Knowledge about Laser Soldering Machine

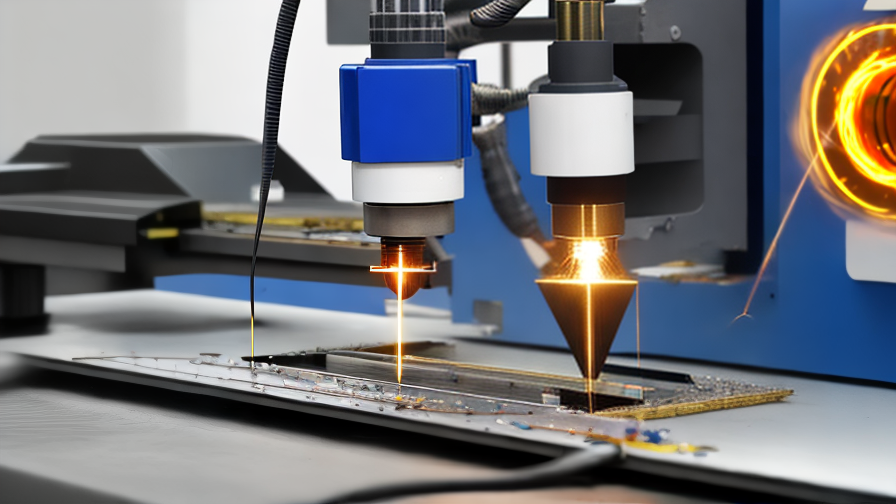

Laser soldering machines are the latest addition to the field of soldering technology. These machines use high-powered laser beams to join two or more metal components together. Since lasers emit a tremendous amount of energy, these machines can solder extremely small components with precision.

One of the main advantages of laser soldering machines is that they emit very little heat. This means that they can be used to solder temperature-sensitive components without creating any damage. In addition, laser soldering machines can create strong, clean, and precise solder joints that are critical for sensitive electronic applications.

Laser soldering machines are also quite fast. They are capable of completing a solder joint in just a fraction of a second. This speed is essential when working with sensitive and delicate electronic components. Assembly lines can operate at high speeds while maintaining quality control, which increases productivity while reducing costs.

The technology can be used to join a variety of metals such as copper, aluminum, stainless steel, and gold. The contact between the two components is minimal compared to other soldering processes. This reduces the possibility of contamination and oxidation, resulting in a cleaner, stronger, and more reliable solder bond.

Laser soldering machines are ideal for small and intricate applications, such as microelectronics, medical device fabrication, and optical component assembly. They also allow for a high degree of customization and flexibility due to their programmability. The laser’s intensity and position can be adjusted with ease to control the size, shape, and location of the solder joint.

In conclusion, laser soldering machines are an efficient and reliable alternative to traditional soldering methods. They provide fast, accurate, and clean solder joints, making them ideal for electronic and biomedical applications. As the demand for compact and complex electronic devices increases, the use of laser soldering machines is likely to become more widespread in the industry.

Various Types of Laser Soldering Machine

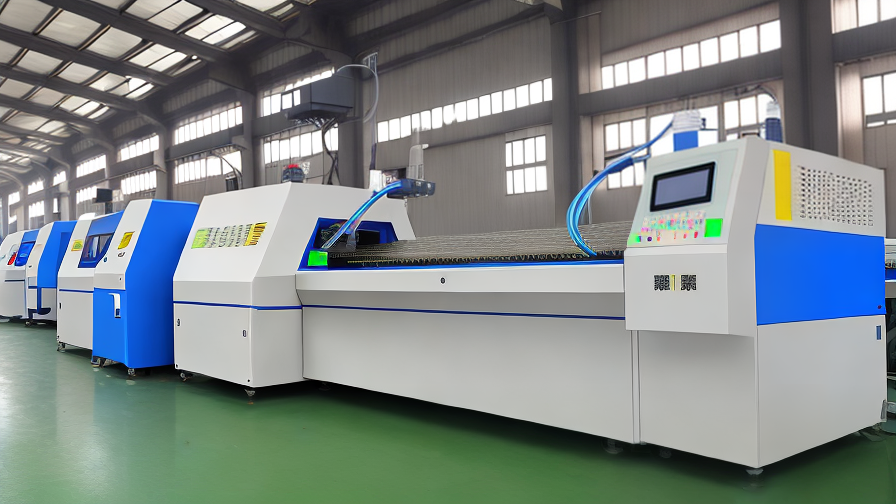

Laser soldering machines have become an essential tool in many industrial applications. They provide a non-contact and precise method of soldering, reducing the number of rejects and increasing production efficiency. There are varied types of laser soldering machines based on the type of laser source used and the soldering technique.

