Introduce about laser cnc engraver guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

Laser CNC engravers are advanced machines used for precision engraving and cutting on various materials such as wood, acrylic, metal, and more. This guide aims to provide an overview of laser CNC engravers, including quality, cost, suppliers, certification, market trends, tips, frequently asked questions (FAQ), all within a concise 300-word limit.

Quality: Laser CNC engravers vary in quality depending on factors like power, precision, and durability. Higher-quality machines offer better engraving results and longevity, making them ideal for professional use.

Cost: The price range for laser CNC engravers varies significantly based on factors like power, size, and brand. Entry-level models can start around $500, while industrial-grade machines can reach several thousand dollars.

Supplier: Numerous suppliers offer laser CNC engravers globally, both online and offline. Renowned brands like Epilog, Trotec, and Boss are popular choices due to their reliability and customer support.

Certification: It is crucial to ensure that the laser CNC engraver complies with relevant safety and quality standards, such as FDA (for US markets) or CE (for European markets). Certification ensures the machine meets safety requirements and maintains industry standards.

Market: The laser CNC engraver market is growing rapidly due to increased demand in industries such as woodworking, signage, and personalized gifts. The market is witnessing innovations with new features like autofocus, rotary attachments, and high-speed engraving.

Tips: To maximize the performance of a laser CNC engraver, it is essential to choose the appropriate materials, set accurate power and speed settings, and maintain the machine regularly. Additionally, learning software like CorelDRAW or Adobe Illustrator can enhance design capabilities.

FAQ: Common questions include the difference between CO2 and fiber lasers, the maintenance required, suitable materials for engraving, and software compatibility. Regularly clean the machine, check optical alignment, and apply appropriate cooling methods to ensure optimal performance.

In conclusion, laser CNC engravers offer precise engraving and cutting capabilities on various materials. Consider quality, cost, suppliers, certification, market trends, tips, and FAQ to make an informed decision when purchasing a laser CNC engraver.

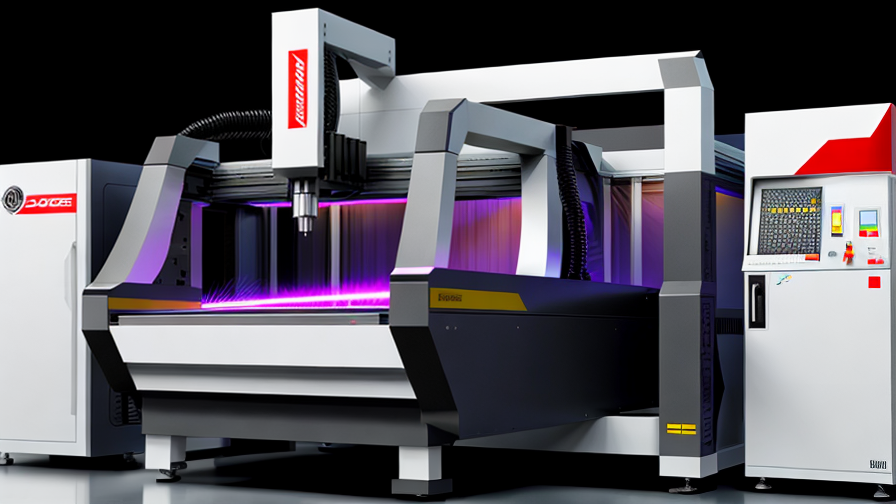

Types of laser cnc engraver

There are several types of laser CNC engravers available in the market, each with its own unique features and capabilities. These machines use lasers to engrave or mark on a variety of materials such as wood, acrylic, glass, metal, and leather. Here are some common types:

1. CO2 Laser Engravers: These machines use a carbon dioxide laser to engrave or cut materials. CO2 laser engravers are popular for their versatility, allowing for high-quality engraving on a wide range of materials. They are commonly used in industries like signage, woodworking, and personalized gift manufacturing.

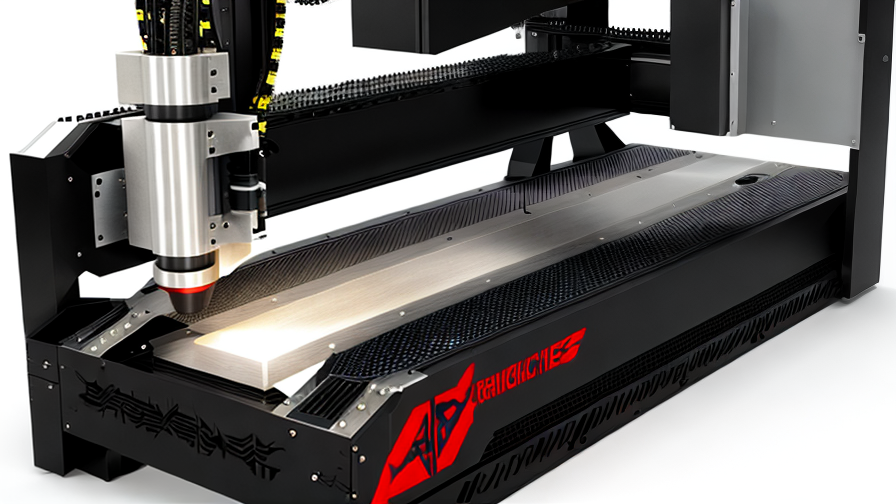

2. Fiber Laser Engravers: Fiber laser engravers are specifically designed for high-speed engraving and marking on metals. They use fiber-optic cables and pump diodes to generate a focused laser beam that is highly efficient for engraving metal materials, including stainless steel, aluminum, and brass.

3. Diode Laser Engravers: These machines use diodes as the laser source and are typically small and compact. Diode laser engravers are suitable for engraving on softer materials like plastics, rubber, and certain types of wood. They are often used in crafts, hobbyist projects, and small-scale engraving applications.

4. UV Laser Engravers: UV laser engravers utilize ultraviolet light to engrave on materials like glass, ceramics, and plastic. With their high-precision capabilities, they are commonly used for producing intricate designs and details on delicate materials.

5. YAG Laser Engravers: YAG (Yttrium Aluminum Garnet) laser engravers are used for deep engraving or marking on metals or hard materials like stone. They are suitable for applications like serial number engraving, tool marking, and jewelry customization.

6. Hybrid Laser Engravers: Hybrid laser engravers combine the technology of different types of lasers, such as CO2 and fiber lasers, to provide a wider range of capabilities. These machines offer greater flexibility and are often used in industries where engraving on various materials is required.

It is important to consider the specific requirements of your engraving projects and the intended materials before choosing the appropriate type of laser CNC engraver best suited for your needs.

