Knowledge about Pipe Laser

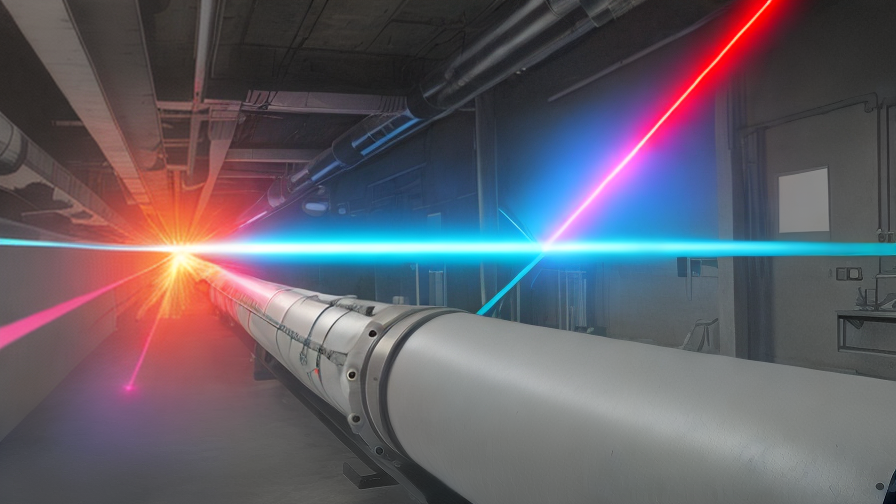

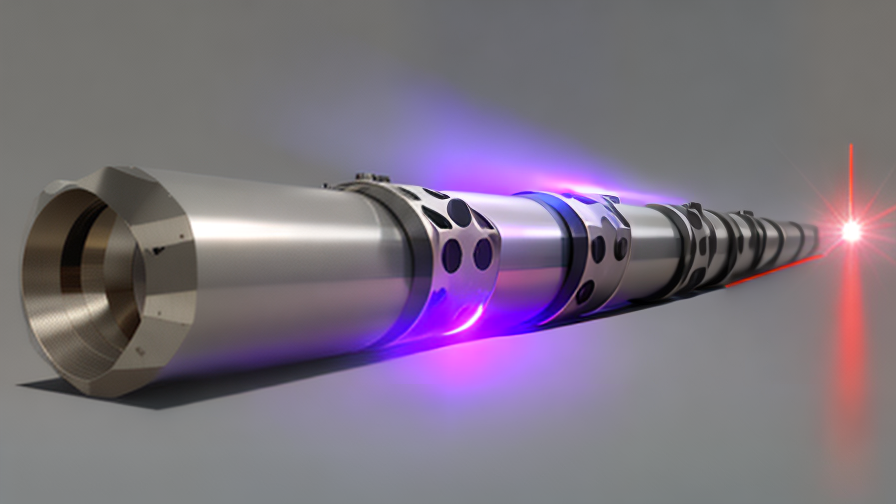

A pipe laser is a powerful construction tool that assists contractors in various construction processes for the perfect laying of pipes. It is an advanced laser level that allows users to install pipes with precision and confidence, even in the most challenging terrain.

The knowledge of using a pipe laser is a vital skill for any civil engineer or construction worker. Essentially, pipe lasers help ensure accurate pipe grading by delivering a constant level across any given distance. Gradient pipes are now feasible, thanks to the pipe laser’s accuracy and speed. The device beams a laser onto the pipeline’s centerline or onto a target placed on the pipe’s top to provide an exceedingly precise alignment.

The pipe laser is the visual output of its expanded functionality. It can function as an accurate tool for measuring distances between points, highlighting the maximum height difference between two points, and leveling among other functions. It has a varying range of radius and sizes designed to cater to different pipe diameters.

One of the most significant advantages of using a pipe laser is the speeding up of the construction process. It speeds up completion times by providing instant and accurate readings while eliminating the need for intermediate measuring devices.

Pipe lasers also come in weather-resistant and waterproof housing, which can endure harsh environments such as snow, rain, and moisture. With the pipe laser, construction projects get completed faster, accurately, and more qualitatively, reducing errors and increasing efficiency.

