Knowledge about Part Manufacturing

Part manufacturing is the process of creating components that are used in a wide range of industries, from automotive to aerospace. Understanding the basics of part manufacturing is important for those who work in these industries and those who want to learn about the manufacturing process.

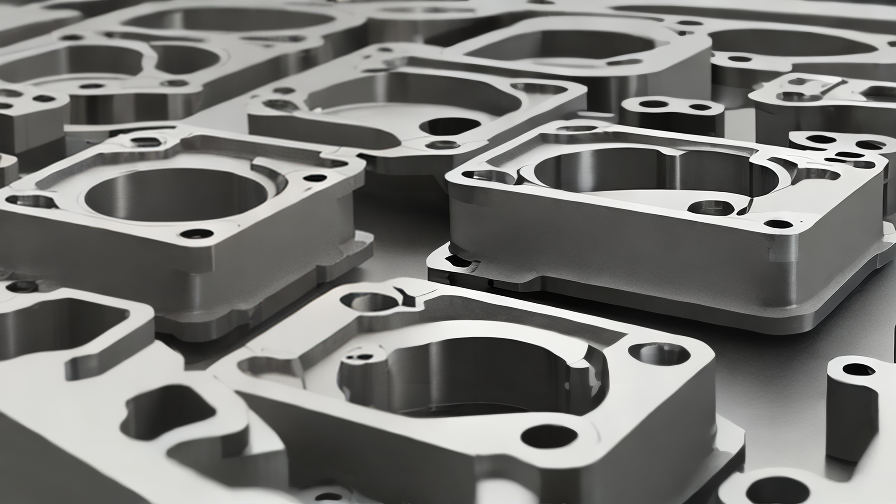

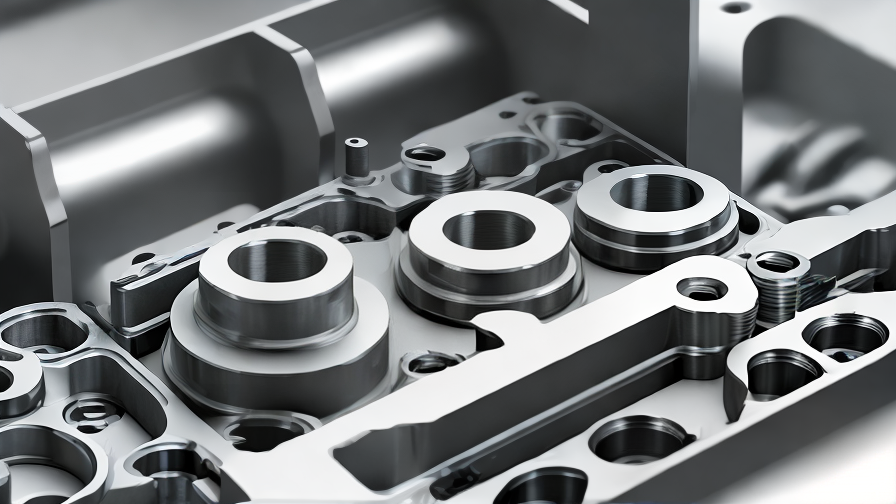

One of the key components of part manufacturing is the production of the actual parts themselves. This involves a range of activities such as casting, forging, and machining. Casting involves creating a mold of the part, pouring molten metal or material into the mold, and allowing it to cool and solidify. Forging involves shaping metal using heat and pressure while machining involves using precision tools to cut, shape, and drill the part.

Another important aspect of part manufacturing is quality control. This involves testing and inspecting the products to ensure they meet the required standards. This can include visual inspections, measurements, and testing the part under load. The parts must also meet the specified tolerances and a variety of tests may be run to check the properties of the part.

When designing parts, engineers must also take into account the materials that will be used. The material must be carefully selected to ensure the part can withstand the loads and stress it will be subject to in its intended use. Different materials have different properties such as strength, weight, and durability, so the choice of material can make a big difference in the final quality of the part.