Pros and Cons of Using laser cnc engraver

A laser CNC engraver is a versatile machine that can engrave and cut various materials with precision. However, like any technology, it has its pros and cons.

Pros:

1. Precision: Laser CNC engravers offer high precision and accuracy. They can create intricate and complex designs with fine details that are not easily achievable with other engraving methods. This makes them ideal for applications that require precision, such as jewelry making or architectural models.

2. Versatility: Laser CNC engravers can work with a wide range of materials, including wood, plastic, metal, glass, leather, and more. This versatility allows for a diverse range of applications, from signage and branding to custom product development.

3. Speed: Laser engraving is typically faster than traditional methods. The laser beam moves quickly across the material, engraving or cutting as it goes. This efficiency can save time in production and allows for high-volume output.

4. Automation: Laser CNC engravers can be programmed to repeat the same design multiple times, reducing the need for manual intervention. This automation saves time and minimizes the chances of errors or inconsistencies in the engraving.

Cons:

1. Cost: Investing in a laser CNC engraver can be expensive, particularly for high-quality machines. Additionally, there are ongoing costs, such as maintenance, replacement parts, and consumables like laser tubes or lenses.

2. Limited Depth: Laser engraving is primarily surface-level, which means it may not be suitable for applications that require deep engraving or cutting all the way through the material. This limitation can be overcome by multiple passes, but it may affect efficiency.

3. Material Limitations: While laser CNC engravers can work with a wide range of materials, some materials are not suitable for laser engraving due to their chemical composition. For example, PVC can release toxic fumes when cut with a laser. It is essential to consider material compatibility before using a laser CNC engraver.

4. Learning Curve: Operating a laser CNC engraver requires technical knowledge and expertise. Learning how to use the software, set up the machine, and troubleshoot potential issues can be time-consuming. Additionally, the calibration process for achieving optimal results can be challenging.

In conclusion, a laser CNC engraver offers precision, versatility, speed, and automation. However, the cost, limited depth, material limitations, and learning curve are important factors to consider when deciding to utilize this technology.

laser cnc engraver Reference Specifications (varies for different product)

A laser CNC engraver is a versatile machine used for engraving designs onto a variety of materials such as wood, acrylic, glass, leather, and metal. The reference specifications may vary depending on the product, but typically include the following features:

1. Laser Power: The laser power determines the intensity of the laser beam and is measured in watts or milliwatts. Higher power allows for faster engraving and the ability to engrave on thicker and harder materials.

2. Engraving Area: The engraving area refers to the maximum size of the material that can be engraved. It is typically measured in millimeters or inches and can range from small desktop models to large industrial machines.

3. Laser Type: Various laser types are used, such as CO2 lasers, fiber lasers, or diode lasers, each with its own characteristics. CO2 lasers are commonly used for engraving non-metallic materials, while fiber lasers are suitable for engraving metals.

4. Resolution: The resolution determines the level of detail in the engraving. It is measured in dots per inch (DPI) or micrometers (µm). Higher resolution results in finer and more precise engravings.

5. Speed: The engraving speed refers to the rate at which the laser moves across the material. It is measured in millimeters per second (mm/s) or inches per second (in/s). Higher speeds allow for faster engraving but may affect the quality of the engraving.

6. Software Compatibility: Laser CNC engravers require software to control the machine and design the engravings. Compatibility with popular design software such as CorelDRAW, AutoCAD, or Adobe Illustrator is essential for seamless operation.

7. Safety Features: Laser engravers should have safety features like an emergency stop button, interlocks, and protective enclosures to prevent accidents and ensure user safety.

8. Connectivity: Connectivity options such as USB, Ethernet, or Wi-Fi allow for easy transfer of design files from a computer to the engraver.

9. Additional Features: Some laser engravers may offer additional features like rotary attachments for engraving cylindrical objects or autofocus systems for improved focus control.

These reference specifications provide a brief overview of the essential features to consider when selecting a laser CNC engraver. It is important to understand that specifications may vary across different products, and choosing the right machine depends on specific requirements and intended applications.

Applications of laser cnc engraver

Laser CNC engravers are versatile tools that have a wide range of applications across various industries. Here are some of the key applications of laser CNC engravers:

1. Personalization and customization: Laser engraving is commonly used to personalize and customize various items like phone cases, jewelry, trophies, and promotional items. It offers precise and detailed engraving, allowing for unique designs, logos, and personalized messages to be etched onto a wide range of materials.

2. Signage and advertising: Laser engravers are widely used in the signage industry to create high-quality and durable signage. They can engrave on materials such as wood, acrylic, plastics, and metals, making them ideal for creating signs, displays, and advertising materials. Laser-engraved signs are often more visually appealing and provide a professional finish.

3. Industrial marking and labeling: Laser CNC engravers are employed for permanent marking and labeling in industries such as automotive, aerospace, and electronics. They can engrave serial numbers, part numbers, barcodes, and other important information directly onto various materials including metals, plastics, ceramics, and glass. This provides traceability and ensures product identification and authenticity.

4. Art and crafts: Laser engraving has become a popular technique in the art and crafts community. Artists can use laser CNC engravers to create intricate and detailed designs on different mediums such as wood, leather, paper, and fabrics. This allows artists to experiment with various engraving techniques, textures, and patterns.

5. Packaging and product branding: Laser engraving can be used to create unique and eye-catching packaging designs. It can engrave logos, brand names, and product details onto various packaging materials like cardboard, wood, or plastic. This helps in enhancing brand identity, product branding, and creating a premium look and feel.

6. Medical and pharmaceutical applications: Laser engravers are utilized in the medical and pharmaceutical industries for marking surgical instruments, medical devices, and pharmaceutical packaging. The permanent identification ensures traceability, sterilization safety, and compliance with regulatory standards.

7. Architectural and interior design: Laser CNC engravers enable architects and interior designers to create intricate patterns and designs on materials like wood, metal, and glass. They can be used to engrave panels, partitions, decorative wall panels, furniture, and art installations. This allows for unique and intricate designs to be incorporated into architectural and interior design projects.

These are just a few examples of the applications of laser CNC engravers. The versatility, precision, and speed offered by these machines make them invaluable tools across various industries, providing endless possibilities for creativity and innovation.

The Work Process and how to use laser cnc engraver

The work process of a laser CNC engraver involves several steps. Firstly, the design or pattern that needs to be engraved is created using computer software such as AutoCAD or Adobe Illustrator. This design is then exported as a vector file.

Next, the vector file is imported into the laser CNC engraver’s software. The software allows the user to adjust various settings such as laser power, laser speed, and depth of engraving to achieve the desired results. Once all the settings are configured, the material to be engraved is placed on the engraving bed.

