Benefits of Leather Laser Engraving Machine

.

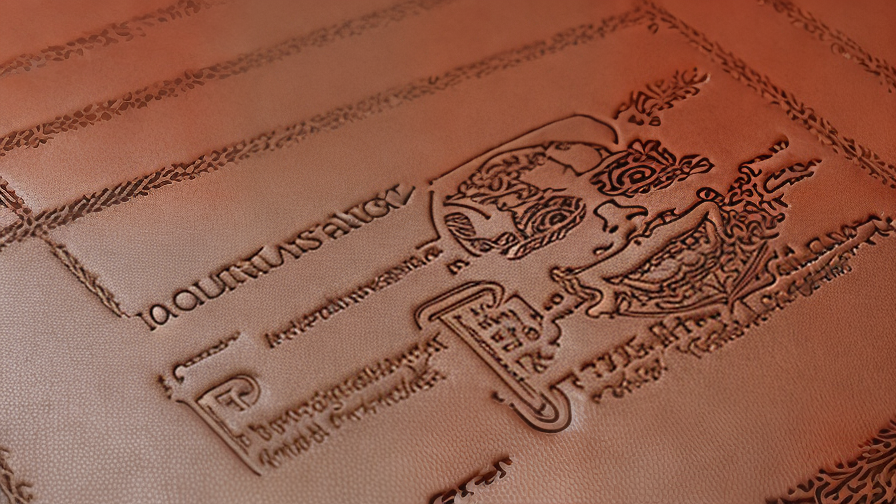

Leather laser engraving machines have transformed the leather industry in many ways. Leather engraving is the process of making permanent marks on a surface by using a laser beam. The laser beam removes the top layer of the leather and leaves a permanent mark on the material. This process can be used to create intricate designs and patterns on leather products such as wallets, belts, shoes, and jackets.

One of the primary benefits of using a leather laser engraving machine is the level of precision it offers. Laser engraving is a highly accurate process that produces fine and detailed designs. This level of precision ensures that the engraving is consistent across all products, thereby improving the overall quality of the product.

Another significant advantage of leather laser engraving machines is the level of customization they offer. With laser engraving machines, customers can add their personal touch to a product by engraving their name, logo or any design of their choosing. This makes the product unique and special, thereby attracting more customers.

The use of leather laser engraving machines is also environmentally friendly. Traditional engraving methods such as printing and stamping use harmful chemicals, which can be hazardous to the environment. Laser engraving, on the other hand, uses a beam of light to engrave the surface, thereby reducing the use of chemicals.

With the increasing demand for customized products, leather laser engraving machines have become a popular choice for businesses in the leather industry. These machines are cost-effective and save time, thereby reducing production times and increasing profits.

In conclusion, leather laser engraving machines offer many benefits to businesses in the leather industry. They provide precision, customization, and environmental benefits. With the increasing demand for customized products, leather laser engraving machines have become a necessity for the growth of the industry.

