Benefits of Lantech Stretch Wrapper

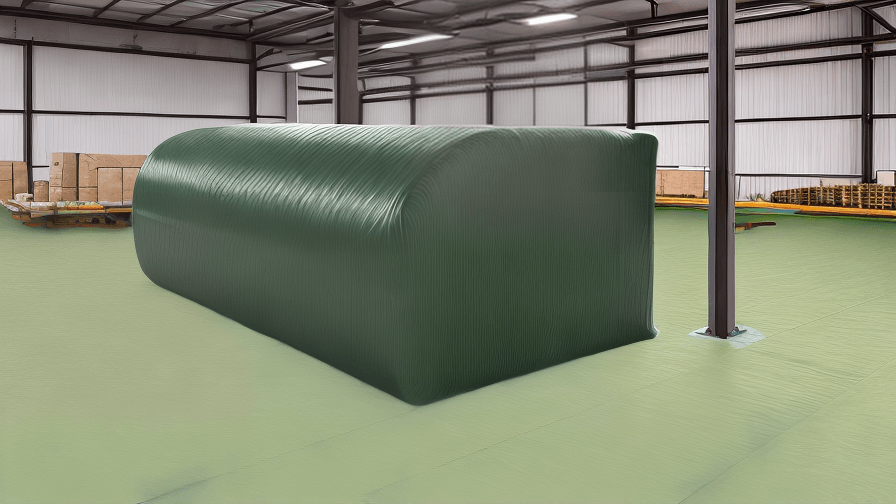

Lantech stretch wrappers are machines utilized in different industries to wrap pallets and ensure that items are well-packaged and protected. There are various benefits to using Lantech stretch wrappers that can benefit businesses, no matter the size.

Firstly, it saves time and increases productivity. With the help of Lantech stretch wrappers, multiple pallet loads can be wrapped within a short period, reducing the time and effort required to wrap them manually. This allows workers to be more efficient in their daily tasks, leading to increased productivity levels, which ultimately impact the company’s bottom line.

Secondly, it provides consistent wrapping. Lantech stretch wrappers employ technology that allows them to apply an equal amount of stretch film around each pallet. This consistency in wrapping ensures that all pallets are well-packaged, and items are protected throughout their journey.

Thirdly, it reduces waste. The technology used in Lantech stretch wrappers ensures that the right amount of stretch film is applied to each pallet load, eliminating waste and reducing the cost of materials.

Fourthly, it provides a secure load. Lantech stretch wrappers provide a secure and stable load, which minimizes the risk of items shifting or falling off during transit. This ensures that the items reach their destination in good condition and reduces the likelihood of damages or returns.

Lastly, it promotes workplace safety. With the use of Lantech stretch wrappers, workers do not have to exert themselves in physically demanding tasks such as manually wrapping pallets. This reduces the risk of workplace injuries and promotes a safe working environment.

In conclusion, the benefits of Lantech stretch wrappers cannot be overemphasized. They save time, increase productivity, provide consistent wrapping, reduce waste, provide a secure load, and promote workplace safety. Therefore, businesses that want to enhance their packaging processes and increase their bottom line should invest in Lantech stretch wrappers.