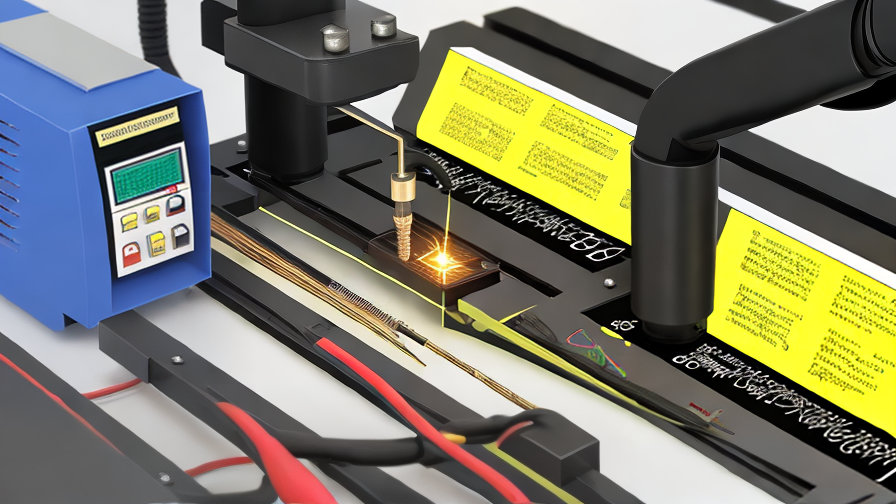

Fiber laser soldering machines are a popular type of laser soldering machine. They utilize fiber-optic cables to deliver the laser beam. These machines are efficient and have high power, resulting in fast processing and high precision. The fiber laser machines have high beam quality with low divergence, making them optimal for small-sized soldering.

Another type of laser soldering machine is the diode-pumped laser soldering machine. This type of laser soldering machine emits a continuous wave laser. They use semiconductor diodes to pump light into the laser rod, which produces high-energy pulses. They can be used to target a specific area on the electronic board, making them handy in intricate soldering tasks.

The pulsed laser soldering machine is another type that emits a light pulse with finite duration. They are ideal for thicker electronic boards with larger components. The pulsed type machines use a Q-switch technology that allows for high peak powers of up to hundreds of kilowatts, making them efficient in removing metal oxide layers on the surface of the metal parts.

Additionally, the UV laser soldering machine is a newly developed type of laser soldering machine that emits UV laser light. It performs at shorter wavelengths, and these machines are better for soldering metals with a high-surface energy. The UV laser is used for more technical applications that require extreme precision.

In conclusion, each of the various types of laser soldering machines has its unique features that make them efficient and ideal for specific soldering tasks. The choice of the type of laser soldering machine used is dependent on the size of the components, the thickness of the board, and the level of precision required. With the advancement in technology, the

FAQ sourcing Laser Soldering Machine manufacturer from China

Frequently Asked Questions about Sourcing Laser Soldering Machine Manufacturer from China

1. How do I find a reliable laser soldering machine manufacturer in China?

Answer: You can find a reliable manufacturer by searching for their online profile, checking customer reviews, and going through their product portfolio. You might also consider contacting a sourcing agent or visiting China for a factory tour.

2. How much does a laser soldering machine cost in China?

Answer: The cost of a laser soldering machine depends on the specifications, size, and features. On average, you might expect to pay between $10,000 and $100,000 for these machines.

3. How long does it take to receive a laser soldering machine from China?

Answer: The delivery time depends on your location, the manufacturer, and the shipping method. Typically, the lead time is 2-8 weeks after payment, and then standard shipping or air freight can take an additional few days to a couple of weeks, depending on your location.

4. Can I customize a laser soldering machine in China?

Answer: Yes, many manufacturers offer customization services, and some may even provide tailored solutions to meet specific needs. However, the cost and delivery time may be affected by the extent of customization required.

