Knowledge about Interlocking Bricks Machine

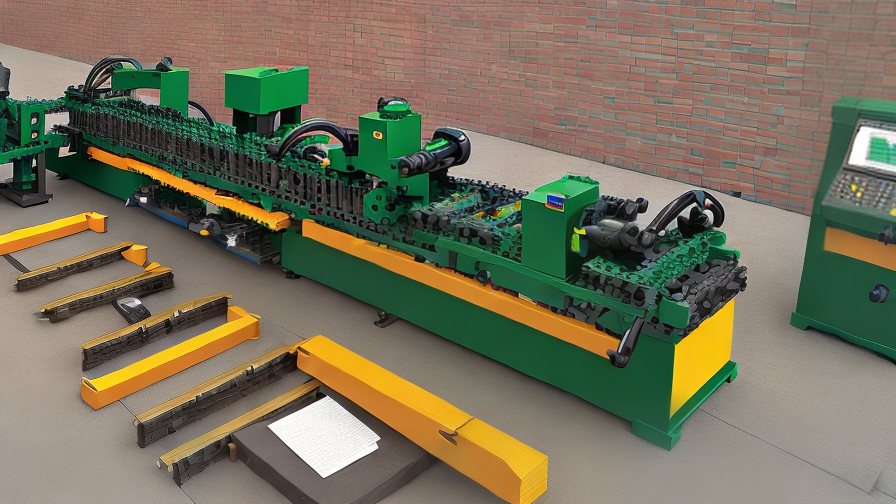

Interlocking bricks machine is a revolutionary invention that has completely transformed the construction industry. The machine allows for the production of strong, durable, and affordable interlocking bricks that can be used to build all types of structures quickly and easily.

The interlocking bricks machine works by compressing soil, cement, and water into form-fitting bricks that interlock securely when stacked together. The machine is easy to operate, and it can be operated by anyone with basic knowledge of construction.

One important thing to note before using an interlocking bricks machine is the type of soil to use. The best type of soil for interlocking bricks is red soil, which is widely available. The quality of the soil affects the strength and durability of the bricks produced, so it is essential to use the right kind of soil.

Another factor that affects the quality of the bricks is the amount of cement and water used in the production process. Too much cement will make the bricks brittle, while too little will result in weak and uneven bricks. It is important to strike the right balance between cement and water to produce high-quality bricks.

Operating an interlocking bricks machine requires proper maintenance, including regular cleaning, lubrication, and replacement of worn-out parts. Regular maintenance ensures that the machine operates efficiently, resulting in high-quality bricks and extended machine lifespan.

In conclusion, interlocking bricks machines have revolutionized the construction industry by making the production of strong and durable bricks affordable, quick, and easy. Ensuring that the right type of soil, cement, and water is used, combined with regular maintenance of the machine, will result in the production of high-quality interlocking bricks. With this knowledge, any construction project can be completed using this innovative technique of interlocking bricks construction.

Various Types of Interlocking Bricks Machine

Interlocking bricks are becoming increasingly popular these days, thanks to their eco-friendliness and durability. They are designed to interlock and hold together tightly, eliminating the need for cement and other adhesives. In this article, we’ll discuss the various types of interlocking brick machines that make these special bricks.

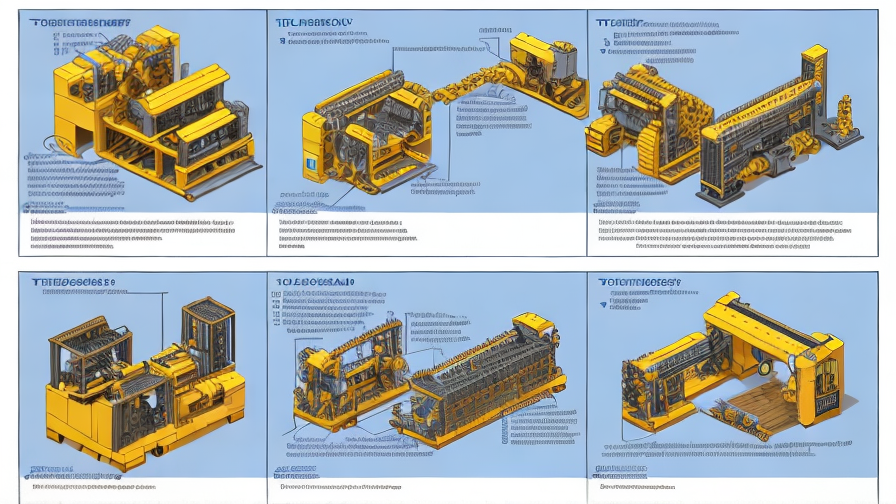

1. Manual interlocking brick machine: This is the most basic type of interlocking brick machine. It requires no electricity and relies solely on human power to produce bricks. It’s lightweight, portable, and easy to operate, making it a popular choice for small-scale operations.

