Knowledge about Laser Engraver For Plastic

A laser engraver for plastic is an excellent tool for creating detailed and precise designs, patterns, and text on a wide range of plastic materials. Here are some key pieces of knowledge that you should have to ensure that you get the most out of your laser engraver:

1. Types of plastic: Before you begin engraving, you need to be aware of the different types of plastics that you can use. Some of the most common varieties include acrylic, PET, and polycarbonate. Each of these materials has unique properties, so it’s essential to choose the right one for your specific project.

2. Laser power and speed: The power and speed of your laser will significantly impact the quality of your engraving. Be sure to choose the appropriate laser settings based on the type of plastic you’re using and the design you want to create.

3. Ventilation and safety precautions: Laser engraving can produce harmful fumes, so proper ventilation is crucial. Always ensure that the area where you’re working is adequately ventilated, and wear appropriate personal protective equipment, such as goggles and gloves.

4. Design software: To create designs for your laser engraver, you will need to use design software. Many different options are available, such as CorelDRAW, Adobe Illustrator, and AutoCAD. Be sure to choose the software that best fits your skills and project requirements.

5. Maintenance and cleaning: Keeping your laser engraver clean and well-maintained is essential for ensuring its longevity and performance. Be sure to follow the manufacturer’s recommendations for maintenance and cleaning.

In conclusion, laser engraving is an excellent way to add detailed and precise designs to plastic materials. By knowing the different types of plastic, laser settings, safety precautions, and maintenance practices, you can create stunning, professional-grade products that are both functional and aesthetically pleasing.

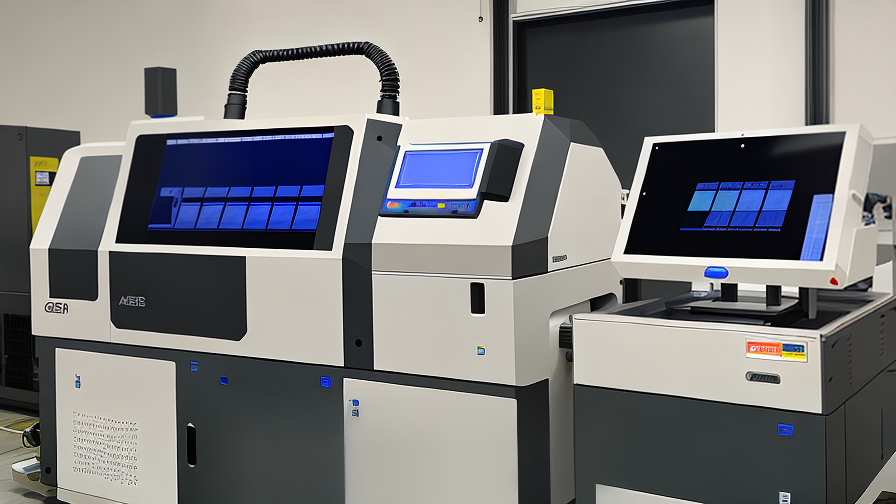

Various Types of Laser Engraver For Plastic

Laser engraving is the process of laser marking or etching into the surface of an object, leaving a permanent mark. When it comes to plastic materials, laser engraving is considered to be one of the most effective ways to personalize and create intricate designs. Laser engravers are machines capable of implementing this process efficiently, and there are various types available.

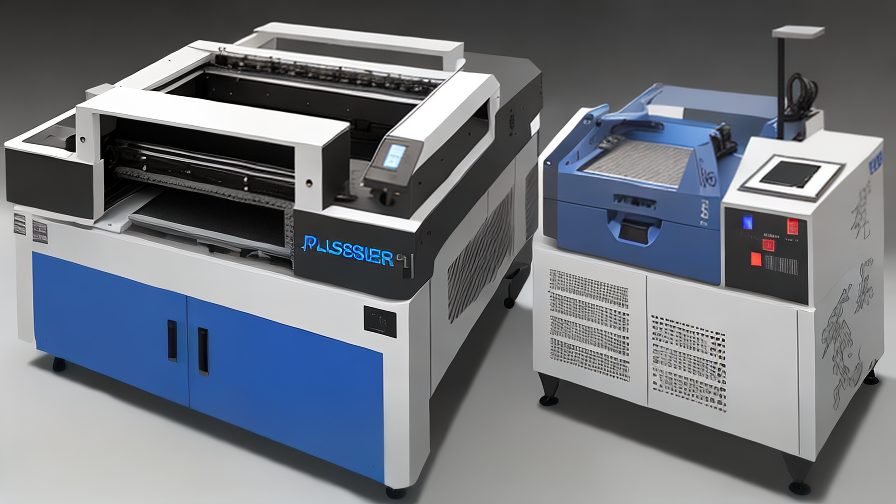

The first type of laser engraver for plastic is the CO2 laser engraver, which is popular among many industries. This type of engraver uses a carbon dioxide gas mixture to produce a powerful beam, which is then focused onto the plastic surface. The CO2 engraver is known for its versatility, as it can work with a broad range of materials.