5. What are the payment terms for purchasing a laser soldering machine from China?

Answer: Most manufacturers require an upfront deposit, typically 30% of the total value. The payment balance usually transfers before delivery, and payment methods vary from bank transfer, Western Union to PayPal. It is important to communicate with the manufacturer regarding payment terms before placing your order.

In conclusion, sourcing laser soldering machines from China involves careful research, due diligence, and effective communication with the manufacturer. By following these steps and seeking advice from a sourcing agent or partner, you can find the right manufacturer, customize your machine, and receive your purchase in a timely and cost-effective manner.

Applications of Laser Soldering Machine

Laser soldering machines have become a popular tool in the manufacturing industry due to its high precision and speed. The machine uses a laser beam to heat and melt the solder for a seamless and accurate bonding process. This technology has several applications in various industries.

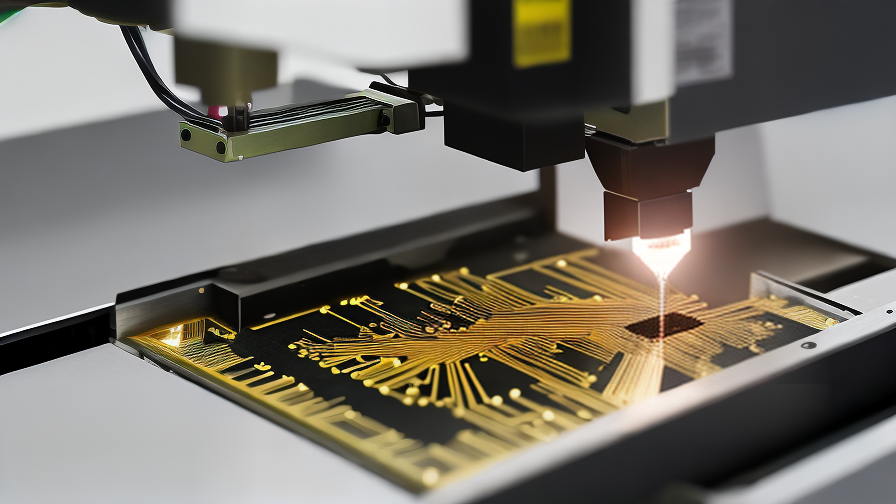

One of the primary applications of laser soldering machines is in electronics manufacturing. The machine is used to connect tiny components like resistors, capacitors, and integrated circuits on printed circuit boards (PCBs). The laser beam can accurately melt and join the solder to the PCB, eliminating the need for additional manual soldering on delicate electronic components.

Another application of laser soldering machines is in the production of medical devices. These machines are used to connect small metal wires and connections used in pacemakers and other medical equipment. The precision of laser soldering ensures that the device functions properly and is safe for use in the human body.

Laser soldering machines are also used in the automotive industry to join metal parts. The machine can join metals of different thicknesses and shapes, making it ideal for welding car frames and body panels. The use of laser soldering eliminates the need for additional coatings or adhesives, providing a secure and durable joint between metal parts.

The aerospace industry also utilizes laser soldering machines. The machine can join numerous small parts in the production of planes and spacecraft. The use of the laser ensures the integrity of the aircraft as well as the safety of the crew and passengers.

In conclusion, laser soldering machines have become a vital tool in several industries. The machine’s high precision and accuracy increase the efficiency of the manufacturing process, ensuring a seamless and safe final product. The applications mentioned are just a few as the machine is continually evolving, and its uses are expanding.

Manufactured Products made of Laser Soldering Machine

The rise of laser soldering machines has revolutionized the manufacturing industry. These machines use lasers to melt and join metal components, resulting in highly productive, accurate, and efficient manufacturing processes. The laser soldering machine is used in various industries, including aerospace, automotive, electronics, and medical devices manufacturing.

One key benefit of using laser soldering machines is the ability to produce complex shapes and designs. The high accuracy and precision offered by these machines allow manufacturers to create intricate products that would have been impossible using traditional welding techniques.

Another advantage of laser soldering is its cost-effectiveness. With faster and more efficient production, manufacturers can produce products at a lower cost, resulting in more affordable products for consumers.

