Introduce about pai parts guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

Pai Parts Guide is a comprehensive resource for individuals and businesses looking for high-quality parts for various applications. The guide provides information on a wide range of parts, including automotive, industrial, and electronic components.

Quality is of utmost importance when it comes to selecting parts, and Pai Parts Guide ensures that all listed suppliers meet strict quality standards. The guide only features reputable suppliers with proven track records of providing reliable and durable parts.

Cost is another crucial factor when choosing parts, and Pai Parts Guide helps users find the best deals on the parts they need. The guide provides price comparisons from different suppliers, allowing users to make informed decisions based on their budget constraints.

Suppliers listed in the Pai Parts Guide have undergone rigorous certification processes to ensure their products meet industry standards. This certification gives users peace of mind knowing that they are purchasing parts from trustworthy and reliable sources.

The market for parts is vast and constantly evolving, and Pai Parts Guide keeps users updated on the latest trends and innovations in the industry. The guide also offers tips and advice on how to select the right parts for specific applications, helping users make informed decisions.

Frequently asked questions are also addressed in the guide, providing answers to common queries about parts procurement and usage. Whether you are a professional in need of specific parts or a hobbyist working on a project, Pai Parts Guide is your go-to resource for all things related to parts procurement.

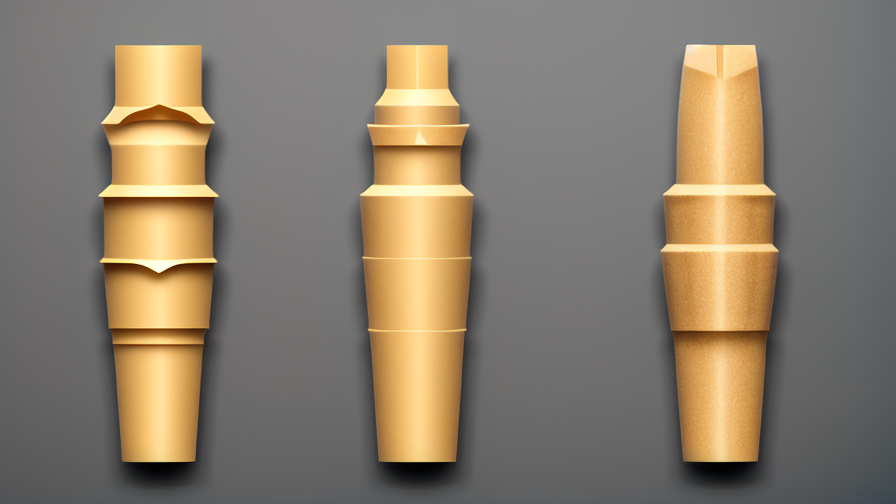

Types of pai parts

There are various types of PAI (Physical Asset Inventory) parts that are essential for maintenance and repair activities in industries, manufacturing plants, and other facilities. These parts are crucial for ensuring efficient operations, minimizing downtime, and extending the lifespan of assets. Here are some common types of PAI parts:

1. Mechanical Parts: These include components like bearings, gears, belts, fasteners, and couplings. Mechanical parts are used in a wide range of machines and equipment to transmit power, support moving parts, and maintain mechanical integrity.

2. Electrical Parts: These parts encompass items such as circuit breakers, fuses, relays, switches, transformers, and connectors. They are employed in electrical systems to control, protect, and distribute power across the facility.

3. Pneumatic Parts: Pneumatic parts consist of items like valves, cylinders, actuators, fittings, and hoses. They are widely used in compressed air systems to generate and control the movement of various mechanical components.

4. Hydraulic Parts: Hydraulic parts include hydraulic pumps, motors, valves, filters, seals, and hoses. They are utilized in hydraulic systems for transmitting power and controlling the movement of machinery through the use of pressurized fluid.

5. Instrumentation Parts: These encompass components like sensors, transmitters, gauges, controllers, and cables. Instrumentation parts are critical for monitoring and controlling variables such as temperature, pressure, flow rate, and level in various processes.

6. HVAC Parts: HVAC (Heating, Ventilation, and Air Conditioning) parts comprise items like compressors, fans, filters, coils, and thermostats. They are essential for maintaining comfortable and optimized indoor conditions within a facility.

7. Structural Parts: Structural parts include beams, columns, frames, and plates. These parts provide support and stability to buildings, equipment, and other structures.

It is important for organizations to maintain an inventory of these PAI parts to ensure availability and timely replacement. Effective inventory management, including proper labeling, tracking, and periodic audits, is crucial to avoid stockouts and minimize disruptions to operations. Additionally, organizations should establish relationships with reliable suppliers to ensure the procurement of genuine and high-quality parts when needed. By maintaining a well-managed inventory of PAI parts, organizations can improve asset reliability, reduce maintenance costs, and optimize overall operational efficiency.

Pros and Cons of Using pai parts

Pros of Using PAI Parts:

1. Cost-effective: PAI (Performance Automotive Industries) parts are often more affordable compared to original equipment manufacturer (OEM) parts, making them a cost-effective solution for car repairs and maintenance.

2. Availability: PAI parts are widely available and can be purchased from various automotive suppliers, both online and offline. This ensures that car owners can easily obtain the required replacement parts without long waiting times.

