Introduce about laser engraving machine price guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

Laser engraving machines are widely used in various industries for their precision, efficiency, and versatility. When considering purchasing a laser engraving machine, several factors need to be taken into account, including price, quality, cost, supplier, certification, market availability, and some beneficial tips.

In terms of pricing, laser engraving machines can have a broad price range, typically ranging from a few hundred dollars to several thousand dollars, depending on factors such as power, size, and features. It is important to choose a machine that suits your specific engraving needs while keeping your budget in mind.

Quality is a critical aspect to consider while purchasing a laser engraving machine. Higher quality machines often offer better precision, longer lifespan, and more reliable performance. It is recommended to opt for well-known brands and read customer reviews or seek expert advice to ensure you are investing in a high-quality machine.

The total cost of a laser engraving machine goes beyond its initial purchase price. Other costs to consider include maintenance, replacement parts, electricity consumption, and training if required. It is advisable to consult with the supplier or manufacturer to get a clear understanding of the overall costs.

Choosing a reputable supplier is crucial to ensure good after-sales service, technical support, and warranty coverage. Research and compare different suppliers, read customer feedback, and consider factors such as shipping options and delivery time.

Certification, such as CE or FDA compliance, indicates that a laser engraving machine meets specific safety standards and regulations. Ensure that the machine you choose has the necessary certifications to avoid any legal or safety issues.

The market for laser engraving machines is expanding rapidly, driven by various industries such as manufacturing, jewelry, advertising, and crafts. It is essential to assess the market demand, competition, and future growth potential before making a purchase.

Here are some tips to consider: accurately assess your engraving needs, consider the material compatibility of the machine, evaluate the software and user interface, and explore additional features or accessories that may enhance your engraving capabilities.

Frequently Asked Questions (FAQs) will vary depending on individual needs, but common questions revolve around machine performance, compatibility, maintenance, and technical support. It is advisable to consult with the supplier or manufacturer to address any specific concerns or queries.

In conclusion, considering the price, quality, cost, supplier, certification, market availability, and beneficial tips is essential when purchasing a laser engraving machine. By thoroughly researching and carefully assessing these factors, you can make an informed decision that aligns with your specific requirements.

Types of laser engraving machine price

There are several factors that determine the price of a laser engraving machine. Here are some of the common types of laser engraving machines and their price ranges:

1. Desktop/Personal Laser Engravers: These machines are compact and designed for small-scale projects. They are suitable for hobbyists and small businesses. The price range for desktop laser engravers is typically between $200 and $3,000.

2. CO2 Laser Engravers: CO2 laser engravers are versatile machines that can engrave on materials like wood, acrylic, glass, and leather. They are commonly used in small to medium-sized businesses. The price range for CO2 laser engravers starts from around $3,000 and can go up to $20,000 or more, depending on the size and specifications.

3. Fiber Laser Engravers: Fiber laser engravers are primarily used for metal engraving and marking applications. They are known for their high precision and speed. The price range for fiber laser engravers starts from around $8,000 and can go up to $100,000 or more, depending on the power and capabilities.

4. Galvo Laser Engravers: Galvo laser engravers are designed for high-speed and high-precision engraving on small and curved objects. They are commonly used in the jewelry and electronics industries. The price range for galvo laser engravers starts from around $15,000 and can go up to $100,000 or more.

5. Large Format Laser Engravers: Large format laser engravers are used for engraving and cutting large materials like acrylic sheets, wood panels, and signage. They are typically used in industrial settings. The price range for large format laser engravers starts from around $15,000 and can go up to $100,000 or more, depending on the size and specifications.

It is important to note that these price ranges are approximate and can vary depending on the brand, specifications, and additional features offered by the manufacturer. Furthermore, prices may also fluctuate over time due to market demand and technological advancements in the industry.

Pros and Cons of Using laser engraving machine price

Pros and Cons of Using Laser Engraving Machine:

Laser engraving machines have become popular in various industries due to their precision and versatility. However, like any other technology, there are pros and cons associated with their use. Here are some key points to consider when evaluating laser engraving machines:

Pros:

1. Precision: Laser engraving machines offer unparalleled precision, allowing for detailed and intricately engraved designs. This precision is especially beneficial for industries that require intricate designs or small text.

2. Versatility: Laser engraving machines can work on a wide range of materials, including wood, metal, glass, plastic, and more. This versatility makes them suitable for various industries, including manufacturing, jewelry making, and signage.

3. Speed: Laser engraving machines can complete tasks quickly, which is a major advantage for businesses with high production demands. The speed of laser engraving machines can lead to improved efficiency and reduced production time.

4. Automation: Many laser engraving machines are highly automated, allowing for easy setup and minimization of human error. These machines often come with user-friendly software that enables a seamless engraving process.

5. Customization: Laser engraving machines enable businesses to offer custom products to customers, increasing customer satisfaction and potentially leading to higher sales. This customization capability is particularly valuable for the personalization of items like jewelry, awards, and promotional products.

Cons:

1. Initial Cost: Laser engraving machines can be expensive to purchase, making them a significant investment for businesses. Additionally, maintenance and replacement parts can also add to the overall cost.

2. Training Required: Operating a laser engraving machine requires training to ensure safe and accurate use. As a result, businesses may need to invest time and resources in training their employees or hiring skilled operators.

3. Limited Depth: While laser engraving machines offer precision, they have limitations when it comes to engraving depth. The depth of the engraving can vary depending on the material being engraved and the power of the laser, which may not be suitable for some applications.

4. Safety Measures: Laser engraving machines utilize high-powered lasers, which can be hazardous if not used properly. Businesses need to implement safety measures and provide appropriate protective equipment to ensure the well-being of operators.

5. Material Limitations: Although laser engraving machines can work with a wide range of materials, there are some materials that are not suitable for laser engraving. Materials such as reflective metals, certain plastics, and ceramics may not engrave well or can even be damaged during the process.

In conclusion, laser engraving machines offer numerous benefits in terms of precision, versatility, speed, automation, and customization. However, businesses need to consider the initial cost, training requirements, limitations of engraving depth, safety measures, and material compatibility before investing in a laser engraving machine. By carefully evaluating these factors, businesses can determine if a laser engraving machine is the right investment for their specific needs.

laser engraving machine price Reference Specifications (varies for different product)

Laser engraving machines are highly versatile and efficient tools used for engraving designs, patterns, and markings on various materials like wood, metal, glass, plastic, and more. The price of a laser engraving machine can significantly vary based on several factors such as the machine’s features, power, build quality, brand, and additional accessories.