In the aerospace industry, laser soldering is used to join airplane parts, reducing weight and improving fuel efficiency. In the automotive industry, laser soldering is utilized to produce intricate designs and achieve cost-effectiveness. In the electronics industry, it’s used to join small components and miniaturize electronic devices.

Remaining at the forefront of technological developments, the medical equipment manufacturing industry has benefited greatly from the use of laser soldering machines. The precision welding done by laser soldering machines produces smaller and compact medical devices that are less invasive and increase effectiveness in medical procedures.

In conclusion, laser soldering machines have proven to be a valuable tool in modern manufacturing. The ability to produce intricate designs, achieve cost-effectiveness in production, and create smaller and more effective products has made laser soldering machines essential in many industries. The high-speed production and high-accuracy capabilities of laser soldering machines make them an excellent investment for any manufacturer looking to improve production and profitability.

The Evolution history of Laser Soldering Machine

The evolution of laser soldering machines has been a fascinating journey that has transformed the way soldering is done. The machines first came into existence in the early 1970s and were used to apply heat to the metal surfaces for soldering.

Over the years, the design and construction of these machines have undergone several changes to make them more efficient and reliable. The introduction of computer-aided design (CAD) systems in the 1980s paved the way for more accurate and precise precision soldering, thereby reducing defects and increasing production yields.

With the advent of fiber-optic technology in the 1990s, laser soldering machines became faster, more accurate and more flexible. This technology allowed for smaller, more compact machines that could be used to solder components on a printed circuit board (PCB) without causing damage or distortion.

The introduction of laser marking, engraving and etching capabilities in the late 1990s added even more value to these machines. They could now mark and identify components on the PCB, adding an extra layer of traceability and visibility in the manufacturing process.

Today, there are several types of laser soldering machines on the market, each with its unique set of capabilities and advantages. Some machines use UV lasers for the soldering of certain types of materials while others use CO2 lasers for higher power applications.

In conclusion, the evolution of laser soldering machines has been instrumental in advancing the electronics industry. The machines have become more accurate, faster, and more reliable, making the soldering process more efficient and efficient. With the continued development of technology, we can expect to see even more advancements in the future.

The Process of Laser Soldering Machine

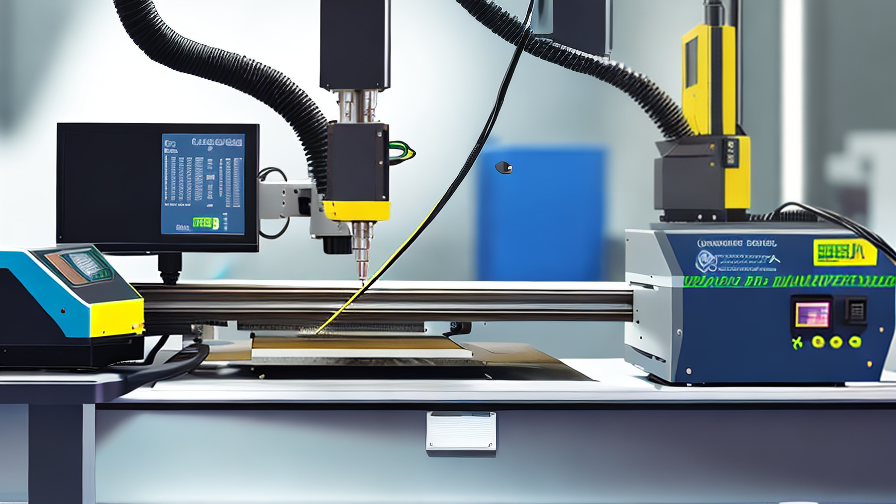

Laser soldering is a process that uses focused light beams to heat up and melt metal alloys, allowing them to fuse together. It is an efficient and precise way of connecting electronic components and other small parts, and is widely used in the manufacturing of various products.