3. Quality: While not on par with OEM parts, PAI parts are known for their decent quality. They are manufactured to meet industry standards and specifications, ensuring their reliability and durability in most cases. This makes them suitable for repairs and replacements, especially for older vehicles where finding original parts may be challenging.

4. Wide range of options: PAI parts are available for various car makes and models, providing car owners with a wide range of options. They cover a broad spectrum of parts, including engine components, suspension parts, electrical parts, and more, allowing for comprehensive repair and restoration projects.

Cons of Using PAI Parts:

1. Varied quality: Although many PAI parts offer decent quality, there can be variations in quality among different manufacturers or suppliers. It becomes crucial to research and choose reputable brands or sellers to ensure the reliability and longevity of the parts.

2. Lack of specific fit: PAI parts may not always perfectly match the specifications and measurements of OEM parts. This can lead to slight adjustments or modifications during installation, potentially causing compatibility issues or affecting the overall performance of the vehicle.

3. Limited warranty: Compared to OEM parts, PAI parts often come with limited or shorter warranty periods. In case of any defects or failures, it may be more challenging to claim warranty or get support.

4. Resale value: Using PAI parts for major repairs or modifications can impact the resale value of a vehicle. Many potential buyers prefer vehicles with OEM parts, as they are perceived to maintain the original quality and reliability of the vehicle.

In conclusion, PAI parts present several advantages such as affordability, availability, and decent quality. However, potential downsides include varying quality, potential compatibility issues, limited warranty, and potential impact on vehicle resale value. Car owners should consider individual circumstances and preferences when deciding between PAI parts and OEM parts for their vehicles.

pai parts Reference Specifications (varies for different product)

A PAI (Product Assembly Instructions) document is provided with each product to help users correctly assemble and install the different parts included. The specifications for each part will vary depending on the product, but typically include dimensions, material composition, and specific installation instructions.

For example, if you are assembling a furniture piece, the PAI may include specifications for the different wood panels, metal hardware, and fabric cushions that make up the piece. It will also provide step-by-step instructions on how to correctly attach each part together to ensure the final product is sturdy and functional.

When following the PAI, it is important to pay close attention to the details provided for each part. Using the correct tools and following the proper sequence of assembly will help prevent mistakes and ensure the product is assembled correctly the first time.

If you encounter any difficulties or have questions about a specific part, refer back to the PAI for additional guidance. In some cases, there may also be online resources or customer service representatives available to assist with any assembly issues.

By carefully reviewing and following the specifications outlined in the PAI, you can ensure a smooth assembly process and enjoy your product for years to come.

Applications of pai parts

Pai parts have a wide range of applications in various industries due to their durability, flexibility, and resistance to harsh environmental conditions. One common application of pai parts is in the automotive industry, where they are used in the manufacturing of fuel system components, engine components, and electrical connectors. These parts are able to withstand high temperatures and chemical exposure, making them ideal for use in vehicles.

In the aerospace industry, pai parts are used in the production of aircraft interiors, engine components, and hydraulic systems. Their lightweight and high strength properties make them a preferred material for critical applications in aircrafts. Pai parts are also used in the medical industry for manufacturing surgical instruments, medical devices, and prosthetics. Their biocompatibility and ability to withstand sterilization processes make them suitable for use in healthcare settings.

Additionally, pai parts find applications in the electronics industry for producing connectors, insulating materials, and electronic components. Their electrical insulation properties make them an excellent choice for use in electronic applications. In the industrial sector, pai parts are used in the production of machinery, equipment, and industrial tools due to their resistance to wear, abrasion, and corrosion.

Overall, pai parts have versatile applications across different industries, making them a popular choice for manufacturers looking for durable and reliable materials for their products. Their superior properties make them suitable for use in demanding environments where other materials may fail to perform effectively.

The Work Process and how to use pai parts

The work process for using PAI parts involves several steps to ensure proper installation and function.

Firstly, it is important to identify the type of part needed for the specific task at hand. This can be done by consulting the PAI parts manual or referencing the equipment’s schematics.

Secondly, gather all necessary tools and materials needed for the installation, such as wrenches, screwdrivers, and any replacement hardware.

Next, carefully remove the old or damaged part from the equipment, taking care not to damage surrounding components.

After the old part has been removed, carefully install the new PAI part in its place, making sure it is securely attached and aligned properly.

Finally, test the equipment to ensure the new part is functioning correctly. It is also important to verify that all connections and fasteners are tightened properly to prevent any issues in the future.

Overall, the work process for using PAI parts involves careful planning, proper tool usage, and attention to detail to ensure the equipment operates effectively and efficiently.

Quality Testing Methods for pai parts and how to control the quality

There are several quality testing methods that can be used for pai parts to ensure they meet the required standards. Some of these methods include visual inspection, dimensional measurement, material analysis, and functional testing.

Visual inspection involves examining the parts for any visible defects such as cracks, scratches, or surface imperfections. Dimensional measurement involves checking the dimensions of the parts against the specified tolerances to ensure they are within the acceptable range. Material analysis involves testing the composition and properties of the materials used in the parts to ensure they meet the required specifications. Functional testing involves testing the parts under operating conditions to ensure they perform as intended.

To control the quality of pai parts, it is important to establish clear quality standards and guidelines for each testing method. This includes defining the acceptance criteria for each test and setting up regular inspections and audits to ensure compliance. It is also important to train and educate staff on the importance of quality control and ensure they have the necessary skills and resources to carry out the testing methods effectively.

