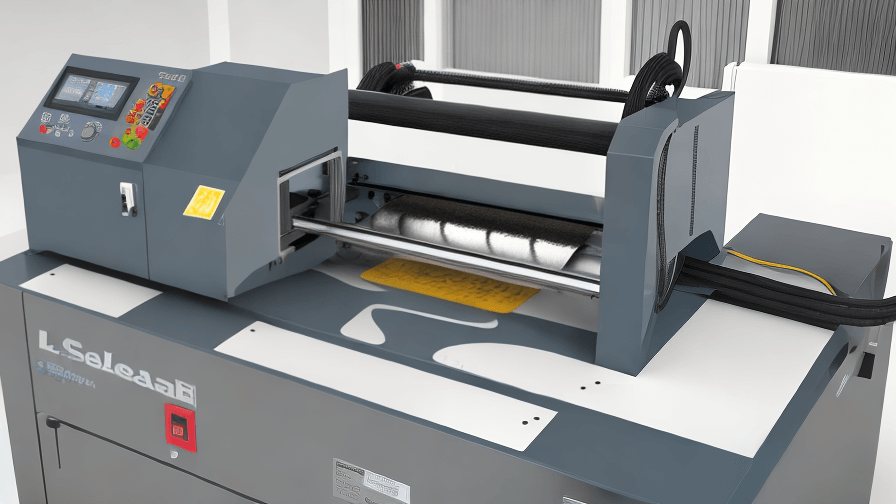

Benefits of L Sealer Machine

L sealer machine is used in various industries to wrap and seal products. These machines are highly efficient and offer several benefits to businesses that use them. Here are some of the benefits of the L sealer machine:

1. Cost-Effective

One of the main benefits of the L sealer machine is its cost-effectiveness. These machines are designed to operate consistently, with minimal maintenance and repair costs. This makes them a cost-effective option for businesses of all sizes looking to optimize their operational costs.

2. Increased Productivity

L sealer machines are fast and efficient. They are designed to seal a large number of products quickly and effectively, which can help increase productivity. With increased productivity comes increased profitability, and businesses will experience a more efficient workflow as a result of using these machines.

3. Greater Flexibility

The L sealer machine is versatile and can be used to wrap and seal a wide variety of products. Because of this, businesses can use this machine to package different products as needed, eliminating the need for several machines. The machine also offers excellent flexibility in terms of seal type, seal strength, and packaging material.

4. Consistent Sealing Quality

L sealer machines are built to deliver consistent and high-quality sealing. The machine’s advanced technology and precision control ensure that every package is sealed appropriately, reducing the chance of product damage or loss during transit or storage. This consistent sealing quality also improves the product’s overall aesthetic appeal.

5. Reduced Waste

Using an L sealer machine can help reduce waste in the packaging process. These machines can cut packaging materials to a specific size, reducing material waste and overall product expenses. This reduced waste resulting from the L sealer machine also helps in protecting the environment by decreasing the carbon footprint.

In conclusion, the L sealer machine is a useful and cost-effective tool that can help businesses in several industries improve their efficiency and profitability. Utilizing an L sealer machine can help businesses save money, increase productivity, offer flexibility, maintain consistency, reduce waste and provide an overall positive customer experience. Businesses should consider integrating these machines to improve their packaging process.