The second type is the fiber laser engraver, which is ideal for plastic engraving. This type of engraver uses a high-intensity beam of light generated by rare-earth metals to etch or mark on the plastic’s surface. Fibre engravers are known for their speed and precision, and they can achieve high-quality results even on small items.

Another type of laser engraver for plastic is the diode laser engraver. This type of machine uses semiconductor technology to produce a concentrated beam of light. Diode laser engravers are ideal for working on small or intricate projects, making them perfect for marking fonts or detailed designs onto plastics.

Lastly, the green laser engraver is another excellent option for plastic engraving. The green light produced by this machine is the most visible light to the human eye, making it an effective choice for engraving plastics. Green lasers are perfect for creating clean, precise lines, and they are ideal for use in art and crafts or for smaller projects.

In conclusion, there are various types of laser engravers available for plastic materials. Each type has unique features, making them suitable for different applications or projects. When selecting the type of laser engraver to use, it is essential to consider factors such as the material being etched, the size

FAQ sourcing Laser Engraver For Plastic manufacturer from China

If you’re considering sourcing a laser engraver for plastic from a manufacturer in China, you likely have a lot of questions about the process. Here, we’ve answered some of the most common questions about sourcing laser engravers, along with a few potential solutions.

Q: How can I find a reputable manufacturer for my laser engraver?

A: Start by doing research online and looking for reviews and ratings. You might also want to consider working with a sourcing agent who can help connect you with trustworthy manufacturers.

Q: How do I ensure that the laser engraver will meet my specifications?

A: Before you commit to working with a manufacturer, be sure to communicate your specific requirements and ask for detailed information on their manufacturing process. You may also want to request a sample to ensure that the final product will meet your standards.

Q: What types of materials can the laser engraver handle?

A: Be sure to communicate your specific materials to the manufacturer to ensure that their laser engraver can handle them. Some laser engravers have limitations on the types of plastic they can work with, so it’s important to be clear about your needs.

Q: How long will it take to receive my laser engraver?

A: The timeline will depend on a variety of factors, including the complexity of the engraver and the manufacturer’s current workload. Be sure to clarify the timeline with the manufacturer before placing an order.

Q: What should I do if the laser engraver arrives damaged or defective?

A: Before placing an order, be sure to clarify the manufacturer’s policies on returns and refunds. If the engraver arrives damaged or defective, be sure to document the issue and communicate it to the manufacturer as soon as possible.

In conclusion, sourcing a laser engraver for plastic from a manufacturer in China requires careful research and communication to ensure a successful outcome. By asking the right questions and clarifying your requirements, you can find a trustworthy manufacturer who can deliver a high-quality product that meets your needs.

Applications of Laser Engraver For Plastic

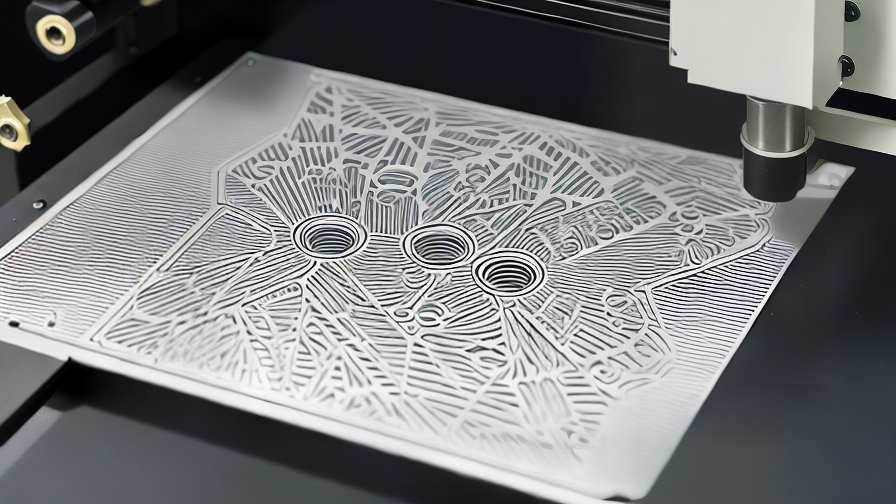

Laser engraving is a technique that involves the use of a laser to etch or engrave a design or pattern onto a material. Laser engraving has become increasingly popular in recent years, particularly in the plastics industry. There are a variety of applications for laser engravers when it comes to plastic materials.