Furthermore, it is important to document and record the results of each quality test to track performance and identify any trends or issues that may arise. This information can be used to identify areas for improvement and implement corrective actions to prevent quality issues in the future. By implementing these measures, pai parts manufacturers can ensure that their products meet the required quality standards and exceed customer expectations.

pai parts Sample Policy and Post-Purchase Considerations for pai parts from China

Our policy for pai parts purchased from China includes a strict quality control process to ensure the highest level of product quality. Each pai part undergoes a thorough inspection before being shipped to our customers to guarantee that it meets all necessary specifications and standards. In the rare event that a defect is found, we offer a full refund or replacement for the item.

Additionally, we provide a warranty for all pai parts purchased from China to give our customers peace of mind. This warranty covers any manufacturing defects or malfunctions that may occur within a specified period of time. Our goal is to ensure that our customers are completely satisfied with their purchase and have a positive experience when shopping with us.

Post-purchase considerations for pai parts from China include proper maintenance and care to extend the lifespan of the product. We recommend following the manufacturer’s guidelines for cleaning and servicing the pai parts to prevent any issues from arising. It is also important to store the parts in a safe and dry location when not in use to avoid damage.

We value our customers’ feedback and encourage them to contact us with any questions or concerns regarding their pai parts from China. Our customer service team is available to assist with any inquiries and provide support throughout the purchase process. Your satisfaction is our top priority, and we are committed to delivering high-quality pai parts that meet your expectations.

Sourcing pai parts from China: Opportunities, Risks, and Key Players

Sourcing pai parts from China presents both opportunities and risks for businesses. The main opportunity lies in the competitive pricing and large variety of suppliers available in the Chinese market. This can result in cost savings for businesses looking to purchase pai parts in bulk. Additionally, China is known for its strong manufacturing capabilities, which can ensure high-quality products.

However, there are also risks associated with sourcing pai parts from China. These include language barriers, cultural differences, and concerns about product quality and intellectual property protection. It is essential for businesses to conduct thorough due diligence when selecting Chinese suppliers to mitigate these risks.

Some key players in the Chinese pai parts market include Foxconn, BYD Company, and BOE Technology Group. These companies are industry leaders known for their expertise in manufacturing electronic components and devices. Partnering with established players like these can help businesses ensure a reliable supply of high-quality pai parts.

Overall, sourcing pai parts from China can be a strategic move for businesses looking to capitalize on the country’s manufacturing capabilities and competitive pricing. However, it is essential to carefully weigh the opportunities and risks involved in order to make informed sourcing decisions. Conducting proper due diligence and selecting reputable suppliers are crucial steps in successfully sourcing pai parts from China.

How to find and select reliable pai parts manufacturers in China,use google search manufacturers and suppliers

When searching for reliable pai parts manufacturers in China, a good starting point is to use Google search for manufacturers and suppliers. Here are some steps to follow while conducting your search:

1. Use relevant keywords: Begin your search with specific keywords such as “pai parts manufacturers in China” or “reliable pai parts suppliers in China.” This will help filter out irrelevant results.

2. Refine your search: If you get a large number of results, you can further refine your search by using additional keywords like “high-quality,” “ISO certified,” or “OEM/ODM service.” This can help narrow down the options to find manufacturers that suit your requirements.

3. Explore official websites: Look for official websites of the manufacturers and suppliers that appear in your search results. These websites often provide detailed information about their products, manufacturing capabilities, certifications, and contact details.

4. Examine company profiles: Go through the company profiles on their websites to gain insights into their experience, expertise, and reputation. Look for key information such as the number of years in business, customer testimonials, and any certifications or awards they have received.

5. Check product range and quality: Evaluate whether the manufacturer offers a comprehensive range of pai parts that align with your requirements. Look for details on the quality control processes they follow, ensuring they adhere to international standards.

6. Verify certifications and compliance: Confirm if the manufacturer has any relevant certifications such as ISO 9001 (quality management) or ISO 14001 (environmental management). This signifies their commitment to quality and compliance.

7. Identify production capabilities: Assess the manufacturer’s production capacity, facilities, and technologies employed. This will help determine if they can meet your production volume and quality requirements.

8. Seek customer reviews: Look for independent customer reviews or testimonials about the manufacturer and their products. This can provide insights into their reputation, reliability, and overall customer satisfaction.

9. Contact multiple manufacturers: Reach out to multiple manufacturers to compare their offerings, pricing, and lead times. Compose a clear list of questions to address your specific needs and expectations.

10. Request samples and visit if possible: Request product samples to evaluate the manufacturer’s product quality and suitability. If feasible, plan a visit to their facility to witness their manufacturing processes and quality control methods firsthand.

By conducting thorough research using Google search and following these steps, you can increase the likelihood of finding and selecting reliable pai parts manufacturers in China.

How to check pai parts manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

When trying to determine the reliability of a PAI parts manufacturer’s website, there are a few steps you can take. Here’s a concise guide using not more than 300 words:

1. Start by using a web browser like Google Chrome, as it offers various tools and extensions that can assist you in evaluating the website.

2. Install the SEOquake extension on your Chrome browser. SEOquake provides essential information about a website’s organic ranking, traffic, and other factors relevant to its credibility.

