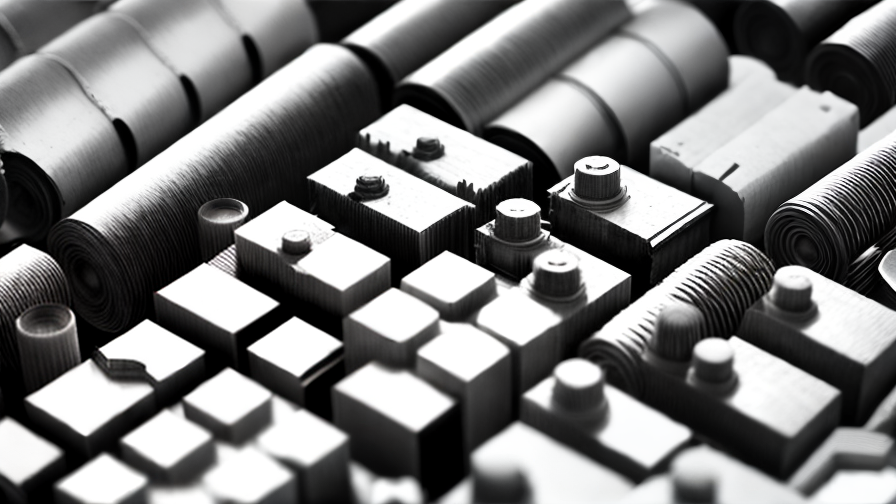

Types and Applications of metal cartridges

Metal cartridges are used in a variety of industries for various purposes. They can be made from different materials like stainless steel, brass, aluminum, nickel, and titanium. The type of material used depends on the application requirement.

One of the primary applications of metal cartridges is for water filtration. They are used to remove impurities from water, such as dirt, rust, and sediment. Metal cartridges are durable and can be cleaned and reused, making them a cost-effective filter option for many industries.

Another application of metal cartridges is in the pharmaceutical industry. Metal cartridges are used in the production of drugs and vaccines to filter out impurities and provide a sterile environment to prevent contamination. The high-quality materials used in these cartridges ensure that they meet the strict hygiene standards required for pharmaceutical production.

Metal cartridges are also used in the oil and gas industry. They help to remove impurities and contaminants from the fluids used in drilling and production processes. The cartridges are designed to withstand the harsh conditions of the oil and gas industry, and they can be cleaned and reused, minimizing waste and reducing costs.

In the aerospace industry, metal cartridges are used for air and fuel filtration. The cartridges can withstand high temperatures and pressures and are designed to filter out particles, gases, and liquids that can damage aircraft engines.

In conclusion, metal cartridges have a wide variety of applications in different industries and are designed to meet specific requirements. They are durable, cost-effective, and environmentally friendly, making them an excellent choice for many filtration needs.

Benefits and Feature of Utilizing metal cartridges

Metal cartridges have become increasingly popular in recent years as they provide several benefits over traditional plastic cartridges. These benefits include increased durability and longer shelf life of the cartridges, leading to less waste and decreased environmental impact. Additionally, metal cartridges are more reliable and have a higher resistance to damage from extreme temperatures and other harsh conditions. They are also more resistant to corrosion and oxidation, making them ideal for use in industrial applications.

Furthermore, metal cartridges are more easily recyclable, making them an eco-friendly option for those looking to reduce their carbon footprint. This means that they can be reused efficiently and effectively, further reducing the amount of waste produced.

Another benefit of metal cartridges is their versatility. They can be used with a variety of different substances, including oils, lubricants, and solvents. This makes them an excellent choice for a broad range of industries, from manufacturing to healthcare.

In terms of features, metal cartridges offer a range of benefits over plastic cartridges. Most notably, they are more robust and have a higher resistance to damage, which can prolong the life of the cartridge and reduce the amount of waste produced. They are also more easily recyclable, which makes them a more sustainable option for businesses.