In conclusion, knowledge about part manufacturing is critical for those who work in industries that require high-quality parts. Understanding the basics of manufacturing, quality control, and material selection is important to ensure the parts produced are of the required standard. By having a thorough understanding of these principles, it is possible to produce components that are reliable, durable, and meet the demands of their intended use.

Various Types of Part Manufacturing

Manufacturing is a complex process that involves turning raw materials into finished products. One of the key aspects of manufacturing is part manufacturing. There are various types of part manufacturing processes, each of which has its own unique advantages and disadvantages.

One of the most common types of part manufacturing is injection molding. This process involves injecting molten plastic into a mold, which then cools and hardens to form the desired part. The advantages of injection molding include high production rates, low cost per part, and the ability to produce complex shapes. However, it may not be suitable for all types of materials and may require additional post-processing steps.

Casting is another type of part manufacturing, which involves pouring molten metal or other materials into a mold. Once the material cools and hardens, the mold is removed to reveal the finished part. Casting has the advantage of being able to produce large, complex parts with high accuracy. However, it can be time-consuming and may require additional processing steps to achieve the desired finish.

Machining is a more traditional method of part manufacturing, in which the material is removed from a solid block to create the desired shape. This process can be used with a range of materials, including metals, plastics, and ceramics. Machining offers high accuracy and can produce parts with complex geometries. However, it can be time-consuming and may not be ideal for larger parts.

Other types of part manufacturing include stamping, forging, and extrusion. Each of these processes has its own unique advantages and limitations, depending on the material and design requirements of the part being produced.

In conclusion, part manufacturing is a vital aspect of the manufacturing process. There are various types of part manufacturing processes, each of which is suited to different materials and design requirements. Choosing the right process is crucial to achieving the desired quality, cost-effectiveness, and production efficiency.

FAQ sourcing Part Manufacturing manufacturer from China

FAQ sourcing part manufacturing manufacturer from China with multiple answers

1. What is part manufacturing?

Part manufacturing is the process of creating a specific component or part that will be used in the final product. This could include pieces of machinery, electronic components or parts for automobiles.

2. Why do people source part manufacturers from China?

China has become a popular location for sourcing part manufacturers because of its competitive prices compared to other countries. They also have a large labor force and advanced manufacturing technology.

3. Can I trust Chinese manufacturers with my product?

Yes, many Chinese manufacturers are reliable and produce high-quality products. However, it is important to do your research and vet potential manufacturers before entering into a business relationship.

4. How can I find a good Chinese part manufacturers?

There are several ways to find a reputable Chinese part manufacturer. You can search online marketplaces, such as Alibaba or Global Sources, attend trade fairs, or seek recommendations from other businesses.

5. How do I communicate effectively with my Chinese manufacturer?

Language barriers and cultural differences can make communication challenging. It is important to have clear and concise documentation, use simple language, and establish open lines of communication with your manufacturer.

6. How long does it take to ship parts from China?

Shipping times vary depending on the distance and method of shipping. It could take anywhere from a few days to several weeks.

In conclusion, sourcing part manufacturers from China can be a viable option for businesses looking for cost-effective and high-quality products. However, it is important to do your research and establish clear communication with your manufacturer to ensure a successful business relationship.