Entry-level laser engraving machines typically have lower power capabilities, ranging from 20 to 60 watts. These machines are suitable for engraving on softer materials like wood or acrylic. Their prices can range from $200 to $3,000, depending on the brand and quality.

Mid-range laser engravers have higher power outputs, ranging from 60 to 100 watts. These machines are more versatile and can engrave on a wider range of materials, including metals. The price range for mid-range laser engraving machines is usually between $3,000 and $10,000.

High-end laser engraving machines are powerful and capable of engraving on all types of materials with precision. These machines typically have power outputs above 100 watts and provide features like rotary engraving capability or advanced autofocus systems. The price for high-end laser engraving machines can range from $10,000 to $50,000 and even more.

Additionally, the price of laser engraving machines can vary based on the size of the working area. Smaller machines with a working area of around 12×12 inches are generally less expensive, while larger machines with a working area of 24×36 inches or more will have higher prices.

It is important to consider the additional costs associated with laser engraving machines, such as maintenance, software, and accessories like rotary attachments or air compressors.

Overall, the price range for laser engraving machines is wide and depends on the specific needs and requirements of the user. It is recommended to conduct thorough research, compare prices, and consider the intended applications before making a purchase to ensure the machine’s suitability and value for money.

Applications of laser engraving machine price

Laser engraving machines have a wide range of applications across various industries due to their precision, versatility, and efficiency. The price of laser engraving machines depends on various factors such as power, size, and functionality. Below are some of the applications and benefits of laser engraving machines at different price ranges.

Low-Cost Laser Engraving Machines:

1. Personalized Gifts: Low-cost laser engraving machines are popular among individuals and small businesses for creating personalized gifts such as engraved keychains, phone cases, and custom jewelry.

2. Arts and Crafts: These machines can be used by artists and hobbyists to create intricate designs on various materials like wood, acrylic, and leather, enabling them to produce unique and personalized artwork.

3. Prototype Development: Small businesses and entrepreneurs can utilize low-cost laser engraving machines to create prototypes for product development, enabling them to quickly iterate and bring ideas to life.

Mid-Range Laser Engraving Machines:

1. Industrial Marking: Mid-range laser engraving machines are commonly used in industrial applications for marking and engraving serial numbers, barcodes, logos, and other identification marks on metal, plastics, and other materials.

2. Signage and Branding: These machines are employed in the signage industry to produce high-quality engraved signs, plaques, and labels for businesses, enhancing their brand visibility and professionalism.

3. Customization in Manufacturing: Mid-range laser engraving machines find applications in the manufacturing sector, allowing for high-precision customization of products, such as engraving serial numbers on electronic components or personalizing packaging materials.

High-End Laser Engraving Machines:

1. Jewelry and Watchmaking: High-end laser engraving machines enable intricate engraving on precious metals and gemstones, making them ideal for creating intricate designs on jewelry and watches.

2. Medical Industry: These machines are utilized in the medical industry for marking and engraving surgical instruments, surgical implants, and medical devices, ensuring proper identification and traceability.

3. Aerospace Industry: High-end laser engraving machines are employed in the aerospace sector for engraving unique identifiers on aircraft parts and components, facilitating maintenance, repair, and traceability.

These are just a few examples of the applications of laser engraving machines across different price ranges. The versatility and precision of these machines make them invaluable tools in various industries, enabling enhanced customization, efficiency, and brand promotion.

The Work Process and how to use laser engraving machine price

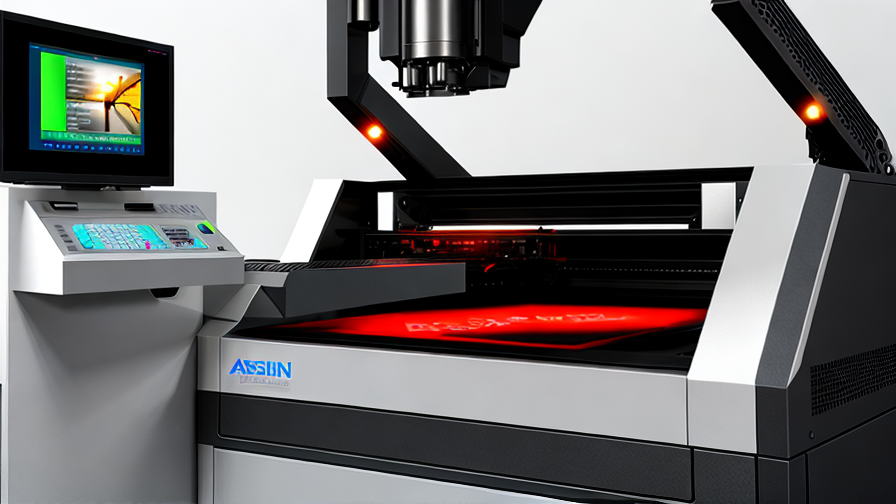

The work process of a laser engraving machine involves using a laser beam to etch or engrave designs, patterns, or texts onto various materials. These materials can include wood, acrylic, glass, metal, leather, and many more. The machine typically consists of a laser module, control panel, work bed, and software.

To use a laser engraving machine, start by selecting the appropriate material and design you want to engrave. Then, adjust the laser settings such as power and speed according to the material’s properties. Place the material onto the work bed securely, ensuring it is leveled and positioned correctly.

Next, import or create the design in the laser engraving software. Adjust the design placement and size as needed. Define the laser cutting path for the design, which determines the movement of the laser beam during engraving.

After finalizing the settings and design, start the engraving process. The laser beam will follow the defined path, emitting intense heat that vaporizes or melts the material, resulting in the desired design. The machine’s exhaust system removes any fumes or debris generated during the process.

Once the engraving is complete, carefully remove the engraved material from the work bed. Clean the engraved surface to remove any residue or debris. The laser engraving machine price can vary depending on various factors such as the size of the machine, power capacity, and additional features. It is essential to consider these factors before purchasing a machine to ensure it meets your specific engraving needs.

In summary, the work process of a laser engraving machine involves selecting the material and design, adjusting the laser settings, positioning and securing the material, importing the design into software, defining the laser cutting path, starting the engraving process, and finally cleaning the engraved material. The laser engraving machine price varies based on specific features and considerations, but it is crucial to choose a machine that suits your engraving requirements.

Quality Testing Methods for laser engraving machine price and how to control the quality

Quality testing methods for laser engraving machines are essential to ensure the reliability and performance of the equipment. Here are some commonly employed methods to control the quality of laser engraving machines:

1. Visual inspection: A thorough visual examination is performed to check for any visible defects, damages, or irregularities in the machine’s structure, frame, components, and electrical connections. Any abnormalities are noted and rectified during the production process.