In conclusion, a pipe laser is an invaluable tool for civil engineers and construction workers, and acquiring knowledge on its use is essential to produce quality works in the field. It offers an accurate, safe, and fast way to gauge distance, levels, and pipes’ gradients. Furthermore, it has weatherproof features and offers performances suited for any given terrain. Therefore, it is an excellent tool for delivering quality and efficient pipeline construction projects.

Various Types of Pipe Laser

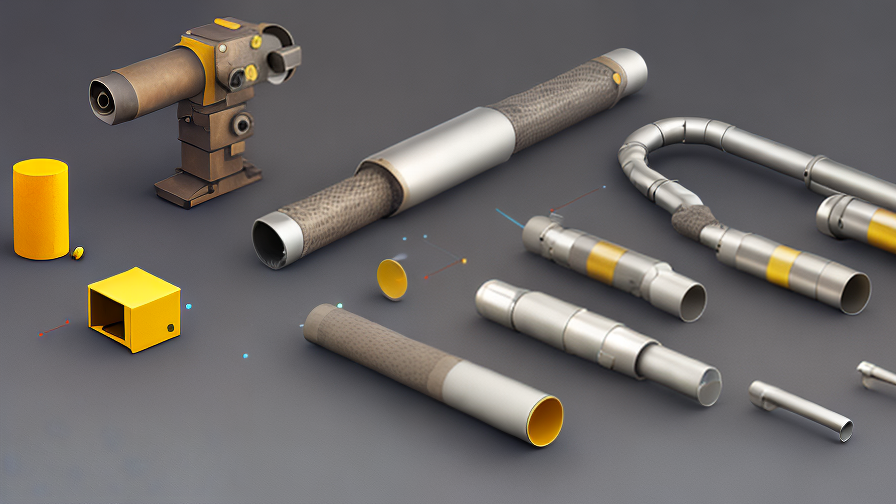

A pipe laser is a type of laser level that is designed to be used in underground construction, particularly when laying pipelines. There are various types of pipe lasers available on the market that cater to different construction needs. In this article, we’ll take a look at some of the different types of pipe lasers.

Rotary Pipe Laser

A rotary pipe laser is the most common type of pipe laser. It is designed to be mounted on a tripod or directly on the pipe being laid. It emits a self-leveling beam that rotates 360 degrees and provides a level reference for the crew.

Alignment Pipe Laser

An alignment pipe laser is typically used for drainage, grading or sewer line installation. Unlike a rotary pipe laser, an alignment pipe laser produces a visible beam that can be aimed precisely, so that the pipe can be perfectly aligned to the desired slope.

Green Beam Pipe Laser

A green beam pipe laser emits a green-colored laser light. This is particularly helpful when working in bright sunlight, as the green color is more visible than the red color of traditional pipe lasers.

Grade Pipe Laser

A grade pipe laser is specifically designed for fine-tuning the grade of the pipeline being installed. It emits a thin, highly visible laser beam that is used to set the grade to within millimeters of precision.

Dual Grade Pipe Laser

A dual grade pipe laser allows the contractor to set two slopes at once, saving time and reducing the need for multiple setups. This type of laser is ideal for projects where a lot of grade work needs to be done, such as sports fields or golf courses.

In conclusion, choosing the right pipe laser for a project depends on the type of job being performed. Rotary pipe lasers are the most versatile and commonly used, while alignment pipe lasers are more specialized for specific tasks. Green beam pipe lasers are great for outdoor use, and grade pipe lasers and dual grade pipe lasers offer high levels of precision for more demanding projects. By understanding the differences between these various types of pipe lasers, construction

FAQ sourcing Pipe Laser manufacturer from China

FAQ sourcing Pipe Laser manufacturer from China with multiple answers

When it comes to sourcing a Pipe Laser manufacturer from China, one may have several questions in mind. Here are some frequently asked questions (FAQ) with multiple answers that may help in making an informed decision.

1. What is a Pipe Laser and why is it useful?

A Pipe Laser is a specialized laser tool that helps in the accurate and efficient alignment of pipes in construction projects. It can be used for laying pipes at a specific slope or grade and ensures that the pipes are level and properly aligned. It saves time, reduces labor costs and increases accuracy in the pipe laying process.

2. What are the key factors to consider when sourcing a Pipe Laser manufacturer from China?

Some key factors to consider are the quality of the product, pricing, production capacity, after-sales service, certifications, and ease of communication. It is essential to choose a reputable manufacturer that meets these requirements and has a proven track record of delivering high-quality products.

