and customs declaration form. Importers should accurately declare the value, quantity, and specifications of the goods. The customs authorities may also require additional documents, such as certificates of compliance or test reports, to verify the quality and safety of the products.

Customs duties and taxes may be applicable to the import of injection plastics. Importers should be aware of the applicable tariff rates and ensure that they have the necessary financial resources to cover these costs.

To sum up, importers of injection plastics from China should be aware of the country’s regulations and industry standards certifications. They should ensure that the products they import comply with the necessary requirements and complete the required customs paperwork accurately. By doing so, they can ensure a smooth and compliant import process.

Sustainability and Environmental Considerations in injection plastics Manufacturing

In injection plastics manufacturing, sustainability and environmental considerations are crucial to mitigate the negative impact on the environment. One key aspect is the use of recycled materials in the production process. By incorporating recycled plastics into manufacturing, the industry can reduce the demand for virgin materials, minimize waste, and lower energy consumption. This not only helps in conserving natural resources but also reduces greenhouse gas emissions.

Another important factor to consider is the proper disposal and recycling of plastic waste generated during the manufacturing process. Implementing efficient waste management practices, such as segregating and recycling scrap materials, can significantly reduce the amount of waste sent to landfills. Additionally, companies can explore innovative solutions like converting plastic waste into energy or other usable materials to further minimize environmental impact.

Furthermore, manufacturers should prioritize energy efficiency in their operations. By adopting energy-saving technologies and practices, such as optimizing heating and cooling systems, utilizing renewable energy sources, and implementing energy-efficient lighting, companies can reduce their carbon footprint and contribute to a cleaner environment.

In conclusion, sustainability and environmental considerations are essential in injection plastics manufacturing to minimize the industry’s impact on the environment. By incorporating recycled materials, implementing efficient waste management practices, and prioritizing energy efficiency, manufacturers can work towards a more sustainable and eco-friendly production process.

List The Evolution history of “injection plastics”

Injection plastics, also known as injection molding, have gone through a significant evolution since their inception. The process involves injecting molten plastic material into a mold and allowing it to cool and solidify to form a desired shape. Here is a brief overview of the evolution history of injection plastics:

1. Early Developments (19th century): The origins of injection molding can be traced back to the late 19th century when metal and celluloid materials were used. These early attempts were slow and limited in terms of materials and design capabilities.

2. Bakelite era (early 20th century): In the early 20th century, Leo Hendrik Baekeland invented and patented Bakelite, a thermosetting plastic. Bakelite revolutionized injection molding due to its ability to withstand high temperatures and its excellent electrical insulating properties.

3. Post-war advancements (1940s-1950s): After World War II, the demand for consumer goods increased, leading to advancements in injection molding techniques. The widespread adoption of new materials, such as polystyrene and polyethylene, enabled the production of a wide variety of plastic products.

4. Introduction of hydraulics (1950s-1960s): In the 1950s, hydraulic systems were introduced to injection molding machines, allowing for faster and more efficient production. This innovation increased the precision and speed of the injection process.

5. Computerization and automation (1970s-1980s): The integration of computers and automation systems in the 1970s and 1980s revolutionized injection molding. Computer-aided design (CAD) and computer-aided manufacturing (CAM) systems enabled the design of complex molds and improved quality control.

6. Development of new materials (1990s-present): The injection molding industry continued to evolve with the development and use of advanced materials, such as thermoplastic elastomers, bioplastics, and composites. These materials offer enhanced properties like durability, biodegradability, and recyclability.

7. 3D printing and additive manufacturing (2000s-present): The injection molding industry has taken advantage of the advancements in 3D printing and additive manufacturing technologies. Rapid prototyping using 3D printing allows for the validation of mold designs before mass production, reducing costs and lead times.

Overall, the evolution of injection plastics has been marked by advancements in materials, machinery, automation, and design capabilities. These developments have transformed injection molding into a highly efficient and versatile manufacturing process, enabling the production of a wide range of plastic products that have become a central part of our modern lives.

The Evolution and Market Trends in injection plastics Industry

The injection plastics industry has undergone significant evolution and market trends over the years, driven primarily by advancements in technology and changing customer demands. This industry involves the manufacturing of plastic products through injection molding, a process that involves injecting molten plastic material into a mold to shape and form the desired product.

One notable evolution in the injection plastics industry has been the development of new and improved materials. Manufacturers are now able to produce high-quality plastic products that offer better strength, durability, and resistance to various environmental factors. This has expanded the applications of injection plastics to a wide range of industries such as automotive, electronics, packaging, medical, and consumer goods.

Another crucial evolution is the incorporation of automation and robotics in the injection molding process. Automation has significantly increased production efficiency, reduced labor costs, and improved quality control. With the help of robots and advanced software, manufacturers can now achieve precise and consistent molding, resulting in higher productivity and faster turnaround times.

Furthermore, market trends in the injection plastics industry have been shaped by changing consumer preferences and environmental concerns. There is a growing demand for sustainable and eco-friendly materials, leading manufacturers to explore biodegradable and recycled plastics. Additionally, consumers are increasingly seeking customizable and personalized products, prompting manufacturers to adopt advanced technologies like 3D printing in the injection molding process.

The COVID-19 pandemic has further impacted the market trends in the injection plastics industry. There has been a surge in demand for plastic medical supplies and personal protective equipment (PPE), leading to increased production and innovation in this sector. The emphasis on hygiene and safety measures has also influenced the development of antimicrobial and easy-to-clean plastic products.

In conclusion, the injection plastics industry has evolved significantly over time, driven by advancements in materials, automation, and changing consumer demands. The market trends reflect a shift towards sustainability, customization, and the development of plastic products that cater to the current global health crisis. As technology continues to advance, it is likely that the industry will further innovate and adapt to meet the evolving needs of various sectors.