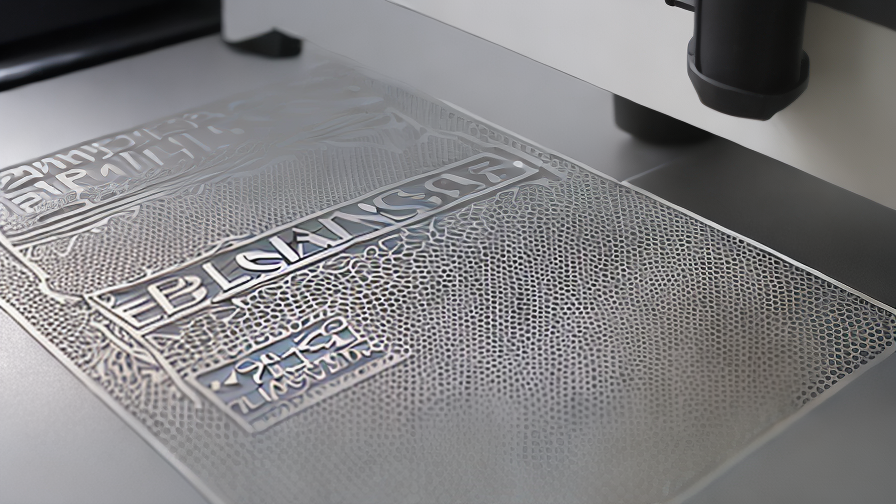

One of the most common applications of laser engravers is in the field of sign making. Laser engraving is ideal for creating detailed and intricate designs on plastic signs. The precision of laser engraving means that even small text and fine details can be engraved with incredible accuracy, resulting in clean and professional-looking signs.

Another use of laser engravers in the plastic industry is for the creation of promotional items. Laser engraving can be used to create branded keychains, pens, and other small items that can be used as give-aways or souvenirs. The high level of detail that can be achieved with laser engraving means that logos and branding can be reproduced accurately and consistently across a wide range of materials.

Laser engravers are also used in the creation of custom awards, trophies, and plaques. Laser engraving can be used to engrave names, dates, and other information onto plastic materials, resulting in a personalized and unique award or trophy. The laser engraving process can also be used to create intricate and eye-catching designs that can be used to make the award or trophy stand out.

Finally, laser engraving can also be used for creating custom products, such as phone cases, laptop covers, and other plastic accessories. Laser engravers can be used to etch designs or patterns onto plastic materials to create personalized and unique accessories that can be sold to consumers.

In conclusion, laser engraving is a versatile and powerful tool for creating high-quality designs on plastic materials. Whether for signage, promotional items, awards, or custom products, laser engraving can help businesses and individuals create unique and impressive designs with a high level of accuracy and detail.

Manufactured Products made of Laser Engraver For Plastic

Manufactured Products made of Laser Engraver For Plastic

The laser engraving technology has revolutionized the way in which plastic products are produced. The utilization of laser engravers has opened up a world of possibilities, allowing manufacturers to create intricate and precise designs that are beyond the scope of traditional engraving techniques. This article will explore some of the manufactured products made using laser engravers for plastic.

Signs and Nameplates

Laser engravers are a popular choice for producing high-quality signs and nameplates. These products are often used for labeling and identification purposes and require precision and durability. Laser engravers create deep, permanent markings on plastic surfaces, ensuring that the text or image will not fade or wear off over time.

Awards and Trophies

The intricate designs and details of awards and trophies are easily achievable with laser engravers. These products often require customization, and laser engravers allow for easy personalization with names, dates, and logos.

Consumer Goods

Laser engravers are also used in the manufacturing of consumer goods such as phone cases, keychains, and water bottles. The ability to create intricate designs and patterns on plastic surfaces allows for unique and eye-catching products that stand out from the competition.

Electronic Components

Laser engravers are also used to produce electronic components such as circuit boards, switches, and buttons. The high level of precision achieved with laser engraving ensures that these products function correctly and reliably.

Overall, the use of laser engravers for plastic products has transformed the manufacturing industry, allowing for precise and intricate designs that were previously unattainable. From signs and nameplates to consumer goods and electronic components, the applications for laser engraving technology are endless.

The Evolution history of Laser Engraver For Plastic

The history of laser engraving technology for plastics is a long and interesting one. It started in the late 1960s when the first laser was invented. At that time, lasers were mainly used for scientific research and military applications. However, in the early 1970s, the first laser engraving machine was developed, which used a CO2 laser to engrave plastics.

