Types and Applications of manual gate valve

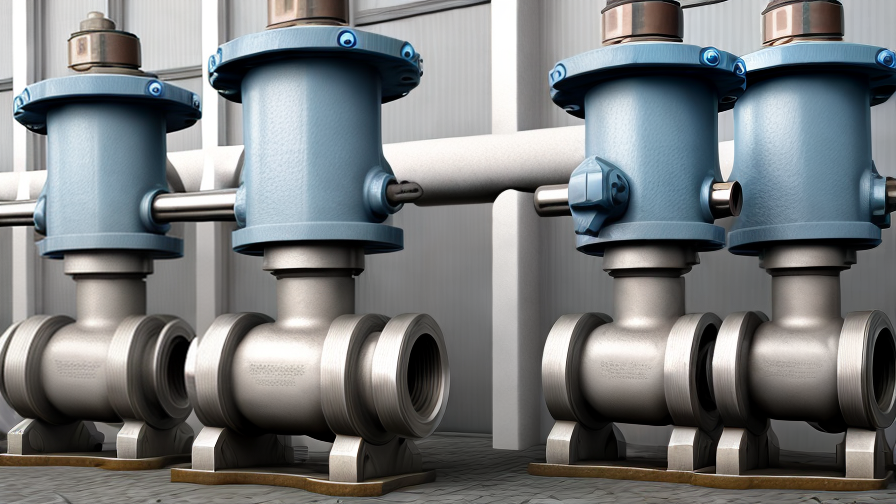

Manual gate valves are commonly used in various industries for controlling the flow of different types of fluids, especially liquids. They are a type of linear motion valve that employs a gate or wedge to control the fluid flow.

There are generally two types of manual gate valves – rising stem and non-rising stem valves. In the rising stem type, the stem moves up and down linearly to open and close the valve. Whereas in the non-rising stem type, the stem does not move, but the gate or wedge opens and closes in a parallel motion to the pipe line.

Manual gate valves are widely used in different applications, such as chemical processing, food and beverage industries, water treatment plants, oil and gas refineries, and pharmaceuticals. They are suitable for various types of fluids, including corrosive and abrasive fluids. Manual gate valves offer low resistance to the fluid flow, and they are easy to operate, reliable, and cost-effective.

Some of the common applications of manual gate valves include:

1. Isolation and regulation of fluid flow in various processing systems.

2. Control and measurement of fluid flow in pipelines and storage tanks.

3. Controlling the flow and pressure of steam and other gases in industrial plants.

4. Used for diverting flow in pipelines, such as for directing the flow to different equipment or storage tanks.

5. Shut-off valve for emergency situations, like preventing fluid leaks or preventing equipment damage.

In summary, manual gate valves are an essential part of various industries that require controlling the fluid flow. The type and application of the valve vary depending on the operating conditions, fluid type, and required functionality. Nonetheless, the manual gate valve remains a popular choice for its durability, efficiency, and cost-effectiveness.

Benefits and Feature of Utilizing manual gate valve

Manual gate valves are widely used in various industries as they offer several benefits and features that are essential in controlling the flow of fluids.

Benefits:

1. Cost-effective – Manual gate valves are relatively inexpensive compared to other types of valves, making them a popular choice for small-scale applications or places with a limited budget.

2. Low maintenance – As manual gate valves do not have any complicated parts or mechanisms, they require minimal maintenance. They are also easy to repair and replace, which can mean less downtime and increased efficiency.

3. Dependability – Manual gate valves are known for their reliability and durability. They can withstand high pressures and temperatures without suffering from leaks or corrosion, which makes them ideal for heavy-duty applications.

4. Versatility – Manual gate valves can be used in various settings, including chemical, pharmaceutical, water treatment, and industrial plants. They can handle different types of fluids, such as water, oil, gas, and acid.

Features:

1. Full opening and closing – Manual gate valves have a gate that can be fully opened or closed to regulate fluid flow.

2. Low pressure drop – Manual gate valves have a minimal pressure drop that makes them ideal for applications where maintaining fluid pressure is essential.