Features of L Sealer Machine

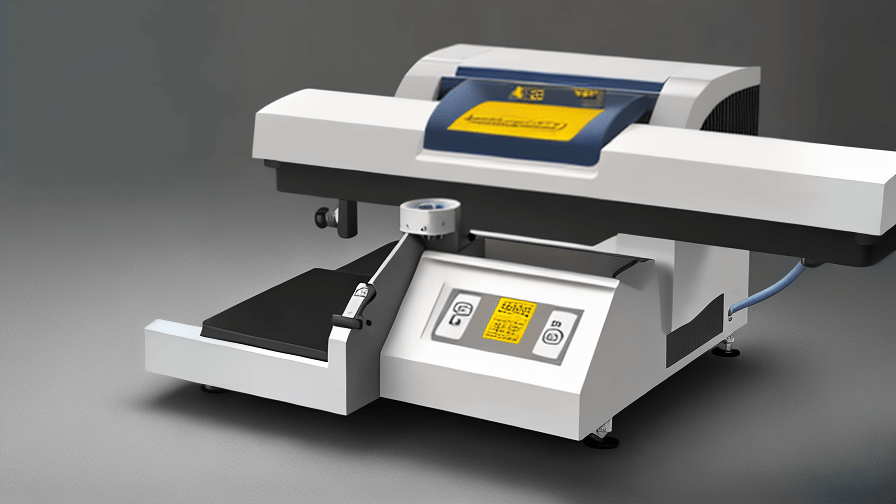

An L sealer machine is a packaging machine that makes use of heat to wrap different products in a secure and professional manner. It is mostly used in industries that deal with packaging, such as the food, pharmaceutical, and cosmetic industries, to guarantee the safety and durability of products during transportation and storage. Here are some of the features that make the L sealer machine an essential piece of equipment.

One of the main features of the L sealer machine is its versatility. It can be used to wrap products of varied sizes and shapes, making it an ideal choice for businesses that package multiple products. Additionally, it can handle different packaging materials such as shrink films, polyethylene, or PVC, providing a protective layer to the product.

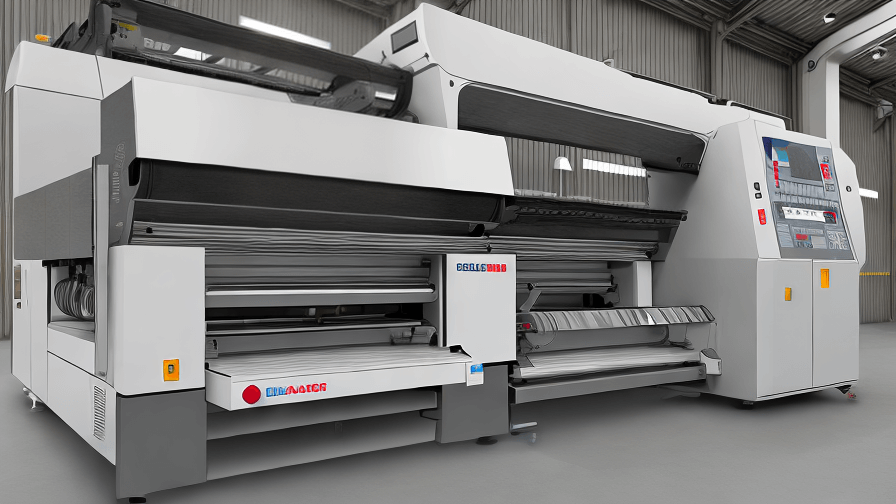

Another feature is the speed and efficiency of the L sealer machine. It can wrap up to thousands of items per hour, saving businesses time and labour costs. Its automated sealing feature means it requires less attention, freeing up staff to handle other tasks.

Most L sealer machines feature a digital control panel that allows users to adjust the temperature and sealing time to ensure the correct level of sealing is applied to products. The machine is also equipped with safety features such as emergency stop buttons, ensuring the safety of operators when in operation.

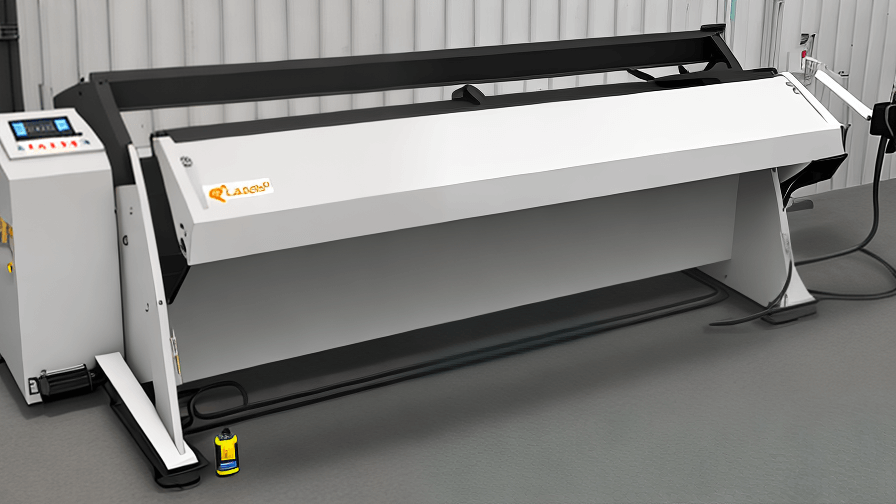

The L sealer machine has a small footprint, making it a space-saving option for businesses with limited floor space. It is also easy to install and operate, requiring minimal training, reducing the time and cost associated with personnel training.

