Types and Applications of laser diameter gauge

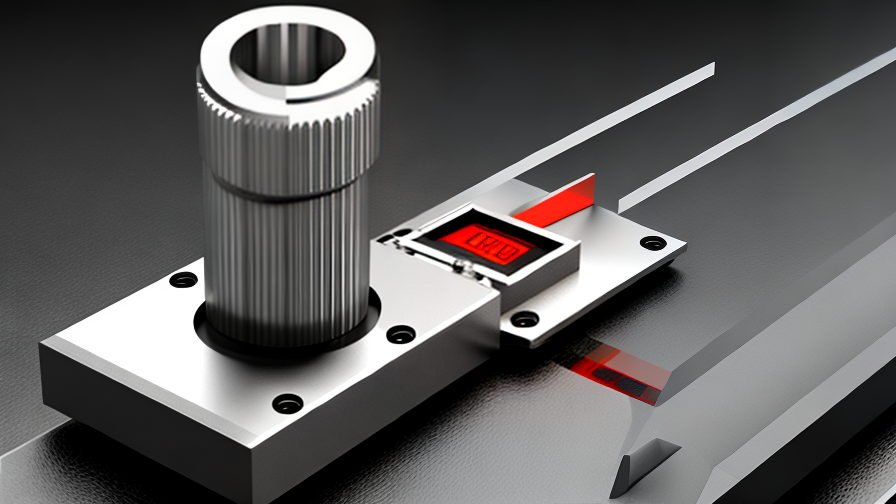

Laser diameter gauges are tools that are used to measure the diameter of wires, cables, tubes, and other cylindrical objects. These gauges use a laser beam to accurately measure the diameter of the object, providing a precise reading that can be used in a variety of applications. There are several different types of laser diameter gauges available, each with their own unique features and applications.

The first type of laser diameter gauge is the stationary gauge. This type of gauge is typically used in manufacturing environments where a continuous measurement of the diameter of a product is required. Stationary gauges use a laser beam that is directed at the surface of the object being measured. The beam is then reflected off the object and directed back to the gauge, where the diameter is calculated based on the amount of time it took for the beam to travel from the gauge to the object and back.

Another type of laser diameter gauge is the handheld gauge. Handheld gauges are typically used in applications where the measurement needs to be taken on-site or in the field. Handheld gauges are portable and can be easily carried from one location to another. They use a similar principle to stationary gauges, but they are designed to be operated by a single person.

Finally, there are laser diameter gauges that are designed specifically for measuring the diameter of small and delicate objects. These gauges use a low-powered laser beam that is focused on the object being measured, which allows for more accurate readings.

The applications of laser diameter gauges are numerous. They are commonly used in the wire and cable manufacturing industry, where the accurate measurement of wire diameters is critical for quality control. Additionally, laser diameter gauges are used in the medical device industry to measure the diameter of catheter tubing and other small medical devices. They are also used in the automotive industry to measure the diameter of brake lines and fuel injectors.

In conclusion, laser diameter gauges are highly accurate and reliable tools that are used to measure the diameter of cylindrical objects. There are several different types of laser diameter gauges available, each with their own unique features and applications. These gauges are used in a variety of industries, including manufacturing, medical device, and automotive.

Benefits and Feature of Utilizing laser diameter gauge

A laser diameter gauge is a precision measurement tool designed to measure the diameter of objects accurately. The primary benefit of utilizing a laser diameter gauge is that it can provide highly accurate measurements of the object’s diameter, which can be difficult to achieve using manual or traditional measurement tools. The following are some of the key benefits and features of utilizing a laser diameter gauge:

1. Precision and accuracy: Laser diameter gauges are designed to provide highly accurate measurements that are precise and repeatable, making them an ideal tool for applications that require high precision.

2. Non-contact measurement: Unlike traditional measurement tools, laser diameter gauges do not need to make direct contact with the material being measured. This non-contact approach eliminates the potential for damage to the material and makes the measurement process faster and more efficient.

3. Wide range of applications: Laser diameter gauges can be used in a variety of industries and applications, including wire and cable manufacturing, plastic extrusion, aerospace, and automotive manufacturing.

4. Real-time measurements: Laser diameter gauges can provide real-time measurements, allowing operators to make adjustments to the manufacturing process in real-time and improving overall efficiency.

5. Data recording and analysis: Many laser diameter gauges come equipped with data recording and analysis capabilities, allowing for the collection and analysis of data for further analysis and process optimization.

6. Easy to use: Laser diameter gauges are easy to use, and many models have intuitive user interfaces that require minimal training.

In conclusion, using a laser diameter gauge provides significant benefits to industries and the manufacturing process, including precision and accuracy, non-contact measurement, data recording and analysis, and real-time measurement. Also, this tool is easy to use and has a wide range of applications, making it an ideal tool for various industries and applications.

The Process of laser diameter gauge

A laser diameter gauge is a device that uses a non-contact measurement method to determine the diameter of a material. The gauge works by emitting a laser beam onto the material and measuring the amount of light that is reflected off the surface.

The process of using a laser diameter gauge begins with calibration. The gauge must be calibrated to ensure that its measurements are accurate. Calibration involves measuring a known diameter using the gauge and comparing the result to the actual diameter. The gauge is then adjusted to ensure that it provides an accurate measurement.

Once the gauge is calibrated, it can be used to measure the diameter of the material. The material is passed through the gauge, and the laser beam is directed onto the surface. As the material passes through the gauge, the diameter is measured. The gauge provides a real-time measurement, which means that the diameter can be monitored continuously.

The laser diameter gauge may need to be adjusted if the material being measured changes. This may involve changing the calibration of the gauge to ensure that it provides an accurate measurement.