Before starting the engraving process, it is important to ensure that the material is securely clamped to prevent any movement or vibration during the engraving. This is crucial as it can affect the accuracy and quality of the engraving.

Once everything is set up, the laser CNC engraver is turned on, and the engraving process begins. The laser beam emitted from the engraver moves according to the design file, tracing the desired pattern onto the material. The laser beam’s intensity and duration controlled by the software result in varying depths and shades of engraving.

While the engraving is in progress, it is essential to monitor the process to check for any issues such as overheating or incorrect engraving depth. Upon completion, the material is removed from the engraving bed, and any excess debris or dust is cleaned off.

In summary, using a laser CNC engraver involves creating a design, importing it into the engraver’s software, setting up the material, and initiating the engraving process. Monitoring the process and ensuring proper cleaning afterwards is essential for optimal results.

Quality Testing Methods for laser cnc engraver and how to control the quality

Quality testing methods for laser CNC engravers involve evaluating the accuracy, precision, durability, and overall performance of the machine. To ensure quality control, several methods can be implemented.

Firstly, accuracy testing is crucial for laser CNC engravers. This can be done by engraving a test pattern on various materials and measuring the deviation from the intended design. A high-resolution camera or measuring tool can be used for this purpose.

Secondly, precision testing involves assessing the repeatability of the machine. This can be achieved by engraving multiple identical patterns and measuring the variations in their positioning and depth. A laser interferometer or a coordinate measuring machine can help quantify the precision of the engraver.

Thirdly, durability testing is essential to assess the machine’s long-term performance. This can be done by subjecting the engraver to continuous operation for an extended period and monitoring its stability, power output, and overall functionality. Any equipment degradation or malfunctions should be recorded and addressed.

Furthermore, testing the engraver’s compatibility with different materials is necessary. This involves engraving different materials with varying hardness, thickness, and surface finishes. The quality of the engravings, such as smoothness, accuracy, and clarity, should be evaluated.

Additionally, conducting user trials and obtaining feedback is vital to identify any usability issues or concerns. Feedback from operators regarding ease of use, software functionality, and machine settings can help optimize the overall quality.

To control the quality of laser CNC engravers, regular maintenance and calibration must be performed. Following the manufacturer’s guidelines, conducting periodic inspections, and ensuring all components are functioning properly are crucial. Implementing a standard operating procedure for routine cleaning, lubrication, and maintenance tasks is also recommended.

Moreover, implementing quality assurance protocols, such as ISO standards, can help establish consistent quality control. This includes documenting and tracking all engraving parameters, conducting regular audits, and addressing any deviations from the set standards.

Overall, a combination of accuracy, precision, durability, compatibility, user feedback, and adherence to quality control protocols are essential in ensuring the quality of laser CNC engravers.

laser cnc engraver Sample Policy and Post-Purchase Considerations for laser cnc engraver from China

Sample Policy:

When purchasing a laser CNC engraver from China, it is important to understand the sample policy. Many manufacturers offer samples of their products for potential buyers to review before making a bulk purchase. It is recommended to request a sample of the specific laser CNC engraver model you are interested in to ensure the quality, performance, and compatibility of the machine. This will help you make an informed decision and avoid any potential issues.

Post-Purchase Considerations:

After purchasing a laser CNC engraver from China, there are several important considerations to keep in mind:

1. Quality Inspection: Upon receiving the machine, conduct a thorough inspection to ensure it matches the specifications provided by the manufacturer. Check for any damages or defects that may have occurred during shipping.

2. Warranty and Support: Inquire about the warranty period and the availability of technical support from the manufacturer. This will be crucial in case you encounter any issues or require assistance with setting up or operating the engraver.

3. Voltage Compatibility and Power Supply: Verify if the laser CNC engraver is compatible with the voltage and power supply in your country. It is essential to avoid any electrical issues and ensure smooth functionality.

4. Customs and Import Duties: Familiarize yourself with your country’s customs regulations and import duties. Determine any additional costs involved in the importation process to avoid any surprises.

5. User Manual and Software: Ensure that the laser CNC engraver comes with a comprehensive user manual in English or your preferred language. Check if the necessary software and drivers are included or downloadable from the manufacturer’s website.

6. Safety Precautions: Understand and follow all safety precautions associated with operating a laser CNC engraver. This includes wearing appropriate protective gear and setting up the machine in a well-ventilated area.

By keeping these sample policies and post-purchase considerations in mind, you can minimize potential risks and make a well-informed decision when purchasing a laser CNC engraver from China.

Sourcing laser cnc engraver from China: Opportunities, Risks, and Key Players

Sourcing laser CNC engravers from China presents various opportunities and risks, with key players dominating the market. China has emerged as a major manufacturing hub, offering competitive prices, a wide range of product options, and advanced technology. The country has become a leading producer of laser CNC engraving machines, providing opportunities for global buyers to access cost-effective solutions.

One significant opportunity lies in the affordability of Chinese laser CNC engravers. The lower manufacturing and labor costs in China make these machines more competitively priced than those produced in other countries. This cost advantage allows businesses to acquire high-quality engravers at a lower budget, increasing their overall profitability.

Additionally, China’s vast network of suppliers and manufacturers ensures a wide range of options when sourcing laser CNC engravers. Buyers can choose from numerous models, specifications, and features tailored to their specific requirements. The availability of customization services further enhances the flexibility in purchasing decisions, making it easier for businesses to find the perfect engraving solution.

However, there are certain risks associated with sourcing laser CNC engravers from China. The most notable risk is the potential for product quality issues. While China has made significant improvements in manufacturing standards, some lower-cost options may compromise on quality, resulting in reliability issues or shorter product lifespans. Buyers must carefully research and verify the reputation and certifications of the suppliers to ensure the desired quality level.

Another risk lies in intellectual property protection. China has been notorious for intellectual property infringements, including counterfeiting and unauthorized reproduction of products. Buyers should exercise caution and conduct due diligence to protect their proprietary technology or designs when sourcing from Chinese manufacturers.

Key players in the Chinese market for laser CNC engravers include companies such as Han’s Laser, Shenhui Laser, and Perfect Laser. These companies offer a wide range of engraving machines, from entry-level models to industrial-grade solutions. They have a strong presence and reputation both domestically and internationally, ensuring reliable products and after-sales support.

In summary, sourcing laser CNC engravers from China presents significant opportunities in terms of cost-effectiveness, variety of options, and advanced technology. However, buyers must be aware of potential risks related to product quality and intellectual property protection. By carefully selecting reputable suppliers and conducting thorough due diligence, businesses can benefit from the advantages offered by the Chinese market in this industry.