Applications of Part Manufacturing

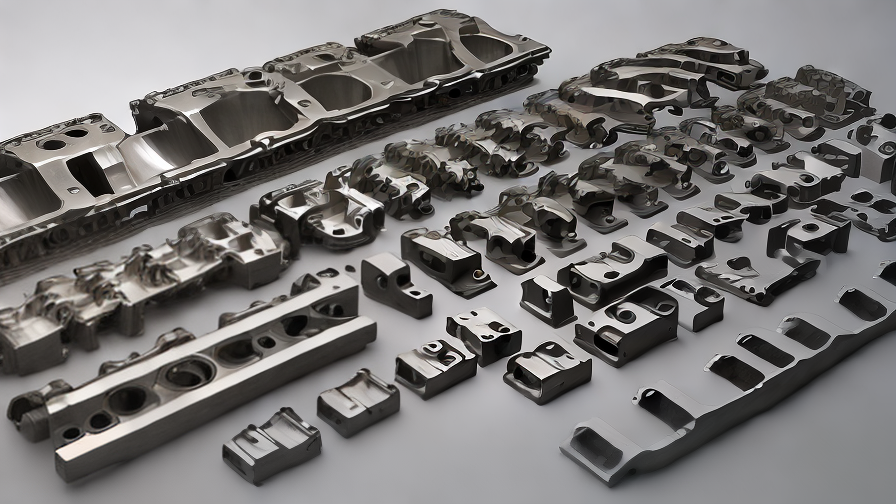

Part manufacturing plays an essential role in many industries ranging from automotive to aerospace. It is the process of creating individual parts that will later be used in larger systems or machines. There are several applications of part manufacturing, including creating spare parts or replacement parts for equipment, producing components for vehicles, and manufacturing custom parts or prototypes.

One of the most common applications of part manufacturing is creating replacements for broken or worn-out parts. In industries such as manufacturing, this can be critical to keep machines in working order and avoid costly downtime. Many companies will have entire departments dedicated to creating replacement parts for their equipment to ensure they can operate at peak efficiency.

Another application of part manufacturing is in the creation of components for vehicles. Whether it’s cars, trucks, or airplanes, there are countless parts that make up each vehicle. Many of these parts need to be manufactured to precise specifications to ensure they function correctly and are long-lasting. This requires specialized machinery and skilled technicians who understand the tolerances and requirements for each component.

Finally, part manufacturing is frequently used to create custom parts or prototypes. This is particularly important in product development, where designers need to create a physical version of their concept to test and refine. Using computer-aided design (CAD) software, designers can create intricate parts with exact specifications, which can then be manufactured using various manufacturing techniques.

In conclusion, part manufacturing has many applications, from creating replacement parts for equipment to producing vehicle components and manufacturing custom parts. Advances in technology and processes have made it possible to produce complex and detailed parts quickly and accurately, allowing industries to operate more efficiently and effectively.

Manufactured Products made of Part Manufacturing

Part manufacturing is a fundamental process that involves the creation of various components for products. These components are later assembled to create a final product. The manufacturing process involves the use of raw materials, machines, and skilled labor to produce high-quality components.

Manufactured products made of part manufacturing are those products that rely on parts manufactured in the part manufacturing process. Products such as cars, bicycles, toys, electronics, and machinery all require parts that are manufactured separately before they are assembled. Part manufacturing involves different techniques such as casting, forging, machining, and stamping to create parts with varying levels of complexity.

In today’s global marketplace, the demand for products made of part manufacturing is on the rise. The manufacturing industry has experienced significant growth and innovation over the years, leading to the production of high-quality components and assembled products that meet the needs of consumers. Part manufacturing has become a crucial aspect of the manufacturing process, and manufacturers are investing in production facilities that enable them to create high-quality parts that meet the specific needs of their customers.

Manufactured products made of part manufacturing offer several benefits to consumers. These benefits include high-quality and durable products, a wide range of product options, and affordable pricing. Part manufacturing allows manufacturers to produce various components that can be combined to create different product configurations, meeting the specific needs of consumers.

In conclusion, manufactured products made of part manufacturing are crucial in the manufacturing industry. The integration of part manufacturing in the manufacturing process has led to the production of high-quality and durable products. As the demand for these products continues to rise, manufacturers are investing in production facilities that enable them to create high-quality parts for various products.

The Evolution history of Part Manufacturing

Part manufacturing has come a long way since its inception. From the earliest forms of handmade tools to the advanced manufacturing processes used today, the evolution of part manufacturing has been a continuous journey of technological advancement.