2. Laser alignment test: Laser alignment is a critical aspect of laser engraving machines. By employing alignment tools, technicians ensure that the laser beam is properly aligned with the engraving surface. This test ensures accurate engraving and avoids any potential errors.

3. Power and energy test: Power and energy measurements are conducted to verify that the laser engraving machine is producing the desired output. The laser power is measured using a power meter, while energy tests determine the energy level delivered by the laser system. These tests ensure consistent engraving results.

4. Resolution test: The resolution capability of the laser engraver is tested by engraving a fine pattern or text with varying levels of precision. The resulting engraved pattern is evaluated under magnification to assess the machine’s resolution capabilities.

5. Material compatibility test: Different materials require specific laser settings for optimal engraving results. The machine must be tested on various materials to determine the appropriate laser parameters. This test ensures that the engraving machine can handle a wide range of materials without compromising quality.

6. Durability and stability test: Stress tests are conducted to assess the durability and stability of the laser engraving machine. These tests include subjecting the machine to extreme temperatures, running it continuously for extended periods, and testing its ability to handle varying workload conditions. The machine’s performance and reliability are closely monitored during these tests.

7. User acceptance test: Prior to mass production, selected users may be invited to assess the machine’s performance. Their feedback and suggestions are carefully considered and implemented, if feasible.

Implementing comprehensive quality testing methods helps to ensure that laser engraving machines meet the expected quality standards, produce accurate results, and operate reliably over their lifetime. By adopting these testing methods, manufacturers can control the quality and create a durable and high-performing laser engraving machine.

laser engraving machine price Sample Policy and Post-Purchase Considerations for laser engraving machine price from China

When purchasing a laser engraving machine from China, it is important to understand the sample policy and consider certain factors after the purchase. Here is a brief overview of these considerations within a limited word count of 300.

Sample Policy:

Before making a bulk purchase, it is advisable to request a sample of the laser engraving machine from the supplier. The sample policy typically involves the following:

1. Cost: Inquire about the cost of the sample machine, including any shipping charges. Some suppliers may offer sample machines at a discounted price or may even provide them for free, excluding shipping costs.

2. Specifications: Ensure that the sample machine meets your specific requirements. Compare its features, performance, and output quality to ascertain its suitability for your intended applications.

3. Payment: Determine the acceptable modes of payment for the sample machine. Payment methods often include wire transfer or payment through online platforms like PayPal or Alibaba Trade Assurance.

Post-Purchase Considerations:

After purchasing the laser engraving machine, the following factors should be taken into consideration:

1. Shipping and Customs: Communicate with the supplier about the shipping process, estimated delivery time, and any necessary customs documentation. Ensure that you are aware of the shipping costs and any applicable import duties or taxes.

2. Installation and Training: Assess whether the supplier provides installation and training services. If not, consider hiring a professional to install and calibrate the laser engraving machine to ensure optimal performance.

3. Warranty and Support: Inquire about the warranty period for the machine and the availability of technical support. Understand the terms and conditions of the warranty, such as coverage for parts, labor, and shipping.

4. Spare Parts and Maintenance: Seek information about the availability of spare parts and their costs. It is essential to have access to high-quality replacement parts in case of breakdowns or malfunctions. Additionally, inquire about the recommended maintenance and cleaning procedures to maximize the machine’s lifespan.

5. Training Materials: Request any user manuals, operation guides, or software tutorials from the supplier to aid in understanding and efficiently operating the laser engraving machine.

Considering the sample policy and post-purchase factors discussed above will help facilitate a successful procurement experience when purchasing a laser engraving machine price from China.

Sourcing laser engraving machine price from China: Opportunities, Risks, and Key Players

In recent years, China has become a popular destination for sourcing laser engraving machines due to the country’s advanced manufacturing capabilities and cost advantages. While there are opportunities to take advantage of competitive prices and a wide variety of suppliers, there are also risks and factors to consider.

Opportunities:

1. Competitive prices: Chinese manufacturers can offer laser engraving machines at lower prices compared to their counterparts in other countries. This is mostly due to lower labor and production costs.

2. Wide range of suppliers: China has a vast network of suppliers, allowing buyers to access a wide range of options in terms of machine specifications, sizes, and capabilities.

3. Advanced manufacturing capabilities: Chinese manufacturers have made significant advancements in the production of laser engraving machines, ensuring high quality and precision.

Risks:

1. Quality control: While there are many reputable manufacturers in China, it is essential to carefully research and select suppliers to avoid potential quality issues. Conducting due diligence, requesting samples, and visiting factories can help mitigate this risk.

2. Intellectual property infringement: China has had a reputation for intellectual property issues in the past. It is crucial to work with trustworthy suppliers and have proper legal safeguards in place to protect designs, patents, and technology.

3. Communication and cultural barriers: Language barriers and cultural differences can sometimes pose challenges in communicating specifications and requirements. Clear communication and having a reliable local representative or agent can help overcome these barriers.

Key players:

1. Han’s Laser: Han’s Laser is one of the leading laser equipment manufacturers in China, offering a wide range of engraving machines for various industries.

2. Thunder Laser: Thunder Laser manufactures laser engraving machines known for their high precision and quality.

3. Jinan Bodor CNC Machine Co., Ltd.: Bodor CNC is a well-known manufacturer of laser cutting and engraving machines, providing a range of options to suit different customer needs.

In conclusion, sourcing laser engraving machines from China can offer opportunities in terms of cost, variety, and quality. However, it is important to carefully assess suppliers, address potential risks, and work with reputable key players to ensure a successful sourcing experience.

How to find and select reliable laser engraving machine price manufacturers in China,use google search manufacturers and suppliers

When searching for reliable laser engraving machine manufacturers in China, Google search can be an effective tool. Here are some steps you can follow to find and select reputable manufacturers:

1. Start by conducting a Google search using relevant keywords like “laser engraving machine manufacturers in China” or “reliable laser engraving machine suppliers.” This will provide you with a list of potential manufacturers.

2. Review the search results and visit the websites of different manufacturers. Look for important information such as company background, product range, certifications, and customer reviews/testimonials. A well-designed and informative website is often an indicator of a reliable manufacturer.

3. Verify the manufacturer’s credibility and reputation by checking online directories, industry associations, and trade platforms. Trusted directories like Alibaba, Global Sources, or Made-in-China can provide extensive information about the supplier’s credibility, certifications, and business history.