Features of Lantech Stretch Wrapper

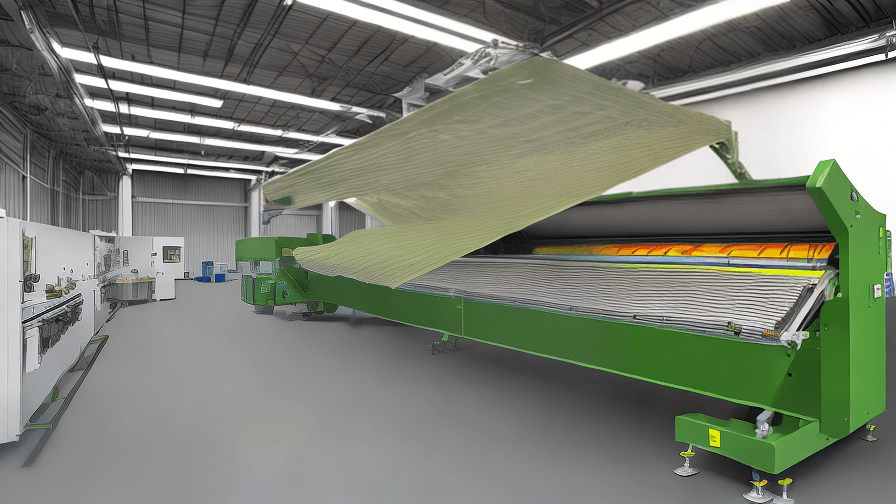

Lantech stretch wrapping machines are designed to help businesses streamline their packaging operations. These machines are designed to simplify the otherwise manual and time-consuming task of wrapping pallets with stretch film. Here are some of the features that make Lantech Stretch Wrapper stand out.

Automated Wrapping

Lantech Stretch Wrappers come with a wide range of automated features that guarantee consistency and accuracy during the stretching process. The machine wraps pallets automatically, ensuring that every wrapping is performed consistently.

Increased Efficiency

Lantech Stretch Wrappers are designed to increase speed and efficiency, thus boosting productivity. They can handle pallets of different shapes and sizes, wrapping them quickly and accurately.

User-Friendly

Lantech Stretch Wrapper machines come with intuitive touch screens and easy to use software that simplifies the experience of wrapping pallets. The software provides step-by-step guidance through the wrapping process, significantly reducing the need for additional training.

Flexible

Lantech Stretch Wrappers can handle film widths of up to 30 inches. This makes it flexible to use different film gauges and widths, depending on the application. The machines are also compatible with multiple film types such as PVC, Polyethylene, and Polyolefin.

Increased Safety

Lantech Stretch Wrappers provide a safer wrapping environment by eliminating the need for manual labor. It also reduces the risk of injury caused by heavy-lifting or repetitive movements.

Minimal Maintenance

Lantech Stretch Wrappers are designed with low wear and tear parts, which significantly reduce maintenance costs. Unlike other stretch wrapping machines that require constant, expensive upkeep, Lantech’s machines require minimal maintenance and downtime.

In conclusion, Lantech Stretch Wrappers are designed to meet the packaging needs of businesses. They offer increased efficiency, flexibility, safety, and minimal maintenance. Investing in this stretch wrapping machine can help optimize packaging processes significantly.

Various Types of Lantech Stretch Wrapper

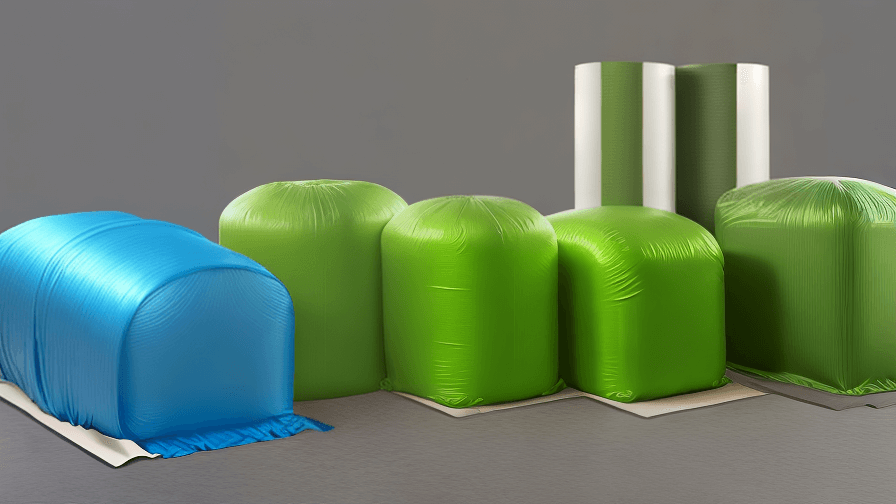

Lantech is a leading manufacturer of stretch wrapping machines that are designed to meet the various requirements of different industries. They offer a wide variety of stretch wrapper machines to cater to the different demands of different industries. In this article, we shall take a closer look at the various types of Lantech Stretch Wrapper machines available.