The earliest forms of part manufacturing date back to ancient civilizations, where craftsmen would create tools and parts by hand using basic tools like chisels, hammers, and fire. It wasn’t until the Industrial Revolution in the 18th and 19th centuries that machinery was developed to automate many of the manufacturing processes.

One of the most significant advancements in part manufacturing came with the development of the assembly line by Henry Ford in the early 20th century. This allowed for the mass production of parts and reduced the time and cost required to produce them. With the growth of the automotive industry, this new approach to manufacturing quickly spread across other industries.

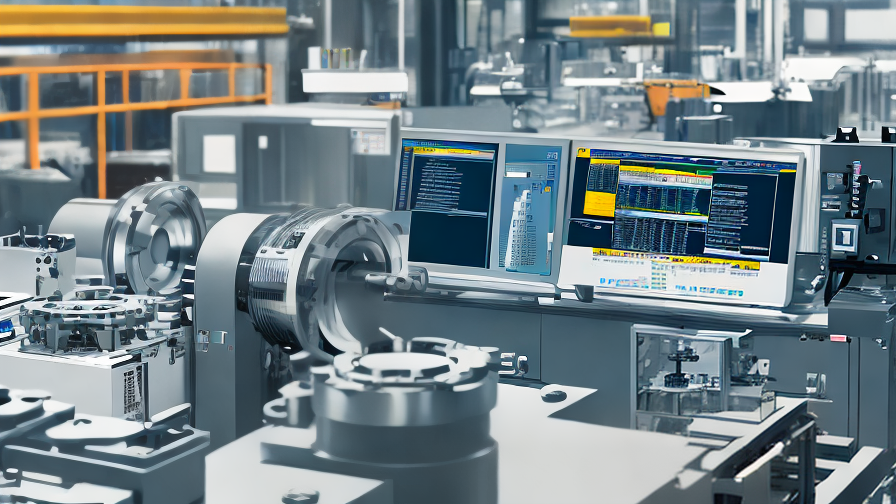

In the latter half of the 20th century, the computer revolutionized part manufacturing. Computer-aided design (CAD) software allowed engineers to create complex 3D models and quickly test different designs. Computer numerical control (CNC) machines enabled manufacturers to create parts with incredible precision and speed.

More recently, advancements in automation techniques such as robotics have further enhanced the manufacturing process, allowing for greater productivity and efficiency. Additionally, 3D printing has revolutionized part manufacturing by allowing for the production of highly customized parts on-demand.

In conclusion, part manufacturing has undergone an incredible evolution over time. From the earliest forms of handmade tools to the highly specialized, automated machines used today, the history of part manufacturing is a testament to human ingenuity and innovation. As technology continues to advance, we can expect even more revolutionary changes in the future.

The Process of Part Manufacturing

Part manufacturing is the process of creating components that will be used in the production of a finished product. The manufacturing process involves several stages, including designing, prototyping, tooling, and production.

The first step in part manufacturing is designing the component. Engineers use computer-aided design (CAD) software to create a 3D model of the part, which is then optimized for manufacturing. This process involves determining the most efficient way to create the part in terms of material usage, cost, quality, and time.

Once the design is complete, the next step is prototyping. A prototype of the part is created to test its functionality and appearance. If any changes need to be made, they are made at this stage.