Overall, the benefits and features of utilizing metal cartridges are clear. They offer superior durability, resistance to damage, and recyclability, making them ideal for use in a wide range of industrial applications. Additionally, their increased environmental sustainability makes them an excellent choice for businesses looking to reduce their carbon footprint and promote eco-friendly practices.

The Process of metal cartridges

Metal cartridges are cartridges made up of metallic materials that are used in various applications such as ammunition, paintball, medical devices, and more. The process of manufacturing metal cartridges is complex and involves several steps that should be followed to achieve the desired result.

The process of manufacturing metal cartridges starts with the selection of the raw materials. The most commonly used metals for cartridge manufacturing are brass and steel. The selected metal is then subjected to a series of processes, including blanking, annealing, and drawing to produce a cartridge case.

In blanking, the metal sheets are cut into the desired shape and size for further processing. Annealing involves heating the metal sheet to a predetermined temperature to make it easier to work with, as well as to reduce the risk of cracking or breaking during the drawing process.

The next step in the manufacturing process is the drawing process where the metal sheet is drawn through a series of dies to shape the metal into the desired cartridge shape. The diameter and length of the cartridge are determined by the dimensions of the dies used. The process of drawing also helps to increase the strength of the metal by aligning the grain structures.

After the drawing process, the cartridge is trimmed to the desired length, and the base is formed. The base assembly includes resizing, depriming, and primer pocket swaging. The final cartridge is then inspected for quality and tested to ensure that it meets the required specifications.

Overall, the manufacturing process for metal cartridges is highly complex and requires skilled labor, sophisticated equipment, and stringent quality control measures. However, the end result is a high-quality metal cartridge that can be used in a wide variety of applications and is built to last.

How to use metal cartridges

Metal cartridges are used for a variety of purposes, from storing and transporting food and beverages to holding industrial fluids and gases. They are typically made of steel or aluminum and come in different shapes and sizes depending on their intended use. Here are some recommendations for using metal cartridges effectively and safely:

1. Choose the right cartridge for the job: Depending on the type of material you need to store, you may need a cartridge with specific features such as airtight seals, coatings, or pressure requirements. Make sure to read the label and specifications for each cartridge before use.

2. Clean the cartridge before use: Metal cartridges should be free of rust, dirt, and other contaminants before filling them. Use a degreaser or other cleaning agent to remove any debris.

3. Fill the cartridge carefully: When filling the cartridge, make sure to use the correct nozzle or funnel, and avoid overfilling or spilling. This can lead to wastage and safety hazards.

4. Label and store the cartridges properly: Once filled, label the cartridge with the contents and date and store it in a dry, cool place away from direct sunlight and heat. Avoid stacking them too high or near any sources of ignition.

5. Dispose of the cartridges responsibly: Metal cartridges can be recycled, so make sure to dispose of them appropriately. Check with your local recycling center for instructions.

In summary, metal cartridges are versatile and durable containers that can be used for a variety of purposes. Proper handling and storage can help ensure their efficiency and safety, while also minimizing waste and environmental impact.

metal cartridges Manufacturer,Supplier and Wholesale

As a metal cartridges manufacturer, supplier, and wholesale distributor, we offer a wide range of high-quality metal cartridges for all types of applications. Our metal cartridges are made from the finest materials and are designed to provide the best performance in any given environment. We use advanced manufacturing techniques and equipment to produce our metal cartridges, ensuring consistent quality and reliability.

Our metal cartridges are ideal for use in a variety of industries, including electronics, automotive, aviation, medical, and more. We can provide metal cartridges for a wide range of applications, including filters, compression springs, electrical contacts, and more. We offer both standard and custom metal cartridges, giving our customers the flexibility to choose the right product for their needs.

At our facility, we have an experienced team of engineers and technicians who can work with our customers to design and develop custom metal cartridges that meet their unique requirements. Whether you need a special size, shape, or material for your metal cartridges, we can work with you to create the perfect product.

We take pride in our ability to provide exceptional customer service and support. Our team is dedicated to delivering high-quality products and services that meet or exceed our customers’ expectations. Whether you need a small or large quantity of metal cartridges, we can deliver them to your door on time, every time.