In conclusion, the laser diameter gauge is an important tool used in the manufacturing industry to measure the diameter of materials accurately. The process of using a laser diameter gauge involves calibration, passing the material through the gauge, and obtaining a real-time measurement. Calibration may be necessary if the material changes, to ensure that the gauge provides accurate measurements.

How to use laser diameter gauge

A laser diameter gauge is a device that is used to measure the diameter of a cylindrical object. It uses a non-contact method to provide highly accurate measurements. The gauge works by emitting a laser beam that passes through the center of the object being measured. The gauge then receives the reflected light and uses it to determine the diameter of the object.

To use a laser diameter gauge, the first step is to connect it to a power source and turn it on. The gauge should be placed perpendicular to the object being measured and the laser pointed at the center of the object. The gauge should then be adjusted until the laser beam is aligned with the center of the object.

Once the gauge is aligned, the measurement process can begin. The gauge should be set to the appropriate measurement range, which is usually indicated on the device. The gauge should then be moved along the length of the object, taking multiple measurements at different points. The gauge will provide an accurate measurement of the diameter of the object.

After taking the measurements, it is important to record the data and analyze it. The data can be used to determine if the object is within specification or if it needs further processing or adjustment.

In conclusion, laser diameter gauges are highly accurate and efficient tools for measuring cylindrical objects. They are easy to use and provide accurate results in a non-contact manner. With proper calibration and use, these devices can improve manufacturing efficiency and quality control processes.

laser diameter gauge Manufacturer,Supplier and Wholesale

We are a leading manufacturer, supplier and wholesale distributor of laser diameter gauges. Our company specializes in providing high-quality, reliable and precise measuring solutions for various industries.

Our laser diameter gauges are designed to accurately measure the diameter of a variety of materials, including metal, plastic, paper, and wire. The gauges use advanced laser technology to provide accurate measurements in real-time. They are easy to use and provide quick and reliable results, which makes them ideal for use in a wide range of applications.

Our team of skilled professionals has extensive experience in the industry and is committed to providing the highest quality products and services. We use state-of-the-art manufacturing equipment and techniques to ensure that our laser diameter gauges meet the highest standards of quality and reliability.

We are committed to providing our customers with exceptional products and services. Whether you need a single laser diameter gauge or a large order for your business, we can accommodate your needs. Our prices are competitive and we offer fast, reliable shipping to ensure that your order arrives on time.

We also provide excellent customer support and are always available to assist with any questions or concerns you may have. Our knowledgeable team is dedicated to providing you with the information and guidance you need to select the right laser diameter gauge for your needs.

In conclusion, if you are in need of a reliable and accurate laser diameter gauge, look no further than our company. We are committed to providing high-quality products, excellent customer service, and competitive prices. Contact us today to learn more about our laser diameter gauges and how we can help you meet your measuring needs.

laser diameter gauge Price

A laser diameter gauge is a measurement device that uses laser technology to accurately measure the diameter of a cylindrical object. It is widely used in various industries such as wire and cable manufacturing, plastic extrusion, paper manufacturing, and textile production.

The price of a laser diameter gauge varies depending on its features and specifications. Simple models with basic features can cost as low as $500, while more advanced models with additional features like data logging and wireless connectivity can cost several thousand dollars.

Some popular brands of laser diameter gauges include Zumbach, Beta LaserMike, and NDC Technologies. These brands offer a wide range of models with different specifications and capabilities to suit different applications and budgets.

When considering the price of a laser diameter gauge, it is important to also consider the potential cost savings it can bring to the manufacturing process. Accurate diameter measurements can help reduce material waste, improve product quality and consistency, and increase overall efficiency.

In conclusion, the price of a laser diameter gauge can range from a few hundred dollars to several thousand dollars depending on its features and capabilities. However, its potential cost savings and benefits make it a valuable investment for many industries.

FAQ sourcing laser diameter gauge manufacturer from China with multiple answers

1. What should I consider when sourcing a laser diameter gauge manufacturer from China?

When sourcing a laser diameter gauge manufacturer from China, you should consider their experience in the industry, reputation, quality of products, certifications, pricing, and customer service. It’s advisable to work with a manufacturer that has years of experience in the production of laser diameter gauges, and has a good reputation in the market. Quality should also be a priority, so look for a manufacturer whose products meet international standards and have the necessary certifications. Pricing is also a crucial factor, so compare different quotes from different manufacturers and determine the best value for money.

2. How do I ensure quality when sourcing from a Chinese manufacturer?

To ensure quality when sourcing from a Chinese manufacturer, conduct thorough research, and look for reviews from previous customers. You can also request product samples or arrange for a factory visit to inspect the production process. It’s also recommended to ask for product certifications, such as CE and ISO certification, to ensure the product meets international standards.

3. Can Chinese manufacturers customize laser diameter gauges?

Yes, most Chinese manufacturers can customize laser diameter gauges to suit your specific needs. It’s essential to provide clear specifications of what you require and communicate all the necessary details with the manufacturer. A good manufacturer will work with you to ensure that the final product meets your requirements.

4. What is the lead time for shipping products from China?

The lead time for shipping products from China varies depending on various factors such as the manufacturing volume, shipping method, and destination country. Generally, it takes between 15 and 30 days for orders to be processed and shipped from China. However, you should always confirm the lead time with the manufacturer before placing an order.

5. How can I pay for products sourced from a Chinese manufacturer?

Chinese manufacturers accept different forms of payment, including wire transfer, PayPal, and credit cards. It’s best to agree on payment terms with the manufacturer before placing an order to avoid any misunderstandings. Some manufacturers may ask for partial payment upfront or a deposit before commencing production.