Knowledge about Laser Engraver For Stainless Steel

Laser engraving on stainless steel is a process that requires knowledge and expertise. A laser engraver uses a high-powered laser beam to mark or cut designs and patterns on stainless steel surfaces. This technology is ideal for creating permanent markings on stainless steel components such as jewelry, medical equipment, and industrial parts.

When working with a laser engraver for stainless steel, it is important to choose the correct laser wavelength. A wavelength of 1064 nm is recommended as it provides the best results for marking and cutting stainless steel surfaces. The laser power should also be set to an appropriate level to ensure the desired depth of engraving.

Another important factor to consider when using a laser engraver for stainless steel is the type of marking involved. For example, deep engraving requires a larger beam spot size and higher laser power, while surface engraving requires a smaller beam spot size and lower laser power.

It is also vital to prepare the target surface before the engraving process. The stainless steel surface must be cleaned and degreased to ensure proper adhesion of the marking materials, which are typically applied using fiber laser or CO2 laser engraving machines.

In terms of design, the best results are achieved when using vector-based graphics software such as Adobe Illustrator or CorelDRAW. These programs allow for precise control over the shapes and patterns to be engraved, as well as the positioning and size of the engraving.

Overall, understanding the principles behind laser engraving on stainless steel is key to achieving high-quality, accurate results. By taking the time to choose the correct laser wavelength, laser power, and appropriate marking method, as well as to properly prepare the target surface and design the engraving, it is possible to create durable and impressive markings on stainless steel with a laser engraver.

Various Types of Laser Engraver For Stainless Steel

Laser engraving has become a popular method of personalizing stainless steel products such as jewelry, cookware, and metal signs. With the technological advancements in laser technology, various types of laser engravers are now available for use.

The first type is a CO2 laser engraver. This type of engraver uses a tube filled with gas, carbon dioxide, that creates the laser beam. This engraver is perfect for engraving on stainless steel jewelry, trophies, and awards. CO2 engravers are also used for engraving serial numbers and barcodes on stainless steel products.

The second type is fiber laser engravers. These engravers use a solid-state laser to engrave on stainless steel. Fiber laser engravers are more precise, faster, and more efficient. They are used for engraving intricate designs and logos on stainless steel signs or metal parts.

The third type is a diode-pumped laser engraver. This type of engraver uses crystals to amplify the laser beam. A diode laser engraver is best for small to medium-sized stainless steel parts and can also be used for marking and engraving on jewelry, surgical instruments, and firearms.

The fourth type is a green laser engraver. This type of engraver is a combination of a diode laser and a frequency-doubling crystal. It produces a green laser beam that is ideal for engraving on stainless steel, particularly precision parts.

Finally, the fifth type is an ultraviolet (UV) laser engraver. This type of engraver uses a UV laser beam to engrave on stainless steel, and it is used in the production of electronic devices, medical implants, and automotive parts.

In conclusion, laser engraving has revolutionized the way stainless steel items are customized and personalized. The various types of laser engravers available offer different benefits, depending on the type and size of the stainless steel product being engraved. Whether for commercial or personal purposes, laser engraving on stainless steel is a

FAQ sourcing Laser Engraver For Stainless Steel manufacturer from China

Looking to source a laser engraver for stainless steel from China? Here are some frequently asked questions and answers that may help you in the process:

Q: What factors should I consider when choosing a laser engraver for stainless steel?

A: Power, precision, software compatibility, and maintenance requirements are among the most important factors to consider.

Q: What is the typical power requirement for a laser engraver for stainless steel?

A: Depending on the thickness and hardness of the stainless steel being engraved, a power range of 50-100 watts is typically required.

Q: What level of precision can I expect from a laser engraver for stainless steel?

A: A high-quality laser engraver can achieve a precision of 0.001 inches or even greater.

Q: Do I need any special software to operate a laser engraver for stainless steel?

A: Yes, most laser engravers require proprietary software that is compatible with the machine’s controls.

Q: How often will my laser engraver need maintenance?

A: It depends on how frequently the machine is used and the conditions in which it is operated. In general, routine maintenance may be required every few months or so.

Q: Are there any safety considerations I should keep in mind when operating a laser engraver for stainless steel?

A: Yes, laser engravers can be hazardous if not used properly. Ensure that all safety protocols are followed and that operators are properly trained.

When sourcing a laser engraver for stainless steel, be sure to carefully evaluate your options and choose a reputable manufacturer with a proven track record of quality and customer service. With the right machine and some practice, you can create high-quality, precision engravings on stainless steel for a variety of applications.