The early laser engravers were slow and expensive, and were mainly used for industrial applications. It was not until the late 1980s that laser engraving became a viable option for small business and home use. This was due to advances in technology that made the machines faster, more reliable and easier to use.

In the early 1990s, the first desktop laser engravers were developed. These machines were small enough to fit on a desk, but powerful enough to engrave plastics with great accuracy. They were also relatively affordable, which made them popular among small businesses and hobbyists.

In the late 1990s and early 2000s, laser engraving technology continued to advance rapidly. New materials were developed that could be engraved, such as acrylics and polycarbonates. The machines themselves became even more powerful and versatile, allowing for complex engravings and shapes.

Today, laser engraving technology is used extensively in many different industries, including jewelry making, signage and trophy engraving, and even in the medical field. The machines are faster and more precise than ever before, and can engrave a wide variety of materials, including plastics, wood, metal and glass.

In conclusion, the evolution of laser engraving technology for plastics has come a long way from its early days as a slow and expensive industrial process. Today, it is a common and affordable option for small businesses and hobbyists alike. The future of laser engraving technology looks bright, with new materials and applications constantly being developed.

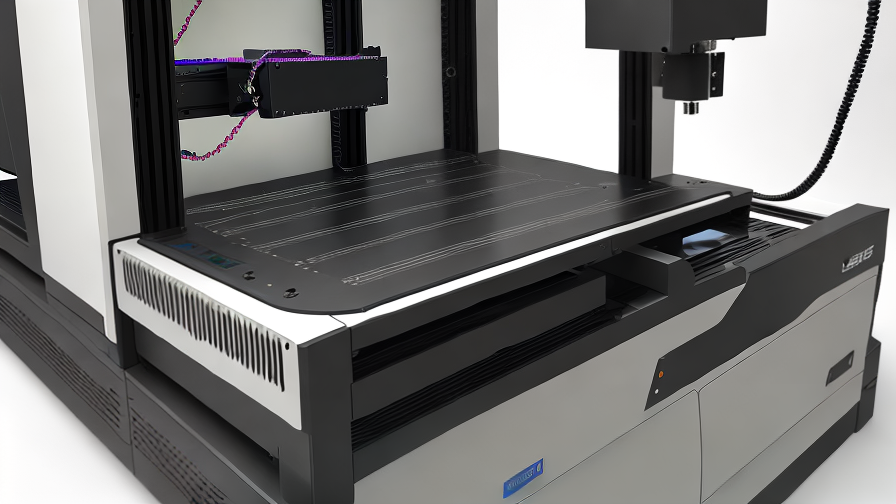

The Process of Laser Engraver For Plastic

Laser engraving is becoming increasingly popular, and for good reason. Laser engraving is a precise and efficient way to engrave or cut materials, and the results are stunning. In this article, we will talk about the process of laser engraving plastic.