3. Tight seal – Manual gate valves have a tight seal that prevents fluid leakage, which is crucial in sensitive applications.

4. Easy to operate – Manual gate valves are straightforward to operate, requiring only a simple turn of the handle to open or close.

In conclusion, manual gate valves offer essential benefits and features that make them a cost-effective and reliable choice for controlling the flow of fluids in various applications. Businesses should consider utilizing manual gate valves to increase efficiency and reduce maintenance costs.

The Process of manual gate valve

Manual gate valve is a type of valve that uses a wedge-shaped disc to control the flow of a fluid in a pipeline. It consists of a body, a bonnet, a gate, and a stem. The body is the outer casing that houses the internal components, while the bonnet is the top cover that allows access to the internal parts of the valve. The gate is the component that moves up and down to control the flow, and the stem is the part that connects the gate to the handle.

The process of operating a manual gate valve involves turning the handle to lift or lower the gate to open or close the flow path. When the handle is turned clockwise, the gate moves down, and the flow is shut off. When the handle is turned counterclockwise, the gate moves up, and the flow is allowed.

To maintain the valve, it is necessary to periodically open and close it to prevent it from seizing up due to corrosion or debris buildup. In addition, the valve may require lubrication to ensure smooth operation.

When repairing or replacing a manual gate valve, the first step is to shut off the flow in the pipeline using another valve upstream. Then, the bonnet is removed to access the internal components. The stem is disassembled from the gate, and the gate is lifted out of the body. The valve seat and body are inspected for signs of wear or damage, and the internal parts are cleaned and lubricated before reassembly.

Manual gate valves are commonly used in industrial, commercial, and residential applications where manual operation is preferred or necessary, such as in fire protection systems, water treatment plants, and irrigation systems.

How to use manual gate valve

A manual gate valve is a type of valve used to control the flow of fluid or gas through a pipeline. It is mainly used in industrial and commercial applications, such as in power plants, refineries, and chemical plants. Here are the steps to use a manual gate valve:

1. Locate the valve: First, locate the valve that needs to be opened or closed. This will depend on the specific application and the pipeline layout.

2. Check the valve position: Before operating the valve, make sure to check the valve position. If it is a gate valve, the valve may have a stem that moves up and down to open and close the gate. Make sure the valve is fully closed before opening it.

3. Turn the handwheel or lever: To open the valve, turn the handwheel or lever in the counter-clockwise direction. This will move the stem up and allow the gate to open. To close the valve, turn the handwheel or lever in the clockwise direction. This will move the stem down and close the gate.

4. Monitor the flow: Once the valve is open, monitor the flow of fluid or gas through the pipeline. If you need to adjust the flow rate, you can partially open or close the valve by turning the handwheel or lever to a specific position.

5. Close the valve: When you are finished using the valve, make sure to close it fully. This will prevent any leaks or spills and ensure the safety of the pipeline.

In summary, using a manual gate valve is a simple process. Just remember to check the valve position, turn the handwheel or lever to open or close the valve, monitor the flow, and close the valve when finished.

manual gate valve Manufacturer,Supplier and Wholesale

We are a leading manufacturer, supplier and wholesale dealer of manual gate valves. Our valves are widely used in various industrial sectors such as oil and gas, water treatment, chemical, power generation and many others. We have a team of highly skilled professionals who ensure that our valves are manufactured to the highest standard of quality to meet the needs of our clients.

Our manual gate valves are made with high-quality materials that guarantee their long-lasting durability and functionality. We provide a wide range of manually operated gate valves in different sizes, pressure ratings, and end connections, as per the specific requirements of our clients. Our valves are easy to install, operate and maintain.

We use modern technology in our manufacturing process to ensure that our valves meet high precision standards. Our valves are tested rigorously to guarantee reliability, safety and long-term performance. Our products comply with industry standards and we are ISO certified, ensuring consistent quality and value.

We are committed to providing excellent customer service and support and work closely with our clients to ensure that their specific requirements are met. We offer competitive pricing and on-time delivery, ensuring that our clients get the best value for their investment.