Applications of Laser Engraver For Stainless Steel

Laser engraving is a process that involves the use of high-powered laser beams to etch designs onto a variety of surfaces. One of the most versatile materials that can be laser-engraved is stainless steel. With its toughness, durability, and corrosion resistance, stainless steel is an ideal material for a wide range of applications, and laser engraving adds to its aesthetic appeal and versatility.

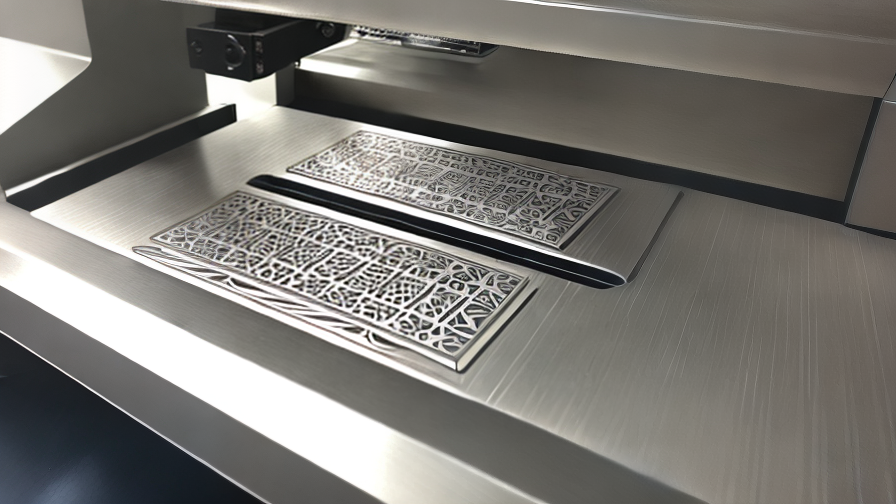

One of the most common applications of laser engraving on stainless steel is for identification and branding purposes. Stainless steel tags and plates are laser-engraved with serial numbers, logos, barcodes, and other markings that are crucial for tracking and inventory purposes. Stainless steel signs, markers, and plaques are also commonly engraved with company logos, names, product information, and other details. This helps to enhance brand recognition and promotes a professional, high-quality image.

