Knowledge about Laser Engraving Machine For Metal

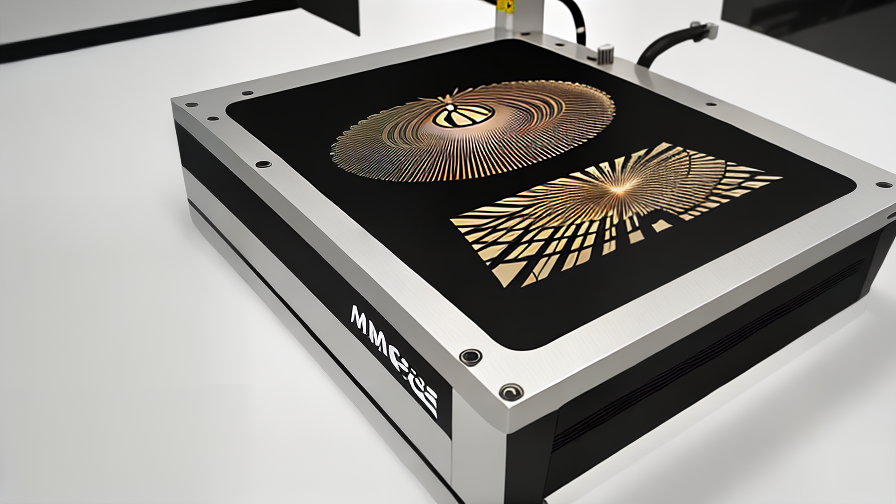

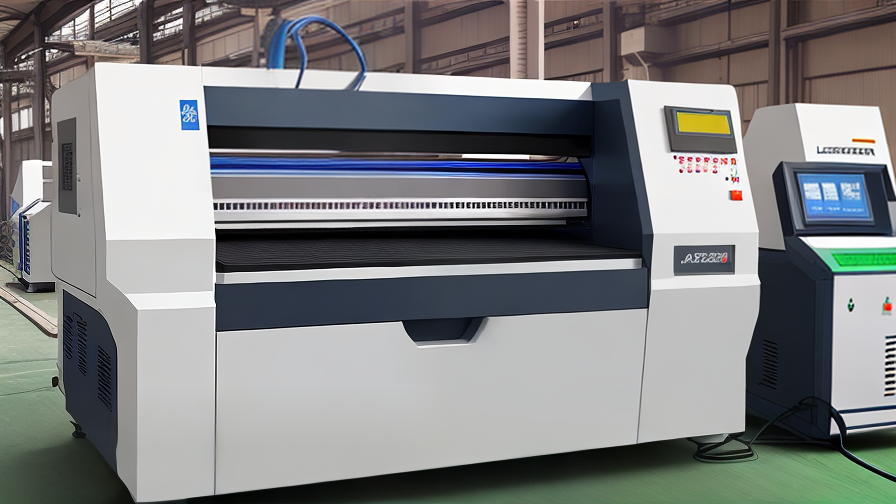

Laser engraving machines for metal are gaining popularity due to their ability to produce clean and precise engravings. This technology uses a high-powered laser beam to etch designs onto the surface of metal objects.

There are various types of laser engraving machines that can be used on metal including CO2, fiber, and diode lasers. CO2 lasers produce the highest quality engravings while fiber lasers are faster and more efficient. Diode lasers are the most cost-effective option but are not suitable for large-scale projects.

One of the many advantages of laser engraving on metal is that it is a non-contact process, meaning there is no physical contact between the machine and the material. This reduces the risk of damage or distortion of the metal. Laser engraving also allows for intricate designs with a high level of detail and accuracy.

Before engraving metal, it is important to ensure that the surface is clean and free from oils, dust, and other particles. Any impurities on the metal could affect the quality of the engraving.

The design to be engraved is first uploaded to the machine’s software, which then guides the laser over the metal surface to create the design. It is essential to select the correct power setting and speed for the laser for the desired result.

Timing is also a crucial aspect of laser engraving. The length of time that the laser is applied to the metal determines the depth of the engraving. It is important to consider the thickness and hardness of the metal being engraved as this can impact the length of time required for the laser to adequately etch the design.