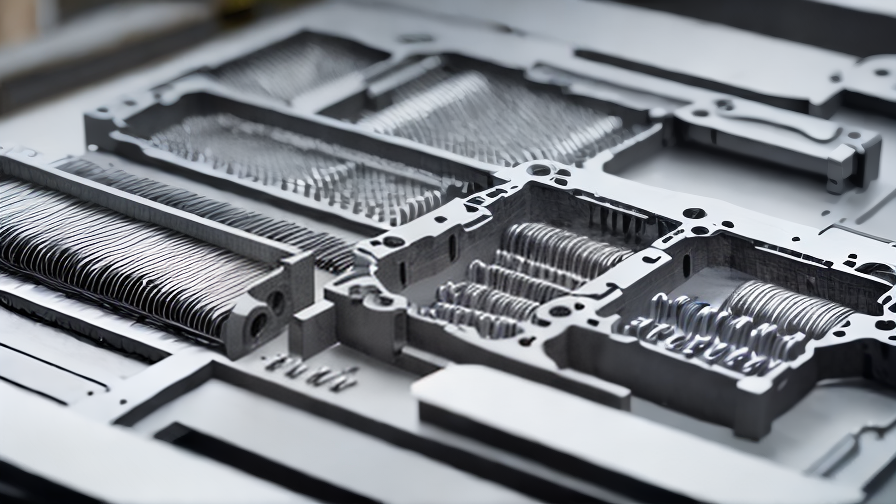

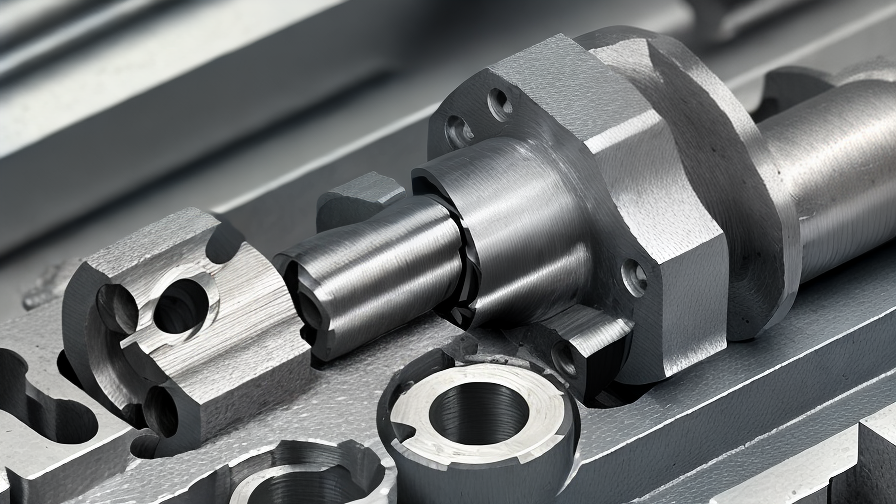

After the prototype is tested and approved, tooling is developed to create the part on a larger scale. Tooling involves creating molds, dies, or machines that will be used to manufacture the part repeatedly. The tooling is typically custom-made for each part, and it must be designed to withstand the forces and speeds of the manufacturing process.

Finally, the production stage involves using the tooling to create the part repeatedly. Depending on the complexity of the part and the desired production rate, different manufacturing processes may be used, including injection molding, casting, machining, or 3D printing.

Throughout the manufacturing process, quality control is essential to ensure that the parts meet the required specifications. This may involve inspections, testing, and documentation to ensure each part meets the necessary standards before being shipped to the customer.

In conclusion, part manufacturing involves several stages, including design, prototyping, tooling, and production. Each stage must be carefully planned and executed to ensure the part is efficiently and precisely manufactured. Quality control is an essential aspect of the process to ensure the final product meets the required specifications.

Benefits Advantages of Utilizing Part Manufacturing

Part manufacturing has become a vital aspect of the manufacturing industry, and there are several benefits and advantages to utilizing it in production processes. Part manufacturing involves the production of specific components or parts that are essential in the assembly of products. These parts can be manufactured using different materials and production methods, depending on the requirements of the product.

One of the benefits of part manufacturing is that it allows for greater flexibility in product design. With the ability to produce different parts in-house, manufacturers can create unique and innovative products that cater to specific needs and market demands. This, in turn, gives them a competitive edge in the marketplace.

In addition, part manufacturing enables manufacturers to control the quality of the parts used in their production process. By manufacturing parts in-house, they can ensure that they meet the necessary quality standards and specifications. This also helps to minimize the risk of defects or failures, which can lead to costly recalls or damage to a company’s reputation.