Lastly, the L sealer machine is cost-effective. It uses automated processes that minimize wastage, save raw materials, and reduce labour costs. It does not require frequent maintenance, making it a reliable and durable investment for businesses.

In summary, the L sealer machine is a valuable asset for businesses in the packaging industry. Its features, such as versatility, speed and efficiency, safety, ease of use, small footprint and cost-effectiveness, make it an essential piece of equipment that can help businesses improve their packaging process and enhance productivity.

Various Types of L Sealer Machine

L-sealer machines are widely used in the packaging industry for sealing and shrinking of various products, including food, electronic items, personal care products, and more. They provide an efficient and cost-effective way of packaging products while ensuring their safety and quality. Here are some of the commonly available types of L sealer machines:

1. Manual L-Sealer Machine:

These machines are operated manually, and the operator needs to place the product in the sealing area manually. Once it’s placed, the operator pulls down the sealing arm using a handle, and the sealing and cutting process is done automatically. These machines are often used in small businesses and shops that do not require high production levels.

2. Semi-Automatic L-Sealer Machine:

Semi-automatic L-sealer machines are more efficient than manual machines. They have a partially automated sealing process, where the product is placed on the sealing table, and the sealing arm is brought down automatically. However, the operator needs to push the product into the seal area and remove it after sealing manually. These machines are suitable for small or medium-sized businesses that require better production efficiency.

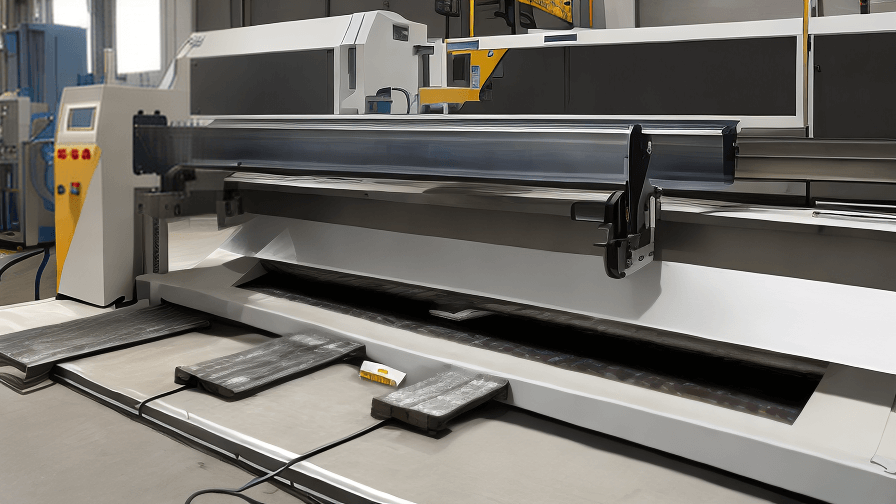

3. Automatic L-Sealer Machine:

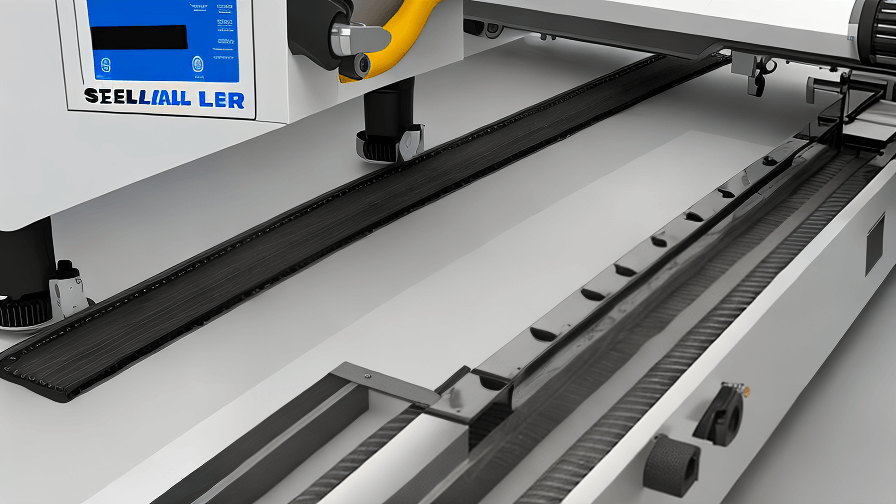

These L-sealer machines are fully automated, and they can handle a high volume of products in a short time. They have an automatic conveyor belt that carries the products to the sealing area, and the sealing arm comes down automatically to form the seal and cut the excess material. These machines are ideal for large-scale businesses that require high production levels.