In conclusion, laser engraving machines for metal have revolutionized the way in which designs are etched onto metal surfaces. With the ability to produce precise and intricate designs, it is no surprise that laser engraving is becoming increasingly popular in the metalworking industry.

Various Types of Laser Engraving Machine For Metal

Laser engraving is a technique that uses a laser beam to etch designs on a metal surface. This technology is versatile, precise and efficient, making it an ideal option for a variety of engraving applications. Here are the various types of laser engraving machines for metal:

1. CO2 Laser Engravers – this type of laser engraving machine is ideal for engraving organic materials, including wood, leather, and plastics. It uses a carbon dioxide-based gas mixture to create the laser beam.

2. Fiber Laser Engravers – this type of laser engraving machine is ideal for engraving metals and alloys. It uses a fiber optic laser beam to produce high-quality and precise engravings.

3. Diode Laser Engravers – this type of laser engraving machine is best for high-speed marking and engraving on metal surfaces. It uses a PC board in conjunction with a diode laser beam to create the engravings.

4. YAG Laser Engravers – this type of laser engraving machine is suitable for use with metals and crystalline materials. It uses a Nd:YAG (neodymium-doped yttrium aluminum garnet) crystal as the laser medium.

Each type of laser engraving machine has its unique application and benefits. Some, like the CO2 laser engravers, are versatile enough to handle a variety of materials, while others, like the YAG laser engravers, are more specialized for specific materials.

In conclusion, laser engraving is a precise and efficient technology for metal engraving. The type of machine used depends on the type of material being engraved and the desired outcome. Whether you are looking to engrave aluminum, steel, brass, or other metals, there is a laser engraving machine that can do the job.

FAQ sourcing Laser Engraving Machine For Metal manufacturer from China

If you’re looking to source a laser engraving machine for metal from a manufacturer in China, you’re likely to have some questions. Here are some frequently asked questions (FAQs) and answers that can help you make an informed purchase decision.

Q. What type of laser should I choose for metal engraving?

A. Fiber laser is the best option for metal engraving because it has a high power density and can effectively etch on metals like stainless steel, aluminum, brass, and copper.

Q. What is the maximum thickness of metal I can engrave?

A. The thickness of material you can engrave is dependent on the wattage of your laser machine. A common machine of 20W can engrave on metals with a thickness of up to 1.5 mm while another that has 30W can handle up to 2mm. The ideal power level will depend on the type of metal you’re engraving on.

Q. What kind of software do I need to operate my laser engraving machine?

A. Most manufacturers will provide the necessary software for the machine. Some common software include LaserGRBL, LightBurn, and RDWorks. Just make sure the software is compatible with the laser engraving machine you purchase.

Q. How do I maintain my laser engraving machine?

A. Regular cleaning, lubrication, and alignment checks need to be maintained. Ensure that your machine is kept in a clean environment, as dust accumulation can negatively affect the performance of your machine. You should also keep an eye on the laser tube, lens and mirrors for cleaning and possible replacements when needed.

Q. What is the lead time for delivery?

A. Lead times vary depending on the supplier, but it typically ranges between 7 to 30 days.

In conclusion, buying a laser engraving machine from a manufacturer in China can be a great investment if you ask the right questions. Make sure to consider the wattage, software, maintenance, and lead time to ensure you

Applications of Laser Engraving Machine For Metal

Laser engraving machines are widely used in the metal industry for their high precision and speed. The use of laser technology in metal engraving has replaced the traditional methods of etching, stamping, and milling. The applications of laser engraving machines for metal are numerous, and they include:

1. Personalized Gift Items: Laser engraving machines can create custom designs on metal gift items like keychains, bracelets, and jewelry. Personalized gifts appeal to customers who are looking for unique and one-of-a-kind gifts.

2. Nameplates and Identification Plates: Industrial and commercial settings require durable nameplates and ID plates to identify machinery, equipment, and products. Laser engraving machines can create high-quality nameplates and ID plates that can withstand harsh environments.

3. Customized Signs: Customized metal signs are used for indoor and outdoor signage. Laser engraving machines can engrave lettering and logos onto metal plates that can be affixed to walls, doors, and fences.