Another advantage of part manufacturing is that it can lead to cost savings. By producing parts in-house, manufacturers can significantly reduce the cost of purchasing these parts from external suppliers. Additionally, the ability to produce parts on demand can also help to eliminate the costs associated with holding large inventories of spare parts.

Moreover, part manufacturing can also provide manufacturers with greater control over their supply chain. By having the ability to produce essential components in-house, they can reduce their dependence on external suppliers and minimize the risks associated with supply chain disruptions.

Overall, part manufacturing offers several benefits and advantages to manufacturers. It allows for greater flexibility in product design, control over the quality of components used, cost savings, and reduced dependence on external suppliers. With these benefits, it’s no wonder that part manufacturing has become an essential aspect of the manufacturing industry.

Disadvantages Part Manufacturing

Part manufacturing is a crucial aspect of the manufacturing industry. It involves the production of intricate and complex components used in various products. However, despite its immense benefits, there are several disadvantages associated with part manufacturing that manufacturers need to be aware of.

One of the significant disadvantages of part manufacturing is the high initial investment required for the production process. The cost of meeting the stringent manufacturing standards and acquiring high-tech machinery and tools can be prohibitive, especially for small and medium-scale businesses. Without proper financial resources, such businesses may not be able to compete effectively in the global market.

Another disadvantage of part manufacturing is that it often involves a lengthy and time-consuming process. This may be a result of the need for precision and achieving high-quality manufacturing standards. Because of this, manufacturers may have to invest heavily in personnel, equipment, and facilities to ensure production is efficient and effective.

Additionally, part manufacturing is susceptible to production delays and quality control issues. These could be attributed to factors such as human error, lack of standardized processes, and inadequate equipment. Such challenges can significantly disrupt production schedules and lead to long lead times.

Part manufacturing also presents environmental challenges, particularly in the area of waste management. The production process generates a significant amount of waste, including scrap materials, which require special disposal procedures, and can be detrimental to the environment if not handled properly.

In conclusion, part manufacturing, while vital to the production of different products, has its disadvantages. These include high initial investments, lengthy and time-consuming processes, production delays and quality control issues, and environmental challenges. It is essential to be aware of these challenges to take measures to mitigate them and ensure efficient, effective, and sustainable business operations.

Selecting the Ideal Manufacturer Part Manufacturing

When it comes to selecting the ideal manufacturer for part manufacturing, there are several factors that should be taken into consideration. First of all, it is important to choose a manufacturer that has experience and expertise in the specific type of part that you need manufactured. This will ensure that the manufacturer has the necessary knowledge and equipment to produce the part to the desired specifications.

Another important factor to consider when selecting a manufacturer for part manufacturing is their production capacity. You should choose a manufacturer that has the capacity to produce the required quantity of parts within the required timeframe. This will help to ensure that your production schedule is not delayed and that you are able to meet your customer’s needs.

Quality is also a critical factor in part manufacturing. You should choose a manufacturer that has a proven track record of producing high-quality parts that meet the required standards. This will help to ensure that your parts are reliable and will perform as expected.

In addition to experience, capacity, and quality, there are several other important factors that should be considered when selecting a manufacturer for part manufacturing. These may include factors such as cost, location, and communication. It is important to select a manufacturer that is able to provide competitive pricing while still maintaining high standards of quality and timely delivery. Location can also be a factor, as manufacturers that are located closer to your facility may be more convenient and cost-effective to work with.

Finally, effective communication is essential when working with a manufacturer for part manufacturing. You should choose a manufacturer that is responsive and able to communicate clearly and effectively throughout the manufacturing process. This will help to ensure that any issues or concerns are addressed quickly and that the finished product meets your expectations.

In conclusion, selecting the ideal manufacturer for part manufacturing requires careful consideration of several key factors including experience, capacity, quality, cost, location, and communication. By taking the time to evaluate these factors and choosing a manufacturer that meets your needs, you can ensure that your parts will be produced to the highest standards and delivered on time and within budget.