1. Orbital Wrapper: This machine is designed for wrapping long and bulky products in a horizontal fashion. It features a ring-shaped wrapping tool that rotates around the product while simultaneously wrapping it with cling film.

2. High Profile Wrapper: This machine is designed for wrapping tall and unstable loads without the need for additional support. It utilizes a pre-stretch unit to stretch the cling film, which allows for better load stability and reduced film cost.

3. Low Profile Wrapper: This machine is designed for wrapping low-profile products that are less stable and require additional support. It features a turntable that rotates the product while simultaneously wrapping it with a pre-stretched cling film.

4. Mobile Wrapper: This machine is designed for wrapping products that are located in different areas of the warehouse or production facility. It is mounted on wheels, which makes it easy to move around and wrap products in different areas.

5. Robotic Wrapper: This machine is designed for fully automatic wrapping of products. It features a robotic arm that automatically wraps the product with cling film, making it ideal for high-volume production facilities.

In conclusion, Lantech Stretch Wrapper machines offer a variety of capabilities to satisfy the different requirements of different industries. From the safety and durability of the orbital wrapper to the high capacity of the robotic wrapper, Lantech has a solution for every application.

Applications of Lantech Stretch Wrapper

Lantech stretch wrapper is a vital component of the manufacturing industry, designed to wrap and secure products using stretchable films. The applications for Lantech stretch wrappers are numerous, ranging from food to pharmaceutical, e-commerce to logistics, and even aerospace industries.

One of the primary applications of Lantech stretch wrapper is in the food industry. It is used to secure food products such as fruits, vegetables, meat, and poultry to prevent contamination, spoilage, and dehydration during transportation and storage. In addition, the stretch wrap also helps to maintain freshness and increase the shelf life of food products.

Another application of Lantech stretch wrapper is in the pharmaceutical industry, where it is used to wrap and protect drugs during transportation, storage, and distribution. The stretch wrap used in this industry goes through a rigorous quality control process to ensure that they conform to the industry’s safety and quality standards.

E-commerce and logistics companies also use Lantech stretch wrappers to secure goods for transportation. It is particularly useful for shipping delicate or high-value items that may require additional protection during transport. The stretch wrap helps to prevent damage, loss, or theft of goods, ensuring that they arrive at their intended destinations in the right condition.

Another application of Lantech stretch wrappers is in the aerospace industry, where it is used to protect delicate and sensitive components during transportation. The stretch wrap helps to prevent damage caused by exposure to moisture, dust, and other environmental elements, ensuring that the components remain in good condition.

In conclusion, Lantech stretch wrappers are a necessity for many industries. They provide an effective and efficient way of securing products for transportation and storage. With the increasing demand for goods and products worldwide, the importance of stretch wrapping cannot be overstated.

The Process of Lantech Stretch Wrapper

Lantech stretch wrappers are highly efficient machines designed to stretch wrap products and materials. The process of using a Lantech stretch wrapper involves a few simple steps that ensure the safety and securing of products before they are shipped.