How to find and select reliable laser cnc engraver manufacturers in China,use google search manufacturers and suppliers

Finding and selecting reliable laser CNC engraver manufacturers in China can be a daunting task. However, with a strategic approach and the use of Google search, you can streamline the process. Here are some steps to follow:

1. Begin by conducting a Google search for “laser CNC engraver manufacturers China.” This will provide you with a list of manufacturers and suppliers in the industry.

2. Narrow down your search by using specific keywords such as “reliable,” “trusted,” or “high-quality” alongside the term “laser CNC engraver manufacturers China.” This will help filter out less reputable or lower-quality options.

3. Look for manufacturers with a professional and well-designed website. A good website is often indicative of a reliable business. Check if they have comprehensive product information, details about their manufacturing process, and contact information.

4. Check if the manufacturers have any certifications or quality assurance marks. Certifications like ISO 9001 or CE indicate that the company follows international standards and produces reliable products.

5. Look for manufacturers with positive customer reviews and ratings. Search for online forums or platforms where customers share their experiences and opinions about the manufacturers you are considering. This will give you an indication of their reputation.

6. Contact the manufacturers directly via email or phone. Ask specific questions about their products, manufacturing process, delivery times, and after-sales service. Reliable manufacturers should respond promptly and address all your queries satisfactorily.

7. Request samples or visit the manufacturer’s facility if possible. This will allow you to assess the quality of their laser CNC engravers firsthand.

8. Consider the manufacturer’s experience and track record. A company with years of experience in the industry and a proven track record is more likely to be reliable.

9. Verify the manufacturer’s production capacity and capabilities. Ensure that they have the infrastructure, machinery, and resources to meet your specific requirements and demands.

10. Compare prices and terms from multiple manufacturers. However, be cautious of excessively low prices, as they may indicate compromised quality.

By following these steps and being diligent in your research, you can find and select reliable laser CNC engraver manufacturers in China. Remember to consider factors such as reputation, quality, certifications, customer reviews, and direct communication with manufacturers to make an informed decision.

How to check laser cnc engraver manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To ensure the reliability of a laser CNC engraver manufacturer’s website, follow these steps:

1. Use Google Chrome: Start by opening the website in the Google Chrome browser. It offers useful extensions and tools that can assist in evaluating website reliability.

2. Install SEOquake Extension: Install the SEOquake extension in your Google Chrome browser. SEOquake is a powerful tool that provides valuable data on website rankings, traffic, and various SEO parameters.

3. Check Website Ranking: Once the SEOquake extension is installed, click on its icon in the browser toolbar. It will generate a report about the website you are visiting. Look for the website’s ranking under the “Search Engine Indexes” section. Ensure that the website is ranking within the top 10 million results, which signifies decent online visibility.

4. Explore Website Content: Browse through the website and carefully review the information it provides. Check for in-depth product descriptions, specifications, customer testimonials, and user reviews. Authentic and detailed content indicates the manufacturer’s commitment to providing accurate information.

5. Verify Contact Information: Look for the manufacturer’s contact information, including their physical address, phone number, and email address. A reliable manufacturer will provide clear and visible contact details, allowing customers to reach out for inquiries or support.

6. Assess Website Design: A professionally designed website with a user-friendly interface, clear navigation, and well-structured layout often indicates credibility. If the website appears outdated or lacks essential features, it may raise concerns about the manufacturer’s reputation.

7. Research the Manufacturer: Conduct a separate search for the manufacturer’s name to gather additional information. Look for their presence on social media platforms, online forums, and industry directories. Verify if they have any certifications or awards that prove their credibility.

In conclusion, to check the reliability of a laser CNC engraver manufacturer’s website, use Google Chrome with the SEOquake extension to check their search engine ranking and evaluate their online presence. Additionally, ensure that the website provides comprehensive product information, visible contact details, and has a professional design. Through research on the manufacturer, you can gain further insights into their reputation and credibility.

Top 10 laser cnc engraver manufacturers in China

China is known for its vast manufacturing industry, including the production of laser CNC engravers. Here are the top 10 laser CNC engraver manufacturers in China:

1. Han’s Laser Technology Industry Group Co., Ltd.: Han’s Laser is a leading company in the laser industry with a diverse range of laser products, including laser CNC engravers. They have advanced technology and a strong global presence.

2. Perfect Laser (Wuhan) Co., Ltd.: Perfect Laser is a renowned manufacturer of laser CNC engravers. They provide a wide range of models with various specifications and are known for their excellent precision and reliability.

3. Jinan Senfeng Technology Co., Ltd.: Senfeng Technology is a prominent manufacturer of laser CNC engravers, offering high-quality machines suitable for various materials. They constantly innovate and improve their products to meet customer demands.

4. Shandong Leize Intelligent Technology Co., Ltd.: Leize Intelligent Technology specializes in the production of laser CNC engravers, providing customized solutions for different industries. They have a strong focus on research and development.

5. Shenzhen Superwave Laser Technology Co., Ltd.: Superwave Laser Technology is a leading manufacturer of laser CNC engravers, offering a range of machines for different engraving needs. They have a reputation for excellent customer service and technical support.

6. Guangzhou Han Ma Automation Control Equipment Co., Ltd.: Han Ma Automation Control Equipment is known for its high-quality laser CNC engravers used in various industries. They have a strong emphasis on innovation and technological advancement.

7. Beijing Shengpu Weiye Science & Technology Co., Ltd.: Shengpu Weiye Science & Technology specializes in the production of laser CNC engravers with a focus on precision and stability. They offer a range of models catering to different customer requirements.

8. Wuhan Golden Laser Co., Ltd.: Golden Laser is a reputable manufacturer of laser CNC engravers, known for their advanced technology and reliable performance. They provide comprehensive solutions for engraving applications.

9. Wuhan BCXLaser Technology Co., Ltd.: BCXLaser Technology is a leading manufacturer of laser CNC engravers, offering high-speed and precision machines. They have a strong reputation in the industry for their quality products.

10. Dongguan Sunshine Laser Technology Co., Ltd.: Sunshine Laser Technology is a trusted manufacturer of laser CNC engravers, providing a wide range of models suitable for various materials. They focus on precision cutting and engraving solutions.

These top 10 laser CNC engraver manufacturers in China have established themselves through their commitment to technological advancements, innovation, and providing high-quality products and services to their customers.

Background Research for laser cnc engraver manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to laser CNC engraver manufacturers in China, several companies stand out in terms of reliability, quality, and customer satisfaction. This background research focuses on three prominent companies: JINAN STYLE MACHINERY CO., Ltd., Wuhan Sunic Photoelectricity Equipment Manufacture Co., Ltd., and Shanghai Sihao Machinery Equipment Co., Ltd.