2. Semi-automatic interlocking brick machine: This type of machine is partially automated and requires some form of electrical power to function. It’s ideal for medium-scale operations and can produce more bricks per hour than a manual machine.

3. Fully-automatic interlocking brick machine: This machine is fully automated and requires no human intervention. It’s suitable for large-scale operations and can produce many bricks per hour.

4. Hydraulic interlocking brick machine: This type of machine relies on hydraulic power to generate pressure and produce bricks. It’s ideal for producing high-quality bricks and can handle various types of soil.

5. Compressed earth block machine: This type of interlocking brick machine is specifically designed to produce compressed earth blocks, which are eco-friendly and sustainable. It’s ideal for producing bricks using unpaved roads or agricultural land.

6. Interlocking paver block machine: This machine is designed to produce interlocking pavers, which are widely used in landscaping and outdoor spaces. It’s perfect for producing decorative bricks with unique designs.

In conclusion, there are various types of interlocking brick machines available in the market, and choosing the right one depends on your specific needs and requirements. Whether you’re a small-scale operator or a large-scale manufacturer, there’s an interlocking brick machine that’s suitable for you.

FAQ sourcing Interlocking Bricks Machine manufacturer from China

Interlocking bricks are gaining popularity as a sustainable building solution around the world. More and more construction projects are opting for interlocking bricks due to their low cost, durability, and easy installation, paving the way for the popularity of interlocking brick machines in the market. China has emerged as a leading manufacturer of interlocking brick machines, offering a wide range of options for buyers worldwide. However, as with any international purchase, sourcing a reliable interlocking brick machine manufacturer from China can be challenging. In this article, we answer some of the most commonly asked questions about sourcing an interlocking brick machine manufacturer from China.

1. Can I trust Chinese manufacturers for interlocking brick machines?

China is a leading manufacturer of interlocking brick machines and has a reputation for providing cost-effective solutions while maintaining quality. However, it’s essential to do your research and vet potential manufacturers thoroughly, checking their reputation, reviews, and certifications.

2. What features should I look for in an interlocking brick machine?

Key features to look for in interlocking brick machines include production capacity, power consumption, mobility, and customization options. It’s important to choose a machine that fits your specific needs and budget.

3. How do I ensure quality control when importing from China?

Before importing, ensure that the manufacturer follows international quality control standards and that the machine undergoes rigorous testing before shipment. Request a sample, and hire a third-party inspection service to check for quality control before finalizing the purchase.

4. How do I find the right supplier for interlocking brick machines in China?

The best way to find a reliable manufacturer is through specific industry events and conferences, trade shows, and online platforms such as Alibaba and Made-in-China.com. It’s crucial to review each supplier’s sales history, product quality, and customer feedback before making a purchase.

5. How do I handle logistics and shipping?

Identify a reliable logistics and shipping partner with experience in the import-export industry. The shipping method and the transit time will depend on the

Applications of Interlocking Bricks Machine

Interlocking bricks machine is a revolutionary construction device used for producing high-quality interlocking bricks. These bricks are made by pressing soil, cement, and other materials and are widely used in the construction of houses, schools, hospitals, and other buildings. The machine is versatile in its application and has various benefits that make it an important tool in the construction industry.

The interlocking bricks machine has a wide range of applications. One of the main applications is in the construction of low-cost housing. These machines produce high-quality bricks that are perfect for building affordable housing for low-income families. As a result, housing can be easily made available to those who cannot afford it otherwise.

Another significant application of the interlocking bricks machine is in the construction of schools and hospitals in rural areas. The brick-making process is simple, and the machine can be easily transported, making it ideal for use in remote areas that are difficult to reach. The bricks produced by the machine are also strong and durable, making them suitable for building structures that are needed in these areas.