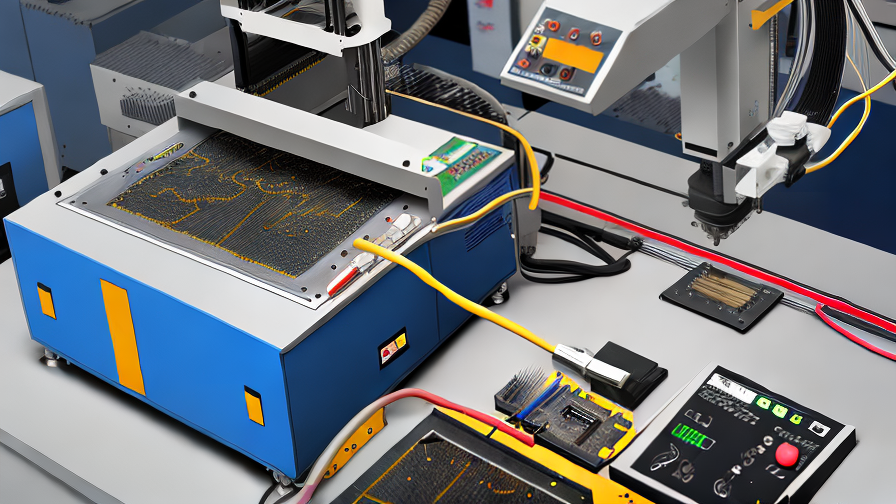

Laser soldering machines are equipped with high-quality laser sources, along with various other components such as optics, motion control systems, and software. The process begins with the selection of the appropriate solder alloy, which is chosen based on the type of components being joined and the required performance standards.

Once the solder alloy has been chosen, the components are positioned in the machine’s work area, typically under a microscope or camera to ensure accurate alignment. The laser is then directed onto the area to be soldered, producing intense heat that melts the solder and fuses the components together.

One of the most significant advantages of laser soldering is its precision. The focused laser beam provides an unprecedented level of accuracy, enabling manufacturers to join even the tiniest parts with extreme precision. This makes laser soldering an ideal process for high-tech applications such as microelectronics, medical devices, and aerospace components.

In addition to its precision, laser soldering also offers other benefits over traditional soldering methods. For instance, it produces less heat, reducing the risk of thermal damage to sensitive components. It also uses less solder, reducing waste and improving production efficiency.

Overall, laser soldering is a sophisticated and highly effective process that is rapidly gaining popularity in many industries. With its precision, speed, and reliability, it offers a range of benefits over traditional soldering methods, making it a valuable tool for manufacturers looking to improve their production processes and product performance.

Benefits Advantages of Utilizing Laser Soldering Machine

Laser soldering machines are becoming increasingly popular among manufacturers due to their many benefits and advantages. These machines use high-intensity beams of light to melt solder and join two materials together. Here are some of the benefits of utilizing laser soldering machines:

1. Accuracy and Precision

Laser soldering machines are incredibly accurate and precise. They can target tiny areas and create a strong bond between the materials. This accuracy means that manufacturers can create intricate designs and join multiple small components without damaging adjacent parts.

2. No Damage to Surrounding Areas

When using traditional soldering methods, especially with hand-held tools, there is always a risk of damaging surrounding areas. However, with laser soldering machines, the focused beam ensures that only the intended area is affected. This reduces the chances of collateral damage and saves manufacturers from costly repairs.

3. High Production Rate

Laser soldering machines can work at high speeds, making them ideal for production lines. The use of automation with these machines also means that they can work continuously, 24/7, making them ideal for mass production.

4. Reduced Cost

While the initial investment in a laser soldering machine may be high, over time, these machines can help reduce costs. The machine’s accuracy and precision mean that there is less waste material, leading to fewer rejects or failures. Additionally, the high production rate means that manufacturers can produce more products in a short period, leading to increased profits.

5. Versatility

Laser soldering machines can be used on a variety of materials, including metals, plastics, and ceramics, making them versatile. This flexibility means that manufacturers can use a single machine for multiple products, reducing machinery costs and increasing productivity.

In conclusion, the use of laser soldering machines has many benefits and advantages for manufacturers. They provide accuracy, precision, reduce damage to surrounding areas, have a high production rate, reduce costs, and offer versatility in the materials they can work with. As technology advances, these machines are likely

Disadvantages Laser Soldering Machine

Laser soldering machines are often used for producing high-quality electronic products. However, like any other machines, there are some disadvantages that come with using a laser soldering machine.

One disadvantage of laser soldering machines is their high cost. They are more expensive compared to other soldering machines, and this cost can be a barrier for small-scale manufacturers. Also, the maintenance cost of a laser soldering machine is higher, especially if it breaks down and requires specialized repair.