4. Side Feed L-Sealer Machine:

Side feed L-sealer machines are suitable for long and narrow products such as books, magazines, and other similar items. These machines have a side conveyor that feeds the products into the sealing area, where the sealing arm comes down to seal and cut the material.

In conclusion, L-sealer machines come in different types and sizes, depending on the type of product and production level. By understanding the different types of L-sealer machines available, businesses can select the right one to suit their needs.

Applications of L Sealer Machine

L sealer machines are versatile pieces of equipment that are capable of sealing a wide variety of products. From food to consumer goods, they are an essential tool for many industries. Here are some of the common applications of L sealer machines.

Food packaging: L sealer machines are widely used in the food industry for sealing products such as snacks, baked goods, fresh produce, and frozen foods. They can be used for both manual and automatic packaging, and in some cases, can even use modified atmosphere packaging (MAP) technology to extend the shelf life of the product.

Consumer goods: L sealer machines are also used to package a wide variety of consumer goods such as electronics, toys, and household goods. They ensure the products are properly sealed and protected during shipping and storage.

Pharmaceuticals: L sealer machines are used to seal pharmaceutical products to ensure they stay safe and secure during shipping. They can accommodate a wide variety of packaging materials, including foils, films, and laminates.

Cosmetics: L sealer machines are used to seal cosmetic products such as lotions, creams, and serums. This ensures the products remain sterile and safe for use by consumers.

Textiles: L sealer machines are used in the textile industry to package garments, accessories, and other textiles. This ensures the products arrive at their destination in pristine condition.

In conclusion, L sealer machines are incredibly versatile and have a wide range of applications across various industries. They are an essential tool for any business that needs to package products safely and securely. They are an investment that can provide long-term benefits, including increased productivity and efficiency.

The Process of L Sealer Machine

L-Sealer is an important machine used for packaging products. It is a type of packaging equipment that is used to package products with a plastic wrap. The packaging process is quite simple and straightforward and can be completed in few steps.

First, the product is placed on the conveyor belt which moves it to the sealing area. Once in the sealing area, the operator then activates the machine which seals the plastic wrap around the product.

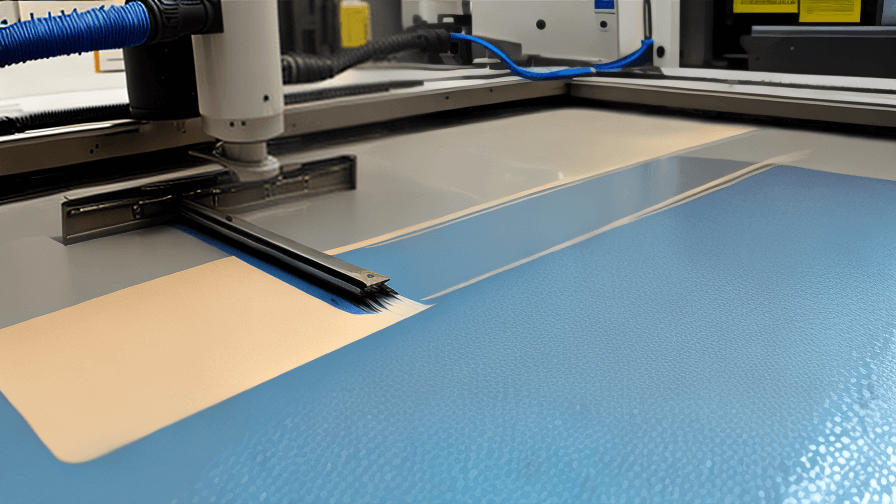

During the sealing process, the L-Sealer machine uses heat to seal the plastic wrap around the product. The sealing process ensures that the product is well-packaged and protected against dust, moisture, and other contaminants.

After the sealing is complete, the packaged product is moved to the shrinking tunnel. The tunnel uses heat to shrink the plastic wrap around the product, giving it a tight, secure and professional look.

The L-Sealer machines are easy to operate and require minimal maintenance. They are available in different sizes and shapes to fit different products. Some L-Sealer machines come with additional features like adjustable sealing height, automatic sealing, and cutting functions.