The interlocking bricks machine is also used in the construction of roads, pavements, and other infrastructure projects. The bricks produced by the machine make for excellent and durable road and pavement materials. Moreover, interlocking bricks are eco-friendly as they require minimal cement content and reduce the dependence on natural resources such as sand and stone.

In conclusion, the interlocking bricks machine has various applications that make it a highly valuable tool in the construction industry. It is used in the production of low-cost housing, schools and hospitals in rural areas, and infrastructure projects such as roads and pavements. The machine produces high-quality bricks that are strong, durable, and eco-friendly. With its versatility, the interlocking bricks machine has become a must-have for construction companies looking to improve their building projects’ quality while keeping costs low.

Manufactured Products made of Interlocking Bricks Machine

Interlocking brick machines have revolutionized the way we manufacture bricks. These machines have proved to be efficient and cost-effective. One of the biggest advantages of these machines is that they can produce interlocking bricks that are strong and durable. These bricks can be used to manufacture a variety of products.

One of the main products made using interlocking brick machines is paving blocks. Paving blocks made using interlocking bricks are durable and can withstand heavy traffic. They are also slip-resistant, making them an ideal choice for driveways, walkways, and patios.

Besides, interlocking bricks are used to make roofing tiles. The roofing tiles are incredibly strong and are not easily damaged by weather elements. They give homes an aesthetic appeal, and due to their interlocking attributes, the roofing structures last longer hence saving on costs.

Interlocking bricks are also used in the construction of retaining walls. These walls are used to prevent soil erosion and maintain a leveled surface. Using interlocking bricks in construction guarantees the walls’ durability and strength as they are interlocked helping them to withstand enormous pressures and prevent cracking.

Another use of interlocking bricks is in designing and manufacturing of interlocking blocks used in the construction of houses. These bricks are not only strong and durable but also eco-friendly in comparison with ordinary blocks. They don’t require additional mortar, cement or adhesives, which increases productivity while minimizing the carbon footprint.

In the current world, many people are looking for sustainable building materials that are environmentally friendly. The use of interlocking bricks eliminates the need to use additional building materials that would have produced waste material to the environment.

In conclusion, the use of interlocking brick machines has revolutionized the way we manufacture products. These machines have enabled efficient and cost-effective production of bricks that have diverse uses. From paving blocks to roofing tiles, the possibilities are endless. Manufacturers using interlocking bricks produce products that are durable, strong, and environmentally friendly.

The Evolution history of Interlocking Bricks Machine

Interlocking bricks, also known as compressed earth blocks, are a popular building material in many parts of the world. This innovative technology has been evolving for centuries, with various advances in design and technology over time.

The first interlocking brick machine was invented by the Dutch engineer Henk van Kruysdijk in the late 1940s. This machine was powered by a hand crank and used a mixture of soil and cement to create solid bricks that interlocked with each other. While the design was simple and effective, it required a lot of manual labor and was limited in its production capacity.

In the 1950s, Chinese engineers developed a more advanced interlocking brick machine that was powered by electricity. This machine used a combination of hydraulic pressure and vibration to compress soil and cement into interlocking bricks. This technology quickly gained popularity in developing countries as an affordable and sustainable building material.

In the 1980s, a number of small-scale manufacturers began to produce interlocking brick machines using hydraulic pressure to create high-quality bricks. These machines featured improved designs and production capacity, making them suitable for larger building projects.

In recent years, there has been increasing interest in using interlocking bricks as a sustainable alternative to traditional building materials. This has led to the development of new and improved interlocking brick machines that use advanced technologies like computer-aided design and automated manufacturing processes.

Today, interlocking brick machines are available in a variety of sizes and configurations to meet the needs of different builders and projects. They are used in a wide range of applications, from low-cost housing to schools, hospitals, and commercial buildings.

In conclusion, the evolution history of interlocking brick machines has been a story of innovation and adaptation to the changing needs of builders and communities around the world. As we continue to explore more sustainable and affordable building materials, interlocking bricks will likely play an increasingly important role in meeting these needs.

The Process of Interlocking Bricks Machine

Interlocking brick machines are becoming increasingly popular as a sustainable way to construct buildings. The process of interlocking brick machine involves assembling different bricks in such a way that they interlock and provide more stability to the whole structure.