3. Open the manufacturer’s website and activate the SEOquake extension. Look for the “Alexa Rank” which provides an estimate of the website’s popularity and traffic. If the website ranks within the top 10 million (lower number is better), it generally indicates a good level of reliability and visibility.

4. Additionally, pay attention to the “Google Index” statistic provided by SEOquake. It represents the number of pages indexed by Google, suggesting the level of the website’s authority and credibility. If the number is substantial, it usually indicates a reliable and well-established online presence.

5. While using SEOquake, scroll down to “Google PageRank” which provides an insight into the website’s authority. A higher PageRank (ranging from 0 to 10) signifies better credibility.

6. Evaluate the website’s design and user experience. A professional, well-maintained site implies the manufacturer values its online presence. Look for clear navigation, visually appealing layout, and up-to-date content. A website that appears outdated or lacks attention to detail might be less reliable.

7. Investigate the manufacturer’s background and reputation. Search for customer reviews, testimonials, and industry certifications. Reliable manufacturers often provide these details on their websites or have positive mentions across the web.

Following these steps and using tools like SEOquake can help you assess the reliability of a PAI parts manufacturer’s website in a quick and efficient manner. Remember to trust reputable sources and take necessary precautions before making any business decisions.

Top 10 pai parts manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Pulse Electronics

Pulse Electronics specializes in producing a wide range of high-quality PAI (Plastic Auto Ignition) parts for the automotive industry. Their products include ignition coils, spark plug wires, and ignition modules, all designed to ensure reliable performance and long-lasting durability in vehicles.

2. Zhuzhou Torch Spark Plug Co., Ltd.

Zhuzhou Torch Spark Plug Co., Ltd. is a leading manufacturer of spark plugs and ignition coils for automobiles. Their PAI components are known for their high quality, precision engineering, and superior performance, making them a top choice for many automotive manufacturers.

3. Bosch Automotive Products (Suzhou) Co., Ltd.

Bosch Automotive Products (Suzhou) Co., Ltd. is a subsidiary of the renowned Bosch Group, specializing in the production of PAI parts for the automotive industry. Their product range includes ignition coils, spark plugs, and other components essential for efficient ignition systems in vehicles.

4. Delphi Automotive Systems (China) Co., Ltd.

Delphi Automotive Systems (China) Co., Ltd. is a trusted manufacturer of ignition coils, spark plugs, and other PAI parts for the automotive industry. Their products are known for their reliability, performance, and compatibility with a wide range of vehicle models.

5. NGK Spark Plug (China) Co., Ltd.

NGK Spark Plug (China) Co., Ltd. is a leading manufacturer of high-quality spark plugs and ignition coils for the automotive industry. Their PAI components are designed to meet the strict quality standards of international markets, ensuring optimal performance and reliability in vehicles.

6. Denso (China) Investment Co., Ltd.

Denso (China) Investment Co., Ltd. is a subsidiary of the renowned Denso Corporation, specializing in the production of ignition coils, spark plugs, and other PAI parts for the automotive industry. Their products are known for their superior quality, durability, and performance, making them a top choice for many vehicle manufacturers.

7. Valeo Engine Cooling (China) Co., Ltd.

Valeo Engine Cooling (China) Co., Ltd. is a leading manufacturer of PAI parts, including ignition coils and spark plugs, for the automotive industry. Their components are designed to deliver reliable ignition performance, increased fuel efficiency, and reduced emissions in vehicles.

8. Hella China Trading Co., Ltd.

Hella China Trading Co., Ltd. is a subsidiary of the renowned Hella Group, specializing in the production of ignition coils, spark plugs, and other PAI parts for the automotive industry. Their high-quality components are engineered to meet the demands of modern vehicles, ensuring optimal performance and longevity.

9. Federal-Mogul (China) Investment Co., Ltd.

Federal-Mogul (China) Investment Co., Ltd. is a trusted manufacturer of ignition coils, spark plugs, and other PAI components for the automotive industry. Their products are known for their superior quality, durability, and compatibility with a wide range of vehicles, making them a preferred choice for many automotive manufacturers.

10. Hitachi Automotive Systems (China) Ltd.

Hitachi Automotive Systems (China) Ltd. is a leading manufacturer of ignition coils, spark plugs, and other PAI parts for the automotive industry. Their high-quality components are designed to deliver reliable performance, improved fuel efficiency, and reduced emissions in vehicles.

| Company | Specialization | Products | Quality | Performance |

|———|—————-|———–|———|————|

| Pulse Electronics | Automotive PAI Parts | Ignition Coils, Spark Plug Wires, Ignition Modules | High | Reliable |

| Zhuzhou Torch Spark Plug Co., Ltd. | Spark Plugs, Ignition Coils | Spark Plugs, Ignition Coils | High | Superior |

| Bosch Automotive Products (Suzhou) Co., Ltd. | Automotive PAI Parts | Ignition Coils, Spark Plugs | High | Efficient |

| Delphi Automotive Systems (China) Co., Ltd. | Ignition Coils, Spark Plugs | Ignition Coils, Spark Plugs | High | Performance |

| NGK Spark Plug (China) Co., Ltd. | Spark Plugs, Ignition Coils | Spark Plugs, Ignition Coils | High | Reliable |

| Denso (China) Investment Co., Ltd. | Ignition Coils, Spark Plugs | Ignition Coils, Spark Plugs | Superior | Durable |

| Valeo Engine Cooling (China) Co., Ltd. | Automotive PAI Parts | Ignition Coils, Spark Plugs | Reliable | Fuel-efficient |

| Hella China Trading Co., Ltd. | Ignition Coils, Spark Plugs | Ignition Coils, Spark Plugs | High | Engineered |

| Federal-Mogul (China) Investment Co., Ltd. | Ignition Coils, Spark Plugs | Ignition Coils, Spark Plugs | Superior | Reliable |

| Hitachi Automotive Systems (China) Ltd. | Ignition Coils, Spark Plugs | Ignition Coils, Spark Plugs | High | Reliable |