In summary, we are a trusted manufacturer, supplier and wholesale dealer of high-quality manual gate valves that are designed to meet the demands of different industries. Our valves are made of durable materials, easy to use, safe and reliable, and we provide excellent customer service and support.

manual gate valve Price

Manual gate valves are used to regulate the flow of fluids in a wide range of industries, such as petrochemicals, water treatment plants, and oil and gas. They are also gaining popularity in residential plumbing systems. These valves have a simple design, consisting of a gate or wedge that moves up and down to open or close the flow of fluids. The operation is manual, meaning that the valve is opened and closed by a handwheel or lever.

The price of manual gate valves varies depending on several factors, such as size, material, pressure rating, and brand. The most common sizes range from 1/2 inch to 24 inches, with larger sizes available for industrial applications. The materials used for construction can be cast iron, ductile iron, stainless steel, carbon steel, and bronze. Each material has unique properties, such as corrosion resistance, durability, and thermal conductivity.

The pressure rating of manual gate valves determines the maximum pressure that the valve can withstand without leaking or failing. The standard pressure ratings range from 150 pounds per square inch (psi) to 2500 psi, with some valves capable of handling higher pressures. Generally, higher pressure ratings lead to higher prices, as the valves require more rigorous testing and certification.

Finally, the brand of manual gate valves can also affect the price. There are many reputable brands in the market, such as Crane, Mueller, and Jamesbury, that offer high-quality valves at competitive prices. However, some premium brands, such as Velan and Cameron, command a higher price due to their advanced features and reliability.

In summary, the price of manual gate valves can range from a few dollars for small sizes to thousands of dollars for large sizes and high-pressure ratings. It is essential to choose a valve that meets the specific needs of the application, rather than simply selecting the cheapest option. This will ensure a reliable and efficient operation and reduce the risk of downtime and maintenance costs.

FAQ sourcing manual gate valve manufacturer from China with multiple answers

1. What should I consider before sourcing a manual gate valve manufacturer from China?

Before sourcing a manual gate valve manufacturer from China, you should consider the quality of the products, the manufacturer’s reputation, their ability to meet your requirements, and their pricing. You should also verify the manufacturer’s certifications and licenses to ensure they meet industry standards.

2. How can I verify the manufacturer’s certifications and licenses?

You can verify a manufacturer’s certifications and licenses by requesting their certificates and checking with the relevant authorities. You can also use third-party verification services to ensure the manufacturer complies with industry standards.

3. What is the lead time for manufacturing manual gate valves from a manufacturer in China?

The lead time for manufacturing manual gate valves in China depends on the manufacturer’s production capacity, the quantity ordered, and the complexity of the product. It is advisable to confirm the lead time with the manufacturer before placing an order.

4. Can I customize the design of the manual gate valves from a manufacturer in China?

Most manual gate valve manufacturers in China offer customization services to meet the specific needs of their clients. You can work with the manufacturer to modify the design, materials, and finishes of the valve to meet your requirements.

5. How can I ensure the quality of the manual gate valves from a manufacturer in China?

You can ensure the quality of the manual gate valves by requesting samples from the manufacturer, conducting factory inspections, and using third-party inspection services. You should also have a quality control plan in place to ensure the products meet your specifications.

6. What payment methods do manual gate valve manufacturers in China accept?

Most manual gate valve manufacturers in China accept payment methods such as wire transfers, credit cards, and PayPal. You should confirm the payment options with the manufacturer before placing an order.

7. What is the minimum order quantity for manual gate valves from a manufacturer in China?

The minimum order quantity for manual gate valves from a manufacturer in China depends on the products and the manufacturer’s policies. Some manufacturers have a minimum order quantity of 50 to 100 units, while others require a larger order quantity.

8. How do I communicate with a manual gate valve manufacturer in China?

You can communicate with a manual gate valve manufacturer in China via email, phone, or online chat. Some manufacturers also have representatives who can communicate with you in your preferred language. It is important to establish clear communication channels to avoid misunderstandings.