To begin the process, a mixture of cement and soil is created, called the brick mix. This mixture is then fed into the interlocking brick machine. The machine consists of a mould box, which is used to mould the bricks into the desired shape. Once the brick mould is filled with the brick mix, the machine compresses the mixture, creating a tightly compacted brick.

The interlocking bricks formed by the machine are then left to dry in the sun for a few days. The bricks are then ready to be assembled. The process of interlocking involves arranging the bricks in a specific pattern, allowing them to interlock with each other. Interlocking bricks are unique in that they require minimal cement and can be assembled without the use of mortar.

Compared to traditional building methods, interlocking brick machines offer numerous benefits. They are more affordable, energy-efficient, and eco-friendly. Interlocking bricks are also able to withstand earthquakes and other natural disasters, making them a reliable choice for building in areas prone to seismic activity.

In conclusion, the process of interlocking brick machines involves creating a mixture of cement and soil, which is then fed into the machine. The machine moulds the brick mix into tightly compacted bricks, which are then assembled in an interlocking pattern. This sustainable way of building offers numerous benefits and has proven to be a popular choice for many builders worldwide.

Benefits Advantages of Utilizing Interlocking Bricks Machine

Interlocking bricks have gained immense popularity in the construction industry for their sturdy build and ease of installation. With the use of interlocking bricks machines, construction businesses and individuals can now produce high-quality interlocking bricks that accurately fit together. Here are some benefits and advantages of utilizing interlocking bricks machine.

– Durability: Interlocking bricks are known for their durability, as they can withstand heavy loads and harsh weather conditions. These bricks are made from high-quality materials that are compressed under high pressure, resulting in a strong bond. With the use of interlocking bricks machine, you can produce sturdy and high-quality bricks for your construction project.

– Energy-efficient: Interlocking bricks machines are energy-efficient, as they require less power to operate compared to traditional brick-making machines. This means that you can save on your energy bills and reduce your carbon footprint while still producing high-quality bricks.

– Time-saving: Interlocking bricks machine can produce a large number of bricks in a short period, making it a time-saving investment. With the use of modern interlocking bricks machines, you can produce up to 15,000 bricks per hour.

– Cost-effective: Using interlocking bricks for construction projects can be cost-effective, as they require less cement and are easy to install. Additionally, interlocking bricks machines eliminate the need for skilled labor or manual labor, reducing labor costs for your construction project.

– Environmentally friendly: Interlocking bricks are eco-friendly, as they help reduce construction waste and promote sustainable construction practices. These bricks are made from natural materials, such as clay or soil, which are readily available and sustainable.

In conclusion, investing in an interlocking bricks machine is a smart move for any construction business or individual looking to save time, money, and energy. The benefits and advantages of utilizing interlocking bricks machine are numerous, making it an attractive investment for anyone looking to produce high-quality interlocking bricks.

Disadvantages Interlocking Bricks Machine

Interlocking bricks machines have become popular in the construction industry due to their ease of use and affordability. However, just like any other machine, they come with their disadvantages. In this article, we will explore the disadvantages of using interlocking bricks machines.

1. High initial cost – Interlocking bricks machines are expensive. Their high initial cost can be a barrier for small businesses or individuals who want to invest in them. This makes it difficult for small entrepreneurs to compete with more established players in the market.

2. Limited production capacity – Interlocking bricks machines are designed for small to medium-scale production. This means they may not be suitable for large projects. If you need to produce a large number of bricks, you will have to invest in several machines, which can be expensive.

3. High maintenance costs – Interlocking bricks machines require regular maintenance to ensure that they are operating efficiently. Maintenance costs can be high, especially if the machine breaks down frequently or requires replacement parts.

4. Dependence on electricity – Interlocking bricks machines require electricity to operate. This makes them unsuitable for areas with frequent power outages or where electricity is not available.

5. Limited variety of bricks – Interlocking bricks machines can only produce interlocking bricks. This limits the variety of bricks that can be produced. For example, it is impossible to produce regular bricks with interlocking bricks machines.

In conclusion, interlocking bricks machines have their disadvantages. While they are affordable and easy to use, their limited production capacity, high initial cost, high maintenance costs, dependence on electricity, and limited variety of bricks make them unsuitable for large projects or areas with frequent power outages. Before investing in an interlocking bricks machine, it is necessary to consider both the advantages and disadvantages.

