Benefits of Planetary Gearbox Manufacturer

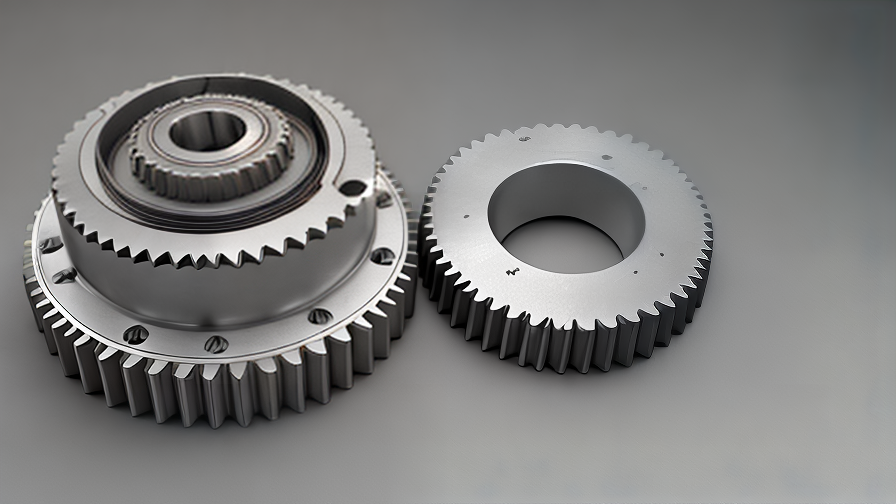

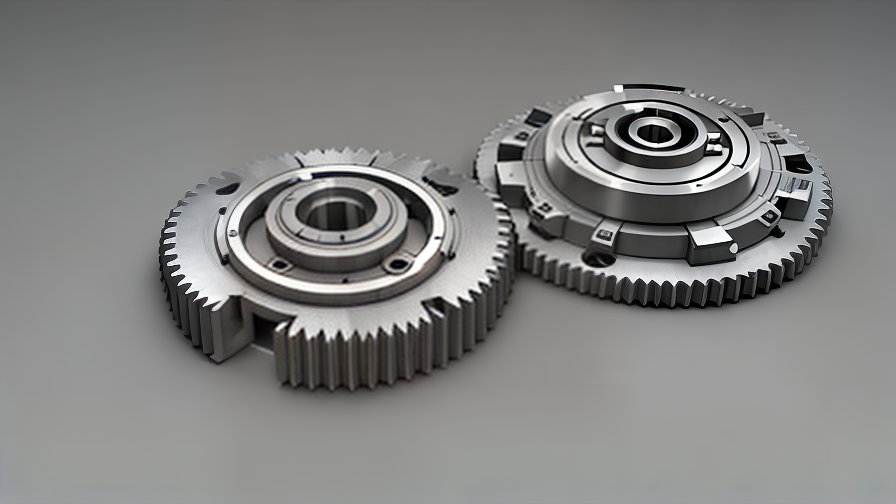

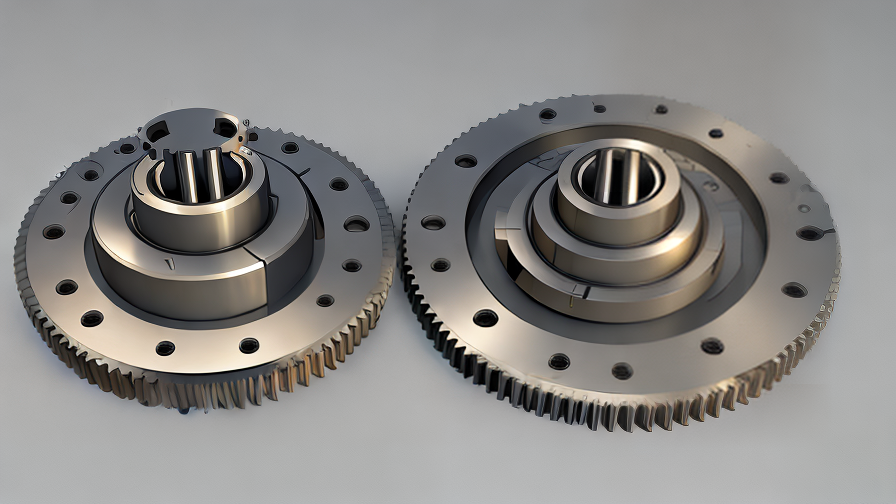

A planetary gearbox is a mechanical device that has multiple gears components arranged in a manner similar to our solar system, with the largest gear serving as the central “sun” and smaller gears orbiting around it. Planetary gearboxes are reliable and efficient in transmitting power from an input source to an output shaft; they are commonly used in a wide range of industrial equipment, including machinery, vehicles, and robotics.

One of the most significant benefits of working with a planetary gearbox manufacturer is that they offer custom designs to meet specific application requirements. By working closely with customers to understand their needs, manufacturers can develop a gearbox that delivers optimal performance, durability, and efficiency.