3. How can I ensure the quality of the product?

One can ensure the quality of the product by conducting a product inspection, testing and certification, visiting the factory and reviewing the manufacturer’s quality control process. It is also important to select a manufacturer that has a reputation for providing quality products and has a solid track record of delivering to other markets.

4. What is the expected delivery time?

Delivery time may vary depending on the quantity of the order, the complexity of the product, and the manufacturer’s production capacity. It is important to communicate with the manufacturer and get a clear timeline and delivery schedule beforehand.

5. Are there any warranty or after-sales services provided by the manufacturer?

Many manufacturers provide warranty or after-sales services for their products, such as repair or replacement, technical support, and training. It is important to inquire about these services and ensure they are provided before finalizing an order.

In conclusion, sourcing a Pipe Laser manufacturer from China can be a valuable investment for construction projects. By considering the key

Applications of Pipe Laser

Pipe lasers are sophisticated and highly accurate tools used in construction, landscaping, and other related industries. They provide precise and reliable measurements, allowing contractors and engineers to increase their work efficiency and ensure high-quality results. In this article, we will explore some of the most common applications of the pipe laser.

1. Pipeline Construction – Pipe lasers are invaluable tools in constructing pipelines. They can accurately measure slope and grade and ensure that the pipeline is laid at the correct angle. This reduces the chances of leaks and improves the overall durability of the pipeline.

2. Landscaping – Pipe lasers can be used in landscaping to level land for lawns and gardens. They provide accurate measurements of the slope and grade of the land, making it easy for landscapers to level the land evenly.

3. Road Construction – Pipe lasers are also used in road construction. They can accurately measure the slope of the road, ensuring that the road is laid at the correct angle to provide proper drainage. This reduces the likelihood of erosion and helps ensure the road’s longevity.

4. Sewer and Drainage Systems – Pipe lasers are used extensively in the construction of sewer and drainage systems. They can measure the slope at which the pipes should be laid to ensure proper drainage, reducing the chances of blockages and leaks.

5. Building Construction – Pipe lasers are also used in building construction. They are used to measure the slope and angle of foundations and walls to ensure that they are level, straight, and stable.

In conclusion, pipe lasers are highly valuable tools in the construction industry. They can be used for a variety of applications, including pipeline construction, landscaping, and road construction. By providing accurate and reliable measurements, pipe lasers help ensure that projects are completed efficiently, accurately, and with high-quality results.

Manufactured Products made of Pipe Laser

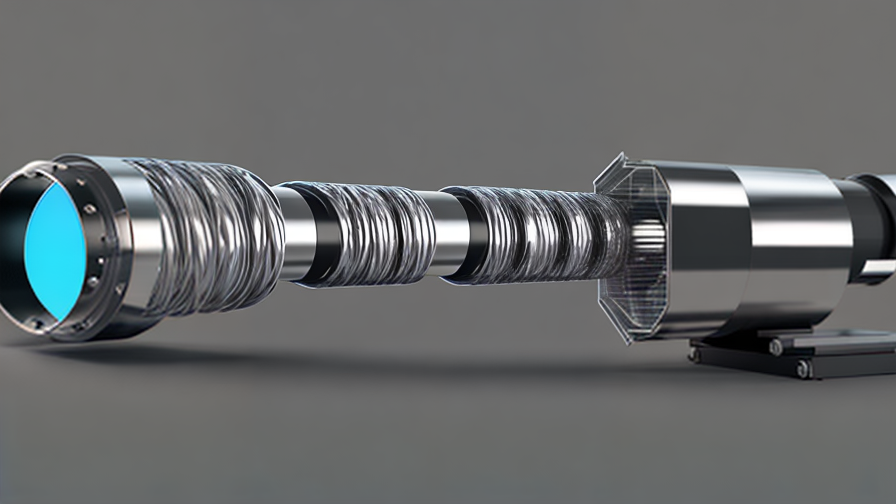

Pipe laser technology has revolutionized the way we manufacture products made of metals. These products are mostly of high quality and seamless finish. The use of pipe laser machines has allowed us to produce tubes, pipes, and other products that are suitable for construction industries, manufacturing, and other various applications.