4. Look for real customer feedback and reviews. Check if the manufacturer has a presence on social media platforms, review websites, or forums where customers share their experiences. This can give you insights into the manufacturer’s product quality, delivery times, and after-sales support.

5. Contact multiple manufacturers to request product specifications, pricing, and any other necessary information. Evaluate their response time, professionalism, and willingness to address your concerns. This will help you gauge the manufacturer’s communication and customer service abilities.

6. Consider visiting the manufacturer’s facility or arranging a virtual meeting if feasible. This can give you the opportunity to assess their production capabilities, quality control measures, and overall manufacturing process.

7. Obtain price quotes from different manufacturers and compare them based on factors such as product quality, features, warranty, technical support, and delivery time. Make sure to ask for a detailed breakdown of included services and potential additional costs.

8. In the final selection, consider choosing a manufacturer with a proven track record, good customer support, and a competitive price relative to the quality offered. Keep in mind that the lowest price may not always guarantee the best product or service.

By following these steps and thoroughly researching potential manufacturers, you can increase the chances of finding reliable laser engraving machine manufacturers in China.

How to check laser engraving machine price manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To check the reliability of a laser engraving machine manufacturer’s website and their pricing, you can use a combination of techniques including using Google Chrome, SEOquake, and limiting your content to 300 words. Here’s how you can go about it:

1. Open the manufacturer’s website: Start by accessing the laser engraving machine manufacturer’s website that you want to check the price on.

2. Use Google Chrome browser: Make sure you are using Google Chrome as your web browser. If not, download and install it onto your device.

3. Install SEOquake extension: Search for the SEOquake extension on the Chrome Web Store and install it on your browser. This extension provides various SEO metrics for websites.

4. Check the website’s credibility: Look for any trust signals on the website such as secure payment methods, customer testimonials, certifications, or affiliations with reputable industry organizations. These indications can help validate the manufacturer’s credibility.

5. Analyze website ranking: Open the SEOquake extension by clicking on its icon in the top-right corner of your browser. In the overview section, you will find the Alexa Rank which shows the popularity of the website. Ideally, a manufacturer’s website should be ranked within the top 10 million to have a decent online presence.

6. Navigate to pricing section: Locate the section or page on the manufacturer’s website where they display the pricing of their laser engraving machines.

7. Compare prices: Compare the prices provided on the manufacturer’s website with those offered by other reputable competitors in the market. This will help you determine if the manufacturer’s pricing is competitive or if there are any discrepancies.

8. Gather additional information: While on the website, try to gather any additional details you may need such as machine specifications, warranty information, or any special offers.

9. Keep content within 300 words: If you plan to write or share this information elsewhere, limit your content to no more than 300 words. This ensures your message is concise, informative, and easily digestible for readers.

By following these steps, you can check the reliability of a laser engraving machine manufacturer’s website and evaluate their pricing.

Top 10 laser engraving machine price manufacturers in China with each 160 words introduce products,then use markdown create table compare

Top 10 Laser Engraving Machine Price Manufacturers in China:

1. Han’s Laser Technology Co., Ltd.:

Han’s Laser offers a wide range of laser engraving machines, including CO2, fiber, and UV models. They provide high precision and speed with various power options. Their machines are suitable for engraving on materials like wood, acrylic, leather, and more.

2. Wuhan Golden Laser Co., Ltd.:

Wuhan Golden Laser specializes in fiber laser engraving machines. Their products are highly efficient and deliver excellent engraving results on metals, plastics, and other materials. They are known for their stability, precision, and durability.

3. Perfect Laser (Wuhan) Co., Ltd.:

Perfect Laser offers laser engraving machines suitable for various industries and materials. Their machines are versatile and provide high-resolution engraving on leather, wood, glass, and more. They are known for their affordability and reliable performance.

4. Shenzhen Superwave Laser Technology Co., Ltd.:

Superwave Laser Technology provides laser engraving machines with advanced features like high speed, high precision, and low maintenance. Their range includes CO2, fiber, and UV machines suitable for engraving on a variety of materials.

5. Beijing Reci Laser Technology Co., Ltd.:

Reci Laser Technology specializes in CO2 laser engraving machines for industries like signage, advertising, and crafts. Their machines offer precise engraving on materials such as wood, acrylic, paper, and fabric.

6. Shandong Leize Intelligent Technology Co., Ltd.:

Leize Intelligent Technology manufactures laser engraving machines that are suitable for engraving on various materials like wood, acrylic, plastic, and rubber. Their machines come with user-friendly software and auto focus capabilities.

7. Jinan AOL CNC Equipment Co., Ltd.:

AOL CNC Equipment offers laser engraving machines with high precision and stability. They provide machines for both large-scale industrial applications and small-scale home businesses. Their machines are compatible with materials like wood, leather, acrylic, and more.

8. Liaocheng Dongchangfu Ketai Laser Equipment Co., Ltd.:

Ketai Laser Equipment manufactures CO2 and fiber laser engraving machines suitable for precise engraving on various materials. They provide professional laser solutions with high-quality components and user-friendly interfaces.

9. Guangzhou Great Year Laser Technology Co., Ltd.:

Great Year Laser Technology offers laser engraving machines with advanced features like high speed and precision. Their machines are suitable for engraving on materials such as wood, acrylic, rubber, and more.

10. Dongguan Mactron Technology Co., Ltd.:

Mactron Technology specializes in desktop CO2 laser engraving machines for small-scale applications. Their machines come with easy-to-use software, high precision, and stability. They are suitable for engraving on materials like wood, leather, paper, and more.

|Manufacturer |Specialty |Notable Features |

|————————————–|—————————|————————————————–|

|Han’s Laser Technology Co., Ltd. |CO2, Fiber, and UV |High precision and speed on various materials |

|Wuhan Golden Laser Co., Ltd. |Fiber |Efficiency and durability on metals and plastics |

|Perfect Laser (Wuhan) Co., Ltd. |Versatile |Affordability and reliable performance |

|Shenzhen Superwave Laser Technology Co.|CO2, Fiber, and UV |Advanced features with low maintenance |

|Beijing Reci Laser Technology Co., Ltd.|CO2 |Signage, advertising, and crafts applications |

|Shandong Leize Intelligent Technology Co.|Various |User-friendly software and auto focus capabilities|

|Jinan AOL CNC Equipment Co., Ltd. |High Precision |Suitable for industrial and small-scale businesses|

|Liaocheng Dongchangfu Ketai Laser Equipment Co.|CO2 and Fiber |High-quality components and user-friendly interface|

|Guangzhou Great Year Laser Technology Co.|Various |Advanced features and applications on multiple materials |

|Dongguan Mactron Technology Co., Ltd. |Desktop CO2 |Ease of use on small-scale applications |

These top 10 laser engraving machine manufacturers in China offer a wide range of options to cater to various industries and applications. Whether you need high precision, speed, affordability, or specific material compatibility, you can find a suitable machine from these manufacturers.