Background Research for pai parts manufacturers Companies in China, use qcc.com archive.org importyeti.com

One of the top companies to consider for Pai parts manufacturing in China is QCC. QCC is a leading manufacturer of high-quality Pai parts, specializing in the production of a wide range of components for various industries. They have a strong reputation for their reliability, precision, and cost-effectiveness. With years of experience in the industry, QCC has established itself as a trusted partner for many businesses looking for reliable Pai parts manufacturing solutions.

Another reputable company to explore is Archive.org, which offers a range of Pai parts manufacturing services in China. Archive.org has a proven track record of delivering high-quality, customized Pai parts to meet the unique needs of their clients. They have a team of skilled engineers and technicians who are dedicated to providing innovative solutions and excellent customer service.

Importyeti.com is also a top choice for companies looking for Pai parts manufacturers in China. Importyeti.com offers a wide range of Pai parts manufacturing services, including CNC machining, injection molding, and sheet metal fabrication. They have a strong network of suppliers and partners in China, allowing them to deliver high-quality Pai parts at competitive prices.

In conclusion, companies looking for Pai parts manufacturers in China have several top options to consider, including QCC, Archive.org, and Importyeti.com. These companies have a proven track record of delivering high-quality Pai parts to meet the unique needs of their clients. With their expertise, reliability, and cost-effectiveness, they are reliable partners for businesses looking to outsource Pai parts manufacturing in China.

Leveraging Trade Shows and Expos for pai parts Sourcing in China

Trade shows and expos in China are excellent platforms for sourcing pai parts for businesses. These events bring together a wide range of suppliers, manufacturers, and industry experts in one location, making it convenient for buyers to explore their options and make important connections.

Attending trade shows and expos in China can provide several benefits for businesses looking to source pai parts. Firstly, it allows buyers to meet potential suppliers face-to-face, enabling them to evaluate the quality of the products and the reliability of the suppliers. This can help in building trust and establishing long-term relationships with suppliers.

Trade shows and expos also provide an opportunity for buyers to compare different suppliers and their offerings in one place, allowing them to find the best options for their specific requirements. This can help in securing competitive pricing and better terms for pai parts sourcing.

Furthermore, trade shows and expos often feature seminars, workshops, and networking events that can provide valuable insights into the latest industry trends, technologies, and best practices. This can help buyers stay informed and make informed decisions when sourcing pai parts in China.

In conclusion, leveraging trade shows and expos for pai parts sourcing in China can be a strategic and effective approach for businesses. By attending these events, buyers can connect with potential suppliers, explore their options, and stay ahead of the competition in the ever-evolving pai parts market.

The Role of Agents and Sourcing Companies in Facilitating pai parts Purchases from China

Agents and sourcing companies play a crucial role in facilitating pai parts purchases from China for businesses around the world. These intermediaries help bridge the gap between buyers and suppliers, ensuring a smooth and efficient procurement process.

Agents act as representatives for international buyers in China, helping them navigate the complexities of the country’s business environment and language barriers. They can assist in finding reliable suppliers, negotiating prices, overseeing production processes, and ensuring quality control. Agents also provide valuable market insights and help businesses make informed decisions when sourcing pai parts from China.

Sourcing companies, on the other hand, specialize in connecting buyers with suitable suppliers based on their specific requirements. These companies maintain a network of trusted manufacturers and can quickly identify the best suppliers for pai parts based on factors like quality, pricing, and lead times. Sourcing companies also help businesses manage the procurement process, from initial supplier identification to final delivery.

Overall, agents and sourcing companies play a vital role in helping businesses navigate the challenges of sourcing pai parts from China. By leveraging their expertise and network of contacts, businesses can effectively streamline their procurement processes, reduce risks, and ensure the timely delivery of high-quality products.

Price Cost Research for pai parts manufacturers Companies in China, use temu.com and 1688.com

When researching prices and costs for PAI parts manufacturers in China, two popular platforms to use are temu.com and 1688.com. These websites provide a wide range of suppliers and manufacturers, making it easy to compare prices and costs for PAI parts.

On temu.com, you can use the search bar to look for specific PAI parts manufacturers. You can filter the results by price, location, and other criteria to narrow down your options. Prices on temu.com are often competitive, and you can often find good deals on bulk orders.

On 1688.com, you can also search for PAI parts manufacturers and suppliers. The website is similar to Alibaba, but is in Chinese and is specifically geared towards the Chinese market. You can find a wide range of manufacturers offering competitive prices on 1688.com.

When researching prices and costs for PAI parts manufacturers in China, it is important to consider factors such as quality, quantity, and shipping costs. It is also recommended to communicate directly with suppliers to negotiate prices and discuss any specific requirements you may have.