Another disadvantage is that the laser soldering machine can only be used on specific materials. The machine is only useful for bonding materials that are good conductors of light and heat, like metals and some polymers. This means that it cannot be used for other materials like wood or ceramics, limiting its application.

Laser soldering machines also require a high level of skill to operate. The operator must have adequate knowledge of the machine’s settings and understand how to use it safely. A lack of proper training can lead to accidents or damage to the machine or even the product being soldered.

Laser soldering machines are also known to produce harmful fumes during the soldering process, posing a health hazard to the operator. The fumes released can cause respiratory problems and irritation to the skin and eyes.

In conclusion, laser soldering machines may be efficient and produce high-quality results, but they also have their fair share of disadvantages. Their high cost, limited application, and safety concerns make them unsuitable for certain soldering needs. However, for manufacturers who prioritize quality over cost, laser soldering machines remain a viable option.

Selecting the Ideal Manufacturer Laser Soldering Machine

Laser soldering machines have become a popular option for soldering difficult and complicated components. These machines offer precision, speed, and cost-effectiveness, making them ideal for a range of applications. However, selecting the right manufacturer laser soldering machine can be challenging. Here are some factors to consider when selecting the ideal manufacturer laser soldering machine.

Quality: Select a machine that has a reputation for offering high-quality machines that perform the intended task with minimal issues. The machine should have undergone rigorous testing and made from high-quality materials.

Price: The cost of the machine is a crucial factor to consider. Compare the prices of different brands and select one that matches your budget. However, do not compromise on quality for cost.

Training and Support: A manufacturer who provides training and support ensures you can operate and troubleshoot the machine to get optimal performance. Go for a manufacturer who offers comprehensive training and support, and has a good track record in customer service.

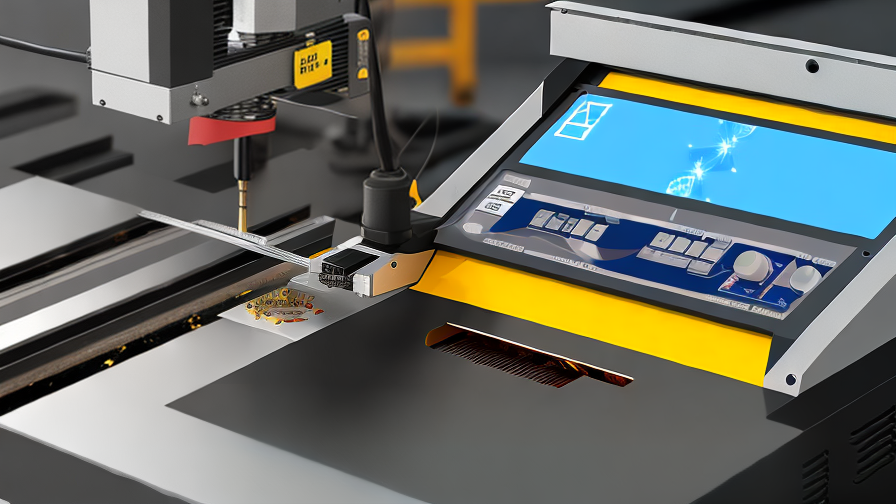

Ease of Use: It is important to choose a machine that is easy to use and maintain to improve productivity. Go for a machine with a user-friendly interface, easy-to-understand instruction manual, and accessible maintenance information.

Speed and Reliability: A laser soldering machine that operates at high speeds and minimal downtime improves productivity. Go for a manufacturer with a proven track record in producing fast and reliable machines.

Customization: The ideal manufacturer laser soldering machine should enable customization to suit your application needs. The machine should allow for the fine-tuning of soldering parameters, which improves the quality of the work.

In conclusion, selecting the ideal manufacturer laser soldering machine involves considering quality, price, training and support, ease of use, speed and reliability, and customization. Do not compromise on any of these factors; it could lead to substandard performance, longer lead times and ultimately, affect the quality of the results. Choose a reputable manufacturer and a machine that suits your specific needs for optimal results.

Things to Consider When Purchasing Laser Soldering Machine

Laser soldering machine is one of the most advanced technologies that can streamline the process of soldering. To invest in a quality laser soldering machine requires an evaluation of several different aspects. Here are few important things to consider when purchasing a laser soldering machine.