Background Research for laser engraving machine price manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to laser engraving machines, China is known for its manufacturing capabilities and competitive prices. Several manufacturers in China offer a range of laser engraving machines to cater to different customer needs. This background research will focus on price information for these machines and highlight some prominent manufacturers.

To gather information on these manufacturers, several websites can be utilized, including qcc.com, archive.org, and importyeti.com. These platforms provide insights into company profiles, past records, product catalogs, and pricing information.

Qcc.com allows users to search for specific companies and provides details such as their registered address, revenue, number of employees, and key executives. Going through company profiles on this website can give an idea about their scale of operations and capabilities.

Archive.org is a valuable resource as it enables access to historical versions of websites. This can be useful in assessing the past product catalogs, customer testimonials, and pricing information of the manufacturers. Comparing this historical data with current information can help track any changes in pricing strategies over time.

Importyeti.com is a website that can provide import and export data of various products. Searching for laser engraving machines on this platform can give insights into the manufacturers exporting these machines, their trade volume, and the countries they commonly export to. This information can assist in identifying manufacturers who have a significant presence in the international market and may offer competitive prices.

By utilizing these platforms, it is possible to gather relevant information about laser engraving machine manufacturers in China. This data includes their company profiles, historical pricing trends, trade volume, and export destinations. This background research can serve as a foundation for further analysis and decision-making regarding the best options for laser engraving machines and their pricing.

Leveraging Trade Shows and Expos for laser engraving machine price Sourcing in China

Trade shows and expos are excellent platforms for sourcing laser engraving machines in China and comparing prices. These events provide an opportunity to directly connect with Chinese suppliers, manufacturers, and industry professionals, allowing for effective price negotiation and better understanding of the market.

Attending trade shows and expos related to laser engraving machines in China can offer several benefits. Firstly, it enables buyers to explore a wide range of products and suppliers under one roof, saving time and effort. Exhibitors often showcase their latest models and technologies, giving buyers a chance to evaluate the quality and features of different machines.

Moreover, participating in trade shows and expos facilitates direct communication with suppliers. This direct interaction allows buyers to inquire about product specifications, customization options, and after-sales services. Negotiations on laser engraving machine prices can be conducted face-to-face, potentially resulting in better deals compared to online inquiries.

Trade shows and expos also offer networking opportunities, enabling buyers to connect with industry experts and other buyers who have experience sourcing from China. Sharing knowledge and gathering insights from these connections can help in making informed decisions regarding product selection and pricing.

To make the most of trade shows and expos, buyers should prepare accordingly. This includes conducting thorough research on the exhibiting companies, identifying the desired features and specifications of the laser engraving machine, and setting a budget. Buyers should also have a clear plan on assessing the suppliers and comparing prices, ensuring that they can make accurate decisions.

In conclusion, trade shows and expos play a vital role in sourcing laser engraving machines in China and comparing prices. These events provide a unique platform to connect directly with suppliers, evaluate products, negotiate prices, and gather industry insights. By leveraging trade shows and expos, buyers can find the most suitable laser engraving machine at competitive prices in the Chinese market.

The Role of Agents and Sourcing Companies in Facilitating laser engraving machine price Purchases from China

Agents and sourcing companies play a crucial role in facilitating laser engraving machine purchases from China. These intermediaries act as a bridge between buyers and suppliers, making the process of finding and purchasing high-quality and affordable machines more convenient for international customers.

Firstly, agents and sourcing companies have a deep understanding of the Chinese market and industry. They are well-versed in identifying reliable suppliers who offer competitive prices. By leveraging their knowledge and network, they can connect buyers with reputable manufacturers or distributors that specialize in laser engraving machines. This saves buyers a significant amount of time and effort that would otherwise be spent on researching and vetting suppliers.

Additionally, agents and sourcing companies provide invaluable assistance in negotiating prices and other terms on behalf of buyers. They have the expertise to navigate the Chinese business landscape and ensure that buyers get the best possible deal. With their language skills and cultural understanding, they can effectively communicate with suppliers, address any concerns, and secure favorable pricing for buyers.

Furthermore, agents and sourcing companies can help buyers overcome language barriers and cultural differences. China has a distinct business culture, and language can often be a challenge for international buyers. Agents and sourcing companies bridge this communication gap, ensuring smooth communication and understanding between buyers and suppliers. This eliminates the risk of miscommunication or misunderstandings that may arise during the purchasing process.

Lastly, agents and sourcing companies offer quality control and inspection services. They can arrange factory visits and product inspections to assess the quality and ensure that the laser engraving machines meet the buyer’s requirements and standards. This reduces the risk of receiving substandard products or encountering any manufacturing defects.

In conclusion, agents and sourcing companies play a pivotal role in facilitating laser engraving machine purchases from China. Their knowledge of the market, negotiation skills, language proficiency, cultural understanding, and quality control services make the whole process more efficient, convenient, and reliable for international buyers.

Price Cost Research for laser engraving machine price manufacturers Companies in China, use temu.com and 1688.com

When it comes to laser engraving machines, China is undoubtedly a major player in the market. Two popular websites that can be utilized to conduct price cost research for laser engraving machine manufacturers in China are Temu.com and 1688.com.

Temu.com is an online sourcing platform that specializes in connecting global buyers with reliable Chinese suppliers. The website offers a wide range of laser engraving machines from various manufacturers. Users can browse through different models, compare prices, and gather information about the features and specifications of each machine. Along with the price, Temu.com also provides details about the minimum order quantity (MOQ) and payment terms, offering buyers a comprehensive understanding of the cost involved.

1688.com, also known as Alibaba China, is another leading online marketplace where buyers can explore laser engraving machines. It hosts a vast number of manufacturers and suppliers offering a diverse range of products, including laser engraving machines. 1688.com enables users to search for specific models or brands and obtain detailed pricing information directly from the manufacturers. Buyers can communicate with the sellers to negotiate prices, inquire about customization options, and discuss shipping and delivery terms.