L-Sealer machines are used in different industries like food, cosmetic, and pharmaceutical among others. Most businesses use L-Sealer machines because they are efficient, cost-effective, and reliable. The machines can handle different types of packaging materials like PVC, polyethylene, and polyolefin among others.

In conclusion, L-Sealer machines are an essential part of the packaging process and are widely used in different industries. The process involves placing the product on the conveyor belt, sealing the plastic wrap around the product, and then shrinking the wrap in the tunnel to give it a tight and secure look. It’s a simple and effective way of packaging products to protect them from environmental contaminants and damage.

How to use L Sealer Machine

L-sealer machines are ideal for packaging and sealing food, cosmetic, pharmaceutical, and other products. These machines are designed to create a tight seal between two layers of plastic film, which ensures that the product remains free from dust, moisture, and contaminants.

Here’s a step-by-step guide on how to use an L-sealer machine:

Step 1: Prepare your product and packaging material. Ensure that your product is clean and dry, and that the packaging material is of the right size and thickness.

Step 2: Set the temperature and sealing time. You should determine the optimum temperature and sealing time for your specific product and film material. You can adjust the temperature and sealing time using the controls provided on the machine.

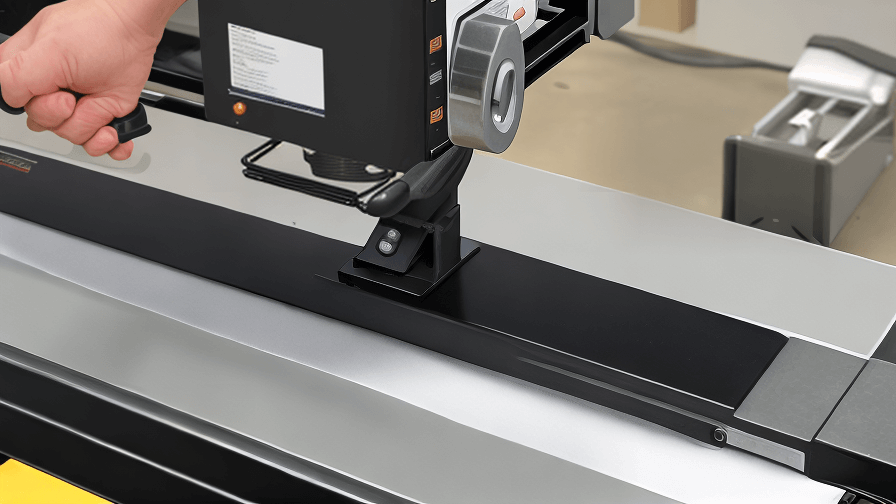

Step 3: Adjust the sealing bar. The sealing bar on the machine can be adjusted to fit the size of your product. Most machines have an adjustable sealing bar that can be moved up or down to accommodate different product sizes.

Step 4: Place the product in the film. Place the product in the center of the film, ensuring that it is centered and not touching the edges of the film.

Step 5: Seal the film. The machine will then automatically feed the film and seal it around the product. The sealing bar will move down, creating a tight seal around the product.

Step 6: Cut the film. After sealing the film, the machine will cut the film to the required length using a cutting blade or wire.

Step 7: Remove the sealed product. After cutting the film, the sealed product can now be removed from the machine. The product should be inspected to ensure that the seal is tight and there are no leaks.

Overall, L-sealer machines are easy to use and require little training. However, it is important to read the manufacturer’s instructions carefully and follow all safety precautions when using the machine. With the right set up, your L-sealer machine will help streamline your packaging process and increase your productivity.

Selecting the Ideal Manufacturer L Sealer Machine

When it comes to selecting an L sealer machine, there are a few factors you should consider to make sure you find the ideal manufacturer. With the right machine, you can streamline your packaging process, boost efficiency, and improve your bottom line.

When looking for a manufacturer, make sure they have a wide range of machines to choose from. Every business has different needs, so you want to be sure that the manufacturer can provide a machine that will work for you. They should offer machines in various sizes, speeds, and levels of automation.

Another important factor to consider is the manufacturer’s reputation. Look for reviews or testimonials from other businesses that have used their machines. If the manufacturer has a good reputation, it’s a good indication that they produce reliable and high-quality machines.

You should also consider the manufacturer’s customer service and support. Make sure they offer technical support and training to help you get the most out of your machine. Additionally, you want a manufacturer that offers a warranty and has parts readily available if anything needs to be replaced or repaired.