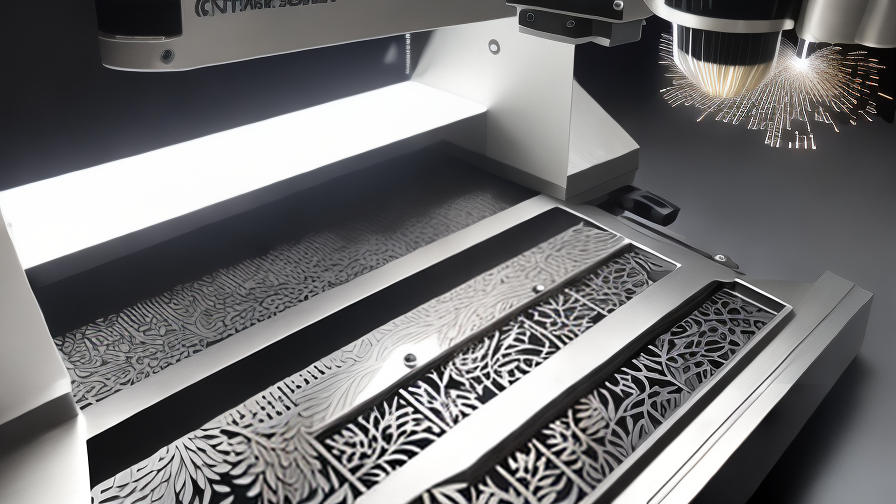

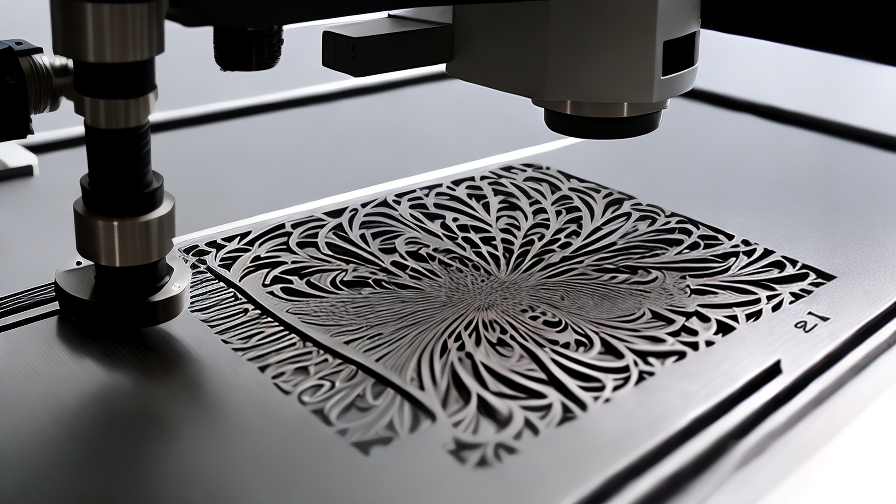

Another popular application for laser engraving on stainless steel is for decorative purposes. Stainless steel has a sleek, modern look that makes it a popular material for jewelry, gifts, and souvenirs. Laser engraving allows designers to etch intricate designs, patterns, and text onto the surface of the stainless steel, creating unique and personalized pieces. This technique is commonly used for engraved wedding bands, commemorative plaques, and personalized gifts.

Laser engraving also has applications in the industrial sector. Stainless steel parts and components used in machinery, equipment, and electronics are often engraved with identification codes, safety warnings, and other important data. This helps to ensure that the parts are installed and used correctly, and makes it easier to diagnose and repair any issues that arise.

In conclusion, laser engraving is a powerful tool for enhancing the appearance and functionality of stainless steel. From branding and identification to decorative applications, laser engraving opens up a world of possibilities for designers and manufacturers. With its combination of durability, versatility, and aesthetic appeal, stainless steel is an ideal material for laser engraving, and its applications are limited only by the imagination of the designer

Manufactured Products made of Laser Engraver For Stainless Steel

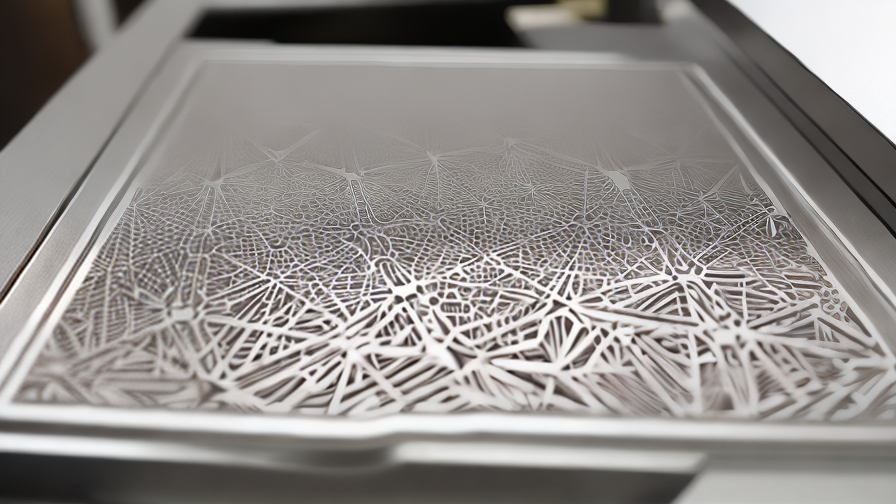

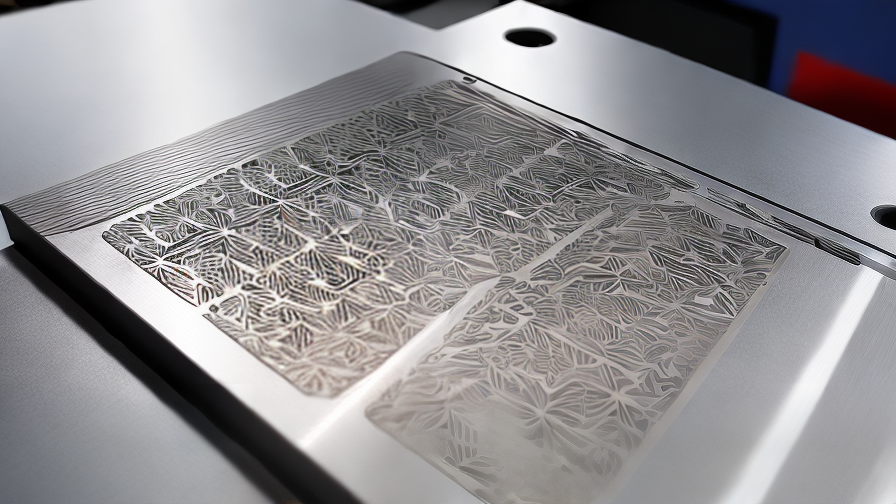

Laser engravers have revolutionized the way we produce stainless steel products. By using a concentrated beam of light, these machines can precisely etch designs onto the surface of stainless steel. This technology has made it possible to create intricate and detailed patterns that were previously impossible to achieve with traditional manufacturing techniques.