Features of Leather Laser Engraving Machine

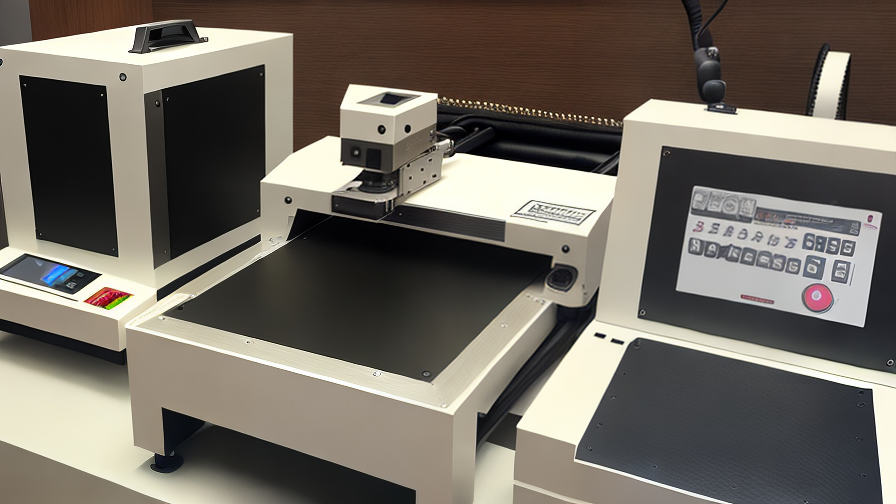

Leather laser engraving machines have gained popularity as a valuable tool for artisans, DIY enthusiasts, fashion and footwear industries amongst others. They provide a precise method of cutting and engraving leather materials, while minimizing the chances of distortion or destruction. The following are the features of leather laser engraving machines.

Precision and Accuracy

Leather laser engraving machines feature a high-quality laser source that ensures precise cutting and engraving. The precision allows for customization and fine details that would be difficult to achieve with traditional methods.

Variety of Materials

Leather laser engraving machines can be used on a variety of leather materials such as suede, cowhide, sheepskin, and synthetic leather. The machines are flexible enough to accommodate a range of thicknesses and textures, something that would be difficult to achieve with traditional methods.

Customization and Versatility

Leather laser engraving machines have software that allows users to adjust the design, spacing, and depth for each project. This means that artisans can customize their designs to reflect their creativity and produce unique pieces of art. The machines are versatile enough to perform engraving, cutting, etching, and marking on all leather items, including belts, wallets, bags, and shoes.

Ease of Use

If you are a beginner, the leather laser engraving machine is simple to use. With the use of a computer, you can customize your design, and the software will guide you through the entire process. The digital interface makes it easy to adjust the speed and power settings necessary for each project.

Time-Efficient

Leather laser engraving machines are incredibly time-efficient compared to traditional methods. The cut and engraving process is speedy and efficient, reducing production time and providing quick turnaround times.

Conclusion

Leather laser engraving machines are an excellent investment for those looking to produce custom leather products or those who want to add intricate details to their leather goods. These machines have revolutionized the fashion and footwear industries, and many artisans are using them to create unique and personalized designs. With their precision, versatility, speed, and ease of use, leather laser engraving machines are a valuable tool for anyone working with leather.

Various Types of Leather Laser Engraving Machine

Leather is one of the oldest materials that have been used for various purposes such as clothes, bags, and footwear. With the advent of technology, the use of leather has undergone several transformations in terms of design and finishes. One of the significant developments is the introduction of laser engraving machines that provide high precision engravings with a lot of flexibility. Here are some of the various types of leather laser engraving machines available in the market:

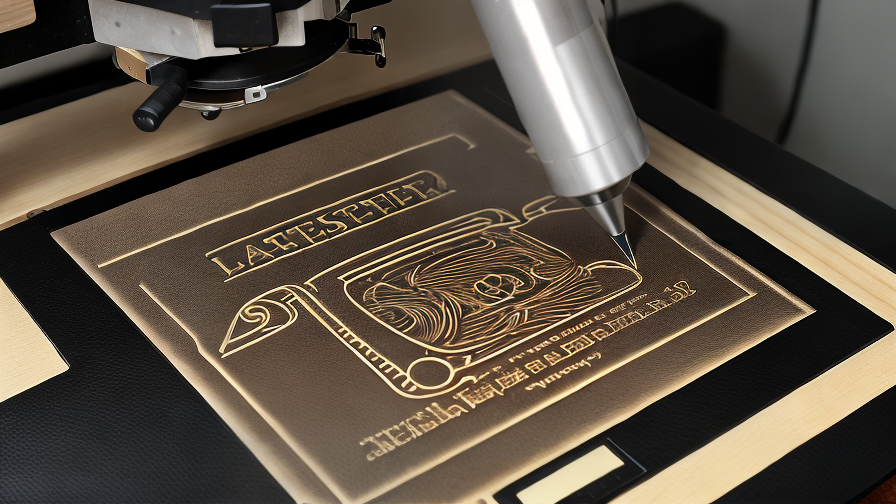

1. CO2 laser engraving machines – this type of machine is suitable for engraving on a wide range of materials such as leather, wood, and plastics. This method is ideal for large-scale engraving because it uses a powerful beam of light to cut through the material.