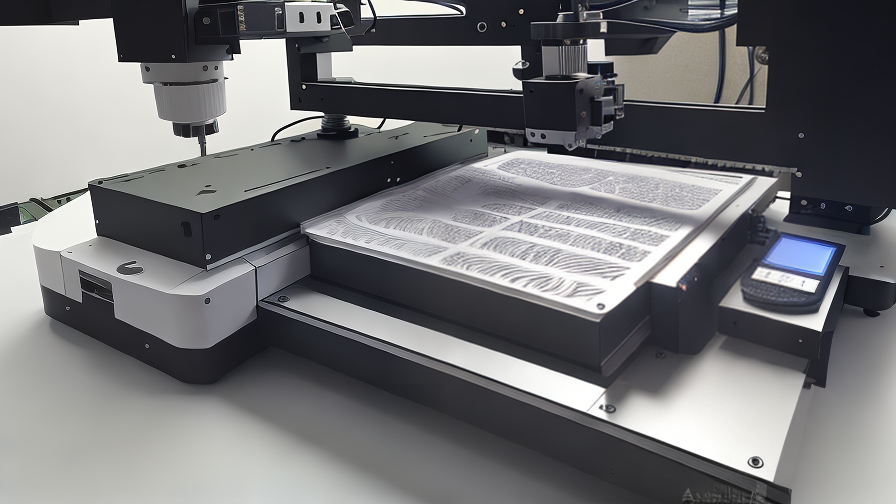

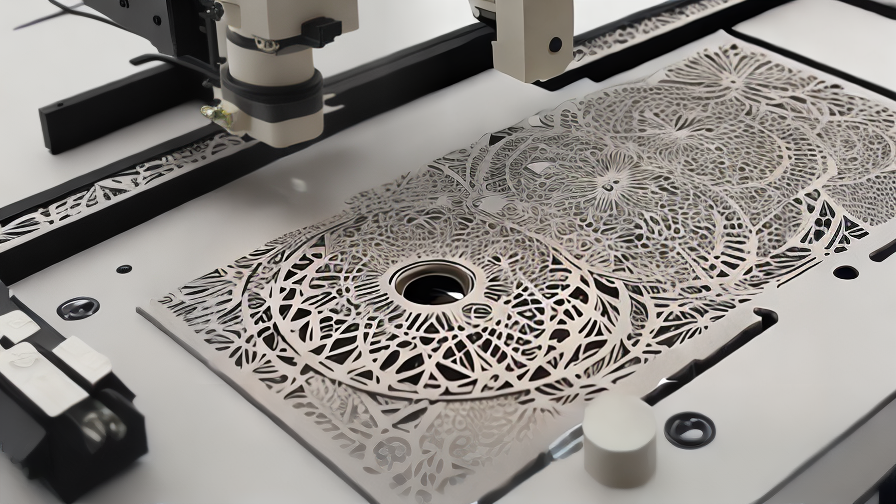

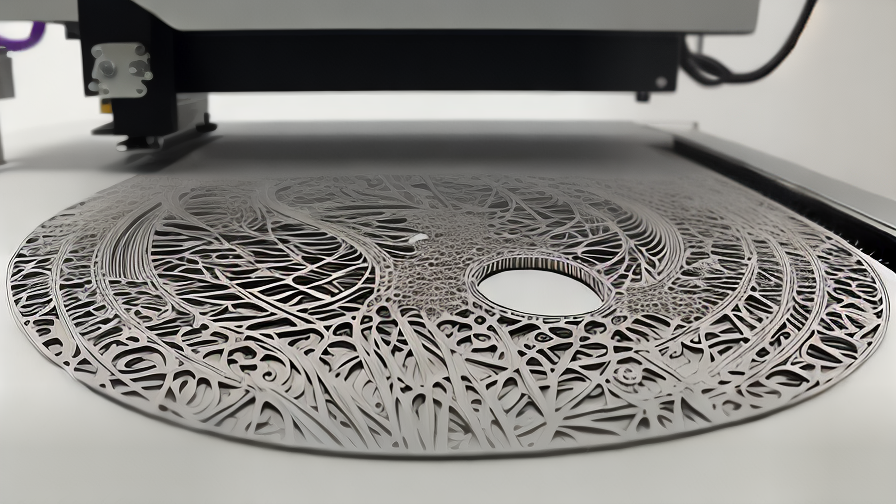

First, you need a high-quality laser engraver that is specifically designed to engrave plastic. The engraving process works by using a laser beam that burns a small section of the plastic material away to create the desired design or text. The laser beam penetrates the surface of the plastic, removing a portion of the material and creating a permanent image.

The process starts with the design, which is uploaded to the laser engraver. The design can be anything from a simple image or text to a complex design with intricate details. The laser engraver then focuses the beam of light onto the surface of the plastic and begins to engrave.

One of the benefits of using a laser engraver for plastic is the ability to adjust the settings to achieve different results. This includes the depth of the engraving, the speed of the laser, and the heat settings. These settings can be adjusted to create different effects, ranging from a smooth, shallow engraving to a deep, rough engraving.

Another benefit of laser engraving plastic is the precision it offers. The laser can engrave very fine details and intricate designs with ease. This precision allows for high-quality images and text that are sharp and clear.

In conclusion, the process of laser engraving plastic is an efficient and effective way to create high-quality images and text. It offers precision and control over the final result, making it an excellent choice for a wide range of applications. Whether you need to engrave plastic for business or personal use, a laser engraver is a great option.

Benefits Advantages of Utilizing Laser Engraver For Plastic

Laser engraving is a process where images, text, or designs are etched onto an object using a focused laser beam. While laser engraving on metal has been a popular choice for many, it is now being increasingly used for plastic materials as well. Laser engraving machines have become a go-to tool for personalizing plastics, creating labels, serial numbers, barcodes, and more. In this article, we will explore the benefits and advantages of utilizing laser engravers for plastic materials.

Firstly, laser engraving is a non-contact process. The laser beam does not touch the plastic material, eliminating the chances of any damage to the item being engraved. This makes laser engraving the perfect solution for delicate or intricately designed items.

Secondly, laser engraving can be done on a variety of plastic materials, including acrylic, polycarbonate, ABS, and PVC. Unlike traditional printing methods like screen printing, laser engraving leaves a permanent mark on the surface that cannot be rubbed off or fade away.