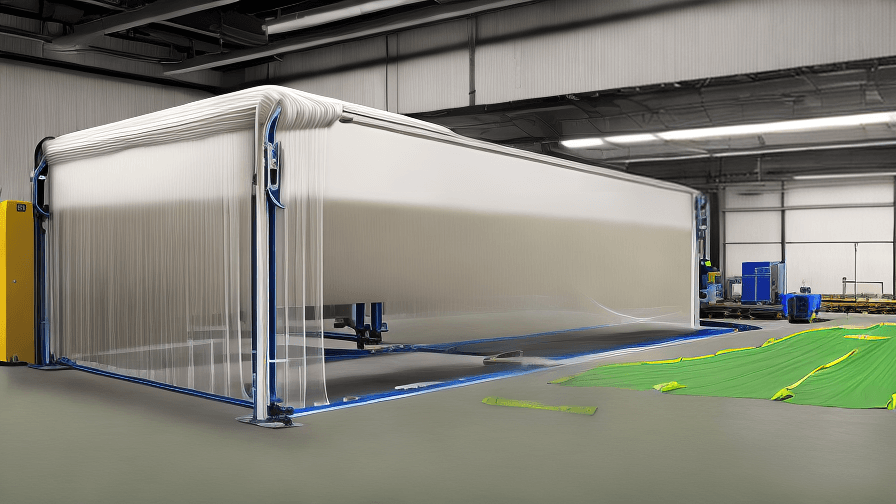

First, the product is loaded onto the wrapper turntable. The turntable can be manual or automatic depending on the specification of the machine. Once the product is loaded, the stretch film is attached to the product to begin the process.

Next, the carriage assembly moves the stretch film up and down along the product as it rotates around the turntable. This movement creates a tight, secure wrap around the product.

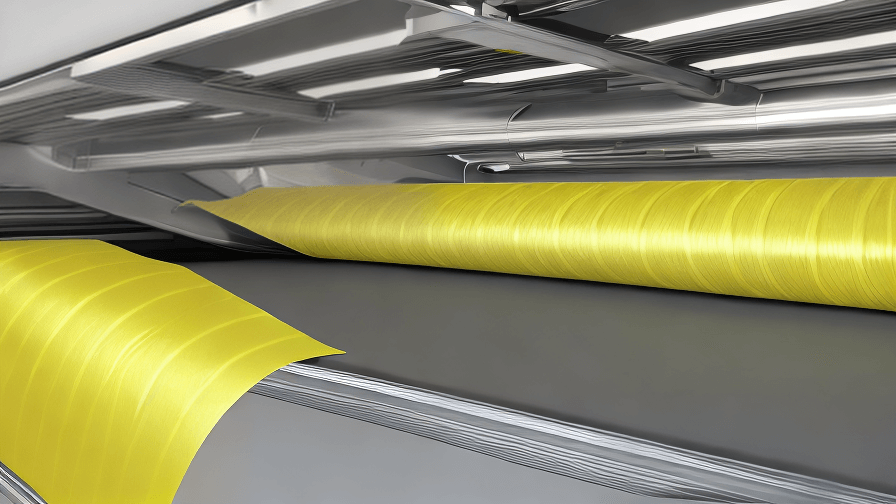

During this process, the amount of film used can be adjusted to meet the required stretch capacity. Lantech stretch wrappers use a patented film delivery system that ensures even and consistent stretching of the film.

As the process is being carried out, the Lantech stretch wrapper constantly monitors the progress of the wrap, and the machine stops automatically when the wrapping is complete. The finished product is then ready for transport.

Lantech stretch wrappers are particularly useful for companies that produce large volumes of goods for shipment, as they provide a reliable and efficient means of packaging. The machines also ensure that the products are well-secured, minimizing the risk of damage during transport.

In conclusion, the Lantech stretch wrapper is a highly effective and efficient machine used for wrapping and packaging products. The process of using a Lantech stretch wrapper is straightforward and easy to follow, and the machine’s ability to continually monitor the wrap ensures that the end result is secure and reliable.

How to use Lantech Stretch Wrapper

Lantech stretch wrapper is a popular packaging machine that offers reliable and efficient wrapping solutions for a wide range of products. If you want to learn how to use this machine, here are some essential steps to follow.

Firstly, ensure that the machine is set up correctly and all safety features are in place. The operator should wear the necessary protective gear, including gloves and goggles, before starting the machine.

The next step is to adjust the machine’s parameters to meet the specific needs of the product being wrapped. This includes setting the proper tension, speed, and film width. Failure to set these parameters correctly may lead to product damage and poor wrapping results.

Once the parameters have been set, the operator should load the product onto the machine’s turntable using a forklift or other suitable equipment. The turntable speed and direction may be adjusted to ensure that the product is evenly wrapped.