4. Metal Labels: Laser engraving machines can create high-quality metal labels that are used for inventory management, asset tracking, and identification purposes. The labels can be attached to products, equipment, and machinery for easy identification.

5. Decorative Metal Engraving: Metal engraved decorations are popular in the automotive and jewelry industries. Laser engraving machines can create intricate designs on metal surfaces that can add a unique touch to products.

6. Electronic Components: Laser engraving machines are used to mark electronic components with serial numbers, logos, and other essential information. The marks are permanent and can withstand harsh environments, making it easy to track products and manage inventory.

In conclusion, the applications of laser engraving machines for metal are vast and varied. The technology has revolutionized the metal engraving industry, making it possible to create unique and high-quality designs quickly and efficiently. Whether it’s personalized gifts or industrial labels, laser engraving machines make it possible to add a custom touch to metal products.

Manufactured Products made of Laser Engraving Machine For Metal

Laser engraving machines are a game-changer in the manufacturing industry. This cutting-edge technology can engrave any metal surface with incredible precision and speed, making it a go-to tool for manufacturers who want to create high-quality products that are both functional and visually appealing.

One of the most significant advantages of laser engraving machines is their versatility. They can engrave intricate designs, text, and logos on a variety of metal surfaces such as brass, stainless steel, and aluminum. This allows manufacturers to create products that stand out from the competition and add value to their brand.

One popular product that is made using laser engraving machines is metal business cards. These cards offer a unique and professional way to introduce yourself or your business. The precision of the laser ensures that the text and design are crisp and clear, making a lasting impression on potential clients.

Another product that utilizes laser engraving machines is custom jewelry. Laser engraving machines can engrave intricate designs and text onto metal, allowing jewelry manufacturers to create unique pieces for their customers. This technology also allows for the engraving of serial numbers or barcodes, which can be used for tracking and authenticity purposes.

Laser engraving machines can also be used to create awards and trophies. The precision of the laser allows for the engraving of detailed images and text, making each award or trophy unique and special. These products can be used for a variety of events, including corporate awards ceremonies, graduation ceremonies, and sporting events.

In conclusion, laser engraving machines offer manufacturers a versatile and precise way to create high-quality products that stand out. Business cards, jewelry, and awards are just a few examples of the products that can be made using these machines. With the demand for unique and personalized products on the rise, laser engraving technology is poised to play an even more significant role in the manufacturing industry in the coming years.

The Evolution history of Laser Engraving Machine For Metal

Laser engraving machines have come a long way since their inception. These machines utilize the power of focused laser beams to engrave designs onto metal surfaces. This technology has revolutionized the way we produce metal products, as it allows for greater precision and faster production times.

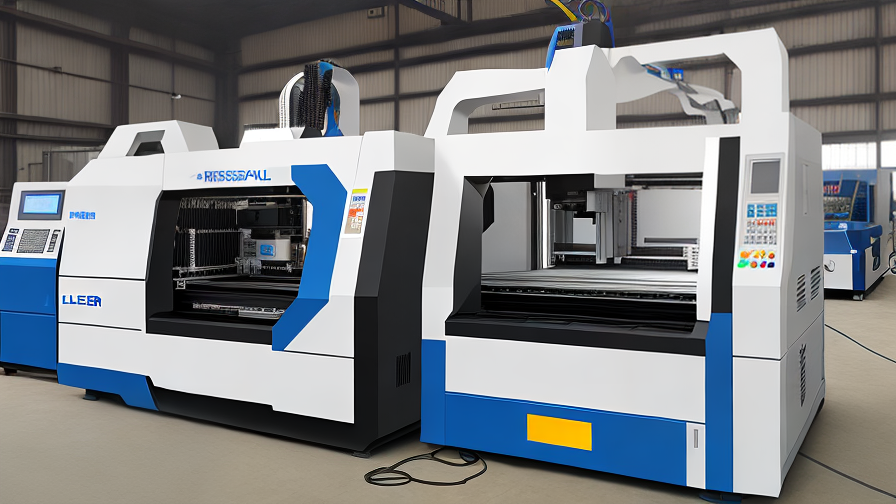

The first laser engraving machine for metal was developed in the early 1960s, but it was not until the 1980s that they became commercially available. These early machines were quite large and expensive, and they could only engrave simple designs onto metal. However, they paved the way for further development of the technology.