Thirdly, laser engraving provides exceptional precision and accuracy. The focused laser beam can etch detailed designs, logos or text onto the surface, creating a sharp and neat finish. This makes it an excellent choice for items like jewelry, awards, and plaques.

Fourthly, laser engraving is also a faster and more efficient method compared to traditional engraving processes. With computer-aided design, files can be easily loaded into the laser engraver, providing a speedy process compared to manual engraving.

Finally, laser engraving is eco-friendly, with no chemicals required in the process. This makes it a sustainable solution, especially for companies that are striving towards eco-friendly and sustainable practices.

In conclusion, laser engraving is an excellent solution for personalizing, enhancing and customizing plastic materials. It provides precision and accuracy, is non-contact, versatile, efficient, and yields a permanent mark that is of high quality. Companies and individuals alike can take advantage of these benefits for

Disadvantages Laser Engraver For Plastic

Laser engravers have become increasingly popular in the world of plastic fabrication, offering a number of advantages over more traditional methods like sandblasting, cutting or engraving. However, while laser engraving is an ideal solution for many applications, it also has some disadvantages that should be considered when choosing the right method for your project.

One disadvantage of laser engravers for plastic is that they can be quite expensive, particularly for larger or more complex projects. This is partially due to the high cost of the machinery itself, which can be as much as tens of thousands of dollars, and also due to the need for skilled operators who can ensure efficient and accurate operation of the laser system.

Another issue with laser engravers for plastic is that they can produce a range of harmful fumes and gases when cutting or engraving certain materials. These substances can be hazardous to both the operator and the environment, particularly if proper ventilation systems are not in place to control the amount of emissions.

Additionally, while laser engraving can produce intricate designs and patterns with high levels of precision, it is not well-suited for creating particularly deep or complex engravings. The depth of an engraving is limited by the power of the laser, which can only etch so deeply into the plastic material.

Despite these limitations, laser engraving continues to be a popular choice for many businesses and individuals looking to create detailed and precise plastic products. Careful consideration of the pros and cons of laser engraving, along with an understanding of the specific needs and requirements of your project, can help you determine whether this technology is the right choice for your application.

Selecting the Ideal Manufacturer Laser Engraver For Plastic

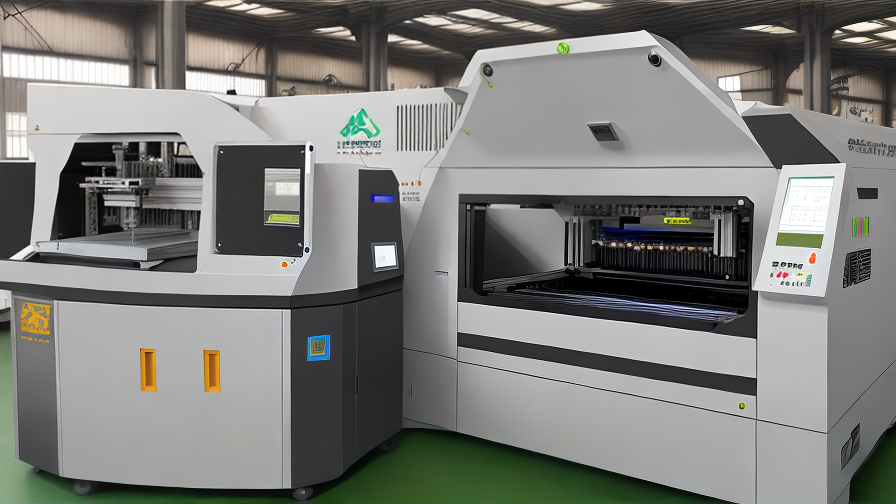

Selecting the ideal manufacturer laser engraver for plastic is crucial to ensure high-quality and precise engraving. When choosing a laser engraver, it is essential to consider several factors such as the size of the machine, the wattage of the laser, the available software, and the price.

Firstly, the size of the machine must be considered based on the requirements. If the engraving work is significant, a machine with a large engraving area will be required. Conversely, for smaller projects, a compact machine will suffice.

Secondly, the wattage of the laser should also be taken into consideration. A higher wattage laser will achieve faster and deeper engravings, allowing for more significant productivity. However, lasers with higher wattages tend to be more expensive.

Another important factor to consider is the available software. The engraving machine should come with easy-to-use software that offers a wide range of options for text, graphics, and images. This software should be compatible with most file formats and enable the import of designs from external sources.

Lastly, cost is an essential consideration when selecting a laser engraving machine. It is essential to weigh the advantages and disadvantages of different machines and select the one that offers the best value for money.