Custom Private Labeling and Branding Opportunities with Chinese injection plastics Manufacturers

Chinese injection plastics manufacturers offer a range of opportunities for custom private labeling and branding. By partnering with these manufacturers, businesses can create unique products with their own branding to differentiate themselves in the market.

One key advantage of working with Chinese manufacturers is their expertise and advanced technology in injection molding, allowing for precise and high-quality production of plastic products. This ensures that the finished products meet the specific requirements and branding standards of the businesses.

Additionally, Chinese manufacturers often provide flexible customization options, allowing businesses to fully customize their products with unique designs, colors, and logos. This customization can help businesses create a strong brand identity and stand out in a competitive market.

Furthermore, partnering with Chinese manufacturers can offer cost-effective solutions for private labeling and branding. With competitive pricing and low production costs, businesses can create customized plastic products without breaking the bank.

Overall, working with Chinese injection plastics manufacturers for custom private labeling and branding opportunities can provide businesses with high-quality, unique products that meet their branding needs, all at an affordable price.

Tips for Procurement and Considerations when Purchasing injection plastics

When it comes to purchasing injection plastics, there are several considerations to keep in mind to ensure a successful procurement process. Here are some tips and factors to consider:

1. Define your requirements: Clearly identify your needs and specifications for the injection plastics. This includes understanding the type, quantity, quality, and characteristics of the plastics required for your application.

2. Research potential suppliers: Conduct thorough research to find reputable suppliers or manufacturers of injection plastics. Look for companies with a proven track record, positive customer reviews, and streamlined production processes.

3. Quality control: Insist on receiving samples and testing them for quality control purposes before placing a bulk order. Ensure that the injection plastics meet your specific requirements and comply with industry standards.

4. Cost and pricing: Compare prices from multiple suppliers to ensure competitive pricing. However, keep in mind that the lowest price does not always guarantee the best quality. Consider the supplier’s reputation and the quality of their products when comparing prices.

5. Supplier capabilities and capacity: Assess the supplier’s ability to meet your production requirements. Examine their production capacity, lead times, and their ability to handle large-volume orders. A reliable supplier should be able to fulfill your orders on time, especially if you have tight deadlines.

6. Material selection: Ensure that the injection plastics you purchase are suitable for your intended application. Consider factors such as durability, heat resistance, chemical resistance, and any specific requirements unique to your industry.

7. Environmental considerations: In today’s world, it is important to consider the environmental impact of the injection plastics you purchase. Look for suppliers that prioritize sustainability and offer environmentally-friendly materials and production processes.

8. Supply chain transparency: Check if the supplier provides information about their raw material sourcing and production processes. Transparency is crucial for ensuring ethical practices, especially if social and environmental responsibility is important to your organization.

9. Communication and collaboration: Establish effective communication channels with the supplier to ensure a smooth procurement process. Discuss delivery schedules, payment terms, and any other details that may affect your order.

10. After-sales support: Inquire about the supplier’s after-sales support. It is beneficial to work with a supplier who offers troubleshooting, warranty, and customer support in case any issues arise with the injection plastics.

By considering these tips and factors, you can make more informed decisions when purchasing injection plastics and find a reliable supplier that meets your needs while delivering high-quality products.

FAQs on Sourcing and Manufacturing injection plastics in China

1. Why should I consider sourcing and manufacturing injection plastics in China?

China has well-established infrastructure, a large pool of skilled labor, and cost-effective manufacturing capabilities. Additionally, the country has a robust supply chain network that can efficiently produce high-quality injection plastics at competitive prices.

2. What are the benefits of sourcing injection plastics from China?

Sourcing injection plastics from China can offer various benefits such as lower production costs, access to a wide range of materials and technology, shorter lead times, and high production capacities. Additionally, China has a diverse supplier base that can meet various manufacturing requirements.

3. How can I find a reliable injection plastics manufacturer in China?

To find a reliable injection plastics manufacturer in China, you can conduct thorough research, seek recommendations from industry peers, attend trade shows and exhibitions, and perform due diligence on potential suppliers. It is essential to establish clear communication channels and visit the manufacturers’ facilities to ensure quality control.

4. What are the challenges of sourcing and manufacturing injection plastics in China?

Some of the challenges of sourcing and manufacturing injection plastics in China include language barriers, intellectual property concerns, regulatory compliance, and cultural differences. It is crucial to work with experienced sourcing agents or consultants to navigate these challenges effectively.

5. How can I ensure quality control in the manufacturing process?

To ensure quality control in the manufacturing process, you can implement quality control measures such as frequent inspections, testing of materials, monitoring production processes, and establishing clear quality standards. It is also essential to work closely with the manufacturer to address any issues promptly and effectively.

Why contact sourcifychina.com get free quota from reliable injection plastics suppliers?

Sourcifychina.com is an online platform that connects businesses with reliable injection plastics suppliers in China. By contacting Sourcifychina.com, you can easily request a free quota from these trusted suppliers, allowing you to compare prices, quality, and services before making a decision. This can help you find the best supplier for your specific needs without having to commit to anything upfront.

Furthermore, Sourcifychina.com only works with verified and reputable suppliers, ensuring that you will be dealing with trustworthy and reliable partners. This can save you time and effort in sourcing and vetting potential suppliers on your own.

By using Sourcifychina.com to request a free quota from reliable injection plastics suppliers, you can access a wide network of high-quality manufacturers in China. This can ultimately result in cost savings, improved product quality, and a smoother supply chain process for your business.

Overall, contacting Sourcifychina.com for a free quota from injection plastics suppliers is a convenient and efficient way to find the right partner for your manufacturing needs in China. With their help, you can easily connect with reputable suppliers and make informed decisions for your business.