In the early 2000s, advances in laser technology led to the development of smaller and more affordable laser engraving machines. These machines were capable of engraving more complex designs onto a variety of metals, including stainless steel, aluminum, copper, and brass.

Today, laser engraving machines for metal have become an essential tool for many businesses in the metalworking industry. They are used to create customized products for a variety of industries, including aerospace, automotive, jewelry, and medical.

The most significant advancement in recent years has been the development of fiber lasers. These lasers are more powerful than traditional CO2 lasers, allowing for faster engraving speeds and greater precision. They are also more energy-efficient and longer-lasting, making them a cost-effective solution for businesses.

In conclusion, the evolution of laser engraving machines for metal has been marked by significant advancements in technology. From the bulky and expensive machines of the past to the smaller and more affordable machines of today, this technology has revolutionized the way we produce metal products. As technology continues to evolve, we can only expect laser engraving machines for metal to become even more sophisticated and efficient in the years to come.

The Process of Laser Engraving Machine For Metal

Laser engraving machines for metal are becoming increasingly popular in various industries, from jewelry-making to automotive manufacturing. These machines use focused beams of light to etch designs, patterns, and text onto metal surfaces. The process of laser engraving can be broken down into several steps.

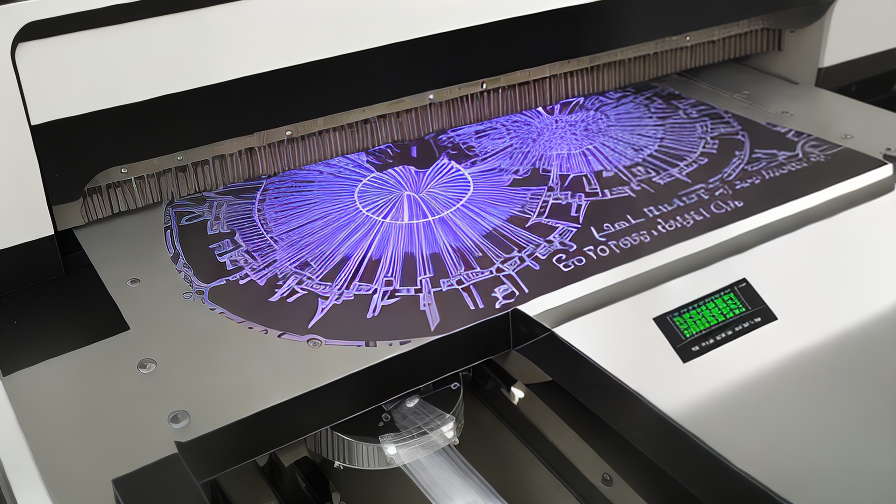

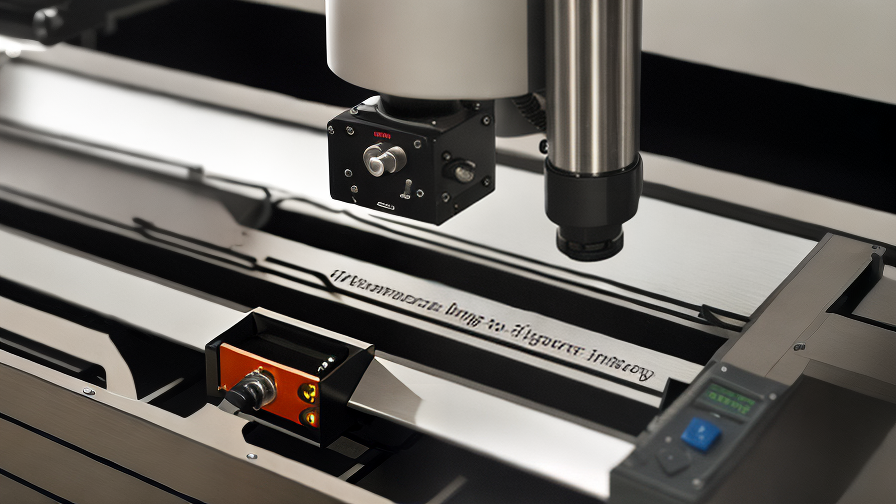

First, the design to be engraved is created using computer software. This design is then uploaded to the laser engraving machine, which uses it as a guide for the etching process. The metal object to be engraved is then placed onto the machine’s work surface.