In conclusion, choosing an ideal manufacturer laser engraver for plastic requires careful consideration of several factors. The machine size, wattage of the laser, software capability, and cost should all be considered before purchasing any laser engraver. By evaluating every option based on these factors, one can select the best laser engraver that meets their requirements and budget.

Things to Consider When Purchasing Laser Engraver For Plastic

Purchasing a laser engraver for plastic can be an overwhelming task, particularly if you are new to the world of laser engraving. With so many options available, it can be challenging to decide which one is the best fit for your needs. However, consider the following factors when purchasing a laser engraver for plastic to make an informed decision.

1. Laser Power:

One of the most crucial factors to consider when purchasing a laser engraver for plastic is the laser power. The higher the laser power, the better the engraving outcome. Low-power laser engravers are suitable for simple designs, whereas a higher-power machine is ideal for complex designs.

2. Bed size:

The size of the bed is another consideration to make when purchasing a laser engraver for plastic. You’ll want to make sure the bed is big enough to accommodate the plastic pieces you’re working on while having some buffer space on each side. The larger bed size, the more versatile the machine and the more options you’ll have.

3. Software compatibility:

When purchasing an engraving machine, ensure the software is compatible with your computer, so you don’t encounter any difficulties or require additional software purchases.

4. Cooling System:

A proper cooling system is essential for a laser engraver. The laser can get extremely hot, which can disrupt the engraving process, so it’s crucial to have efficient cooling.

5. Durability:

A laser engraver for plastic is a long-term investment, so it’s crucial to get one that is sturdy and durable. Ensure that the machine is built to last so that you don’t face any maintenance or malfunctioning issues in the future.

In conclusion, while there are many factors to consider when purchasing a laser engraver for plastic, the most important thing is to ensure it aligns with your specific needs. By using the above considerations while shopping, you’ll be better positioned to find one that will serve your needs for years to come.

Properties of Laser Engraver For Plastic

Laser engraving is a popular process used to create permanent marks on various materials, including plastic. The laser engraver for plastic is a specialized device that utilizes a high-intensity laser beam to etch designs, logos, and letters onto plastic sheets.

One of the significant properties of laser engravers for plastic is precision. These machines are equipped with high-precision laser technology that provides remarkable precision and accuracy, resulting in sharp and detailed engravings. It enables users to create intricate designs on a wide range of plastics with consistent results.

Another property of laser engravers for plastic is versatility. They are compatible with various types of plastics, such as acrylics, polycarbonates, and PVC, among others. The laser engraving process does not require direct contact with the plastic, making it perfect for delicate plastics that could be damaged by traditional engraving methods such as mechanical engraving.

Laser engravers for plastics are also known for their speed. These machines utilize advanced software to streamline the design process, providing speeds up to 100 times faster than traditional engraving machines. Its high speed and precision make it ideal for industries that need to produce mass quantities of plastic components, such as in the automotive industry.

Additionally, laser engravers for plastic are eco-friendly. The process consumes less energy compared to traditional methods, and the material waste is minimal. The laser beam is focusedon the area where the design will be etched, and the process does not require any pre-treatment or cleaning, unlike other engraving methods.

In conclusion, laser engravers for plastic have several essential properties, including precision, versatility, speed, and eco-friendliness. They are essential tools for many industries that require high-speed, accurate, and consistent engraving of plastic components. Laser engraving is fast becoming the preferred option for engraving on plastics because of its efficiency and reliability.

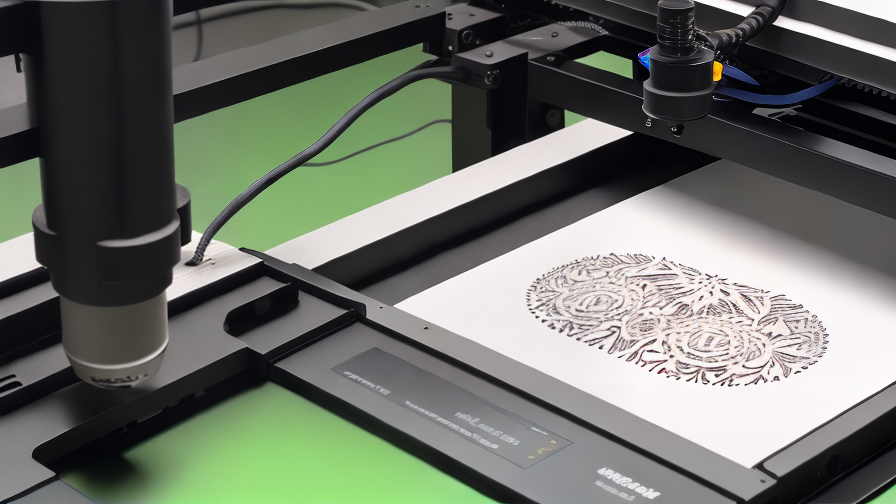

How to use Laser Engraver For Plastic

A laser engraver is a versatile tool that can be used to engrave on a wide range of materials including plastic. Plastic is a popular material as it is easy to work with, comes in a variety of colors, and is cost-effective. Here are some steps to help you use a laser engraver for plastic.