One of the advantages of using a laser engraver is that it allows for greater flexibility in design. With traditional manufacturing techniques, it can be difficult to produce complex shapes and patterns. Laser engravers, on the other hand, can produce intricate designs quickly and easily. This means that businesses can create custom products for their customers, like personalized keychains or custom-engraved jewelry.

Another advantage of using a laser engraver for stainless steel products is that it allows for greater precision. The laser beam can be controlled to create fine lines and detailed text, making it possible to produce high-quality products with a professional finish. This precision also ensures that the product is consistent in its design and quality, which is essential for building a strong and trustworthy brand.

Finally, laser engravers are an eco-friendly solution for producing stainless steel products. Compared to traditional manufacturing techniques, laser engraving uses less material and produces minimal waste. This means that businesses can reduce their environmental impact while still producing high-quality products for their customers.

In conclusion, the use of laser engravers for stainless steel products has transformed the manufacturing industry. With their ability to produce intricate designs quickly and easily, laser engravers offer businesses greater flexibility in design and a more precise final product. Additionally, their eco-friendly production process makes them an attractive option for businesses looking to reduce their environmental impact. Ultimately, the use of laser engravers is a win-win for businesses and consumers alike.

The Evolution history of Laser Engraver For Stainless Steel

The evolution history of laser engravers for stainless steel dates back to the mid-twentieth century. Initially, lasers were used for industrial purposes, such as cutting and welding metals. However, with the advancement of technology, the laser engraving technology has been adopted for personal and commercial use.

In the 1960s, laser technology was introduced commercially in the United States. In 1965, the first laser machine was introduced, but it was not until the 1980s that laser technology became widely available in the market.

Laser engraving on stainless steel began in the early 1990s. Initially, the process was slow and limited to small surface areas. However, with the advancement of technology, laser engraving has become faster and more efficient, allowing for more intricate designs and patterns to be engraved on stainless steel surfaces.

Early laser engravers for stainless steel used CO2 lasers, which had limitations in terms of accuracy and speed. However, with the advent of fiber lasers, the process has become faster and more precise. Fiber lasers are also more energy-efficient, which makes them more cost-effective in the long run.

Today, laser engraving has become a popular decorative method for personalizing stainless steel jewelry, household goods, and industrial products. It is also commonly used for marking products with serial numbers and barcodes.

As technology continues to evolve, we can expect to see even more advancements in laser engraving for stainless steel. With faster and more precise machines, the process will become more accessible to small businesses and individuals, allowing for more creative freedom in the design and customization of stainless steel products.

The Process of Laser Engraver For Stainless Steel

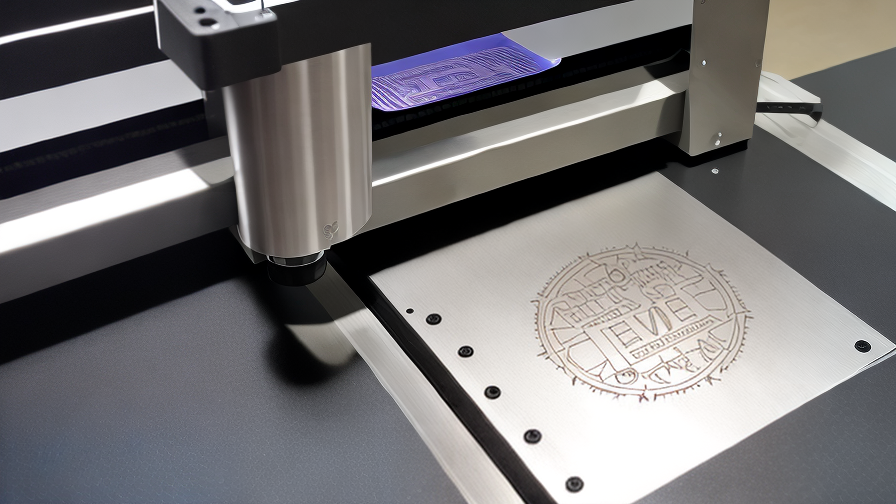

Laser engraving is a process of using a beam of concentrated light to burn an image, design or text on a surface. Stainless steel is a popular material used in industries like aerospace, automotive, and healthcare because of its durability and resistance to corrosion. The laser engraving process allows for precise and intricate designs to be permanently marked onto the stainless steel material.