2. Fiber laser engraving machines – these are ideal for creating intricate designs on leather since they have the highest level of accuracy in terms of marking and engraving. They work by passing a beam of light through a lens that focuses it onto the surface of the leather, creating precise engravings.

3. UV laser engraving machines – while these machines are not commonly used for engraving leather, they work exceptionally well to create intricate designs with high precision. They focus their light onto the leather surface by utilizing a UV beam, which allows you to mark or engrave the material without damaging the surface in any way.

4. Green laser engraving machines – this is suitable for those who want to add some texture and depth to their leather engraving. Green lasers produce vibrations in the material, resulting in a three-dimensional effect that is striking and eye-catching.

In conclusion, leather laser engraving machines come in different types, and it is essential to choose one that best suits the specific engraving needs. Whether you want to create intricate patterns or add texture to a design, there is a perfect leather engraving machine for every task. The advancement in laser technology has made it easier and faster to achieve desired results, and it’s time to upgrade to these machines for better engravings on leather.

Applications of Leather Laser Engraving Machine

Leather laser engraving machine is a powerful tool that has become increasingly popular in the leather industry. With this high-tech device, it is now possible to cut and engrave leather materials, creating unique designs and patterns that were once impossible to achieve using traditional techniques.

The applications of a leather laser engraving machine are numerous. One of the most common uses is in the production of leather products such as wallets, belts, bags, and shoes. With laser engraving, it is possible to create intricate designs on leather that are both beautiful and durable. The machine can also be used to cut shapes and patterns into leather, allowing for precise design elements to be incorporated into the final product.

Another application of the leather laser engraving machine is in the customization of leather goods. With this technology, it is possible to personalize leather items such as phone cases, notebooks, and journals with initials, names or logos. This is particularly useful for companies looking to create branded merchandise or for individuals who want to give unique gifts.

The leather laser engraving machine can also be used in the production of furniture and home décor items. With its precision cutting ability, the machine can cut intricate designs into leather upholstery for chairs, couches, and even wall hangings. This allows for a unique and personalized touch to be added to any living space.

Finally, the leather laser engraving machine can be used in the fashion industry. Designers can use the machine to create unique patterns and designs on leather clothing such as jackets, skirts, and even shoes. This allows for the creation of truly one-of-a-kind pieces that are sure to stand out on the runway or in magazines.

In conclusion, the leather laser engraving machine is a versatile tool that has revolutionized the leather industry. Its ability to cut and engrave leather with precision and accuracy has opened up new possibilities in leather product design and customization. From fashion to home décor, the applications of this technology are endless, and its use is sure to continue to grow in popularity.

The Process of Leather Laser Engraving Machine

Leather is a highly popular material that is used for a variety of products such as belts, shoes, bags, and wallets. With the advancement of technology, the process of engraving leather has become easier with the help of laser engraving machines.

So, what is the process behind leather laser engraving?