The process is simple yet accurate, starting with the insertion of a metal tube into the pipe laser machine. The machine then uses a laser beam to cut and shape the metal according to the desired specifications. The finished product is then ready to be used according to the needs of the customer.

The advantages of using pipe laser machines in the manufacturing process are numerous. Firstly, the process allows for quick and accurate production of products. Secondly, it eliminates the need for manual production, which can be time-consuming and often results in errors. Lastly, the finished products are of high quality with no imperfections, making them ideal for use in various industries.

The products manufactured using pipe laser technology include various types of pipes and tubes, including those made of stainless steel, aluminum, and copper. They are used in a variety of industries, including construction, automotive, aerospace, and medical.

The use of pipe laser technology has enabled us to produce products with tight tolerances, resulting in accurate and precise cuts. This has led to a significant reduction in waste during the manufacturing process, thereby reducing costs and promoting sustainability.

In conclusion, the use of pipe laser machines has revolutionized the manufacturing process of metal products. The benefits of pipe laser technology are numerous and include quick and accurate production, elimination of errors associated with manual production, and high-quality finished products suitable for various industries. With the continued advancements in this technology, we can expect to see even more quality products manufactured in the future.

The Evolution history of Pipe Laser

The pipe laser has been an essential tool for construction workers for decades. It has revolutionized the way that pipes are installed in construction projects. The evolution of the pipe laser has been a long process that has led to the advanced technology we have today.

In the early days of construction, a simple laser beam was used to sight the grade. This method required an aid, like a target or a survey rod, which would allow the user to see the grade level. However, this process was not accurate, and it was difficult to use in the field.

In the 1990s, the first pipe laser was introduced. This device had a self-leveling feature, which allowed workers to have an accurate, stable line that was easy to use. They were expensive, and only a few operators had the training to use them.

As technology advanced, so did the pipe laser. New features like laser pointers and remote controls were added, which made them easier to use, and more accurate. In the 2000s, the pipe laser became more affordable, and more widely used in the construction industry.

Today, the pipe laser is a critical tool in the construction industry. It has come a long way from the days of a simple laser beam. The modern pipe laser can handle even the most complicated pipe installations with ease, and its remarkable features allow for excellent accuracy and reliability. The modern-day pipe laser can be used in various constructions such as sewer lines, drainage pipes, water pipes and even gas pipelines.

In conclusion, the evolution history of the pipe laser has been a long journey. The early days of using a simple laser beam to sight the grade are gone, and now we have a more advanced and reliable pipe laser that can handle even the most complicated pipe installations. It is fascinating to see how technology has revolutionized the construction industry with this remarkable tool – the pipe laser.

The Process of Pipe Laser

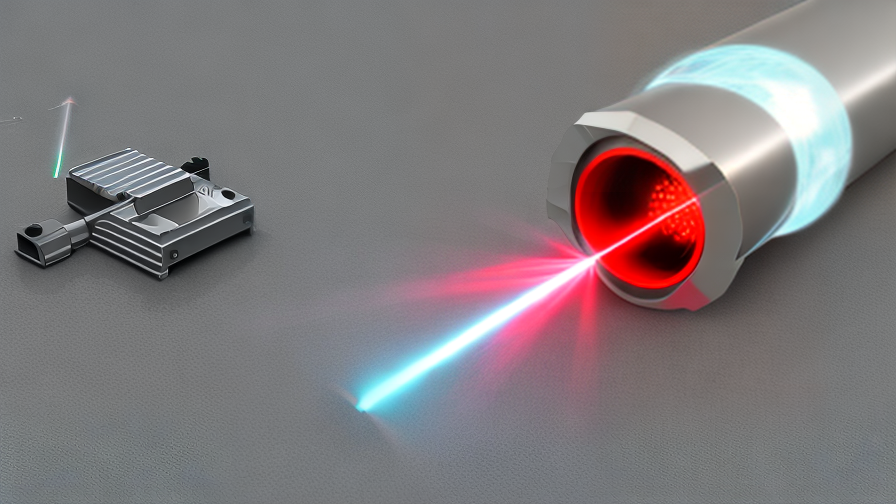

Pipe laser is a powerful tool used in construction projects that involves laying pipes, such as sewer lines or water mains. Its use enables engineers and contractors to achieve precision and accuracy during pipe placement. The pipe laser is easy to use, and its operation follows a process that involves several steps.