The process of laser engraving on stainless steel involves several stages. The first step is to create the design or image that will be engraved onto the material. This can be done using specialized software, which allows for the creation of vector graphics, text, and even photos that can be laser engraved onto stainless steel.

Once the design is created, the stainless steel surface is cleaned thoroughly to remove any impurities or residues that could interfere with the engraving process. This is important because any particles on the surface can result in an imperfect finish.

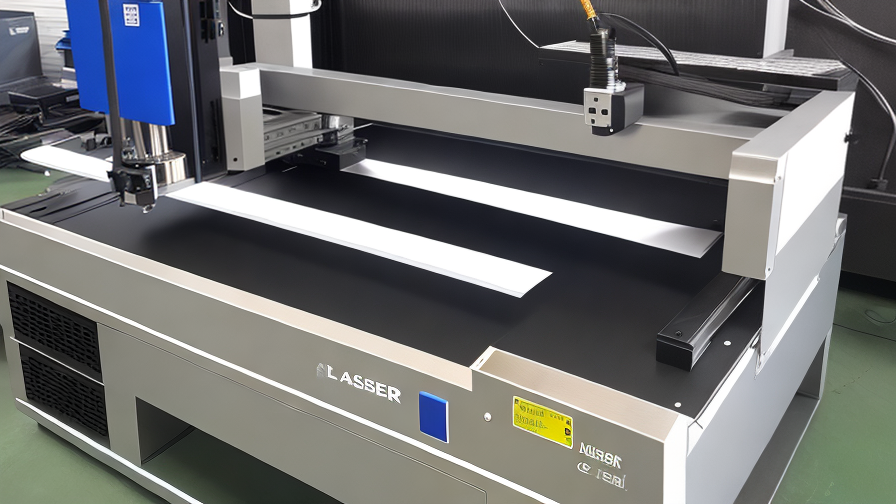

After cleaning, the stainless steel is placed onto the laser engraving machine. The machine consists of a laser beam, which is reflected onto a mirror and then directed onto the surface of the stainless steel. The laser beam is incredibly powerful and heats the surface of the stainless steel to produce a contrast between the engraved area and the background.

The depth of the engraving is controlled by adjusting the power and speed of the laser beam. The operator can adjust the intensity and speed of the beam to achieve the desired depth and accuracy.

Once the engraving is complete, the stainless steel is cleaned again to remove any debris or particles that may have accumulated during the process. The result is a permanent, high-quality design that will not fade, wear off or chip away over time.

In conclusion, the process of laser engraving on stainless steel is a precise and sophisticated process that provides high-quality results. With the use of specialized software, powerful and accurate laser beam technology, and careful attention to detail by the machine operator, laser engraving creates a permanent and long-lasting mark on the stainless steel material.

Benefits Advantages of Utilizing Laser Engraver For Stainless Steel

When it comes to engraving stainless steel, one of the most popular and efficient methods is using a laser engraver. This innovative technology has revolutionized the art of engraving, and it offers numerous benefits and advantages for businesses and individuals.

One of the most significant benefits of utilizing a laser engraver for stainless steel is the precision and accuracy it provides. Laser engraving enables you to create intricate designs and patterns that would be challenging to achieve through traditional engraving techniques. It also allows for consistent and uniform markings across large batches of stainless steel products.

Another advantage of using laser engravers is the speed and efficiency it offers. Laser engravers are incredibly fast and can complete a marking process in a matter of seconds. This is because the laser beam can engrave the stainless steel surface continuously, without any interruptions or delays. As a result, businesses can save a considerable amount of time and money, and increase their productivity levels.

Moreover, laser engraving is a cost-effective solution for businesses, as it eliminates the need for costly tooling and setup expenses. Traditional engraving methods require expensive machinery, materials, and labor, which can increase the production costs significantly. With laser engravers, on the other hand, there are no extra costs involved, and the entire process is completed quickly and efficiently.

Another benefit of using laser engravers for stainless steel is the high-quality and long-lasting markings they create. Laser engraving produces permanent and durable marks that do not fade or wear out easily, even after years of usage. This makes it an ideal option for businesses that want to create a long-lasting impression on their customers.

In conclusion, laser engraving offers numerous benefits and advantages for businesses and individuals who want to create high-quality and durable markings on stainless steel surfaces. Its precision, speed, cost-effectiveness, and long-lasting durability make it the ideal solution for marking, branding, and personalizing products.