After loading the product, the operator should attach the film to the product and start the wrapping process. The machine will automatically wrap the product in a spiral motion, ensuring that it is fully sealed and secured.

Finally, the operator should cut the film using the machine’s built-in cutting mechanism, remove the wrapped product, and repeat the process for the next product.

In conclusion, using a Lantech stretch wrapper is a simple process that requires careful attention to detail and adherence to safety measures. By following the above steps, you can effectively wrap your products and protect them during transit. With proper use and maintenance, Lantech stretch wrappers can significantly improve your packaging efficiency and productivity.

Selecting the Ideal Manufacturer Lantech Stretch Wrapper

Selecting the Ideal Manufacturer Lantech Stretch Wrapper

Choosing the right manufacturer Lantech Stretch Wrapper can help businesses improve their productivity and efficiency. To select the ideal manufacturer Lantech Stretch Wrapper, a few critical factors need to be considered.

Firstly, the right manufacturer should be able to offer a range of options to suit different business needs. This includes customization options, which can help tailor the equipment to meet specific requirements. Additionally, the manufacturer should have a reputation for providing high-quality machinery that is reliable and can handle large volumes with ease.

Secondly, it is essential to consider the price of the equipment. The manufacturer should provide a blend of quality and affordability, ensuring that they offer competitive prices that are affordable to businesses of all sizes.

Thirdly, the right manufacturer should offer excellent customer support. They should have knowledgeable support personnel that can answer any questions that businesses may have about the equipment and its operation. This is essential in ensuring that the purchased equipment is used effectively and efficiently.

Lastly, the manufacturer should have a reputation for excellent after-sales service. This includes offering maintenance and repair services as needed, ensuring that the equipment remains functional and productive for as long as possible.

In conclusion, selecting the ideal manufacturer Lantech Stretch Wrapper requires consideration of several factors, including the range of options, price, customer support, and after-sales service. By assessing these factors, businesses can select reliable and effective machinery, helping them to improve their productivity and efficiency.

list FAQ with answer about Lantech Stretch Wrapper

Lantech is a leading manufacturer in the packaging industry and their stretch wrappers are widely used to ensure product protection and stability during transportation. If you are new to Lantech Stretch Wrappers, it’s normal to have some questions. Here are some of the frequently asked questions about Lantech Stretch Wrappers, along with their answers.

Q: What is a stretch wrapper?

A: A stretch wrapper machine is used to wrap products and items securely in stretch film. This helps to protect the product and ensure it is stable during transportation or storage.

Q: Why choose a Lantech Stretch Wrapper?

A: Lantech Stretch Wrappers are known for their durability, reliability, and efficiency. They are designed to handle the toughest and most challenging packaging applications, providing you with better productivity, uptime, and profitability in your operation.

Q: What types of Lantech Stretch Wrappers are available?

A: Lantech offers a range of stretch wrappers, including semi-automatic, automatic, and specialty wrappers. The semi-automatic stretch wrappers require operator intervention, while the automatic stretch wrappers are completely automated.

Q: How do I choose the right Lantech Stretch Wrapper for my business needs?

A: The right Lantech Stretch Wrapper for your business depends on your packaging needs. Consider factors such as the type of products you are wrapping, the speed of your operation, and your budget.

Q: How does a Lantech Stretch Wrapper work?

A: A Lantech Stretch Wrapper works by taking a roll of stretch film and wrapping it around the products. The film is stretched and elongated to conform to the size, shape, and weight of the product.

Q: How do I maintain my Lantech Stretch Wrapper?

A: Regular maintenance is key to keeping your stretch wrapper running efficiently. Follow the manufacturer’s guidelines for routine maintenance and inspections, such as cleaning, lubrication, and replacing worn parts.

In conclusion, Lantech Stretch Wrappers are a versatile and reliable packaging solution that can help improve your business operations. When choosing a Lantech Stretch Wrapper, carefully consider your specific requirements, and follow the manufacturer’s guidelines for maintenance and operation to get the most out of your machine.