Both Temu.com and 1688.com present buyers with a wide array of laser engraving machine options at competitive prices. It is important to note that when conducting research on these platforms, buyers should consider factors beyond the price alone. Quality, after-sales service, warranty, reputation, and customer reviews are crucial factors to ensure a wise purchase decision.

To summarize, Temu.com and 1688.com are valuable resources for individuals seeking price cost research on laser engraving machines manufactured in China. These platforms provide a simplified and efficient way to explore machine options, compare prices, and engage with suppliers to make informed buying decisions.

Shipping Cost for laser engraving machine price import from China

The shipping cost for importing a laser engraving machine from China can vary depending on several factors. The primary determinants of shipping cost include the weight and dimensions of the machine, the shipping method chosen, and the destination country.

Generally, air shipping is more expensive compared to sea freight. Air shipping is faster, taking around 5-7 days, but can be costlier, especially for heavy and bulky machines. Sea freight, on the other hand, is a more affordable option but takes longer, typically around 25-35 days.

For a laser engraving machine weighing around 200-300 kg, the air shipping cost can range from $1,500 to $4,000, depending on the destination. However, it is important to note that these figures are estimates, and prices may vary depending on the shipping provider and other variables.

Sea freight expenses for the same machine can fall within the range of $500 to $1,500. These estimates include the transportation from the Chinese port to the destination port, customs clearance fees, and local delivery charges. Additional expenses, such as insurance and import duties, are not always included in these figures and should be considered separately.

To minimize shipping costs, it is advisable to choose sea freight for heavy and large machines and air shipping for smaller and more urgent shipments. Additionally, reaching out to multiple shipping providers, comparing their quotes, and negotiating prices may help reduce the overall shipping expenses.

In conclusion, the shipping cost for importing a laser engraving machine from China can range from $500 to $4,000, depending on the weight, dimensions, shipping method, and destination. It is essential to consider all associated expenses and evaluate multiple shipping options to ensure a cost-effective import process.

Compare China and Other laser engraving machine price Markets: Products Quality and Price,Visible and Hidden Costs

China has emerged as a major player in the laser engraving machine market, offering a wide range of products at competitive prices. When comparing China with other laser engraving machine markets, several factors come into play, including product quality and price, visible and hidden costs.

In terms of product quality, both China and other markets offer a variety of options. China has made significant advancements in technology and manufacturing capabilities, enabling them to produce laser engraving machines of high quality. However, other markets, such as Germany and the United States, possess a long-standing reputation for precision engineering and superior product quality. These markets often focus on producing high-end machines that cater to specific industries, ensuring top-notch performance and durability.

When it comes to pricing, China often has a distinct advantage. The cost of labor and raw materials in China is significantly lower compared to other markets, allowing Chinese manufacturers to offer laser engraving machines at more competitive prices. Additionally, the large-scale production capabilities in China provide economies of scale, reducing overall manufacturing costs. On the other hand, markets like Germany and the United States may have higher price tags due to factors such as premium materials, advanced technology, and complex manufacturing processes.

Visible costs, such as the initial purchase price, are generally transparent in both China and other markets. Customers can easily compare prices to make informed decisions. However, hidden costs vary between markets. China’s laser engraving machines may have lower upfront costs, but customers should consider factors like shipping, import duties, and potential language barriers. Other markets may have additional costs, such as higher maintenance fees or advanced technical support, which can impact the total cost of ownership.

In conclusion, China’s laser engraving machine market offers competitive products in terms of quality and price. While other markets like Germany and the United States are renowned for their superior product quality, they often come with higher price tags. However, customers should carefully consider visible and hidden costs when comparing markets. Ultimately, the choice depends on the specific needs and preferences of the buyer.

Understanding Pricing and Payment Terms for laser engraving machine price: A Comparative Guide to Get the Best Deal

When it comes to purchasing a laser engraving machine, understanding pricing and payment terms is crucial to ensure you get the best deal. This comparative guide will provide you with the necessary information in less than 300 words.

To start, it’s important to determine your budget and research the market. Different brands and models offer varying features at different price points, so assessing your needs and comparing prices is essential. Consider the machine’s power, engraving area, and additional features.

Pricing for laser engraving machines can vary depending on their size and capabilities. Entry-level desktop machines can cost around $2,000 to $5,000, while industrial-grade models can range from $10,000 to $50,000 or more. Used machines can be a cost-effective option, but require extra caution and a thorough inspection.

Payment terms also play a significant role in the purchasing process. Some suppliers offer payment plans where you can pay in fixed installments over a specific period, helping to manage your budget. Others may provide financing options through partnerships with banks or leasing companies, allowing you to spread the cost over time.

Consider extra expenses beyond the machine’s purchase price. These may include shipping costs, import duties, taxes, and any necessary accessories or maintenance packages. Evaluating the total cost of ownership will give you a more accurate understanding of what you’ll be spending.

To get the best deal, compare prices and payment terms from multiple suppliers. Look for reputable manufacturers or suppliers with good customer reviews and reliable after-sales service. Don’t hesitate to negotiate the price or ask for additional benefits such as warranties or training.

Lastly, be cautious of deals that seem too good to be true. Ensure that the supplier offers a warranty for the machine and has a dedicated customer support system in case of any issues.

In conclusion, understanding pricing and payment terms is essential when purchasing a laser engraving machine. Determine your budget, research the market, compare prices and payment plans, and consider additional expenses. Remember to choose a reputable supplier and don’t hesitate to negotiate. By following these steps, you’ll be equipped to get the best deal possible.

Chinese Regulations and Industry Standards Certifications for laser engraving machine price,Import Regulations and Customs for laser engraving machine price from China

Chinese Regulations and Industry Standards Certifications for laser engraving machine price:

In China, laser engraving machines are regulated and certified by various government bodies and industry associations to ensure their safety, quality, and compliance with standards. The primary regulatory authority responsible for laser engraving machines is the State Administration of Work Safety (SAWS). SAWS sets regulations and conducts inspections to ensure that the machines meet safety requirements and do not pose any hazards to users.

Additionally, the China Machinery Industry Federation (CMIF) plays a significant role in establishing industry standards and certifications for laser engraving machines. CMIF sets criteria for performance, functionality, and quality, which manufacturers must adhere to in order to receive their certifications.

Import Regulations and Customs for laser engraving machine price from China:

Importing laser engraving machines from China to other countries involves complying with specific import regulations and customs procedures. When importing these machines, it is crucial to ensure compliance with the import regulations of the destination country. These regulations may include product-specific certifications and standards that the machines must meet.