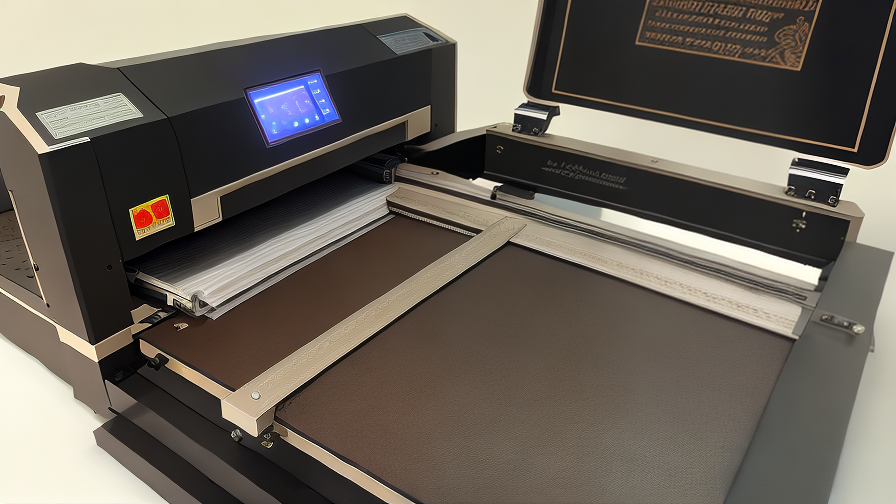

Firstly, you need to create a design or image that you want to engrave on the leather surface. This can be done easily with the help of software that is compatible with the laser engraving machine. Once you have the desired design, you can transfer it to the machine’s computer system.

Next, place the leather material onto the engraving table and ensure it is secured properly. This will prevent any movement or shifting during the engraving process. Then, you can adjust the focus of the laser accurately by using the machine’s software. This step will ensure that the laser engraves the design onto the leather surface precisely.

After that, you can start the engraving process by pressing the machine’s start button. The laser beam will then follow the design you created on the machine’s software and engrave it onto the surface of the leather material. Depending on the complexity of the design, the engraving process can take anywhere from a few minutes to several hours.

Once the process is complete, you can remove the leather material from the machine and admire the finished product. The laser engraving creates a unique and detailed design that is permanent and long-lasting.

In conclusion, the process of leather laser engraving machine involves careful planning, software compatibility, and accurate focusing. With this technology, you can create beautiful and intricate designs on leather products with ease.

How to use Leather Laser Engraving Machine

Leather laser engraving machine is a versatile tool that can be used to create intricate designs on leather. The process of using a leather laser engraving machine involves a few simple steps that can be easily followed by anyone. In this article, we will discuss how to use a leather laser engraving machine.

Step 1: Prepare the Leather

The first step in using a leather laser engraving machine is to prepare the leather. Make sure that the leather piece is clean and free of any dust, dirt, or debris. You can use a damp cloth to clean the leather surface if needed. Once the leather is clean and dry, place it on the laser engraving machine bed.

Step 2: Create Your Design

The next step is to create your design. You can use a graphics software like Adobe Illustrator or CorelDraw to create your design. Once you have created your design, export it as a vector file format like .ai or .eps. This will ensure that the laser engraving machine can read your design properly and accurately.

Step 3: Set Up the Machine

The third step is to set up the laser engraving machine. Turn on the machine and select the appropriate parameters for your leather material. This includes the speed, power, and frequency settings. Make sure that the laser is correctly focused and aligned.

Step 4: Start the Laser Engraving Process

Once the machine and design settings are in place, it is time to start the laser engraving process. Press the start button and let the machine do its work. The laser will move over the leather surface and create the design that you have created.

Step 5: Finishing and Cleaning

Once the laser engraving process is complete, remove the leather from the machine bed. Examine the design for any blemishes or irregularities. If needed, you can use leather cleaners and conditioners to give your leather piece a polished finish.

In conclusion, leather laser engraving machine is a powerful tool that can be used to create intricate designs on leather. By following the simple steps outlined in this article, you can use a leather laser engraving machine to create stunning designs and add a personal touch to your leather creations.

Selecting the Ideal Manufacturer Leather Laser Engraving Machine

When it comes to selecting the ideal manufacturer for a leather laser engraving machine, there are a number of factors to consider. First and foremost, it’s important to choose a manufacturer that has a reputation for producing high-quality machines that are reliable and durable. This means looking for a company that uses only the best materials and employs skilled technicians to build its machines.

Another important consideration is the level of support and service that the manufacturer offers. A good manufacturer should be available to answer questions, provide training, and offer ongoing maintenance and support. They should also offer warranties on their products and provide documentation and user manuals to help you get the most out of your machine.

It’s also important to think about the specific features and capabilities that you need from your leather laser engraving machine. For example, if you plan to engrave very detailed designs, you may need a machine with a high power laser and precise control. Alternatively, if you plan to use your machine for engraving large pieces of leather, you may need a larger work area and a machine with a more powerful motor.