Things to Consider When Purchasing Lantech Stretch Wrapper

When it comes to stretch wrapping machines, Lantech is one of the most trusted and reliable brands in the market. If you are considering purchasing a Lantech stretch wrapper, here are some things to consider:

1. Size and Capacity: Lantech stretch wrappers come in various sizes and capacities to meet different packaging needs. Make sure you choose a machine that can handle your current packaging demands and can also accommodate future growth.

2. Wrapping Options: Lantech offers different wrapping options, such as semi-automatic and automatic machines, as well as vertical and horizontal wrapping options. Consider the type of packaging you need and choose a machine that can provide the right wrapping solution.

3. Flexibility and Customizability: Lantech stretch wrappers can be customized to meet specific needs. Consider whether you need a machine that can handle a variety of products and can be adjusted to different packaging requirements.

4. Maintenance and Durability: Lantech stretch wrappers are built to last, but like any machine, they require regular maintenance to ensure optimal performance. Consider the level of maintenance required and whether it is feasible for your business.

5. Cost: Lantech stretch wrappers are an investment, so consider the total cost of ownership, including maintenance and upkeep, when making your purchase decision.

Choosing the right Lantech stretch wrapper can significantly improve your packaging efficiency and help save costs in the long run. Take the time to evaluate your needs and consider these factors before making a purchase.

Properties of Lantech Stretch Wrapper

Lantech Stretch Wrapper is an advanced and sophisticated machine that has revolutionized the entire shipping and packaging industry. It is designed to wrap packages and products in a highly efficient and effective manner. With its advanced features and capabilities, Lantech Stretch Wrapper has become an essential tool for many businesses that deal with large volume shipping.

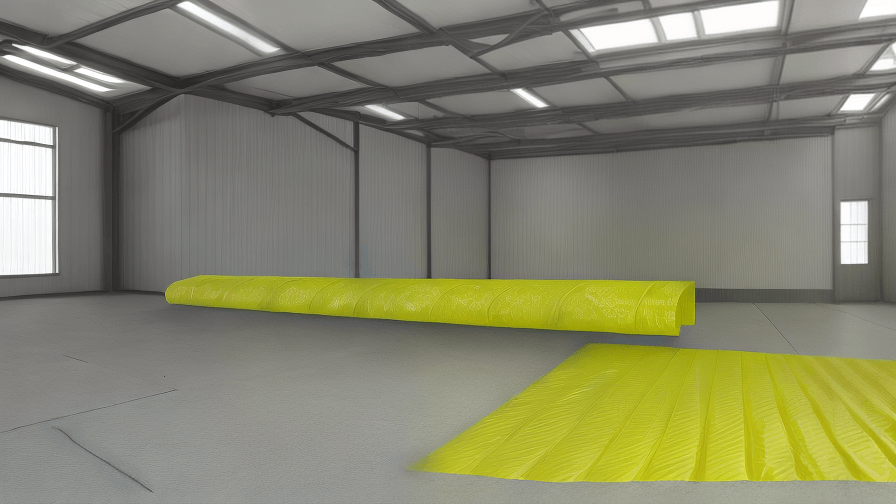

One of the key properties of Lantech Stretch Wrapper is its ability to stretch the film that it uses to wrap the products. This stretching feature allows the machine to use less film while still effectively wrapping the products, thus reducing film costs significantly. This not only saves money but also helps reduce wastage, making it an eco-friendly solution.

Another important property of Lantech Stretch Wrapper is its customization option. Depending on the type of products being wrapped, the machine can be customized to adjust to varying product shapes, sizes, and weights. This enables businesses to use Lantech Stretch Wrapper to wrap a wide variety of products, making it a highly versatile machine.

Lantech Stretch Wrapper is also easy to operate and maintain. It has a user-friendly interface that can be easily understood, even by new operators. This makes training new employees on how to use the machine quick and straightforward. Additionally, it requires minimal maintenance, making it a cost-effective option for businesses.

Finally, Lantech Stretch Wrapper is built with durability in mind. It is made from high-quality materials that are meant to withstand the rigors of daily operation. This means that it can handle even the most demanding of packaging environments, ensuring that businesses can rely on it for years to come.