Things to Consider When Purchasing Part Manufacturing

When it comes to purchasing part manufacturing for your business, it is important to keep certain factors in mind to ensure you are making the best decision. Here are some important things to consider when purchasing part manufacturing:

Quality- Quality is paramount, and should be a top priority when purchasing part manufacturing. Ensure the manufacturer delivers top-quality products that meet industry standards, and also match your business needs.

Cost- Of course, everything boils down to cost. A part manufacturer that offers cost-effective pricing can go a long way in optimizing your business operations. Also, do a cost-benefit analysis of the services provided by different manufacturers to determine the one that matches your business budget.

Experience- More experience in part manufacturing means more expertise in the field. It is advisable to opt for a manufacturer with a solid reputation for producing high-quality parts. They need to be knowledgeable about industry standards, safety regulations, manufacturing best practices, and current trends.

Customization- The ability to customize parts for businesses in different industries is crucial. Look for manufacturers who can produce parts that meet your exact specifications and requirements, including producing a prototype before full production.

Equipment- The equipment and machinery used by the manufacturer also play an important role. The manufacturer should have the latest technology and all the necessary equipment capable of producing high-quality parts quickly and efficiently.

Delivery Time- Timely delivery can greatly influence business operations. Choose a manufacturer that is known for timely work completion without compromising on quality.

Customer Service- Business is relationships, and a good customer service would keep you in business. A good manufacturer must offer excellent customer service. They should be ready to listen to your questions and give answers, as well as provide any necessary support.

In conclusion, choosing the right part manufacturer is critical to the success of your business; therefore, you must consider the factors listed above to make the best decision.

Properties of Part Manufacturing

Part manufacturing is the process of creating individual components that will later be assembled into a final product. This process is incredibly important in a variety of industries, including aerospace, automotive, and industrial manufacturing, to name a few. The properties of part manufacturing have a significant impact on the final product, making it crucial to understand the different factors that go into the manufacturing process.

One of the key properties of part manufacturing is precision. The components must be made with a high degree of accuracy to ensure that they fit together and function correctly. This requires careful planning and attention to detail in every step of the manufacturing process, from design to the final inspection.

Another critical aspect of part manufacturing is consistency. This means that every part must be made to the same specifications and standards to ensure that all of the components fit together perfectly. This requires a highly controlled manufacturing process and strict quality control measures.

Material properties also play a crucial role in part manufacturing. The materials used must be selected based on the specific requirements of the component, including its strength, durability, and resistance to wear and tear. Materials must also be chosen based on their ability to withstand the conditions the component will be exposed to, such as high temperatures or harsh chemicals.

Finally, time and cost are significant factors in part manufacturing. The process must be efficient enough to produce parts quickly and affordably while still meeting the necessary quality and precision requirements. Time and cost savings can be achieved through the use of advanced technologies, such as 3D printing and automation, as well as streamlined production processes.

In conclusion, precision, consistency, material properties, time, and cost are all critical factors in part manufacturing. Manufacturers must carefully balance these properties to ensure that they are producing high-quality components that meet the specific requirements of their customers. By understanding the science and engineering behind part manufacturing, manufacturers can create products that meet the highest standards of quality and performance.

How to use Part Manufacturing

Part manufacturing is an essential process for creating various products such as cars, appliances, and industrial equipment. It involves the production of individual components that are assembled to form a final product. Here are some tips on how to effectively use part manufacturing to create high-quality products:

1. Choose the right manufacturing method: There are various methods of part manufacturing, such as casting, forging, and machining. Each method has its own advantages and disadvantages, so it’s crucial to choose the right one for your specific needs.

2. Utilize computer-aided design (CAD) software: CAD software allows designers to create detailed 3D models of parts, which can then be used to generate manufacturing instructions. This ensures accuracy and consistency in the manufacturing process.

3. Optimize part design for manufacturing: Designing parts that are easy to manufacture can help reduce production costs and increase efficiency. For example, minimizing the number of complex features and using standard-sized components can speed up production and reduce the chances of errors.