Finally, it’s worth considering the price of the machine, as well as any ongoing costs associated with owning and maintaining it. While it may be tempting to go for the cheapest option, it’s important to remember that quality and reliability are often more important in the long run. Look for a machine that offers the best balance of features, cost, and support to meet your needs and budget.

In conclusion, selecting the ideal manufacturer for a leather laser engraving machine requires careful consideration of quality, service, features, and cost. By doing your research and choosing a reputable manufacturer that offers the right combination of features and support, you can be sure that your investment will deliver high-quality, reliable results for many years to come.

list FAQ with answer about Leather Laser Engraving Machine

Leather laser engraving machines have revolutionized the way leather products are customized. These machines make it possible to engrave any design or text on leather with precision and clarity. However, many people have questions about these machines and their use. To help, we’ve compiled a list of frequently asked questions with answers about leather laser engraving machines.

1. What is a leather laser engraving machine?

A leather laser engraving machine is a device that uses a laser to engrave designs, patterns, text, or even photos on leather products.

2. What are the benefits of using a leather laser engraving machine?

Using a leather laser engraving machine offers several advantages. These machines provide precise and detailed engraving, can handle complex designs and patterns, are quick and efficient, and offer a wide range of design options.

3. What types of leather can I engrave with these machines?

You can engrave any type of natural leather, such as cowhide, pigskin, and sheepskin, as well as some synthetic leather materials such as PU and PVC.

4. Can I engrave on finished leather?

Yes, you can engrave on finished leather, but it may not produce the same level of contrast as engraving on raw leather.

5. What level of detail can I achieve with a leather laser engraving machine?

These machines are capable of engraving fine details and intricate designs with a high level of precision and accuracy.

6. Is it safe to use a leather laser engraving machine?

Yes, leather laser engraving machines are safe to use when used according to the manufacturer’s instructions. However, it’s important to wear protective gear such as safety glasses when operating the machine.

7. What file format is required for engraving designs?

The majority of leather laser engraving machines are compatible with a wide range of file formats such as BMP, JPG, PNG, AI, and DXF.

In conclusion, using a leather laser engraving machine offers many benefits and can produce high-quality, precise designs on leather products. Knowing the answers to these frequently asked questions about these machines will help you make an informed decision before purchasing and using one.

Things to Consider When Purchasing Leather Laser Engraving Machine

When it comes to leather laser engraving machines, there are several things to consider before making a purchase. Here are some key factors to keep in mind:

1. Power and speed: The power and speed of the machine will determine how fast and deep the laser can engrave into the leather. Consider the types of projects you will be doing and choose a machine that has enough power and speed for your needs.

2. Size: The size of the machine will also be important, especially if you plan to work with larger pieces of leather. Make sure to measure your workspace and choose a machine that fits comfortably.

3. Quality of the laser: Look for a machine with a high-quality laser that delivers clean and precise engravings. A cheap or low-quality laser can produce fuzzy or uneven results.

4. Software compatibility: Check that the machine’s software is compatible with your computer’s operating system. Some machines only work with specific software programs, so it’s important to make sure you can easily upload designs and patterns.

5. Maintenance and servicing: Engraving machines can require regular maintenance and servicing. Make sure to research the brand’s reputation for customer service and support, and consider the availability of replacement parts if necessary.

6. Price: Finally, consider your budget when choosing a machine. High-end machines can be expensive, but can also offer additional features and capabilities that may be worth the investment.

By keeping these factors in mind, you can choose a leather laser engraving machine that meets your needs and allows you to create beautiful, professional-quality designs on a variety of leather products.

Properties of Leather Laser Engraving Machine

Leather Laser Engraving Machines are highly advanced pieces of technology that are designed specifically for the purpose of engraving customized designs, logos, patterns or text onto leather accessories. These machines come equipped with advanced features that make engraving on a variety of leather materials fast and easy.

One of the most important properties of a leather laser engraving machine is its precision. These machines come with high-precision laser heads that are designed to engrave even the most intricate designs, accurately and efficiently. With the help of this machine, the end-user can create unique and innovative designs that stand out from the rest.