Finally, make sure the manufacturer uses high-quality materials and components when building their machines. You want a machine that will last for a long time and won’t break down easily. Cheaper machines may seem like a good deal, but they often come with costly repairs and downtime.

In summary, when selecting an L sealer machine manufacturer, look for a company with a wide range of machines to choose from, a good reputation, excellent customer service and support, and the use of high-quality materials and components. By doing so, you can find the ideal machine to help improve your packaging process and grow your business.

list FAQ with answer about L Sealer Machine

List FAQ with Answers about L Sealer Machine

An L Sealer Machine is a packaging machine used to pack different products, including food, electronics, and toys, among others. The machine seals the product inside a plastic bag, ensuring that the item is well packaged and protected from external factors like moisture, dust, and fungi. Below are some of the frequently asked questions about this machine and their respective answers.

Q: What are the types of sealing techniques used by L Sealer Machines?

A: There are two main types, including the Impulse Sealing Technique and Constant Heating Technique.

Q: What is the difference between the two techniques?

A: The Impulse Sealing Technique uses a pulse that heats and seals the plastic bag using a timer. The Constant Heating Technique, on the other hand, uses a constant heat supply to seal the plastic bag.

Q: What type of material can the L Sealer Machine seal?

A: The L Sealer Machine can seal different types of plastic films, including Polyethylene (PE), Polypropylene (PP), PVC, and Polyolefine.

Q: What is the maximum packaging size that the machine can handle?

A: The maximum packaging size depends on the size of the sealing bar. Typically, the machine comes with different sealing bar sizes, ranging from 450mm to 1000mm.

Q: What is the power consumption of the machine?

A: The machine’s power consumption varies, depending on the size of the sealing area, voltage, and the type of sealing technique used. The average power consumption ranges between 2KW to 4KW.

Q: What is the maintenance required for the L Sealer Machine?

A: The machine requires minimal maintenance, such as cleaning, regular oiling, and replacement of worn-out parts like sealing bars, blades, and rubber pads.

In conclusion, the L Sealer Machine is an essential packaging machine for businesses dealing with different products. It has multiple benefits, including cost-saving, productivity, and product protection. Understanding the above FAQs and answers will help you choose the right machine for your business needs.

Things to Consider When Purchasing L Sealer Machine

When it comes to efficiently packaging your products, an L sealer machine is an excellent option to consider. This machine works by creating a tight and transparent packaging around your product. However, with so many types of L sealer machines on the market today, selecting the right one can be daunting. Therefore, here are some vital considerations to make when purchasing an L sealer machine.

First and foremost, it is essential to consider the size of the L sealer machine. The ideal machine should be compatible with the size of the products you intend to package. Also, the speed of the machine should match your packaging needs. A machine with faster speed will boost your productivity and may, therefore, be the best choice for businesses with high packaging demands.

Another crucial consideration is the level of automation that the machine offers. An automated machine comes with programmable logic controllers which enable you to control various machine functions remotely. Notably, it will reduce your labor costs and enhance your production process. However, if your business offers a wide range of products with different shapes and sizes, a semi-automatic machine that offers manual adjustments would be the best choice.

Another vital consideration is the machine’s sealing mechanism. L sealer machines use either impulse sealers or constant heat sealers. Impulse sealers are best for packaging polyethylene bags, whereas constant heat sealers are ideal for thicker materials and can be used to package PVC or shrink films.

The construction materials of the L sealer machine also must be considered. The ideal device should be made from high-quality materials that can withstand heavy-duty usage and resist tear and wear.

Finally, consider the maintenance requirements of the machine. The ideal L sealer device should be easy to clean and offer a smooth operation. Also, ensure that the manufacturer offers reliable technical support and repair services.

In conclusion, purchasing an L sealer machine requires specific considerations that include speed, size, automation level, sealing mechanism, construction material, and maintenance requirements. By considering these factors, you will be sure to purchase the right machine that meets your business needs.

Properties of L Sealer Machine

An L sealer machine is a popular packaging machine that is used to wrap products securely for transportation or storage purposes. It is an automated machine that wraps products in shrink film material, to keep them safe from moisture and other environmental factors. The machine has numerous features that make it ideal for use in diverse packaging applications.

One of the properties of L sealer machine is the speed of operation. It is designed to work at high speeds, making it suitable for use in mass production lines. The machine can seal and wrap multiple products within seconds, which increases production output and reduces operation costs.