The laser engraving machine is equipped with a laser beam that is directed onto the metal surface. The laser is capable of removing tiny portions of the metal, allowing the design to be etched into the surface. The laser beam is very precise, and can create very detailed designs in the metal.

The duration of the laser engraving process varies depending on the size of the design and the depth of the engraving required. After the engraving is complete, the metal object is removed from the machine and inspected to ensure that the design is correctly etched into the metal.

The final step is to clean the metal object to remove any debris or remnants from the engraving process. The metal is then polished to make the design stand out and give it a finished look.

Overall, the process of laser engraving for metal is a precise and effective way to etch designs onto metal surfaces. The use of computer software and laser technology makes it possible to create detailed and intricate designs that would be difficult or impossible to achieve with traditional engraving methods.

Benefits Advantages of Utilizing Laser Engraving Machine For Metal

Laser engraving machines are a modern marvel, designed to create intricate designs on different materials using a high powered laser. When it comes to metal, utilizing laser engraving machines has several benefits and advantages, especially for jewelry makers, manufacturers, and machine builders.

Firstly, laser engraving machines offer a high level of accuracy when it comes to marking products. Compared to traditional methods of engraving, laser engraving machines can engrave intricate designs precisely and consistently. This ensures that the finished products have unparalleled quality, ensuring that they are of the highest standard.

Secondly, laser engraving machines can work on a variety of metals from stainless steel to titanium. This is an essential advantage when dealing with multiple product varieties. Laser engraving machines can also be tailored to meet specific marking requirements or product specifications, making them ideal for customizations in jewelry designs and manufacturing.

Thirdly, compared to other types of engraving, laser engraving is fast and efficient. This can speed up production times in a manufacturing process, decreasing the overall production costs.

Fourthly, laser engraving machines are incredibly flexible, enabling you to engrave unique designs and logos on your products at a fraction of the cost of using traditional methods. This can lead to increased brand recognition and customer loyalty.

Lastly, laser engraving machines are eco-friendly, producing very little waste and having a minimal environmental impact. This is because the lasers used to cut and engrave are computer-controlled and require no physical contact, reducing the release of hazardous chemicals.

In conclusion, investing in a laser engraving machine for metal is a wise choice for any jewelry maker, manufacturer, and machine builder. The benefits of using a laser engraving machine are clear: it’s fast, efficient, accurate, and cost-effective, and it provides unparalleled quality and flexibility in customization.

Disadvantages Laser Engraving Machine For Metal

Laser engraving machines for metal are becoming increasingly popular in the manufacturing industry. However, despite their many advantages, they also have some disadvantages.

One of the biggest disadvantages of laser engraving on metal is that the process can create a lot of heat, which can sometimes warp or distort the metal. This can be especially problematic when working with thinner metals, which are more susceptible to warping.

Another disadvantage is that laser engraving can only be done on certain types of metal. For example, metals that contain a high amount of reflective materials or special alloys may not be suitable for laser engraving. This can limit the types of products that can be produced using this process.

Laser engraving machines for metal can also be expensive. While the cost of these machines has come down in recent years, they still represent a significant investment for most businesses. Additionally, maintenance costs can also be high, especially if the machine is being used on a regular basis.

Another potential issue is that the final product may not always be as high-quality as the buyer would like. If the metal being engraved is not properly prepared, the engraving may appear dull or uneven. This can lead to customer dissatisfaction and loss of future business.

Finally, laser engraving machines for metal can be time-consuming to set up and operate. The process typically requires the use of specialized software and training, which can add to the overall cost of using the machine.

In conclusion, despite the many benefits of laser engraving machines for metal, they also have some inherent disadvantages. Businesses that are considering investing in this technology should carefully weigh the pros and cons before making a decision.

Selecting the Ideal Manufacturer Laser Engraving Machine For Metal

Selecting the ideal laser engraving machine for metal can be a daunting task, given the numerous options available. Here are some tips to help you make the right choice:

1. Consider the type of metal you will be engraving: Different metals have different properties that will affect the laser engraving process. Make sure the machine you select is compatible with the type of metal you will be using.