Disadvantages Laser Engraver For Stainless Steel

Laser engraving is a highly popular and reliable method for marking and engraving metals like stainless steel. However, it also has some disadvantages that businesses and consumers should be aware of. Here are some of the main disadvantages of laser engraving for stainless steel:

1. Cost: Laser engraving machines tend to be expensive and require a significant investment upfront. This can make it difficult for small businesses or individuals on a tight budget to afford them.

2. Limited Material Range: Laser engraving is not suitable for all materials, and stainless steel is one of those that must be specially treated with anti-corrosion spray to be suitable. Therefore, restricting the range of materials that can be used compared to mechanical methods.

3. Low Depth: The engraving depth that can be achieved with a laser is typically lower than what can be achieved with traditional engraving methods.

4. Limited Creativity: Traditional engraving methods allow for greater artistic creativity and control over the design. However, laser engraving is more limited as the design is determined by the software used with the machine.

5. Maintenance Costs: Laser engraving machines require maintenance and upkeep to ensure they continue to function correctly. This can lead to additional expenses, and businesses that cannot afford to have maintenance may suffer a poor-quality engraving.

In conclusion, laser engraving is a popular and effective method for engraving stainless steel. However, it has some significant disadvantages that businesses and individuals should be aware of when deciding whether to use the method. Therefore, for applications requiring artistic creativity, traditional engraving may be more suitable, but laser engraving is an excellent option for many other applications.

Selecting the Ideal Manufacturer Laser Engraver For Stainless Steel

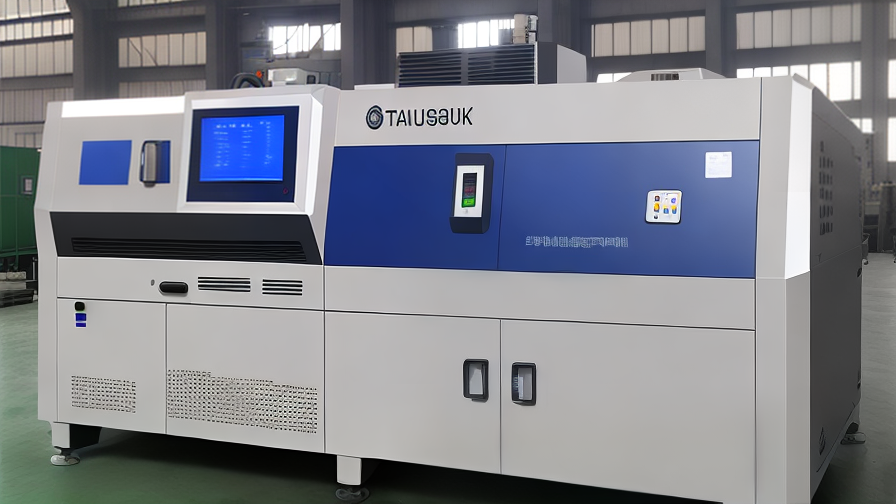

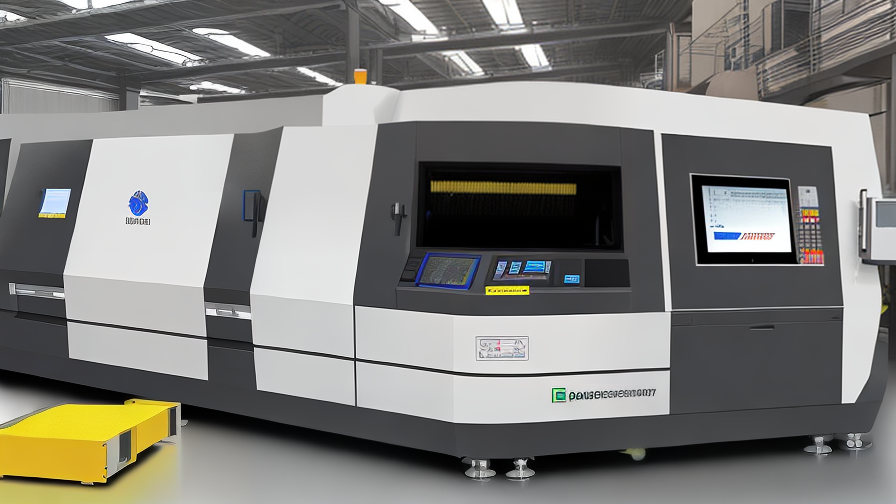

When it comes to laser engraving on stainless steel, selecting the ideal manufacturer laser engraver is vital. It is essential to choose equipment that gets the job done quickly, efficiently, and produces high-quality results.