Another advantage of working with a specialized planetary gearbox manufacturer is their expertise in designing and manufacturing high-precision components. These manufacturers use advanced tools and methods to ensure that each component of the gearbox meets the required specifications and tolerances, resulting in a high-quality product that performs consistently and reliably.

Planetary gearbox manufacturers also provide comprehensive support and maintenance services to ensure that their products function properly throughout their lifespan. These services may include installation assistance, repair and replacement of parts, and regular maintenance to prevent potential failures or breakdowns.

In addition, manufacturers of planetary gearboxes offer cost-effective solutions that can help to reduce overall operational costs. By providing a high-efficiency gearbox that requires minimal maintenance and consumes less power, manufacturers can help their customers to reduce energy consumption and lower their operating expenses.

Finally, working with a planetary gearbox manufacturer provides customers with access to the latest advancements in gearbox technology. These manufacturers invest in research and development to enhance their products’ performance, functionality, and durability. Thus, customers get high-tech gearboxes that meet their evolving needs.

In conclusion, partnering with a reliable and specialized planetary gearbox manufacturer brings many benefits for businesses. Increased efficiency, cost savings, and access to advanced technology are just a few of the advantages that customers can enjoy. Hence, it is advisable to engage with a reputable manufacturer to get the best products and services.

Features of Planetary Gearbox Manufacturer

A planetary gearbox is used to transmit torque and rotational speed in machinery. It consists of several gears, including a sun gear, ring gear, and planet gears, all encased in a gearbox body. To ensure high efficiency and precise functioning, it is important to choose the right planetary gearbox manufacturer. Here are some key features to look for:

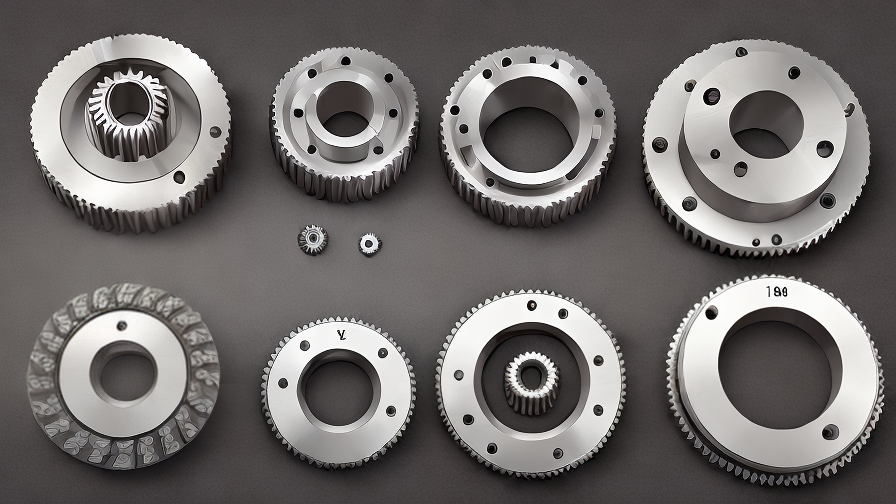

Design flexibility: A good planetary gearbox manufacturer will offer several customization options to cater to the specific requirements of different industries. The ability to design and manufacture gearboxes in different sizes, ratios and specifications helps the customer to optimize performance.

Durability: A planetary gearbox must be able to withstand heavy loads, high-temperature fluctuations, and corrosive environments. The manufacturer should utilize materials and manufacturing processes that result in highly durable products, which can last for years without needing replacement or repairs.

Efficiency: The efficiency of a planetary gearbox is an important factor for customers. A good manufacturer will provide gearboxes that are designed to ensure low friction, minimal noise, and high efficiency across different RPMs (rotations per minute).

Ease of maintenance: A planetary gearbox requires regular maintenance to ensure smooth operation and prevent breakdowns. A reliable gearbox manufacturer will design a product that ensures easy access to maintenance points, thereby reducing downtime and enhancing convenience.

Expertise: A planetary gearbox is complex machinery that requires expertise in design, manufacturing, and application. The manufacturers with industry expertise have a deeper understanding and can offer expert advice on bespoke solutions.

Conclusion: Choosing the right planetary gearbox manufacturer is crucial when it comes to maintaining equipment performance and avoiding breakdowns. Consider features like design flexibility, durability, efficiency, ease of maintenance, and expertise when choosing a manufacturer.

Various Types of Planetary Gearbox Manufacturer

Planetary gearbox is a type of gearbox that is commonly used in a wide range of industrial applications. This gearbox has several components that work together to create a compact, efficient and powerful system. In order to meet the demands of different industries, there are various types of planetary gearbox manufacturers available in the market.

The first type of planetary gearbox manufacturer is a general-purpose manufacturer. These manufacturers produce planetary gearboxes that are suitable for a wide range of applications. These gearboxes are often made from high-quality materials and are designed to be durable, reliable, efficient and long-lasting.

The second type of planetary gearbox manufacturer is a specialist manufacturer. These manufacturers focus on producing planetary gearboxes that are specifically suited to a particular industry or application. For example, some manufacturers specialize in producing gearboxes for the aerospace industry, while others specialize in producing gearboxes for the automotive industry.