Another key property of this machine is its versatility. These machines are suitable for use with a wide range of leather products, from wallets to jackets, footwear, and leather belts. The flexibility of the machine’s laser head enables it to engrave specific designs with ease, regardless of the complexity of the design.

Leather laser engraving machines also offer significant time savings when compared to traditional engraving methods. Engraving once required the use of manual techniques such as chisels or stamps. However, with the use of laser engraving machines, the process can be completed in a short amount of time with increased accuracy and efficiency. Leather laser engraving machines have revolutionized the leather industry by enabling customization of various leather products and providing consumers with a wide range of options to choose from.

In conclusion, a leather laser engraving machine is essential for businesses that want to offer exclusive and personalized leather products to their customers. Such machines are highly precise, flexible, and capable of producing unique designs with speed and precision. Investing in a leather laser engraving machine can significantly enhance the productivity of a leather business, and ultimately help businesses achieve success on a larger scale.

Technical Parameters Terms for Leather Laser Engraving Machine

Leather laser engraving machines have revolutionized the leather industry in recent years. With the ability to engrave images, graphics, text, and patterns, laser engraving machines have become a popular choice for designers and manufacturers alike. However, understanding the technical parameters that govern these machines can be daunting for beginners. Here are some terms to help you navigate the world of leather laser engraving machines.

1. Laser Power

Laser power refers to the strength of the laser beam emitted by the engraving machine. It is measured in watts and determines the thickness and depth of the engraving. A higher laser power means a deeper engraving.

2. Resolution

Resolution refers to the number of dots per inch (DPI) the laser can engrave. The higher the DPI, the more precise the engraving. A resolution of 600DPI is considered standard for leather laser engraving machines.

3. Speed

Speed refers to how fast the laser head moves across the leather surface. Higher speeds can produce faster results but can compromise the accuracy and quality of the engraving.

4. Cutting Capability

Not all laser engraving machines are designed for cutting leather. If cutting leather is necessary, it is important to check if the machine can handle it. Machines with higher laser power and upgraded optics are better suited for cutting.

5. Material Compatibility

Different leather types have different densities and textures, which can affect the engraving quality. Machines that are specifically designed for leather engraving can handle a variety of leather types and thicknesses.

6. Work Area Size

The work area size determines the maximum size of leather that can be engraved. It is important to check the size of the bed and ensure it is suitable for the project at hand.

In conclusion, understanding the technical parameters of a leather laser engraving machine can greatly help in choosing the right equipment for your project. By considering laser power, resolution, speed, cutting capability, material compatibility, and work area size, you can ensure you make an informed decision when purchasing a laser engraving machine.

Leather Laser Engraving Machine Price

A Leather laser engraving machine is a highly advanced and innovative piece of technology that can produce highly precise and delicate patterns as well as intricate designs on leather products. Like any other piece of technology, the price of a leather laser engraving machine can vary greatly depending on the size, features, and functionality.

The price of a leather laser engraving machine can range anywhere from $2,500 for a basic entry-level machine to upwards of $20,000 for a highly advanced and specialized machine that can handle larger projects and has many added features. The price is also influenced by factors such as the quality of the laser, the software used, and the overall quality and precision of the machine.

When considering the price of a leather laser engraving machine, it is essential to note that it is a significant investment, but one that can pay off in the long run. The ability to customize and produce unique designs on leather products can help grow a business, increase product valuations, and ultimately increase profits.

If you are looking to purchase a leather laser engraving machine, it is essential to do your research and compare the different options available. Look for machines with high-quality lasers, user-friendly software, and a sturdy design that can withstand heavy usage. Some models also come with additional features like cooling systems to prevent overheating, making them a great choice for larger projects.

In conclusion, the price of a leather laser engraving machine can vary according to size, features, and functionality. It is a considerable investment, but one that can ultimately help to grow a business and increase profits. By evaluating different options and choosing one with high-quality lasers, software, and a sturdy design, you can create unique and intricate designs to add value to your products.