The L sealer machine also has a user-friendly interface that allows easy operation. The control panel has intuitive buttons that enable operators to adjust settings such as temperature, time, and pressure, for efficient and accurate sealing. Additionally, the machine requires minimal maintenance, which saves time and money.

Another noteworthy property of the L sealer machine is the durability of its components. The machine is built with high-quality materials that can withstand harsh environments and maintain consistent performance over time. This feature enhances the machine’s reliability and longevity, making it more cost-effective in the long run.

The machine can also handle a wide range of product sizes, shapes, and materials. It has adjustable settings that can cater to different product dimensions, ensuring a tight and secure wrap every time. This versatility allows the machine to be used in different industries, including food and beverage, healthcare, and manufacturing.

In conclusion, the properties of L sealer machine make it an essential asset in modern-day industrial operations. Its speed, user-friendly interface, durability, and versatility, make it a valuable asset in packaging. Thus, it saves operation costs, offers cost-effective maintenance, and enhances the safety of packaged products during transportation.

Technical Parameters Terms for L Sealer Machine

Technical Parameters Terms for L Sealer Machine

L sealer machines are commonly used in the packaging industry to pack products of various sizes and shapes. These machines come with several technical parameters that users should understand to ensure optimal performance and efficiency. In this article, we’ll explore some of the critical technical parameters terms for L sealer machines.

Sealing Area

The sealing area is the maximum size of the product that can be sealed using the L sealer machine. This area is determined by the length and width of the sealer, and it’s crucial to ensure it’s adequate for the product being sealed.

Sealing Temperature

The sealing temperature is the temperature at which the sealing bar needs to heat up to melt the film and create an airtight seal. The sealing temperature should be adjustable to accommodate different types of packaging film materials.

Conveyor Speed

The conveyor speed is the rate at which the product moves through the machine from the loading point to the sealing station. The speed should be adjustable to match the product’s size and the type of film used.

Film Roll Specification

The film roll specification is the maximum width and thickness of the film that can be used in the L sealer machine. This parameter is essential as it determines the type of packaging material that can be used to seal the product.

Power Consumption

The power consumption refers to the amount of electricity consumed by the machine when in operation. This parameter should be taken into consideration when choosing an L sealer machine, especially if power consumption costs are a concern.

Operating Voltage

The operating voltage of the machine should be compatible with the power supply available in the production facility. It’s essential to ensure that the voltage rating of the L sealer machine corresponds to the voltage in the facility to avoid damage to the machine or electrical accidents.

In conclusion, understanding the critical technical parameters of an L sealer machine is crucial to ensure optimal performance, efficiency, and longevity. It’s recommended to work with reputable manufacturers or suppliers who can provide technical support and guidance in choosing the right L sealer machine for your specific requirements.

L Sealer Machine Price

An L sealer machine is a crucial piece of equipment for any business looking to efficiently package its products. It helps in wrapping products in a protective layer of plastic, ensuring the items remain safe during transportation and storage. The machine’s price is dependent on different factors, and in this article, we’ll touch upon all of them.

The first factor that determines the L sealer machine price is the machine’s size. The larger the size, the more expensive it will be. Machines that accommodate larger products have a higher capacity, making them more expensive.

The second factor that determines the L sealer machine price is the type of machine. The market has different types of machines, from manual to semi-automatic and automatic machines. Manual machines are the most affordable, with prices ranging from $200-$1000. Semi-automatic machines come at a higher price, ranging from $1000-$2000, while automatic machines have the highest price range, typically above $2000.

The third factor that affects the L sealer machine price is the features that come with the machine. Features such as speed, accuracy, and ease of operation all play key roles in the machine’s price. A machine with higher speed and accuracy features will be more expensive compared to one with basic features.

Lastly, the brand that a client chooses will have an impact on the machine’s price. Top brands typically offer machines with features such as durability, user-friendliness, and high efficiency. Unfortunately, these brands also come at a higher price. However, it’s always recommended that customers go for a reputable brand as they are more likely to have better performance and a longer lifespan.

In conclusion, an L sealer machine’s price can range from $200 to thousands of dollars depending on the machine’s size, type, features, and brand. As much as price is an essential factor when choosing an L sealer machine, customers should also look into the machine’s durability, functionalities, and quality. This way, one can get value for their money and invest in a machine that well-suits their business’s needs.