If you are looking for a reliable metal cartridges manufacturer, supplier, and wholesale distributor, look no further than us. With our experience, expertise, and dedication to customer satisfaction, we are the ideal partner for all your metal cartridge needs. Contact us today to learn more about our products and services.

metal cartridges Price

Metal cartridges are widely used in various industries for their durability, strength and reliability. They are designed to hold a certain amount of liquid or gas that can be dispensed or used for various purposes. The price of metal cartridges can vary depending on their size, material, and application.

Small metal cartridges, typically used for gas-powered tools, can cost between $3 and $10 each. For example, a 16g CO2 cartridge used for inflating bike tires can cost around $3, while a 90g CO2 cartridge used for paintball guns can cost around $10. Medium-sized metal cartridges, typically used for medical or commercial purposes, can cost between $15 and $50 each. For example, a 55mm diameter oxygen cartridge used for medical purposes can cost around $15, while a 70mm diameter CO2 cartridge used for beverage dispensing can cost around $50.

Large metal cartridges, typically used for industrial applications, can cost anywhere from $100 to $500 each. For instance, a 20-lbs propane cartridge used for welding can cost around $100, while a 50-lbs nitrogen cartridge used for industrial cutting can cost around $500. The price of metal cartridges can also vary based on the manufacturer and the quantity ordered. Buying in bulk can result in significant savings.

In conclusion, the price of metal cartridges can vary widely depending on their size, material, and application. While small metal cartridges can cost anywhere between $3 and $10 each, large industrial cartridges can cost anywhere between $100 and $500 each. The price can also vary based on the quantity ordered, and buying in bulk can result in significant savings. Overall, metal cartridges are an essential part of many industries, and their durability and strength make them highly valuable.

FAQ sourcing metal cartridges manufacturer from China with multiple answers

Q: How can I find a reliable metal cartridges manufacturer in China?

A: To find a reliable metal cartridges manufacturer in China, you can leverage different channels. One option is to use B2B platforms and directories like Alibaba, Global Sources, or Made-in-China.com. You can also attend trade shows, such as the Canton Fair or the Shanghai International auto show, to connect with manufacturers. Alternatively, you can work with a sourcing or trading company based in China that can facilitate communication, factory audits, and quality control to identify trustworthy suppliers.

Q: What kind of metal cartridges does the manufacturer typically produce?

A: Metal cartridges manufacturers in China can produce a wide range of products for different industries and applications. Some common types of metal cartridges they make include air filters, oil filters, hydraulic filters, fuel filters, water filters, and dust collectors. These can be made of different metals, such as stainless steel, aluminum, copper, or brass, depending on the compatibility with the fluids or gases they are intended to filter.

Q: What is the minimum order quantity (MOQ) for metal cartridges in China?

A: The MOQ for metal cartridges in China can vary depending on the manufacturer and the product specifications. Typically, MOQs range from 100 to 500 pieces per order, but some suppliers may require higher volumes or offer lower ones for prototyping or testing. It’s important to clarify the MOQ with the manufacturer before placing an order to ensure you can meet the demand and that the pricing is competitive.

Q: What is the lead time for metal cartridges orders from China?

A: The lead time for metal cartridges orders from China can also vary depending on factors such as product complexity, order volume, and shipping options. Generally, it can take between 2 and 4 weeks for production and another 1 to 4 weeks for shipping, depending on the transport mode (air or sea). Some manufacturers may offer expedited lead times or provide updates on the progress of the order to ensure on-time delivery.

Q: How can I ensure the quality of the metal cartridges from a Chinese manufacturer?

A: To ensure the quality of the metal cartridges from a Chinese manufacturer, you should establish clear quality standards and specifications before placing the order. This can include providing samples, drawings, or references that illustrate the desired features, dimensions, and performance criteria. You should also request quality control reports and inspections from the manufacturer at different stages of production, track the certification of the raw materials and components used, and communicate effectively with the supplier to address any concerns or issues that may arise.