Selecting the Ideal Manufacturer Interlocking Bricks Machine

Selecting the Ideal Manufacturer Interlocking Bricks Machine

Interlocking brick technology is relatively new in the construction industry. In recent years, it has become more popular due to its many benefits, including faster construction time, reduced costs, and increased durability. To successfully implement this technology, you need the right equipment, especially the interlocking bricks machine.

When choosing a manufacturer for your interlocking bricks machine, consider the following factors:

Experience

Experience is crucial when it comes to selecting the ideal manufacturer. Consider choosing a manufacturer that has been in the interlocking bricks machine production industry for many years. Such a manufacturer is more likely to have vast experience and expertise in producing good quality machines.

Cost

The cost of the machine is also a critical factor to consider. Different manufacturers offer different prices for their machines. Be sure to compare different manufacturers and choose the one that offers the most reasonable prices without compromising on quality.

Quality

Quality is a non-negotiable element when selecting any machinery. A good quality interlocking bricks machine should produce strong bricks that can withstand harsh weather conditions and frequent use. Check the machine specifications, performance, and durability before making your purchase.

Support and warranty

A good manufacturer should offer support and a warranty period for their machines. This way, you can be sure that you are covered in case of any issues that may arise. You can also seek technical assistance from the manufacturer and be sure that they will be willing to help you.

Conclusion

Selecting the ideal manufacturer of an interlocking bricks machine is essential to ensure you get a quality product that efficiently meets your needs. Be sure to consider the manufacturer’s experience, cost, quality and level of support offered before making a purchase. With these factors in mind, you will find the right manufacturer and enjoy the advantages of interlocking brick technology.

Things to Consider When Purchasing Interlocking Bricks Machine

Looking to purchase an interlocking bricks machine for your business? Here are some key things to consider before making your purchase:

1) Production Capacity: Consider your production needs and choose a machine that can handle the volume required. Machines come in different sizes and production capacities.

2) Power Consumption: Be mindful of the amount of electricity required to operate the machine. Choose a machine that is energy-efficient and environmentally friendly.

3) Material Quality: Look for a machine made with high-quality materials that are durable and long-lasting.

4) Ease of Use: Consider the design, interface, and automated features of the machine. Choose a machine that requires minimal manual labor and is easy to operate.

5) Maintenance and Repairs: Ensure that the machine you choose is easy to maintain and that repairs can be carried out without too much difficulty, ensuring minimal downtime.

6) Cost: The price of the machine should always be considered in relation to the production capacity, quality, and features of the machine.

7) Reputation of the Manufacturer: Choose a machine from a reputable manufacturer with a history of quality and reliability in the industry. Check reviews and customer testimonials before making your final decision.

By carefully analyzing these factors, you will be a step closer to making a wise investment in your business through the purchase of an interlocking brick machine that will save you time and money while increasing your production capacity.

Properties of Interlocking Bricks Machine

Interlocking bricks machines are a popular tool for construction in today’s world. These machines are designed to produce interlocking bricks that are versatile, durable, and attractive. They are ideal for building walls, floors, and other structures that require strength and stability.

One of the properties of interlocking bricks machines is their ability to produce bricks of different sizes and shapes. This feature makes them suitable for a variety of construction projects. They can produce rectangular, square, and even curved interlocking bricks. This versatility enhances their effectiveness and efficiency in construction.

Interlocking bricks machines are also known for their ease of use. They are designed with user-friendly interfaces that make them easy to operate even for individuals with minimal training. The machines come with clear instructions that enable the user to create sturdy and stable interlocking bricks.

Another property of interlocking bricks machines is their speed of production. They can produce large quantities of bricks in a short period, reducing the time required for construction. This feature makes them ideal for large scale construction projects.

Moreover, interlocking bricks machines are environmentally friendly. They are designed to use locally available resources such as soil or clay, which reduces the environmental impact associated with the production of conventional bricks. They require minimal energy input, which translates to lower carbon emissions and reduced energy costs.

In conclusion, interlocking bricks machines are a valuable asset in modern construction. They are versatile, easy to use, fast, and environmentally friendly. Interlocking bricks are becoming increasingly popular due to their durability, strength, and aesthetic appeal, making them an excellent choice for construction projects.

How to use Interlocking Bricks Machine

Interlocking bricks allow you to construct sturdy and long-lasting structures in a fraction of the time. They are made from compressed clay and save you the hassle of using mortar to bind your wall. Interlocking bricks machine come in different sizes and models that cater to the needs of different users. In this article, we will be talking about how to use interlocking bricks machine.