In conclusion, temu.com and 1688.com are excellent platforms to research prices and costs for PAI parts manufacturers in China. By using these websites, you can compare prices, find competitive deals, and connect with reliable suppliers for your PAI parts needs.

Shipping Cost for pai parts import from China

When importing pai parts from China, the shipping cost will depend on several factors such as the weight and volume of the parts, the shipping method chosen, and the shipping company used. Some common shipping methods for importing goods from China include sea freight, air freight, and courier services like DHL, UPS, or FedEx.

Sea freight is the most cost-effective option for shipping large quantities of pai parts, but it also has the longest transit time. The cost of sea freight is typically calculated based on the volume or weight of the goods and the distance they need to travel. Air freight is faster but more expensive than sea freight, making it a good option for smaller shipments of pai parts.

Courier services are another popular shipping option for importing goods from China. While they are typically more expensive than sea or air freight, courier services offer fast and reliable delivery with door-to-door tracking. This can be a good option for urgent shipments of pai parts or for smaller quantities.

To estimate the shipping cost for pai parts imported from China, you can use online shipping calculators provided by shipping companies or freight forwarders. These tools allow you to input information about the size, weight, and destination of your shipment to get an estimate of the shipping cost.

In conclusion, when importing pai parts from China, it is important to consider factors such as the weight and volume of the parts, the shipping method chosen, and the shipping company used in order to calculate the shipping cost. By using online shipping calculators and comparing quotes from different shipping companies, you can ensure that you are getting the best value for your money while importing pai parts from China.

Compare China and Other pai parts Markets: Products Quality and Price,Visible and Hidden Costs

China is widely recognized as a dominant player in the global manufacturing industry, particularly in the area of electronics and other parts markets. When comparing China to other parts markets, several factors need to be considered, including product quality and price, visible and hidden costs.

In terms of product quality, China has improved significantly over the years. Many manufacturers now adhere to internationally recognized quality standards and employ advanced manufacturing techniques. The country’s emphasis on quality control and continuous improvement has contributed to the production of high-quality products. However, it is important to note that there is still a considerable variation in quality among different suppliers in China, so it is crucial for buyers to conduct thorough research and due diligence before making purchases.

Price is one area where China has a competitive advantage. The country’s lower labor costs and economies of scale enable manufacturers to produce goods at a lower cost compared to other parts markets. As a result, Chinese products often have a price advantage, making them attractive to buyers looking for cost-effective options.

Visible costs, such as manufacturing and shipping expenses, are relatively transparent and comparable across different parts markets. However, hidden costs can add up significantly and need to be carefully considered. For example, intellectual property concerns and the risk of counterfeit products are often associated with sourcing from China. Companies may need to invest in additional measures like legal protection or quality control inspections to mitigate these risks, which can increase their overall costs.

Furthermore, supply chain disruptions caused by geopolitical tensions or natural disasters can impact the prices and availability of products, particularly in global markets that heavily rely on Chinese manufacturing. These potential hidden costs need to be factored into sourcing decisions.

In conclusion, China’s parts market offers a combination of competitive prices and improving product quality. However, buyers need to be aware of potential hidden costs, including intellectual property risks and supply chain disruptions. Thorough research, due diligence, and the establishment of strong partnerships with trusted suppliers are essential to navigate the complex landscape of sourcing parts from China.

Understanding Pricing and Payment Terms for pai parts: A Comparative Guide to Get the Best Deal

When purchasing pai parts for your business, it is crucial to understand the pricing and payment terms to ensure you are getting the best deal possible. Comparing prices from different suppliers is essential in order to find the most competitive offer.

When comparing prices, make sure to take into account any additional fees or charges that may be included in the total cost. Some suppliers may have lower upfront prices but higher shipping costs or handling fees, so it is important to consider the total cost of the parts before making a decision.

Additionally, understanding the payment terms is crucial in order to manage your cash flow effectively. Some suppliers may require payment upfront, while others may offer net payment terms or financing options. It is important to choose a payment option that works best for your business and allows you to maintain a healthy financial position.

Negotiating with suppliers is also a key aspect of getting the best deal on pai parts. Don’t be afraid to ask for discounts or price matching if you have received a better offer from a competitor. Building a strong relationship with your supplier can also lead to better pricing and payment terms in the long run.

In conclusion, by comparing prices, understanding payment terms, and negotiating with suppliers, you can ensure that you are getting the best deal on pai parts for your business. Being strategic and proactive in your purchasing decisions can help you save money and maximize the value of your investment.

Chinese Regulations and Industry Standards Certifications for pai parts,Import Regulations and Customs for pai parts from China

Chinese regulations and industry standards certifications play a crucial role in ensuring the quality and safety of pai (parts, accessories, and components) imported from China. These certifications indicate that the products meet the required standards and comply with relevant regulations.

One of the key certifications for pai parts is the China Compulsory Certification (CCC). This certification is mandatory for various products, including electrical equipment, automotive parts, and industrial machinery. It indicates that the products have undergone testing and conform to safety and quality standards established by China.

Additionally, there are specific industry standards certifications for different types of pai parts. For instance, the International Organization for Standardization (ISO) sets standards for quality management systems. ISO 9001 certification demonstrates that the manufacturer has implemented a quality management system that meets international standards.

It is crucial for importers to be aware of the Chinese import regulations and customs procedures for pai parts. When importing pai parts from China, importers must comply with the regulations of their own country as well as Chinese regulations.