The first step in the pipe laser process is the identification of the elevation to which the pipe should be laid. Hence, the surveyor establishes the reference point at the start of the project using an electronic level, and the relevant data is transmitted to the pipe laser. The accuracy of this stage sets the foundation for the entire process.

The second step is to attach the pipe laser to the pipe. The laser is attached to a set of brackets that clamp to the pipe’s exterior side, and once fixed, the pipe laser sends out a laser beam, horizontally and vertically, to mark a reference line. The laser adjusts to the given slope angle set by contractors that’s defined by surveyor and the brackets fixed to it, ensuring utmost accuracy.

The third step of the process involves the calibration of the pipe laser to the correct grade, as set by the surveyor. This step determines the correct level of the laser elevation for proper pipe placement. Calibration enables the pipe laser to send a signal to the operator if the pipe deviates from the intended grade level during pipe installation.

The fourth and final step is the actual placement of the pipe. The placement of the pipe follows the reference line created by the laser beam, adjusting to slope angles, and making sure that the pipe is at the right elevation. The laser beam provides an essential reference point to ensure the pipe remains level throughout the installation process.

In conclusion, the process of pipe laser is straightforward and easy to operate. Using pipe laser in pipe installation projects saves time and reduces job-site errors while improving accuracy and precision. With the right calibration and installation, the pipe laser-aided pipe placement process can be an effective solution for laying pipes of all sizes and shapes.

Benefits Advantages of Utilizing Pipe Laser

A pipe laser is a versatile and powerful tool in the construction industry that can save time and money. The use of pipe lasers has become increasingly popular over the years because of the incredible benefits associated with their use. In this article, we’ll talk about some of the benefits and advantages of utilizing a pipe laser.

One of the significant advantages of using a pipe laser is its high level of accuracy. With its advanced technology, pipe lasers can ensure precise measurement capabilities, making it ideal for large construction projects that require high accuracy. Pipe lasers provide a precise leveling of the pipe, resulting in a smooth flow of water and other liquids.

Another benefit of utilizing pipe lasers is that it makes construction work more efficient. Unlike traditional survey methods, the speed of the pipe laser allows for faster and more accurate results. This not only saves time but also reduces the costs associated with construction.

With the help of pipe lasers, construction workers can work smarter, not harder. The laser’s precision allows crews to work with accuracy and minimal errors, leading to better and more efficient construction projects.

Pipe lasers can also be used for both underground and above-ground structures. These structures include sewage systems, gas pipelines, water pipelines, and drainage systems. With their ability to adapt to any environment, pipe lasers can meet the requirements of any construction project and provide accurate measurements for every type of pipe layout.

Finally, using a pipe laser is easy and requires minimal training. The tool is user-friendly and can be operated by construction workers without any difficulties. This means that the need for specialized staff and long training periods is eliminated, making it an affordable tool.

In conclusion, pipe lasers provide many benefits and advantages that make them an excellent tool for the construction industry. Their accuracy, efficiency, adaptability, and ease of use make them invaluable in construction projects. With these benefits, pipe lasers are becoming increasingly popular and are sure to be a staple tool in the industry for years to come.

Disadvantages Pipe Laser

A pipe laser is a handy tool for measuring the level and slope of pipes during construction. However, this equipment also comes with some disadvantages that need to be considered before using it on a project.

Firstly, one of the major drawbacks of pipe lasers is that they are expensive. Due to their advanced technology and sophisticated features, pipe lasers come with a hefty price tag. Not all construction companies can afford to invest in such equipment, especially for small projects.

Secondly, pipe lasers require regular maintenance and calibration to operate efficiently. Any slight misalignment, damage, or calibration issue can affect the accuracy of the measurements, leading to costly construction errors.

Thirdly, pipe lasers cannot work on all types of pipes. They are suitable only for smooth, uniform surfaces like PVC, concrete, and clay pipes. Therefore, if you’re working with corroded, uneven, or poorly installed pipes, a pipe laser may not work accurately, and manual measurements may be necessary.

Fourthly, pipe lasers require a clear line of sight between the laser and the detector. This means that any obstructions like trees, buildings, or other structures can hinder the laser’s range, resulting in inaccurate readings.