2. Required precision: If you require high precision engraving, you will need a machine with high-resolution optics.

3. Power output: The power of the laser will affect your machine’s ability to engrave to a certain depth. Before purchasing a machine, determine the depth at which you need to engrave and ensure that the machine has enough power to handle it.

4. Ease of use: Choose a machine that is easy to operate, especially if you are a beginner. Look for software that is user-friendly and has easy-to-follow instructions.

5. Maintenance: Consider the machine’s maintenance requirements, and decide whether you are willing to spend the time and money required to maintain it.

6. Customer support: Look for a manufacturer that offers good customer support. It is important to be able to get help quickly when you encounter technical difficulties.

Laser engraving machines are a great investment for any business that engraves metals. Take your time to research and compare different models before making your final decision. By considering the factors above, you can select the ideal machine that will meet your business requirements.

Things to Consider When Purchasing Laser Engraving Machine For Metal

When purchasing a laser engraving machine for metal, there are certain important factors to consider in order to make an informed decision. Here are some of the things to consider:

1. Laser Type

The type of laser varies depending on the metal to be engraved. CO2 lasers are great for general use, while fiber lasers are better suited for metals like aluminum and stainless steel.

2. Engraving Speed

The speed of the machine is important as it can affect productivity. The speed of the machine may depend on the laser type as well as the size and power of the machine.

3. Power Output

The amount of power the machine puts out determines the strength of the laser beam. Larger materials require higher power settings for deeper engraving. The power output required may also depend on the type of metal to be engraved.

4. Engraving Area

The size of the engraving area determines the maximum size of the material that can be engraved. It’s important to consider the size of the material and the size of the machine before making a purchase.

5. Software and Compatibility

The software used is important as it determines the accuracy and precision of the engraving. It’s essential to confirm that the software is compatible with the computer system being used to run it.

6. Cost

The cost of a laser engraving machine varies depending on the size, power, and features of the machine. It’s important to set a budget and find a machine that fits within the budget and has the required features.

In conclusion, when purchasing a laser engraving machine for metal, it’s important to consider the type of laser, engraving speed, power output, engraving area, software and compatibility, and cost. With careful consideration of these factors, one can purchase the right machine and have productive results.

Properties of Laser Engraving Machine For Metal

Laser engraving machines have become a preferred choice for metal engraving due to their precision, durability and cost effectiveness. They are used in a range of applications such as metal fabrication, jewelry making, signage, and parts manufacturing.

One of the most important properties of a laser engraving machine for metal is its power. The power of the laser determines the intensity of the beam and therefore the speed and depth of the engraving. The higher the power of the laser, the faster and deeper the engraving.

Another important property is the wavelength of the laser. The wavelength determines the type of metal that can be engraved. For example, a fiber laser with a wavelength of 1064 nm is suitable for engraving metals like copper, silver, steel and titanium. On the other hand, a CO2 laser with a wavelength of 10.6 μm is used for engraving non-metal materials like wood, leather and plastics.

The size of the engraving area is also a key property to consider. Laser engraving machines for metal typically come in different sizes and abilities to accommodate various needs. Some machines have a smaller engraving area, ideal for small and intricate pieces, while others have a larger engraving area, which is better suited for larger and more complex projects.

Software compatibility is another important property that should be considered. The software controls the laser and provides the necessary graphics for engraving. The software should be compatible with the computer and the operating system.

Finally, the cost is an important factor when choosing a laser engraving machine for metal. Prices vary depending on the size, power, and features of the machine. It is important to consider the cost of maintenance, repair and replacement of parts as well when making a decision.

In conclusion, laser engraving machines for metal offer a range of benefits including precision, durability and cost effectiveness. When choosing a machine, it is important to consider properties such as power, wavelength, engraving area, software compatibility and cost. With these factors

How to use Laser Engraving Machine For Metal

If you are looking for a way to personalize your metal items or create unique designs on them, laser engraving is the perfect solution. The laser engraving machine is a great tool that makes the process easy and efficient. Here are some steps to help you use the laser engraving machine for metal.