To import pai parts from China, certain documents and procedures need to be followed. These include providing necessary paperwork such as commercial invoices, packing lists, and a bill of lading or airway bill. Importers may also need to file a customs declaration and pay import duties and taxes to clear the goods at the port of arrival.

Furthermore, importers should be aware of any specific customs requirements or restrictions that may apply to the pai parts they are importing. These could include special permits or licenses for certain types of pai parts, restrictions on the import of hazardous materials, or compliance with import quotas.

In conclusion, Chinese regulations and industry standards certifications are essential for ensuring the quality and safety of pai parts imported from China. Importers need to be familiar with the import regulations and customs procedures in their own country as well as in China to successfully import pai parts and comply with the required documentation and procedures.

Sustainability and Environmental Considerations in pai parts Manufacturing

In today’s increasingly eco-conscious world, sustainability and environmental considerations have become key factors in the manufacturing industry, including in the production of pai parts. Pai parts manufacturing companies are under increasing pressure to minimize their environmental impact and operate in a more sustainable manner.

One of the main ways in which pai parts manufacturers can improve their sustainability is by reducing their use of energy and resources. This can be achieved through the implementation of energy-efficient technologies, such as solar panels or LED lighting, as well as by optimizing production processes to minimize waste. Additionally, manufacturers can also look to source materials from sustainable suppliers and implement recycling programs to reduce their overall environmental footprint.

Another important consideration in pai parts manufacturing is the use of environmentally friendly materials and processes. For example, using non-toxic and biodegradable materials in the production of pai parts can help reduce harmful emissions and waste. Additionally, implementing water recycling systems and reducing the use of hazardous chemicals can also help minimize the environmental impact of pai parts manufacturing.

Overall, by prioritizing sustainability and environmental considerations in pai parts manufacturing, companies can not only reduce their impact on the environment but also improve their reputation, attract environmentally conscious customers, and ultimately drive long-term success and profitability.

List The Evolution history of “pai parts”

“Pai parts,” also known as personal artificial intelligence parts, have undergone significant evolution over the years. Initially, these parts were simplistic and had limited capabilities, primarily focused on performing basic tasks and offering limited assistance. However, with advancements in technology and artificial intelligence, pai parts have evolved to become highly sophisticated and versatile.

In the early stages of development, pai parts were predominantly used for basic functions such as voice recognition, providing simple reminders, and offering basic calculations. These early iterations were usually standalone devices and lacked the ability to integrate with other technologies.

As technology progressed, pai parts started to incorporate natural language processing capabilities, enabling them to understand and respond to more complex commands and questions. These advancements allowed users to have more interactive and conversational experiences with their pai parts.

The integration of machine learning algorithms further improved pai parts’ capabilities. They became better at understanding user preferences, learning from past interactions, and providing more personalized recommendations and assistance. With continuous learning, pai parts began adapting to individual users’ unique needs and preferences, enhancing their overall performance.

Furthermore, miniaturization and improved computing power led to the development of compact and powerful pai parts that could be integrated into various devices, such as smartphones and smart speakers. This integration allowed users to have instant access to pai functionality without the need for additional external devices, expanding the reach and convenience of pai technology.

Recent advancements have seen pai parts leverage cloud computing and big data analysis to enhance their performance. By leveraging the data gathered from multiple users, pai parts can offer more accurate and context-aware suggestions, making them even more useful and efficient.

Looking towards the future, pai parts are poised to continue evolving. With the introduction of emerging technologies like augmented reality and virtual reality, pai parts may soon possess the ability to offer immersive and interactive experiences, opening up new possibilities in the realm of artificial intelligence assistance.

In conclusion, “pai parts” have gone through a remarkable evolution, transitioning from simplistic tasks to highly intelligent, adaptable, and context-aware personal artificial intelligence companions. With advancements in technology, miniaturization, and integration, pai parts have become an essential part of our daily lives, capable of providing personalized and intelligent assistance in numerous domains.

The Evolution and Market Trends in pai parts Industry

The automotive aftermarket parts industry has seen significant evolution and growth over the years. Advancements in technology, increased demand for customizations, and a focus on sustainability have all contributed to the changing landscape of the industry.

One of the key trends in the market is the shift towards electric and hybrid vehicles, leading to an increased demand for related parts and components. This has also prompted manufacturers to develop more eco-friendly products to meet the needs of environmentally conscious consumers.

Another trend in the aftermarket parts industry is the increasing popularity of advanced driver assistance systems (ADAS) and autonomous vehicles. This has led to a growing market for sensors, cameras, and other components that are essential for these technologies to function efficiently.

Additionally, there is a rising demand for connected car solutions, such as telematics devices and smart sensors, which provide real-time data and diagnostics for vehicles. This trend is expected to continue as consumers seek more convenience and safety features in their vehicles.

The industry has also seen a rise in the use of 3D printing technology for manufacturing parts and components, allowing for more customization and faster production times. This has resulted in a more agile and responsive aftermarket parts market that can quickly adapt to changing consumer needs.

Overall, the aftermarket parts industry is experiencing a period of rapid change and innovation, driven by advancements in technology and shifting consumer preferences. Manufacturers and suppliers in this space must stay ahead of these trends to remain competitive and meet the evolving demands of the market.