1. Choose the right plastic material – Not all plastics are suitable for laser engraving. The best plastic to use is acrylic or plexiglass as they have a high laser tolerance and can be easily engraved. Check the manufacturer’s specifications on your laser engraving machine to ensure the material you are using is safe for use.

2. Set up your laser engraver – Most engraving machines come with software that you can easily install on your computer. This software allows you to control the intensity of the laser, speeds, and power settings. You can experiment with different settings to achieve the desired results.

3. Design your image – You will need a vector file design of your image. You can create your design using vector software such as Adobe Illustrator. If you are not skilled in graphic design, you can also use pre-designed templates or purchase pre-made designs.

4. Load your plastic material – Once you have your image designed and settings in place, you can load your plastic material into the laser engraving machine. The material should be securely attached to the machine bed.

5. Engrave your design – Start the laser engraving process by pressing the start button on your machine. You can monitor the progress of your engraving on your computer screen. Once it is complete, remove the engraved plastic material.

Laser engraving is a simple and effective way to create beautiful designs on plastic materials. By following these simple steps, you can produce high-quality engravings that will stand the test of time.

Glossary Terminology Terms for Laser Engraver For Plastic

In the world of lasers, there are numerous terminologies which can be confusing, especially if you are a newcomer to the field. With the growing popularity of laser engraving on plastic, it’s important to have a good grasp of the terms that are commonly used in this area. Here’s a brief overview of the most commonly used terminology terms for laser engraver for plastic.

1. Vector Graphics: These are graphics that use mathematical formulas to create lines and shapes. They are essential for laser engraving because they can be easily scaled up or down without losing their quality.

2. Bitmapping: This refers to a specific type of image file that is made up of individual pixels. Bitmapping is not recommended for laser engraving because it can lead to a loss of quality.

3. DPI: This stands for Dots Per Inch and refers to the resolution of the image. The higher the DPI, the better the image quality will be.

4. Speed: This refers to how fast the laser is moving across the surface being engraved. A faster speed will result in a lesser quality engraving, while a slower speed will produce a higher quality engraving.

5. Power: This is the strength of the laser beam and determines how deeply it can penetrate the plastic. Higher power settings will produce deeper engravings.

6. Focus: This refers to the point where the laser beam is most concentrated. The focus needs to be adjusted depending on the thickness of the plastic being engraved.

7. Masking: This is the process of covering part of the plastic with masking tape to protect it from the laser beam. It’s important to use masking tape that can withstand the heat generated by the laser.

8. Reverse Engraving: This is the process of engraving the backside of the plastic so that the engraved image appears on the front side.

These are just a few of the numerous terminologies that are used in the world of laser engraving. By having a good understanding of these terms,

Laser Engraver For Plastic Price

Laser engraving technology has emerged as a revolutionary way to personalize and create designs on a variety of surfaces, including plastic. As the demand for customized plastic products rises, so does the need for a reliable and affordable laser engraver. But what’s the Laser Engraver For Plastic Price?

The price of a laser engraver for plastic depends on various factors like the machine’s power, cutting ability, laser type, and software compatibility. Entry-level laser engravers for plastic can cost as low as $200, while high-end models with advanced features and large work areas can go up to $20,000.

For small businesses, hobbyists, or DIY enthusiasts looking for a budget-friendly laser engraver, desktop machines with CO2 lasers are the ideal choice. These machines can perform basic cutting, engraving, and marking functions on plastic and have a price range of $200 to $5,000.

On the other hand, businesses that require high-volume production or specialized plastic materials like acrylic or polycarbonate might opt for a high-powered fiber laser engraver. These machines have faster cutting speed, higher accuracy, and are ideal for large-scale production. However, a fiber laser engraver is relatively expensive, costing between $10,000 and $20,000.

Apart from the machine’s cost, it’s essential to consider other factors that might impact its overall performance and efficiency, such as maintenance costs, software compatibility, customer support, and warranty.

In conclusion, the Laser Engraver For Plastic Price varies depending on the machine specifications, features, and brands. It’s crucial to evaluate your business needs, budget, and production goals before investing in a laser engraver for plastic. With the right machine in hand, you can personalize and create unique designs on plastic products, adding value to your business and satisfying customers’ demands.