In conclusion, Lantech Stretch Wrapper is a highly effective and efficient machine that offers a range of features and capabilities. Its ability to stretch film, customization options, ease of use, low maintenance, and durability make it an excellent investment for businesses that need to wrap products quickly, efficiently, and cost-effectively.

Technical Parameters Terms for Lantech Stretch Wrapper

When it comes to purchasing a Lantech stretch wrapper, there are various technical parameters terms that you need to understand to make an informed decision. Here are some of the key terms to consider.

1. Turntable Diameter

The turntable diameter determines the maximum size of the load that can be wrapped. Typically, the larger the turntable diameter, the larger the load that can be wrapped.

2. Maximum Load Height

The maximum load height refers to the tallest load that the stretch wrapper can accommodate.

3. Wrap Cycle Speed

This refers to the speed at which the stretch wrap is applied to the load. A higher wrap cycle speed means a faster operation.

4. Film Delivery System

The film delivery system is responsible for dispensing the stretch wrap. The two types of film delivery system are powered pre-stretch and mechanical pre-stretch. The powered pre-stretch system stretches the film using motor power while the mechanical pre-stretch system uses gears to stretch the film.

5. Film Tension Control

The film tension control is responsible for maintaining consistent tension on the stretch wrap. It ensures that the wrap is not too loose or too tight, which can affect the effectiveness of the wrapping.

6. Wrapping Modes

There are two wrapping modes: Automatic and Semi-automatic. Automatic mode means that the stretch wrapper will wrap the load without the need for operator intervention. In Semi-automatic mode, the operator will need to start and stop the wrap cycle.

7. Load Capacity

The load capacity determines the maximum weight that the stretch wrapper can accommodate. It is important to ensure that the stretch wrapper can handle the weight of the load that needs to be wrapped.

Understanding these technical parameters terms will help you select the right Lantech stretch wrapper for your needs. It is essential to choose a stretch wrapper that best suits your requirements to ensure optimum results and efficiency.

Lantech Stretch Wrapper Price

Lantech is a respected name in the stretch wrapping industry, providing excellent quality and reliable stretch wrappers to customers globally. One of the most common questions asked by people interested in using Lantech stretch wrappers is, “How much do they cost?” The answer varies, depending on the specific model, size, and features of the stretch wrapper, as well as the manufacturer’s suggested retail price.

There are many factors to consider when purchasing a Lantech stretch wrapper, such as the size of the item being wrapped, the materials used in the wrapping process, and the level of automation required. Some of the most popular models of Lantech stretch wrappers include the Q-300XT series, the S-300XT series, and the Q-400XT series. These stretch wrappers come with different features, such as high-speed wrapping, customizable wrap cycles, and automatic load detection. The price of each model starts from $30,000, with prices ranging up to $100,000 or more, depending on the model and features that you opt for.

Another critical factor in determining the Lantech stretch wrapper’s price is its level of automation. The more automated the system, the higher the price tag. Lantech stretch wrappers can come fully automated, with features like automatic film threading, conveyors, and pallet dispensers, among others. The AJ automatic stretch wrapper is a top-of-the-line model, with all the bells and whistles and a price tag of over $200,000. In contrast, the Q-300 semi-automatic stretch wrapper starts from around $20,000 and is ideal for smaller businesses who need a less advanced option.

It is worth mentioning that while the price of a Lantech stretch wrapper may seem high, it is essential to understand that it is a long-term investment that can save you money in the long run. Stretch wrapping your products securely with Lantech stretch wrappers ensure that your products arrive safely at their destination, reducing the chance of damage during transport. In addition, the use of stretch wrapping can help you reduce waste and save on the cost of wrapping materials.

In conclusion, the price of a Lantech stretch wrapper depends on several factors, such as model, level of automation, and features. While the cost may seem high, it is important to remember that it is a long-term investment that can provide great benefits to your business over time. Therefore, it is essential to choose the appropriate stretch wrapper that fits your business needs and budget.