The manufacturer’s reputation is a crucial factor to consider. There are several options in the market, but you want to choose a manufacturer with a proven track record of producing reliable and efficient machines. You can do this by researching manufacturers to see what customers say in reviews and forums.

Another aspect to look into is the laser engraver’s power and wavelength. Since stainless steel has a high melting point, you want to choose a device that offers high power output to achieve deep engravings. A wavelength of 1064 nm is also ideal as it offers high energy absorption and low reflection.

The built-in features of the machine are also essential. A good engraver should offer features such as automatic marking, adjustable focal length, and a rotary axis for curved surfaces, among others. These features help improve productivity, reduce errors, and enable versatile use.

The size of the laser engraver is also an essential consideration. If you frequently work with larger metals, you want to invest in a larger machine. However, if you only handle small items, then a smaller machine is suitable.

Lastly, price is a critical factor, but it should not be the determining factor. While it may be tempting to choose a lower-priced option, ensure you get the best value for your money. A quality laser engraver should offer a balance of features, efficiency, and affordability.

In conclusion, selecting the ideal manufacturer laser engraver for stainless steel takes time and effort. It is essential to consider the manufacturer’s reputation, power and wavelength, built-in features, size, and price. With careful evaluation, you can make an informed decision and invest in an engraver that meets your needs and delivers high-quality results.

Things to Consider When Purchasing Laser Engraver For Stainless Steel

When it comes to purchasing a laser engraver for stainless steel, there are a few things that you need to keep in mind. This type of machine is ideal for creating intricate designs and detailed engravings on metal surfaces. Here are some things to consider when purchasing a laser engraver for stainless steel.

1. Laser Power – The power of the laser is a crucial factor when choosing a engraving machine. The more powerful the laser, the deeper and wider it can engrave onto the metal surface.

2. Engraving speed – The engraving speed is also an essential factor to consider, as it determines how quickly the machine can create designs on the metal surface. A faster engraving speed can mean increased productivity.

3. Focal length – The focal length of the laser is another key consideration. It determines the distance between the focusing lens and the metal surface. A shorter focal length can produce more precise results, while a longer focal length can be useful for engraving larger areas of metal.

4. Cooling system – The cooling system of the machine must be adequate to prevent the laser from overheating. Overheating can cause damage to the machine and lead to subpar results.

5. Software – The software used to create the designs and send them to the machine is also essential. The software must be user-friendly and easy to navigate, with a range of design options and customization capabilities.

6. Cost – Finally, the cost of the machine is an important consideration. You should invest in a laser engraving machine that is within your budget, but also offers high-quality performance and durability.

In conclusion, when purchasing a laser engraver for stainless steel, you should consider laser power, engraving speed, focal length, cooling system, software, and cost. With these factors in mind, you can choose the right machine to meet your engraving needs efficiently and effectively.

Properties of Laser Engraver For Stainless Steel

A laser engraver is a versatile tool that can etch designs onto different types of materials, including stainless steel. However, not all laser engravers are created equal, and some models are more suitable for engraving on stainless steel than others. In this article, we will discuss the properties of a laser engraver that make it ideal for engraving on stainless steel.

Firstly, the laser power is an essential factor when it comes to engraving on stainless steel. Stainless steel is a hard material, and it requires a high-powered laser to cut through the surface effectively. A laser engraver with a power output of at least 50 watts is necessary to produce a deep, crisp engraving on stainless steel.

Secondly, the laser beam quality is crucial. A high-quality beam can produce intricate designs with fine details on stainless steel. The laser beam should have a small focus spot size and a well-collimated beam for precise engraving.

A third property is the cooling system of the laser engraver. Stainless steel is a material that quickly absorbs and dissipates heat, making it difficult to engrave with a laser. A laser engraver with a good cooling system, such as water-cooled, ensures that the machine operates at a consistent temperature throughout the engraving process. This helps prevent distortions or discoloration on the engraved surface.

Another factor is the accuracy of the engraving process. A laser engraver that utilizes a computer numerical control (CNC) system can provide high accuracy and repeatability, which is essential for engraving intricate designs on stainless steel. The ability to save and repeat previous designs is also useful for engraving multiple pieces with precise consistency.

In conclusion, a laser engraver that is powerful, produces a high-quality beam, has a reliable cooling system, and utilizes a CNC system, is ideal for engraving on stainless steel. Investing in a quality laser engraver with these properties will allow you to create stunning designs, logos, and artwork on

How to use Laser Engraver For Stainless Steel

Laser engraving provides a fast and accurate way to mark or etch stainless steel. With the right settings and technique, you can achieve high-quality results without damaging the material or compromising its integrity. Here’s how to use a laser engraver for stainless steel:

1. Choose the right laser and lens: Make sure your laser engraver is compatible with stainless steel, and choose a lens that’s suitable for the thickness of the material you’re working with. A CO2 laser is typically the best option for stainless steel, as it can produce sharp and precise lines.