JINAN STYLE MACHINERY CO., Ltd. is a leading manufacturer with more than a decade of experience in laser equipment production. The company specializes in CNC routers, laser engravers, and plasma cutting machines. With a wide range of models and power options, JINAN STYLE MACHINERY CO., Ltd. caters to different industries, including advertising, woodworking, and metalworking. Their products have gained international recognition and are exported to more than 150 countries.

Wuhan Sunic Photoelectricity Equipment Manufacture Co., Ltd. is another established company in China, known for its laser equipment manufacturing. They offer a diverse range of products, including CO2 laser engravers, fiber laser markers, and metal cutting machines. With advanced technology and a strong focus on research and development, Wuhan Sunic ensures the production of high-precision and reliable laser engravers. The company has gained significant popularity in both domestic and international markets.

Shanghai Sihao Machinery Equipment Co., Ltd. is a reliable supplier of laser CNC engravers, primarily catering to small-scale businesses and individual users. Their product range comprises various models suitable for engraving on materials like wood, acrylic, and plastic. Shanghai Sihao Machinery Equipment Co., Ltd. focuses on providing cost-effective solutions without compromising quality. They have received positive feedback from customers for their efficient customer service and prompt after-sales support.

These companies have a strong online presence and can be found on platforms like qcc.com and importyeti.com. Additionally, the archive.org platform provides historical data on their past performance, product range, and customer reviews. By utilizing these resources, individuals or businesses looking to procure laser CNC engravers from China can make informed decisions and choose a manufacturer that best meets their requirements.

Leveraging Trade Shows and Expos for laser cnc engraver Sourcing in China

Trade shows and expos can be a valuable platform for sourcing laser CNC engravers from China. These events allow buyers to connect directly with manufacturers and suppliers, providing an opportunity to evaluate products, negotiate prices, and build relationships with reliable suppliers.

Attending trade shows and expos dedicated to laser CNC engravers in China enables buyers to explore the latest technology advancements, witness product demonstrations, and gain insights into the capabilities and quality of different suppliers. Networking at these events allows buyers to directly engage with industry professionals, exchange ideas, and learn about the latest market trends. This firsthand experience helps in making informed decisions while selecting the most suitable laser CNC engraver for individual business needs.

Trade shows and expos are particularly advantageous for international buyers as they often provide a condensed and consolidated platform to meet with multiple suppliers under one roof. This saves time and costs that would have otherwise been spent on individually visiting different factories across China. The face-to-face interaction with suppliers also helps in establishing trust and ensuring the credibility of the supplier, which is crucial when dealing with overseas suppliers.

To maximize the effectiveness of sourcing at trade shows and expos, buyers should thoroughly research the event beforehand, identify key industry players, and prepare a list of targeted suppliers to visit. It is essential to evaluate the suppliers based on their product quality, price competitiveness, production capacity, and their ability to fulfill specific customization requirements, if any.

In summary, trade shows and expos provide an excellent opportunity for sourcing laser CNC engravers from China. By leveraging these events, buyers can gain insights into the market, assess product quality firsthand, establish connections with reliable suppliers, and ultimately make informed sourcing decisions.

The Role of Agents and Sourcing Companies in Facilitating laser cnc engraver Purchases from China

Agents and sourcing companies play a crucial role in facilitating laser CNC engraver purchases from China. These intermediaries act as liaisons between buyers and suppliers, streamlining the procurement process and ensuring transparency and efficiency.

One of the primary functions of agents and sourcing companies is to connect buyers with reliable and reputable Chinese suppliers. With their extensive network and market knowledge, they can identify manufacturers that meet the buyer’s specific requirements in terms of quality, pricing, and production capacity. This saves the buyer significant time and effort in searching for suitable suppliers themselves.

Furthermore, agents and sourcing companies assist in verifying the credibility and reliability of potential suppliers. They conduct thorough background checks, including factory inspections, certifications, and references, to ensure that the supplier has a track record of delivering high-quality products and maintaining ethical business practices.

Additionally, these intermediaries aid in negotiating favorable terms and conditions on behalf of the buyer. They have a deep understanding of the Chinese market, including price ranges and customary business practices, enabling them to secure competitive pricing and favorable payment terms. This can result in cost savings and improved overall purchasing terms for the buyer.

Agents and sourcing companies also play a vital role in managing the logistics and shipment process. They oversee the transportation and handling of the purchased laser CNC engravers, ensuring that the products are adequately packaged, labeled, and comply with all relevant import regulations and documentation requirements.

Finally, they provide ongoing support and act as a bridge between the buyer and the supplier, facilitating effective communication and resolving any issues that may arise during or after the purchase process. This ensures a smooth and efficient transaction, minimizing risks and maximizing customer satisfaction.

In summary, agents and sourcing companies are instrumental in facilitating laser CNC engraver purchases from China. Their expertise in supplier identification, verification, negotiation, logistics management, and customer support streamlines the procurement process and enhances the buyer’s overall experience, making sourcing from China a hassle-free and rewarding process.

Price Cost Research for laser cnc engraver manufacturers Companies in China, use temu.com and 1688.com

When it comes to finding laser CNC engraver manufacturers in China, two popular platforms that can be used for price cost research are temu.com and 1688.com. These platforms provide a wide range of options and enable efficient supplier sourcing for potential buyers.

Temu.com is a comprehensive platform that specifically focuses on industrial machinery and equipment. It provides detailed information about various laser CNC engraver manufacturers in China. The website allows users to filter and search for suppliers based on factors such as location, product specifications, and customer reviews. By comparing prices and features, buyers can make more informed decisions about the most suitable supplier for their needs.

Another well-known platform is 1688.com, which is a subsidiary of Alibaba Group. This platform is primarily designed for domestic business-to-business (B2B) transactions in China. While the website is in Chinese, it can be translated using web browser translation features. 1688.com offers a wide range of laser CNC engraver manufacturers, providing competitive quotes and detailed product descriptions. Users can communicate with suppliers directly through the platform to negotiate prices and discuss specific requirements.

To conduct effective price cost research on these platforms, it is advisable to follow these steps:

1. Specify your requirements: Determine the specific features and specifications you need for your laser CNC engraver. This will help you filter out irrelevant options and find suitable manufacturers.

2. Compare prices and reviews: Analyze the pricing and customer reviews of different manufacturers to understand the market trends and gauge the quality of their products.

3. Contact suppliers: Contact shortlisted suppliers to negotiate prices, discuss customization options, shipping terms, and payment methods. It is recommended to obtain multiple quotes to compare and ensure competitive pricing.

4. Consider other factors: While price is an important consideration, it is also crucial to assess manufacturing capabilities, production capacity, lead times, after-sales service, and the supplier’s reputation.

Remember, when researching prices on temu.com and 1688.com, it is essential to take into account other costs such as shipping fees, import duties, and additional charges, which may vary based on your location and the specific terms negotiated with the supplier.