Step 1: Choose the Right Laser Engraving Machine

The first step in using the laser engraving machine for metal is to select the right machine that is specifically designed for metal engraving. The machine should have a powerful laser that can effectively engrave on metals.

Step 2: Prepare The Design

Once you have selected the right machine, the next step is to prepare the design you want to engrave. You can use a computer-aided design (CAD) software to create the design. Ensure that the design is suitable for metal engraving, and it is in a compatible format with the engraving machine software.

Step 3: Set Up The Engraving Area

After preparing the design, the next step is to set up the engraving area. This involves attaching the metal to the engraving bed securely. It’s important to ensure that the metal is level, and the engraving bed’s dimensions match the design’s size.

Step 4: Setup The Laser Engraving Machine

The fourth step is to set up the laser engraving machine. This includes selecting the right laser settings that suit your metal’s material, thickness, and hardness. You can adjust the laser settings using the software that comes with the machine.

Step 5: Start Engraving

The final step is to start the engraving process. Once the laser settings are correctly configured, hit the start button on the laser engraving machine. The laser will start engraving the design onto the metal accurately.

To sum up, laser engraving is a fantastic solution for engraving and customizing metal items. With the right laser engraving machine and correct settings, you can produce quality en

Glossary Terminology Terms for Laser Engraving Machine For Metal

Laser engraving machines for metal are an essential tool for engravers, jewelers, and various manufacturing industries. These machines offer precise and detailed markings on metal surfaces that cannot be achieved by using traditional methods. Although it might be a daunting task to understand the technical jargon that comes with laser engraving machines, having knowledge of the essential terminology associated with using these machines can be beneficial. Here are some essential glossary terminology terms involved in laser engraving machines for metal:

1. Laser cutter- This is a device that creates the laser beam that is used to engrave the metal surface.

2. Wattage- This term refers to the power output of the laser and is an essential factor in determining the speed and precision of the engraving.

3. Focal length- This term refers to the distance between the laser beam and the metal surface. It is essential to have the correct focal length for optimum engraving results.

4. DPI or Dots Per Inch- This term refers to the resolution of the engraving, where a higher DPI creates a more precise and detailed engraving.

5. Vector graphics- This term refers to an image that is created using mathematical shapes that are either filled with colors or are outlines.

6. Raster graphics- This term refers to an image that is created using pixels, where each pixel has its color value, creating the illusion of a continuous-tone image.

7. CNC machine- This term refers to a computer-controlled machine that can be programmed to perform various engraving functions.

8. Etching- This term refers to the use of chemicals or lasers to create a design on the metal surface by removing specific portions of the metal.

In conclusion, understanding the essential glossary terminology terms related to laser engraving machines for metal is vital in achieving the best results. With the correct understanding of these terms, engravers can be more confident and efficient in their work, ultimately producing high-quality engravings.

Laser Engraving Machine For Metal Price

Laser engraving machines are now an essential part of the modern industry. They help in creating precise and intricate designs on various materials, including metal. However, the price of a laser engraving machine for metal can vary based on the manufacturer, features, and size. In this article, we will discuss the laser engraving machine for metal price.

The cost of a laser engraving machine for metal depends mostly on the type of laser technology it uses. The CO2 laser engraving machines for metal cost between $5,000 and $20,000. However, fiber laser engraving machines, which are far more advanced, can cost up to $100,000. The fiber laser machines are more expensive as they offer higher precision, faster processing, and better engraving quality.

The price of laser engraving machines for metal also varies based on their size. Smaller machines will come at a lower cost, with a starting price of around $3,000. The bigger machines, on the other hand, will cost tens of thousands of dollars. For example, the Trotec Speedy 400 laser engraving machine for metal, which is one of the most popular in the market, costs around $22,000.

However, when it comes to purchasing a laser engraving machine, the price should not be the only factor to consider. Other important factors include the machine’s reliability, durability, features, ease of use, and customer support. Investing more in a quality machine from a reputable manufacturer will pay off in the long run as it will last longer and offer better performance and functionality.

In conclusion, the cost of laser engraving machines for metal can vary significantly, depending on the type of laser technology and size. It is essential to consider other factors besides price, including quality and support when selecting a laser engraving machine for metal. Investing in a higher-end machine may seem expensive, but it’s worth considering the long-term benefits.