Step 1 – Get the right materials

Before using interlocking bricks machine, you need to have the right materials in place. You will require quality soil, clay or cement, water, and a stabilizer to hold the bricks together.

Step 2 – Set up the machine

Once you have gathered all the materials, it’s time to set up your machine. Most interlocking bricks machine will come with a user manual that will guide you on how to set up and operate the machine.

Step 3 – Mix the ingredients

After setting up the machine, you need to mix the ingredients to make the soil-cement mixture. You can use a drum mixer, hand mixer, or a shovel to mix the ingredients. The most recommended ratio is 1 part soil, 1 part cement, and 4 parts sand.

Step 4 – Load the machine

Once the mixture is ready, you can load it into the machine’s hopper. The machine will then compress the mixture into the desired brick size and shape. Ensure that you load the machine with the right amount of mixture to avoid wastage.

Step 5 – Cure the bricks

After making the bricks, you need to leave them to cure for a few days. This will allow the bricks to dry and harden for enhanced stability. You can cure the bricks under a shade to prevent direct sunlight from causing cracks.

Conclusion

Interlocking bricks machine is an excellent tool to use when constructing structures. By following the above steps, you can easily make interlocking bricks for your project. However, it’s essential to adhere to safety measures while using the machine to

Glossary Terminology Terms for Interlocking Bricks Machine

Interlocking brick machines have become increasingly popular in the construction industry due to their affordability, ease of use and ability to produce interlocking bricks in large quantities. However, to fully understand the inner workings of these machines, it is important to understand the terminology that goes with them. Here are some glossary terminology terms for interlocking brick machine you should know.

1. Interlocking bricks: These are bricks that can be easily assembled without using any adhesive or cement.

2. Block making machine: This is the machine used to produce interlocking bricks.

3. Mould: The mould is a metal frame that is used to shape and compress the raw materials into interlocking bricks.

4. Raw materials: The raw materials used in interlocking brick production are usually soil mixed with cement, sand and water.

5. Hydraulic system: This is the system that powers the machine and compresses the raw materials into interlocking bricks.

6. Conveyor belt: This is the mechanism that moves the raw materials into the mould.

7. Pallet: The pallet is a flat wooden or plastic board that holds the interlocking brick as it is being produced.

8. Vibrator: This is a motorized device that shakes and compacts the raw materials to create a more compact interlocking brick.

9. Curing: This is the process of allowing the interlocking bricks to dry and harden for a certain period of time.

10. Output rate: Output rate is the number of interlocking bricks the machine can produce in a given time, usually measured in bricks per hour or bricks per day.

Understanding these terms is essential for anyone looking to purchase, operate or maintain an interlocking brick machine. Whether you are a contractor or a homeowner, knowing the terminology associated with interlocking brick machines is crucial if you want to get the most out of your interlocking brick production process.

Interlocking Bricks Machine Price

Interlocking bricks are a popular alternative to traditional bricks due to their durability and affordability. They are made using a machine that produces interlocking bricks by compressing soil mixed with cement and water. This process is known to yield strong and durable bricks that can withstand harsh weather conditions.

Interlocking brick machines have become increasingly popular in recent years, and they are now widely used in construction projects around the world. With so many different interlocking brick machines available, it can be challenging to determine the price of these machines.

The cost of interlocking brick machines can vary significantly depending on various factors such as the capacity, model, and manufacturer. Some machines are designed to produce a specific number of bricks per day, while others can produce significantly larger quantities of bricks.

The initial investment required for interlocking brick machines can be expensive, but the long-term benefits outweigh the cost. With the ability to produce high-quality bricks that require minimal maintenance and repairs, interlocking brick machines can generate considerable cost savings over time.

The price of interlocking brick machines typically ranges from a few thousand dollars to several thousand dollars. The cost also varies depending on the country in which the machine is manufactured. For instance, interlocking brick machines made in China are generally less expensive than those made in other countries.

In conclusion, interlocking brick machines come at varying prices depending on the manufacturing process and the location of the machine. However, investing in these machines ultimately provides cost savings and other advantages in the long run. It is essential to assess the capacity, model, and manufacturer before settling on any interlocking brick machine to ensure it can meet your production needs.