Customs procedures for importing laser engraving machines generally require providing necessary documentation, such as invoices, packing lists, and certificates of origin. Importers may also need to pay customs duties, taxes, and any additional fees as per the regulations of the destination country.

To facilitate smooth importation, it is advisable to work with a reliable freight forwarder or customs agent who can guide through the entire process and help handle documentation and customs clearance procedures. This ensures compliance with all regulations and reduces the risk of any delays or penalties during the importation process.

In summary, compliance with Chinese regulations and industry standards certifications is essential when dealing with laser engraving machine prices. Importing these machines from China requires adherence to the import regulations and customs procedures of the destination country. Working with experienced professionals can streamline the import process and ensure compliance with all necessary requirements.

Sustainability and Environmental Considerations in laser engraving machine price Manufacturing

Sustainability and environmental considerations play a vital role in laser engraving machine manufacturing.

Firstly, the materials used in the production of laser engraving machines should be chosen carefully to minimize their impact on the environment. Manufacturers should prioritize using materials that are recyclable, non-toxic, and have low carbon footprints. This includes selecting eco-friendly components, such as energy-efficient motors and low-power laser sources.

Secondly, energy consumption during the operation of the machine should be minimized. Implementing energy-efficient designs and technologies can significantly reduce the environmental impact. This includes the use of advanced cooling systems, power-saving modes, and intelligent control systems that optimize energy usage without compromising the performance or engraving quality.

Another important consideration is waste management. Laser engraving produces waste in the form of cut-offs and residue. Implementing proper waste management processes, such as recycling and responsible disposal, can help minimize the negative environmental impact. This could involve setting up collection points for waste materials and partnering with recycling facilities to ensure proper disposal.

Furthermore, reducing the use of harmful chemicals and emissions is crucial in laser engraving machine manufacturing. Manufacturers should strive to use non-toxic and environmentally friendly alternatives for cleaning, maintenance, and treatments. This helps to protect the health of workers and prevents the release of hazardous substances into the environment.

Lastly, manufacturers should prioritize the incorporation of sustainable practices throughout the entire product lifecycle. This includes efficient manufacturing processes, sourcing materials responsibly, and designing machines that can be easily repaired, upgraded, or recycled at the end of their life. By considering the environmental impact from start to finish, manufacturers can contribute to a more sustainable and circular economy.

In conclusion, sustainability and environmental considerations are crucial in laser engraving machine manufacturing. Through careful material selection, energy efficiency, waste management, reduction of harmful substances, and sustainable practices throughout the product lifecycle, manufacturers can minimize the environmental impact of their machines.

List The Evolution history of “laser engraving machine price”

The evolution of laser engraving machine prices can be traced back to the early 1960s when the first lasers were invented. Initially, the technology was expensive, with machines costing hundreds of thousands of dollars. These early models were large and required specialized operators, limiting their accessibility to large industrial applications.

However, as the technology progressed and became more widely adopted, the cost of laser engraving machines began to decrease. In the 1980s, compact and affordable desktop laser engravers were introduced to the market. These machines, although limited in terms of power and capabilities, allowed small businesses and hobbyists to enter the engraving industry at a lower cost.

Throughout the 1990s and early 2000s, advancements in laser technology led to more efficient and powerful machines. This, coupled with increased competition in the market, resulted in further price reductions. Laser engraving machines became more affordable and accessible to a wider range of users. The prices were still relatively high for high-powered or specialized machines designed for specific applications like engraving on metals.

In recent years, with the proliferation of technology and economies of scale, laser engraving machine prices have continued to drop. This has been driven by a combination of factors, including improved manufacturing processes, increased competition, and the development of more cost-efficient laser sources.

Today, a wide range of laser engraving machines is available at various price points, allowing businesses of all sizes to utilize this technology. Entry-level machines can be found for a few thousand dollars, offering engraving capabilities on various materials such as wood, plastics, and fabrics. High-end machines with advanced features, like fiber lasers for metal engraving, still command a higher price, but they have also become more affordable compared to the past.

Overall, the evolution of laser engraving machine prices has seen a significant reduction, making the technology more accessible and affordable for a broad range of users, from hobbyists to large-scale industrial applications. As the technology continues to advance, it is expected that laser engraving machine prices will continue to decrease, further expanding its popularity and adoption.

The Evolution and Market Trends in laser engraving machine price Industry

The laser engraving machine industry has witnessed significant evolution and market trends in recent years. One significant trend is the reduction in prices of laser engraving machines. As technology advances and becomes more accessible, laser engraving machines have become more cost-effective, allowing a broader range of businesses and individuals to afford this technology.

One contributing factor to the decreased prices is the increased competition within the industry. More companies are entering the market, offering a variety of laser engraving machines at different price points. This competition has led to manufacturers finding ways to lower production costs and offer more affordable options to the customers.

Moreover, advancements in laser technology have also helped in reducing the overall costs of laser engraving machines. The development of more efficient and reliable lasers has allowed manufacturers to produce machines at a lower cost, which is then passed on to the customers.

Another market trend in the laser engraving machine industry is the increasing demand for customization and personalization. With the rise of e-commerce and the desire for unique and personalized products, businesses are turning to laser engraving machines to meet these demands. This trend has fueled the growth of the industry and led to an expansion of the customer base.

In addition, there is a growing interest in environmentally friendly solutions in various industries, including laser engraving. As a result, manufacturers are focusing on developing eco-friendly laser engraving machines that consume less energy and produce fewer emissions. This trend aligns with the increasing awareness of sustainability and can drive the market further.

In conclusion, the laser engraving machine industry has evolved significantly, with decreased prices, increased competition, and a focus on customization and sustainability. These trends have made laser engraving machines more accessible to a wider range of customers and have paved the way for further advancements in the industry.

Custom Private Labeling and Branding Opportunities with Chinese laser engraving machine price Manufacturers

Chinese manufacturers of laser engraving machines offer custom private labeling and branding opportunities for businesses worldwide. These manufacturers understand the importance of brand identity and offer flexible options to meet specific needs.

Custom private labeling allows businesses to put their own brand name and logo on the laser engraving machines they purchase. This allows for greater brand recognition and helps businesses establish their presence in the market. Chinese manufacturers understand the importance of this and offer services to help businesses create and apply their own branding to the machines.

Additionally, Chinese manufacturers offer custom options for the appearance and design of the machines. This means businesses can choose specific colors, patterns, or themes that align with their brand identity. Manufacturers can also add custom features or accessories to meet unique customer requirements.