In summary, using temu.com and 1688.com allows buyers to efficiently research and compare prices from laser CNC engraver manufacturers in China. By following the aforementioned steps and considering various factors, buyers can make informed decisions and find the most favorable supplier for their requirements.

Shipping Cost for laser cnc engraver import from China

The shipping cost for importing a laser CNC engraver from China can vary depending on various factors. These factors include the size and weight of the machine, the shipping method chosen, the destination country, and any additional services required. Generally, there are three main shipping methods: air freight, sea freight, and courier service.

Air freight is the fastest but also the most expensive option. It is suitable for smaller, lightweight machines. Shipping costs for air freight can range from $500 to $2000 or more, depending on the machine’s size and destination.

Sea freight is the most cost-effective option for larger and heavier machines. Shipping costs for sea freight can range from $200 to $1000, depending on the volume and the destination port. However, it usually takes longer for the machine to arrive compared to air freight.

Courier services like DHL, FedEx, or UPS are convenient for smaller machines and offer door-to-door delivery. Shipping costs usually range from $500 to $1500, depending on the machine’s weight and destination.

It’s important to note that these shipping costs are estimates and can differ based on negotiations with shipping agents, custom duties, taxes, and other additional services such as insurance or customs clearance.

To reduce shipping costs, one can consider optimizing the packaging to reduce the overall weight and volume of the machine. Negotiating shipping rates with multiple freight forwarders or utilizing international shipping platforms can also help minimize costs.

In summary, the shipping cost for importing a laser CNC engraver from China can vary depending on factors such as the machine’s size, weight, shipping method chosen, and destination. It’s crucial to research and compare different shipping options to find the most suitable and cost-effective solution.

Compare China and Other laser cnc engraver Markets: Products Quality and Price,Visible and Hidden Costs

China is considered one of the largest and most competitive markets for laser CNC engravers globally. When comparing China with other laser CNC engraver markets, several factors need to be analyzed, including product quality, price, and visible and hidden costs.

In terms of product quality, China has made significant advancements and improvements in manufacturing technologies over the years. Chinese laser CNC engravers are often known for their affordability and decent quality. However, it is crucial to note that compared to markets in developed countries like the United States, Europe, or Japan, the overall quality standards of Chinese laser CNC engravers may be slightly lower. This is primarily due to variations in manufacturing processes and quality control systems.

In terms of price, China often offers a significant advantage. Chinese manufacturers have the ability to produce laser CNC engravers at a lower cost due to lower labor costs, economies of scale, and access to raw materials. As a result, Chinese laser CNC engravers are generally more affordable compared to those manufactured in other markets. This cost advantage has made China a favored destination for customers seeking cost-effective solutions.

When considering visible and hidden costs, it is important to note that China may have some disadvantages. Importing laser CNC engravers from China may involve additional expenses such as transportation and customs duties. Moreover, communication and language barriers can sometimes lead to misunderstandings, delays, and additional costs due to the need for more extensive support or customization.

Furthermore, hidden costs may arise when dealing with product warranties and after-sales service. While Chinese manufacturers are continuously improving their customer support, it is essential to carefully consider these factors when evaluating the overall cost of a Chinese laser CNC engraver.

In conclusion, China’s laser CNC engraver market offers competitive prices and decent product quality. However, when comparing it to other markets, differences in quality standards and potential hidden costs need to be considered. Depending on specific requirements and budget constraints, customers can make an informed decision regarding which market to choose for purchasing laser CNC engravers.

Understanding Pricing and Payment Terms for laser cnc engraver: A Comparative Guide to Get the Best Deal

When it comes to purchasing a laser CNC engraver, understanding pricing and payment terms is crucial in order to secure the best deal. Here is a comparative guide to help you make an informed decision.

The first step is to research the market and identify reputable suppliers. Look for manufacturers or distributors that specialize in laser CNC engravers and have a proven track record. Once you have shortlisted a few options, compare their prices.

Pricing for laser CNC engravers can vary significantly depending on factors such as brand reputation, machine specifications, and additional features. It is important to carefully analyze each option and determine if the price aligns with the machine’s capabilities and your specific needs.

Payment terms also play a crucial role in the decision-making process. Some suppliers may offer financing options, allowing you to spread the cost over a certain period. Assess the interest rates and any associated fees before committing to a payment plan. Additionally, consider the warranty provided and the supplier’s after-sales support, as these factors can impact the overall value for money.

It is advisable to request quotes from multiple suppliers to negotiate the best possible deal. Be prepared to ask for discounts or inquire about any ongoing promotions. Remember that it’s not just about the initial cost but also the long-term benefits, including the engraver’s lifespan, maintenance requirements, and potential for upgrades.

In conclusion, understanding pricing and payment terms for a laser CNC engraver requires thorough research and comparison. By carefully analyzing different options, negotiating with suppliers, and considering long-term benefits, you can secure the best deal that meets your needs and budget. Remember to prioritize reputable suppliers and ensure that payment terms align with your financial capabilities.

Chinese Regulations and Industry Standards Certifications for laser cnc engraver,Import Regulations and Customs for laser cnc engraver from China

Chinese regulations and industry standards certifications play a crucial role in ensuring the safety and quality of laser CNC engravers. The two main certifications required for laser CNC engravers in China are the China Compulsory Certification (CCC) and the International Electrotechnical Commission (IEC) certification.

The CCC certification is a mandatory requirement for various products in China, including laser CNC engravers. This certification ensures that the product meets the necessary safety standards and regulations set by the Chinese government. It covers aspects such as electrical safety, electromagnetic compatibility, and laser radiation safety. Without the CCC certification, it is illegal to import and sell laser CNC engravers in China.

In addition to the CCC certification, the IEC certification is also highly recommended. This certification is recognized worldwide and verifies that the laser CNC engraver complies with international standards for safety and performance. It gives customers assurance that the product meets globally accepted quality standards.

In terms of importing laser CNC engravers from China, there are several import regulations and customs procedures to be aware of. Importers must comply with the customs requirements of both the exporting and importing countries. This includes ensuring correct labeling, proper documentation, and adherence to import duties and taxes.

To import laser CNC engravers from China, importers need to submit relevant paperwork, such as commercial invoices, packing lists, and bills of lading or airway bills. It is important to classify the product correctly to determine the applicable import duties and taxes. Any necessary permits or licenses for laser products may also be required.

Customs clearance procedures must be followed, and importers should work closely with customs agents or freight forwarders who have expertise in handling laser CNC engravers. They can provide guidance on the necessary documentation and help ensure smooth customs clearance.