Finally, pipe lasers are not very user-friendly for workers with limited experience, especially in manual control or calibration. The lack of training can lead to misuse or careless handling, which might cause costly damages and project delays.

In conclusion, a pipe laser is a useful tool in construction that offers accurate pipe leveling and sloping measurements. However, it comes with its disadvantages, including its high cost, regular maintenance requirements, limited application, dependence on a clear line of sight, and complexity of use. These factors must be considered before using a pipe laser to ensure its effectiveness and efficiency.

Selecting the Ideal Manufacturer Pipe Laser

When it comes to selecting the ideal manufacturer pipe laser, there are a number of factors that must be taken into consideration. These can include the laser’s accuracy, the range of measurements it is capable of making, its durability, its ease of use, and the level of customer support that the manufacturer provides.

One critical factor to keep in mind is the laser’s accuracy. Depending on the job at hand, even a slight deviation in measurement can have serious consequences. Therefore, manufacturers who can offer consistent accuracy within a certain margin of error can be particularly appealing.

Another important consideration is the range of measurements that the laser can make. A laser that can accurately measure a wide range of diameters and pipe types can be invaluable in a number of applications.

Additionally, the durability of the laser is a critical concern. Depending on the environment in which it will be used, the laser may be subjected to extreme temperatures, moisture, or abrasive material. Therefore, selecting a manufacturer who can offer a laser that is built to withstand these challenges can make all the difference in its longevity.

Ease of use is also a key factor in selecting the ideal manufacturer pipe laser. Ideally, the laser should be easy to set up and operate, even by those who are new to using laser measurement technology.

Finally, the level of customer support that the manufacturer provides can also be a significant consideration. Quality manufacturers will offer strong customer support, including technical assistance and troubleshooting advice, to help ensure that the laser performs optimally over the long term.

In summary, when selecting the ideal manufacturer pipe laser, a number of factors must be taken into account. By considering each of these factors carefully and choosing a manufacturer who can deliver on all fronts, users can be confident that they will have a reliable, accurate, and durable tool in their hands.

Things to Consider When Purchasing Pipe Laser

When it comes to purchasing a pipe laser, there are a few important things that need to be considered in order to ensure that you get the right product for your needs. Here are some of the most important things to keep in mind when purchasing a pipe laser.

Firstly, it is important to take into account the type of pipe that you will be working with. Different pipe lasers are designed for different applications, so make sure to choose one that is suitable for the type of pipes that you will be working with. For instance, if you will be working with large diameter pipes, you will need a pipe laser with a longer range and a higher accuracy rating.

Another important factor to consider when choosing a pipe laser is the range. This is the distance that the laser can accurately measure, and is a crucial consideration when working with longer pipe sections. A longer range is generally better, but it is also important to consider the accuracy of the laser at different ranges.

The accuracy of the laser is also a key consideration. The more accurate the laser, the more precise your measurements will be. Look for a product with a high level of accuracy, as even small inaccuracies can have a big impact on your final results.

Ease of use is also important when selecting a pipe laser. Choose a product that is easy to operate, with clear instructions and a user-friendly interface. This will help to ensure that you can use the laser safely and accurately.

Other factors to consider may include the battery life of the device, the number of functions it offers, as well as its overall durability and build quality.

In summary, when purchasing a pipe laser, it is important to consider the type of pipe you will be working with, the range and accuracy of the laser, ease of use, battery life, and overall build quality. Taking these factors into account will help you to select a product that meets your needs and provides accurate and reliable results.

Properties of Pipe Laser

A pipe laser is a versatile tool used in construction for transferring elevations and slopes. It is used for the purpose of setting grade for sewer, storm drainage, and water pipelines. Pipe laser is a lightweight and portable instrument capable of delivering accurate measurement data on rugged construction sites.

Properties of Pipe Laser:

1. Highly Accurate: Pipe laser is an instrument of high accuracy with a capability of measuring a slope of up to 10 percent. This makes it an ideal tool for use in different areas of construction.

2. Easy To Use: The pipe laser is easy to use and can be operated by a single person, which saves time and ensures accuracy.

3. Long Battery Life: Pipe lasers are powered by rechargeable batteries which can last up to 30 hours, depending on the model.

4. Versatile: Pipe laser is versatile and can be used for various functions like setting grade, installing drainage pipes, and setting survey benchmarks.