Chinese manufacturers also understand the significance of pricing in the competitive global market. They offer competitive prices for their laser engraving machines, ensuring businesses can access affordable options without compromising on quality. By leveraging the global manufacturing capabilities of China, businesses can enjoy cost-effective solutions without sacrificing performance.

Another advantage of working with Chinese manufacturers is their expertise and experience in the laser engraving industry. They continuously research and develop new technologies, ensuring businesses have access to state-of-the-art and innovative machines. This allows businesses to stay ahead of the curve and meet evolving customer demands.

In conclusion, partnering with Chinese laser engraving machine manufacturers presents businesses with excellent opportunities for custom private labeling and branding. These manufacturers prioritize customer satisfaction, offering flexibility in design, competitive pricing, and access to cutting-edge technology. By leveraging these opportunities, businesses can enhance their brand presence and create a competitive edge in the market.

Tips for Procurement and Considerations when Purchasing laser engraving machine price

When considering purchasing a laser engraving machine, there are several factors to take into account, such as machine specifications, price, and overall value for money. Here are some tips and considerations to keep in mind:

1. Machine Specifications: Evaluate the specifications of the laser engraving machine, including power, speed, engraving area, and compatibility with various materials. Ensure that the machine meets your specific requirements and can handle the materials you intend to work with.

2. Quality vs. Price: While price is an important consideration, it should not be the sole determinant. Assess the overall quality and reliability of the machine. Cheaper machines may have lower-quality components and may not last as long, resulting in higher maintenance and replacement costs in the long run.

3. Brand Reputation: Research and consider purchasing from reputable brands known for manufacturing reliable and durable laser engraving machines. Read reviews, testimonials, and seek recommendations from users who have experience with the brand and machine model you are considering.

4. After-Sales Support: Ensure that the supplier or manufacturer provides good after-sales support, warranty, and technical assistance. Laser engraving machines can require regular maintenance and occasional repairs, so having reliable support can save you time and money in the long term.

5. Training and User-Friendliness: Consider the ease of use and the learning curve involved in operating the machine. Look for machines that come with comprehensive user manuals, online tutorials, and training resources to help you get started quickly and efficiently.

6. Upgradability: Explore if the machine offers upgradability options, such as software upgrades or the ability to add additional features or accessories in the future. This can help future-proof your investment and extend the functionality of the machine as your needs change or grow.

7. Safety Features and Compliance: Laser engraving machines emit powerful laser beams, so safety precautions are crucial. Ensure the machine meets necessary safety standards and features protective measures such as an emergency stop button, proper ventilation, and safety goggles.

8. Budget and ROI: Set a budget that aligns with your requirements and evaluate the return on investment (ROI) you expect from the machine. Consider factors such as the machine’s lifespan, maintenance costs, and potential revenue generation through increased efficiency or offering laser engraving services.

In summary, when purchasing a laser engraving machine, consider the machine specifications, balance quality with price, research brand reputation, weigh after-sales support and training options, explore upgradability features, prioritize safety, and budget wisely while considering ROI.

FAQs on Sourcing and Manufacturing laser engraving machine price in China

Q1: What are the factors that determine the laser engraving machine price in China?

A1: Several factors contribute to the pricing of laser engraving machines in China. These include the brand reputation, machine specifications (such as laser power, cutting area, and engraving speed), the type of laser technology used (CO2, fiber, or diode), the overall build quality and durability of the machine, and additional features like automated bed leveling or rotary attachments. Furthermore, the level of after-sales service and technical support provided by the manufacturer also affects the price.

Q2: Are Chinese laser engraving machines cheaper compared to those from other countries?

A2: Generally, laser engraving machines manufactured in China are more cost-effective compared to those from other countries. Chinese manufacturers benefit from lower labor and production costs, allowing them to offer competitive pricing. However, it is important to note that prices can vary significantly between different Chinese manufacturers, as they offer machines at various price points to cater to different market segments.

Q3: How can I source laser engraving machines from China?

A3: There are multiple ways to source laser engraving machines from China. One option is to directly contact manufacturers or suppliers through online platforms, industry trade shows, or sourcing agents. Another option is to work with a trading company or distributor who already has established relationships with Chinese manufacturers.

Q4: What are the potential risks of sourcing laser engraving machines from China?

A4: Some potential risks of sourcing from China include language barriers, cultural differences, quality control challenges, and intellectual property protection. It is crucial to thoroughly research and verify the reputation and credibility of the manufacturer before making any purchase decision. Additionally, conducting thorough due diligence, having a clear understanding of product specifications, and opting for secure payment methods can minimize potential risks.

Q5: What is the typical lead time for manufacturing and shipping laser engraving machines from China?

A5: The lead time for manufacturing and shipping laser engraving machines from China can vary depending on factors such as machine complexity, customization requirements, and the manufacturer’s production capacity. Typically, it can range from a few weeks to a few months. It is advised to clarify the lead time and shipping arrangements with the manufacturer or supplier before placing an order.

In conclusion, the laser engraving machine price in China is influenced by factors like brand reputation, specifications, technology used, build quality, and additional features. Chinese machines are generally more cost-effective, and they can be sourced directly from manufacturers, suppliers, or through trading companies. Potential risks in sourcing from China include language barriers, quality control challenges, and IP protection. The lead time for manufacturing and shipping can vary, and it’s important to conduct thorough research and due diligence before making a purchase.

Why contact sourcifychina.com get free quota from reliable laser engraving machine price suppliers?

Sourcifychina.com aims to connect businesses with reliable suppliers in China. As part of their service, they offer a free quota for contacting laser engraving machine suppliers. This allows businesses to explore their options without any financial commitment upfront.

By offering a free quota, Sourcifychina.com encourages businesses to reach out to multiple suppliers and compare prices. This helps businesses find the best laser engraving machine prices available in the market. Additionally, it allows businesses to evaluate the reliability and quality of different suppliers.

Sourcifychina.com understands that cost is a crucial factor for businesses, especially when sourcing from overseas. They strive to provide businesses with access to trustworthy suppliers who offer competitive prices. The free quota allows businesses to gather quotes from reliable suppliers and negotiate better deals based on their specific requirements.

Contacting suppliers through Sourcifychina.com also provides businesses with the advantage of trusted intermediaries. Sourcifychina.com verifies suppliers to ensure their credibility and legitimacy. This reduces the risk of dealing with fraudulent or untrustworthy suppliers and protects the interests of businesses.

Ultimately, the free quota offered by Sourcifychina.com enables businesses to make well-informed decisions by accessing a range of laser engraving machine suppliers. It empowers businesses to find the best combination of price, reliability, and quality, thus facilitating successful sourcing from China.