1. Quality and Performance – The quality and performance of the laser soldering machine primarily depend on its power, minimum spot size, and accuracy. So, it is essential to invest in a machine that provides consistent heat conductivity and helps in achieving precise and controlled soldering.

2. Size and Configuration – The size and configuration of the laser soldering machine should match your requirements according to the size of your workpiece, the complexity of the job, and your workspace. Take into account the spatial limitations of your workspace, such as weight and height restrictions, and explore the available configuration options to find the machine that will work best for you.

3. Cost and ROI – Investing in a laser soldering machine can be expensive, but it is a significant investment that can have a significant impact on productivity and ROI. Consider the costs associated with each machine, such as maintenance and operating costs, and determine whether the cost is feasible for your business.

4. Compatibility – Ensure the compatibility of the laser soldering machine with your existing equipment and production process. It is essential to consider whether the machine can be integrated into your current work process and whether it is compatible with your existing software.

5. Safety Features – The laser soldering machine is a powerful tool, and it can be dangerous if not handled properly. Consider facilities such as an interlock switch, emergency stop button, and smoke extraction system to ensure a safe work environment.

In conclusion, purchasing a laser soldering machine requires investing in a quality, reliable, and safe machine that fits your production requirements. By taking into account the above aspects, you can make an informed decision that will improve your operations and boost your business growth.

Properties of Laser Soldering Machine

Laser soldering machines are revolutionizing the electronics manufacturing industry. These machines have several properties that make them the ideal choice when it comes to precision soldering.

One of the key properties of laser soldering machines is their ability to deliver high precision solder joints. The laser beam can be precisely focused on small areas, resulting in a highly accurate soldering process. This level of precision is critical when working with micro devices such as microchips and printed circuit boards.

Another important property of laser soldering machines is their speed. The soldering process is completed in a matter of milliseconds, thanks to the laser’s high-speed operation. This is much faster than traditional soldering methods, which can take several seconds to complete a joint. Faster soldering speeds mean higher production rates and increased efficiency.

Laser soldering machines are also very versatile. They can be used to solder a wide range of materials, including metals, ceramics, and plastics. This makes them an ideal solution for a variety of manufacturing applications.

Another advantage of laser soldering machines is their ability to create clean solder joints. The laser beam melts the solder without introducing contaminants or damaging the surrounding materials. This produces a neat and clean joint that is free from impurities.

Lastly, laser soldering machines are easy to operate and require minimal maintenance. They have fewer moving parts than traditional soldering equipment, which means there’s less wear and tear. This reduces the need for frequent maintenance and repairs, resulting in lower operating costs.

In conclusion, laser soldering machines have several properties that make them the ideal choice for precision soldering in the electronics manufacturing industry. They deliver high precision joints, operate at high speeds, are versatile, produce clean solder joints, and are easy to operate and maintain. As the demand for smaller and more complex electronic devices increases, more and more manufacturers are turning to laser soldering machines to meet their production needs.

How to use Laser Soldering Machine

Laser soldering machine is an effective and easy-to-use tool that makes soldering faster and more efficient. Here is a guide to using the laser soldering machine.

1. Preparation

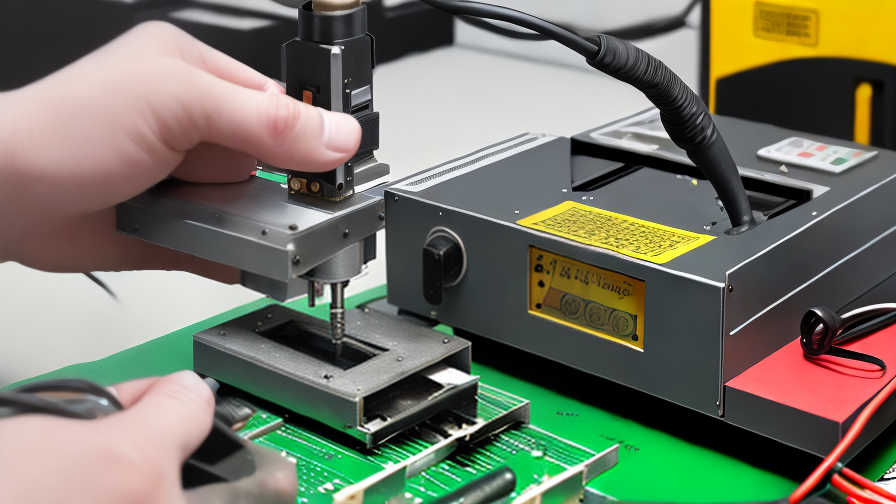

Before beginning the process, ensure that the laser soldering machine is set up correctly, and that all the necessary safety precautions are taken. The soldering area should be clean and free from any obstructions or flammable materials.