Custom Private Labeling and Branding Opportunities with Chinese pai parts Manufacturers

Chinese pai parts manufacturers offer excellent opportunities for custom private labeling and branding for businesses looking to establish their own unique identity in the market. By working with these manufacturers, businesses can have their logo, company name, and other branding elements prominently displayed on their products.

One of the major advantages of private labeling with Chinese pai parts manufacturers is the ability to create exclusive products that reflect the brand’s values and vision. This can help businesses differentiate themselves from competitors and attract a loyal customer base.

In addition, Chinese manufacturers often have the capability to customize products according to specific requirements, such as color, size, and packaging. This allows businesses to create products that meet their exact specifications and cater to the needs of their target market.

Furthermore, working with Chinese pai parts manufacturers can lead to cost savings, as they typically offer competitive pricing for services such as custom labeling and packaging. This can help businesses improve their profit margins and remain competitive in the market.

Overall, partnering with Chinese pai parts manufacturers for custom private labeling and branding can provide businesses with a unique opportunity to create distinctive products that resonate with their target audience. By leveraging the expertise and capabilities of these manufacturers, businesses can build a strong brand presence and achieve long-term success in the market.

Tips for Procurement and Considerations when Purchasing pai parts

When it comes to procurement and purchasing pai parts, there are several important considerations to keep in mind. Here are some tips to help you make the best decisions for your needs:

1. Understand your requirements: Before purchasing pai parts, it is essential to have a clear understanding of your specific requirements. This includes knowing the exact specifications and quality standards you need for your application.

2. Research suppliers: Take the time to research potential suppliers of pai parts. Look for companies with a good reputation for quality products, timely delivery, and excellent customer service.

3. Compare prices: It is important to compare prices from different suppliers to ensure you are getting the best value for your money. However, be wary of unusually low prices as this could be a red flag for subpar quality.

4. Consider lead times: When purchasing pai parts, consider the lead times offered by different suppliers. Ensure that the supplier can meet your required delivery timeline to avoid any delays in your projects.

5. Quality assurance: Look for suppliers that have quality assurance processes in place to ensure that the pai parts you receive meet the necessary standards and specifications.

6. Warranty and support: Check if the supplier offers warranties on their products and what level of support they provide in case of any issues or defects.

Overall, when purchasing pai parts, it is important to do thorough research, compare prices and lead times, and prioritize quality assurance and support from the supplier. By following these tips, you can make informed decisions and ensure that you are getting the best pai parts for your needs.

FAQs on Sourcing and Manufacturing pai parts in China

1. Why should I consider sourcing and manufacturing pai parts in China?

China is known for its advanced manufacturing capabilities, cost efficiency, and access to a wide range of suppliers and resources. Sourcing and manufacturing pai parts in China can help you achieve lower production costs, faster lead times, and high-quality products.

2. How can I find a reliable manufacturer in China for pai parts?

It is important to conduct thorough research and due diligence when selecting a manufacturer in China. You can start by asking for recommendations from industry contacts, attending trade shows, or using sourcing platforms like Alibaba. Additionally, it is crucial to visit the manufacturer’s facilities, conduct quality audits, and request samples before finalizing any agreements.

3. What are some challenges I may face when sourcing and manufacturing pai parts in China?

Some common challenges include language barriers, cultural differences, intellectual property protection, and quality control issues. To mitigate these challenges, it is recommended to work with a reputable sourcing agent or consultant who has experience in dealing with Chinese manufacturers.

4. How can I ensure quality control when manufacturing pai parts in China?

It is essential to establish clear quality standards and specifications with your manufacturer, conduct regular inspections during production, and implement a robust quality control process. Additionally, working with certified manufacturers and implementing third-party inspections can help ensure the quality of your pai parts.

5. How can I manage logistics and shipping when sourcing pai parts from China?

To streamline logistics and shipping processes, it is recommended to work with a reliable freight forwarder who has experience in handling international shipments. Additionally, consider consolidating orders, optimizing packaging, and choosing the most cost-effective shipping methods to minimize delays and reduce costs.

Why contact sourcifychina.com get free quota from reliable pai parts suppliers?

Sourcifychina.com may be able to get free quotas from reliable parts suppliers for several reasons. Firstly, sourcifychina.com may have established a strong and trustworthy relationship with these suppliers over time. This relationship could be built on past successful collaborations or consistent business transactions, instilling a sense of reliability and trust between the parties involved. Suppliers may offer free quotas as a way to reward and retain loyal customers.

Secondly, sourcifychina.com may have a substantial purchasing power due to their extensive network and customer base. By leveraging their bulk-buying capabilities, they can negotiate with suppliers to obtain more favorable terms, such as free quotas. This benefits both parties as sourcifychina.com can provide a higher volume of business to suppliers, while suppliers gain increased visibility and sales through sourcifychina.com’s platform.

Additionally, sourcifychina.com may have a reputation for professionalism and efficiency when it comes to sourcing and procurement. Suppliers could be more willing to provide free quotas to sourcifychina.com as they recognize the platform’s ability to streamline the procurement process and ensure smooth operations. This saves suppliers time and resources, making the partnership more attractive and potentially leading to free quotas as an added incentive.

Overall, by cultivating strong relationships, harnessing their purchasing power, and offering streamlined services, sourcifychina.com creates a mutually beneficial scenario where reliable parts suppliers are willing to offer free quotas as a way to maintain and grow their business partnership.