In conclusion, Chinese regulations and industry standards certifications are essential for laser CNC engravers to meet safety and quality requirements. Compliance with the CCC certification is mandatory, while the IEC certification is highly recommended. Importers must adhere to import regulations and customs procedures when importing laser CNC engravers from China to ensure smooth customs clearance and compliance with local requirements.

Sustainability and Environmental Considerations in laser cnc engraver Manufacturing

In the manufacturing process of laser CNC engravers, sustainability and environmental considerations play a crucial role in minimizing negative impacts on the environment and ensuring long-term sustainability. Here are a few key factors to consider:

1. Energy Efficiency: Laser CNC engravers should be designed to operate with maximum energy efficiency. This includes using energy-saving components, efficient power management systems, and implementing standby/hibernation modes to reduce energy consumption.

2. Material Selection: Choosing sustainable materials for the construction of laser CNC engravers is important. Opting for eco-friendly and recyclable components helps to reduce the environmental footprint. Additionally, manufacturers should prioritize the use of non-toxic materials to avoid harmful emissions.

3. Waste Management: Implementing effective waste management strategies is vital. Manufacturers should focus on reducing waste generation during the manufacturing process and properly disposing of hazardous waste. Reusing or recycling materials whenever possible can significantly minimize environmental impact.

4. Emissions Reduction: Controlling and minimizing emissions is crucial in ensuring the sustainability of laser CNC engraver manufacturing. This includes minimizing the release of volatile organic compounds (VOCs), reducing air pollutants, and implementing effective exhaust systems to capture and treat harmful emissions.

5. Lifecycle Considerations: Manufacturers should consider the entire lifecycle of the product, from production to disposal. This includes designing for durability and ease of repair, as well as incorporating recyclable materials to facilitate proper end-of-life disposal.

6. Supply Chain Management: Promoting sustainability within the supply chain is essential. Collaborating with suppliers who prioritize sustainable practices, such as using renewable energy sources and reducing their own environmental impact, can help achieve overall sustainability goals.

By considering these sustainability and environmental factors, laser CNC engraver manufacturers can minimize their carbon footprint, reduce waste generation, and contribute to a greener and more sustainable future.

List The Evolution history of “laser cnc engraver”

The evolution of laser CNC engravers can be traced back to the 1960s when the concept of laser technology was first developed. Initially, lasers were large, expensive, and only used in industrial settings. However, with advancements in technology, lasers became more compact and affordable, leading to their integration into various applications, including engraving.

In the 1980s, the first laser CNC engravers were introduced to the market. These machines utilized CO2 lasers that emitted high-energy beams to vaporize or remove material from the surface. They provided precise and accurate engraving on a wide range of materials, such as wood, plastic, and metal. At this stage, laser CNC engravers were mainly utilized in professional workshops and manufacturing facilities due to their high cost.

The 1990s saw further improvements in laser CNC engraver technology. The introduction of computer numerical control (CNC) systems allowed for automated and programmable engraving, enhancing the precision and speed of the process. Additionally, the emergence of more powerful laser sources, such as fiber lasers, brought increased versatility and efficiency to the engraving process.

In the early 2000s, laser CNC engravers became more accessible to smaller businesses and hobbyists. Compact desktop models were introduced, featuring user-friendly interfaces and reduced costs. This democratization of laser engraving technology led to its widespread adoption across various industries and personal use.

Recent advancements have focused on improving the capabilities and efficiency of laser CNC engravers. Manufacturers have incorporated innovative features such as rotary attachments for cylindrical objects, autofocus systems, and advanced software for intricate designs. These advancements have made laser CNC engravers even more versatile and precise, enabling them to produce high-quality engravings on a variety of materials with ease.

Furthermore, the integration of artificial intelligence (AI) and machine learning technologies has enhanced the engraving process. AI-powered algorithms can analyze different materials and optimize laser settings, resulting in improved engraving speed and quality.

In conclusion, laser CNC engravers have come a long way since their inception in the 1980s. Through continuous technological advancements, they have evolved from bulky and expensive machines used exclusively in industrial settings to compact and affordable tools accessible to businesses and individuals alike. With further advancements on the horizon, laser CNC engravers are expected to continue empowering creativity and enhancing manufacturing processes.

The Evolution and Market Trends in laser cnc engraver Industry

The laser CNC engraver industry has witnessed significant evolution and market trends in recent years. This technology has revolutionized the traditional engraving process by offering precision, efficiency, and versatility.

One notable evolution in the laser CNC engraver industry is the development of more advanced and powerful machines. Manufacturers are constantly improving the speed and accuracy of laser engravers, allowing for more complex and detailed designs. Additionally, the integration of artificial intelligence and automation in these machines has increased productivity and reduced human error.

Another evolution is the expansion of applications for laser CNC engravers. Initially used primarily for industrial purposes, these machines are now extensively employed in various sectors such as advertising, arts and crafts, jewelry making, automotive, and even healthcare. The ability to engrave on a wide range of materials, including wood, metal, glass, plastic, and leather, has contributed to the growing popularity of laser CNC engravers.

Market trends in the laser CNC engraver industry reflect the increasing demand for personalized and customized products. Consumers are seeking unique and tailored items, resulting in a rising need for engraving and customization services. This trend has propelled the adoption of laser CNC engravers by small businesses and hobbyists, who can now offer personalized products at a competitive price.

Furthermore, sustainability has emerged as a significant market trend in recent years. Laser CNC engravers are considered more environmentally friendly compared to traditional methods, as they produce minimal waste, eliminate the need for chemicals, and consume less energy. This aligns with the growing consumer preference for eco-friendly and sustainable products, further driving the adoption of laser CNC engravers.

Lastly, the market for laser CNC engravers has become more accessible and competitive. The availability of affordable and entry-level machines has allowed small businesses and individuals to enter the market. Additionally, advancements in software and ease of use have simplified the operation of these machines, reducing the learning curve for new users.

In conclusion, the evolution of laser CNC engravers has been characterized by advancements in machine capabilities, expanded applications, and increased accessibility. The market trends emphasize the demand for customization, sustainability, and affordability. As technology continues to improve, the laser CNC engraver industry is expected to witness further growth and innovation.

Custom Private Labeling and Branding Opportunities with Chinese laser cnc engraver Manufacturers

Chinese laser CNC engraver manufacturers offer custom private labeling and branding opportunities for businesses looking to establish their own brand in the market. Private labeling allows companies to create a unique identity and build brand loyalty among customers.

These manufacturers offer the option to customize various aspects of the engraver, such as the appearance, packaging, and even the software interface. By incorporating their own branding elements, companies can create a cohesive and recognizable product line that stands out from competitors.