2. Prepare your design: Use a vector-based design software to create your drawing or logo. Adjust the size and position of the design to fit the area you want to engrave on the stainless steel. Make sure the design is clean and sharp, with no pixels or fuzziness.

3. Set the laser parameters: Adjust the laser power, speed, and frequency according to the thickness and type of stainless steel you’re engraving. Optimal parameters may vary depending on the brand and model of your laser engraver, so consult the manual or ask for technical support if needed.

4. Focus the laser: Ensure the laser is properly focused on the surface of the stainless steel, as this affects the quality and precision of the engraving. Use the auto-focus function or adjust the focus manually by adjusting the Z-axis height.

5. Test the engraving: Before starting the actual engraving process, make a test run on a small piece of stainless steel to check the laser settings and the design quality. Adjust the parameters if necessary, and make sure the design is centered and aligned properly.

6. Engrave the stainless steel: Once you’ve fine-tuned the laser settings and verified the design, start the actual engraving process. Keep the stainless steel in place with clamps or magnetic holders, and ensure the laser head moves smoothly and steadily to avoid marks or scratches.

7. Clean and inspect the engraving: Once the

Glossary Terminology Terms for Laser Engraver For Stainless Steel

Laser engraving has become a popular process for personalizing various products. Stainless steel, in particular, offers a durable and long-lasting surface for laser engraving. However, understanding the terminology used for laser engraving on stainless steel can be confusing. This article aims to clarify and provide a glossary of the most common terms used in laser engraving for stainless steel.

1. Laser: A device that emits a high-powered beam of light used for laser engraving. The most common types of lasers include CO2 and fiber lasers.

2. Engraving: A process of removing material from the surface of stainless steel using a laser beam to create designs, patterns, or text.

3. Etching: A process of creating designs or text on the surface of stainless steel using a chemical reaction. It is often used in combination with laser engraving for more intricate designs.

4. DPI: Dots per inch (DPI) refers to the number of dots a laser can create per inch. The higher the DPI, the finer the details that can be engraved.

5. Power: Power refers to the intensity of the laser beam used for engraving. The power level ranges from 10 to 100 watts, and the higher the power, the deeper and faster the laser can engrave.

6. Speed: The speed of the laser beam as it moves across the surface of the stainless steel. Faster speeds result in shallower engravings, while slower speeds result in deeper engravings.

7. Vector: A vector refers to a line or path used to create a design or text that is then engraved onto the stainless steel. A vector image is created using design software and is required for laser engraving.

8. Bitmap: A bitmap refers to an image made up of pixels that is often used for printing. It is not recommended for laser engraving since the laser cannot distinguish between pixels and cannot create a sharp image.

9. Annealing: A process of heating the surface of

Laser Engraver For Stainless Steel Price

Laser engraving is a popular technique used to etch designs, logos, and text onto various materials like wood, plastic, and metal. However, when working with stainless steel, the process can be quite challenging due to its durability and strength. To achieve high-quality results, a specialized laser engraving machine that can handle the demands of stainless steel is necessary.

One of the critical factors to consider when looking for a laser engraver for stainless steel is its price. The cost of the machine depends on various aspects like the size, power, and quality of the laser beam.

Entry-level laser engravers that can handle stainless steel are typically priced between $2000 and $5000. These machines usually have a low to a moderate power range of 20 to 60 watts and a small or medium work area.

Mid-range laser engravers that are suitable for stainless steel come at a higher price range of $5000 to $10,000. These machines generally have a high-power range of 60 to 150 watts and a large working area, enabling them to work on thicker and more massive stainless steel plates.

Top-of-the-line laser engravers that can effectively etch stainless steel are priced above $10,000. These machines have a high-power range of over 150 watts and a large work area suitable for industrial-grade projects.

It is important to note that the laser engraver’s price is not the only factor to consider when purchasing a machine that can handle stainless steel. Other essential features include ease of use, accuracy, speed, and durability.

In conclusion, laser engraving on stainless steel requires specialized equipment that can handle the metal’s strength and durability. The cost of a laser engraver for stainless steel can range from a few thousand to tens of thousands of dollars, depending on its features and capabilities. Therefore, it is important to consider various factors before purchasing a machine to ensure efficient and high-quality results.