2. Loading the Soldering Material

Place the soldering material near the machine and ensure that it is in the correct form, such as wire or paste. Load the material into the soldering machine according to the manufacturer’s instructions.

3. Aligning the Material

Use the machine’s alignment features to position the soldering material precisely. This will ensure that the laser will hit the solder material directly, melting it in the process.

4. Adjust the Power Settings

Adjust the machine’s power settings according to the type of material being soldered, as different materials require different power settings.

5. Start Soldering

Activate the laser by pressing the trigger, and gently guide the laser to the area that needs to be soldered. The laser will melt the soldering material, creating a strong bond between the two materials.

6. Post-Soldering Cleaning

After the soldering process is complete, ensure that the area is cleaned using a solvent to remove any excess soldering material.

7. Shutdown

Finally, turn the laser soldering machine off and safely store it.

Conclusion

By using a laser soldering machine, the process of soldering can be made much more efficient and effective. With the right precautions and by following the correct steps, using a laser soldering machine can be a straightforward process.

Glossary Terminology Terms for Laser Soldering Machine

Laser soldering is a process that uses laser technology to join metals without using additional soldering material. This technology is widely used in various industries, including electronics, medical devices, and automotive parts. However, before using a laser soldering machine, one must understand the glossary terminology terms that are commonly used in the process.

Power Density: Power density refers to the amount of laser light that is focused on a particular surface area. High power density means that there is a high concentration of laser energy on a small area, creating higher localized temperature and stronger bond.

Spot Size: Spot size is the size of the laser beam that is focused on the material being soldered. It is determined by the lens that is used in the laser welding machine. A smaller spot size leads to a higher intensity of laser beam, allowing for precise and detailed soldering.

Wavelength: Wavelength is the distance between two adjacent peaks or troughs of a laser light wave. The wavelength of a laser is critical, as it can affect the absorption rate and penetration depth of the material being soldered.

Pulse Duration: Pulse duration refers to the length of time that the laser beam is applied to the material. Shorter pulse duration results in less heat input and minimal heat-affected areas on the material, leading to a clean and precise solder joint.

Melt Pool: Melt pool refers to the melted area that is created when the laser beam is applied to the material being soldered. It is essential to control the size and shape of the melt pool to ensure a strong and durable solder joint.

Conclusion: In conclusion, understanding the glossary terminology terms that are commonly used in laser soldering is crucial for ensuring optimal results from the machine. These terms, including power density, spot size, wavelength, pulse duration, and melt pool, play a critical role in the successful soldering process. By taking the time to familiarize oneself with these terms, one can optimize the laser soldering machine

Laser Soldering Machine Price

Laser soldering machines are the latest technology in the field of soldering, and they have been gaining popularity in various industries such as electronics, automotive, aerospace, and medical. The laser soldering machine price varies depending on the model and brand, and it can range from a few thousand dollars to tens of thousands of dollars.

The lower-end laser soldering machines cost around $5,000 to $10,000, and they are suitable for small-scale operations such as repair shops or hobbyists. These machines come with basic features such as a simple user interface, automatic and manual mode, and a limited warranty period.

On the other hand, high-end laser soldering machines can cost up to $100,000 or more, and they are designed for industrial-scale operations with advanced features such as automated production lines, multi-axis motion control, and high-speed processing. These machines have a longer lifespan and come with a more comprehensive warranty and technical support.

When it comes to purchasing a laser soldering machine, there are other factors to consider besides the price, such as the flexibility, precision, and speed of the machine. It is also essential to consider the cost of maintenance and the availability of spare parts and technical support.

In conclusion, laser soldering machine prices can vary significantly depending on the intended use and technical specifications of the machine. While purchasing a laser soldering machine, it is crucial to weigh the cost against the features and suitability of the machine, as well as the long-term cost of maintenance and technical support.