With a vast range of laser CNC engravers available, manufacturers can cater to different industry needs and specifications. They provide customizable options for engraving materials, cutting depths, and engraving speeds, ensuring the final product meets the requirements of the target market.

Chinese manufacturers also offer support throughout the private labeling process, from design to production. They have experienced teams that work closely with businesses to understand their branding needs and offer expert advice. Additionally, they provide samples, allowing companies to test and evaluate the product before finalizing the branding.

Price competitiveness is another advantage of working with Chinese laser CNC engraver manufacturers. They often offer competitive pricing structures due to low production costs in China. This allows companies to establish their brand at a more affordable price point without compromising on quality.

Furthermore, Chinese manufacturers have the capability to handle both small and large orders, making private labeling accessible to businesses of all sizes. Whether a company requires a small batch for a niche market or a large-scale production, these manufacturers have the capacity to accommodate different order volumes.

In conclusion, Chinese laser CNC engraver manufacturers provide custom private labeling and branding opportunities that allow businesses to establish their own unique identity in the market. With a wide range of customizable options and competitive pricing, these manufacturers enable companies to create quality products that resonate with their target customers.

Tips for Procurement and Considerations when Purchasing laser cnc engraver

When purchasing a laser CNC engraver, there are several tips and considerations to keep in mind:

1. Identify your needs: Before making a purchase, assess why you need a laser CNC engraver. Consider the materials you’ll be working with, the size and complexity of the projects, and the desired engraving quality.

2. Budget: Set a budget for your purchase and stick to it. Determine how much you are willing to spend on the engraver, taking into account not just the initial cost but also ongoing maintenance and operational costs.

3. Research different brands and models: Look for reputable brands known for their quality and reliability. Read reviews and compare features, specifications, and capabilities of various laser CNC engravers to find the one that best suits your requirements.

4. Cutting and engraving capabilities: Consider the power and speed of the engraver. Higher power allows for faster cutting and engraving, while speed affects the efficiency of the machine. Find a balance based on your needs.

5. Work area and size: Evaluate the required work area based on the size of the materials you plan to work with. Ensure that the engraver can accommodate the necessary dimensions and thickness of the materials.

6. Software compatibility: Check if the laser CNC engraver is compatible with the design software you intend to use. Compatibility ensures smooth operation and eliminates potential compatibility issues.

7. Safety features: Engraving machines involve lasers that can pose safety risks. Look for engravers with safety measures such as emergency stops, ventilation systems, and protective enclosures to ensure operator safety.

8. Technical support and warranty: Consider the availability of technical support from the manufacturer in case of any issues. Also, check the warranty provided for the engraver to safeguard your investment.

9. Training and user-friendliness: Evaluate the ease of use and the availability of training resources, especially if you are new to laser CNC engraving. Look for machines that offer user-friendly interfaces and provide comprehensive user manuals or tutorials.

10. Future scalability: If you foresee expanding your operations in the future, consider whether the chosen engraver can support your growing needs. Look for options like additional accessories or modular designs that can be upgraded as needed.

By considering these tips and factors, you can make an informed decision when purchasing a laser CNC engraver that best fits your needs, budget, and long-term goals.

FAQs on Sourcing and Manufacturing laser cnc engraver in China

1. What is a laser CNC engraver?

A laser CNC engraver is a machine that uses a focused laser beam to engrave or etch designs onto various materials, such as wood, acrylic, metal, or glass. It is controlled by computer numerical control (CNC) software, allowing for precise and detailed engravings.

2. Why source and manufacture a laser CNC engraver in China?

China is well-known for its manufacturing capabilities and offers a wide range of laser CNC engravers at competitive prices. Chinese manufacturers have extensive experience in producing and exporting these machines, ensuring high-quality products that meet international standards. Additionally, sourcing from China provides access to a large pool of suppliers, enabling greater flexibility in terms of customization options and cost-effective solutions.

3. How to select a reliable manufacturer in China?

It is crucial to conduct thorough research before finalizing a manufacturer. Look for companies with a good reputation and positive customer reviews. Assess their experience in the industry, production capacity, and quality control measures. Request samples or visit their facilities to evaluate the product quality firsthand. Communication is key – ensure they have fluent English-speaking representatives to avoid miscommunication or delays.

4. What are key considerations when sourcing a laser CNC engraver?

Consider factors such as the laser power, working area, engraving speed, accuracy, and compatibility with different materials. Look for machines with user-friendly software interfaces and efficient cooling systems. Additionally, ensure the manufacturer offers comprehensive after-sales support, including technical assistance, warranty coverage, and spare parts availability.

5. How to handle manufacturing and shipping logistics?

When manufacturing in China, it is essential to establish a clear timeline with the manufacturer, including production lead time and shipping arrangements. Production costs, payment terms, and quality control procedures should be outlined in a written agreement. Also, consider hiring a third-party inspection agency to ensure quality standards are met. When shipping, choose a reliable freight forwarder experienced in handling delicate machinery to ensure safe and timely delivery.

In conclusion, sourcing and manufacturing a laser CNC engraver in China provides access to competitive prices, extensive customization options, and a large pool of experienced suppliers. However, thorough research, careful manufacturer selection, and detailed logistics planning are necessary to ensure a successful sourcing process.

Why contact sourcifychina.com get free quota from reliable laser cnc engraver suppliers?

Sourcifychina.com, a reliable sourcing platform for businesses looking to connect with manufacturers in China, offers a free quota for contacting laser CNC engraver suppliers. This service aims to facilitate the sourcing process and provide businesses with a risk-free opportunity to connect with potential suppliers.

There are several reasons why Sourcifychina.com offers this free quota. Firstly, Sourcifychina.com understands the importance of building trust between buyers and suppliers. By providing a free quota, businesses can evaluate different suppliers without any financial commitment. This helps in establishing stronger relationships and finding the most suitable partner for their engraving needs.

Secondly, Sourcifychina.com recognizes that sourcing can be a challenging task, especially for businesses that are new to the Chinese market. Offering a free quota allows businesses to explore a wide range of suppliers and gain a better understanding of the market and their options. This helps them make informed decisions and find the best laser CNC engraver supplier that meets their specific requirements.

Furthermore, Sourcifychina.com aims to promote transparency and efficiency in the sourcing process. By providing a free quota, businesses can directly communicate with suppliers, negotiate terms, and discuss their project needs. This eliminates any intermediaries or additional costs, ensuring a smooth and direct sourcing experience.

In conclusion, Sourcifychina.com offers a free quota for contacting laser CNC engraver suppliers to facilitate the sourcing process for businesses. This helps build trust, provides a risk-free opportunity to explore various suppliers, and promotes transparency in the supplier-buyer relationship. By leveraging this service, businesses can find reliable and high-quality laser CNC engraver suppliers in China.