4. Monitor quality control: Regularly monitoring and testing parts during the manufacturing process can help ensure that they meet quality standards. This can include visual inspections, dimensional measurements, and testing for strength and durability.

5. Consider outsourcing: Outsourcing part manufacturing to a specialized company can be a cost-effective option, especially for small businesses. This allows them to focus on their core competencies while also ensuring high-quality parts are being produced.

In conclusion, part manufacturing is an essential process for creating high-quality products. By following these tips, businesses can effectively utilize part manufacturing to optimize efficiency and minimize production costs.

Glossary Terminology Terms for Part Manufacturing

Manufacturing is a complex process that involves several aspects, including designing, planning, sourcing, and producing. Part manufacturing, in particular, is a process of creating various components that go into larger machines or structures. To understand this process better, it’s essential to familiarize yourself with the following glossary terminology terms for part manufacturing:

1. CAD/CAM- Computer-Aided Design/Computer-Aided Manufacturing: A software system that integrates the design and production process of parts or products.

2. CNC- Computer Numerical Control: A technology that uses computer-controlled machines to produce parts, including lathes, mills, and routers.

3. Injection Molding- A method of producing plastic parts by injecting molten plastic into a mold.

4. Welding- Joining two parts together through the use of heat or pressure.

5. Machining- A process of cutting, shaping, or drilling parts using machine tools, such as lathes, millers, and drills.

6. Casting- Making a part by pouring molten material into a mold.

7. Tolerance- The allowable degree of deviation from a prescribed dimension in a part or product.

8. Tooling- The process of creating the tools used in manufacturing parts or products.

9. Fixture- A device used to hold a part in place during the manufacturing process.

10. Quality Control- The process of ensuring that the parts or products meet the required specifications.

Knowing these terms is instrumental in understanding and communicating effectively with manufacturers when it comes to part manufacturing. Doing so helps ensure that the end product is of high quality and meets the prescribed requirements. By having a clear understanding of the terminology, you can also communicate more effectively with suppliers, designers, and other stakeholders involved in the process.

In conclusion, part manufacturing is a complex process that involves several steps and requires a considerable understanding of the terminology. Understanding the glossary terminology terms mentioned here is beneficial not only for manufacturers but also for end-users, as it helps ensure the

Part Manufacturing Price

Part manufacturing price is an important aspect that directly affects the overall cost of a product. Manufacturers need to keep a close eye on this factor to ensure the viability of their manufacturing process.

Several factors determine the part manufacturing price. These include the quality and quantity of materials, the cost of labor, the level of automation in the production process, the time taken to manufacture the product, and many more.

One of the primary determinants of part manufacturing price is the quality of raw materials used. If high-quality materials are used, the manufacturing process may become more expensive, thereby leading to a higher part manufacturing price. Similarly, the cost of labor also plays a significant role in determining the manufacturing price. Skilled labor is expensive, and as such, manufacturing companies that use a lot of skilled labor tend to have a high manufacturing price.

The level of automation in the manufacturing process also affects the manufacturing price. Highly automated production processes tend to be costlier than manual processes. However, automated processes often result in higher quality products, reduced errors, and shorter production times.

The time taken to manufacture a part is also a significant determinant of manufacturing price. Some products require longer manufacturing times, while others may have shorter production times. The longer the time, the higher the manufacturing price.

To keep part manufacturing prices low, manufacturing companies should consider various strategies. One such strategy is to focus on improving the efficiency of their production processes. This may involve reducing waste, utilizing high-yield manufacturing techniques, and investing in more technology to increase automation.

Another strategy is to leverage economies of scale. By increasing production volume, the manufacturing price may reduce due to lower costs of materials and labor. Manufacturing companies may also consider outsourcing some parts of the manufacturing process to countries with lower labor costs, such as China or India.

In conclusion, part manufacturing price is a crucial aspect of the manufacturing process. Several factors determine the manufacturing price, including the quality of materials, the cost of labor, the level of automation, and the production time.