5. Weather Resistant: Pipe lasers are designed to be used in rugged construction sites, and hence they come with weather-resistant properties to perform even in harsh weather conditions.

6. Remote Control: Some pipe lasers come with a remote control feature that enables the user to operate the instrument from a distance, which makes it convenient for use.

In conclusion, the pipe laser is a versatile and precise instrument designed for measuring slopes and elevations on construction sites. It has features that make it efficient, such as easy to operate, long-lasting battery life, high accuracy, and weather-resistant properties. With its versatility and easy-to-use design, the pipe laser is an essential tool in the construction industry.

How to use Pipe Laser

A pipe laser is a valuable tool for professionals working in the construction industry. It allows them to accurately position pipes with the correct slope and elevation. Here are some steps that will help you use a pipe laser:

1. Setup: Before using a pipe laser, you need to select a stable location to place the laser, which is generally at the end of the pipe. Make sure that the laser is level and turn it on. Also, ensure that the battery of the laser is fully charged.

2. Aligning the Laser: Once the setup is complete, it’s time to align the laser beam with the pipe. Use the adjusting knobs found on the laser to adjust the beam vertically and horizontally until it aligns with the center of the pipe.

3. Set Elevation: Now that the laser beam is aligned with the pipe, set the desired elevation. You can use the control panel of the pipe laser to do this. Ensure that the laser beam is now hitting the target at the desired height.

4. Fine-tuning: Once the pipe laser is set up, you need to ensure that it stays operational. Continuously monitor the laser beam to ensure that it does not drift off the target. You can use a receiver to ensure that the settings are correct.

5. Usage: You are now ready to use the pipe laser to position your pipes. The beam will guide you in positioning the pipes to the correct slope and elevation.

In summary, using a pipe laser requires careful setup and alignment, as well as continuous monitoring to ensure accuracy. With practice, you will become more familiar with operating the pipe laser and will be able to use it more efficiently.

Glossary Terminology Terms for Pipe Laser

When it comes to pipe laser equipment, there are several important terms and definitions that professionals in the construction industry need to be familiar with. Here are some of the key glossary terminology terms for pipe laser:

1. Laser Detector – This is an electronic device used to receive signals from the pipe laser.

2. Grade Control – A system used to maintain the proper elevations and slopes of the pipe being installed.

3. Auto-leveling – A feature that automatically levels the pipe laser when it is placed on an uneven surface.

4. Laser Target – A device used to reflect the pipe laser beam back to the detector.

5. Slope Control – A system used to maintain the proper slope of the pipe being installed.

6. Self-leveling – A feature that automatically levels the pipe laser without the need for manual adjustments.

7. Vertical Alignment – A process used to ensure that the pipe is installed vertically.

8. Self-centering – A feature that centers the pipe laser beam on the pipe being installed.

9. Zero Tilt – A feature that ensures that the pipe laser is perfectly level.

10. Pipe Jack – A support device used to hold the pipe laser in place on the pipe.

Overall, these terms and definitions play an important role in ensuring that pipe laser equipment is used effectively and accurately in construction projects. Understanding them is crucial for professionals in the industry to successfully install pipes and meet precise engineering specifications.

Pipe Laser Price

Pipe laser is a very useful tool in the construction industry as it helps to measure and mark precise levels and angles on pipes. They are usually used in large construction sites and are essential for the installation of pipes.

The price of a pipe laser depends on several factors, including the brand, the features, the range, and the accessories that come with it. Generally, pipe lasers range from $1,000 to $10,000. Some high-end models can cost over $20,000.

A basic pipe laser will have a limited range and minimal features. On the other hand, a higher-end model will have a more extended range, advanced features like automatic levelling and grading, and better accuracy.

When purchasing a pipe laser, it is essential to consider the project’s needs, the level of accuracy required, and the budget. It may be tempting to settle for a cheaper model, but it could result in more time and money spent trying to fix mistakes due to the lack of accuracy.

Moreover, it is also essential to consider accessories like rechargeable batteries, tripods, and remote controls when making a purchase as they could impact the total cost of ownership in the long run.

In conclusion, the price of a pipe laser varies depending on the brand, range, features, and accessories. Therefore, it is essential to weigh the options and consider the project’s needs before making a purchase to ensure the best value for money.