The third type of planetary gearbox manufacturer is a custom manufacturer. These manufacturers work closely with their clients to design and produce planetary gearboxes that are tailored to their specific needs. This can include creating gearboxes that have specific ratios, output torques, input speeds or other unique features.

Overall, there are many different types of planetary gearbox manufacturers available in the market. Each manufacturer has its own unique strengths, weaknesses, and areas of expertise. Regardless of the type of manufacturer you choose, it is important to work with a manufacturer that has a proven track record of producing high-quality, reliable and efficient planetary gearboxes. By doing so, you can ensure that your planetary gearbox will meet your needs and exceed your expectations.

Applications of Planetary Gearbox Manufacturer

Planetary gearbox manufacturer is a versatile technology that has been in use in various fields for several years now. This technology has become popular due to its numerous benefits, including high efficiency, compact size, and reduced noise. Manufacturers have come up with various applications for planetary gearboxes, making them suitable for different machines and tasks.

The first and most common application of planetary gearboxes is in the automotive sector. Planetary gearboxes are used in vehicles’ transmission systems to control the engine’s power and transfer it to the wheels. They offer high efficiency and can reduce mechanical loss, leading to improved fuel economy. Planetary gearboxes also provide smooth and accurate shifting, making driving more enjoyable.

Planetary gearboxes are also essential in the robotics industry. Planetary gearboxes are used in robotic arms and joints to provide torque, control speed, and increase precision. Robotics application benefits from the small size and high efficiency that planetary gearboxes offer, allowing for smaller robot designs with increased performance.

Another crucial application of planetary gearboxes is in the industrial market, where they are used in conveyor belts, cranes, and other heavy-duty equipment. The high torque provided by planetary gearboxes allows these machines to move heavy loads with ease. The compact design of planetary gearboxes also saves space, allowing manufacturers to use them in machines with a limited footprint.

In the renewable energy sector, planetary gearboxes are used in wind turbines to convert the rotational energy of the blades into electricity. These types of gearboxes can operate in extreme environments, including high winds and low temperatures, making them ideal for wind turbines.

Planetary gearboxes are also used in medical equipment, including CT scans and MRIs, where accuracy and precision are crucial. The compact design of planetary gearboxes allows for smaller imaging machines, which can improve patient comfort and reduce radiation doses.

In conclusion, the applications of planetary gearbox manufacturer are endless, and it’s hard to imagine industries operating without them. From automotive, robotics, the industrial market, renewable energy, to medical equipment, planetary gearboxes have proven to be reliable and efficient, making them fit for any task that requires precision and high performance.

The Process of Planetary Gearbox Manufacturer

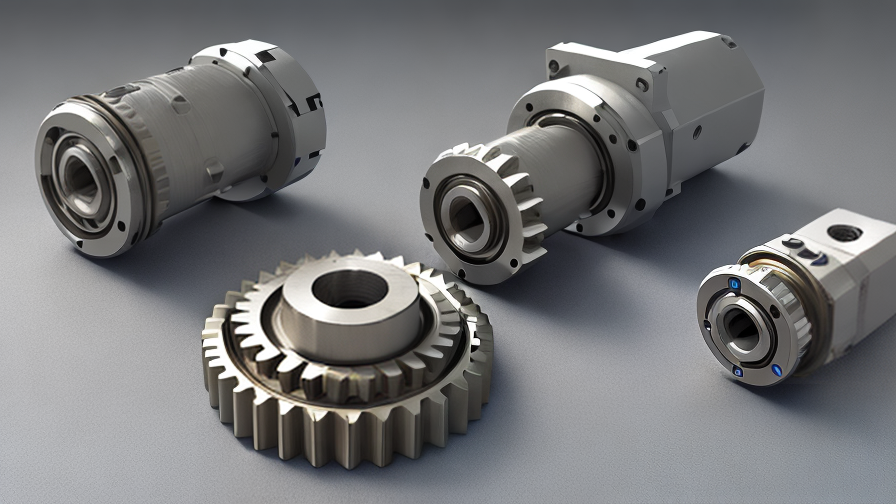

The process of planetary gearbox manufacturer involves several steps to ensure the production of high-quality and durable products. These steps typically include design, machining, assembly, testing, and quality control.

The first step is the design phase, where the manufacturer creates virtual models and simulations of the gearbox to ensure that it meets the required specifications and performance criteria. This phase is critical as it helps to identify any potential design flaws or issues before the actual manufacturing process.

Once the design is finalized, the manufacturer moves on to the machining process. This involves using computer-controlled machines to fabricate the various components of the gearbox, including the gears, shafts, and casings. This process requires high precision to ensure that the components are within the specified tolerances.

After the components are machined, they are assembled to create the planetary gearbox. This process involves carefully fitting the various parts together, aligning them correctly, and securing them in place. The manufacturer must ensure that each component is installed correctly to prevent any potential problems during operation.

Once the gearbox is assembled, it undergoes extensive testing to ensure that it meets the required specifications and performance criteria. This includes functional testing, durability testing, and torque testing. Any issues identified during the testing phase are addressed before the gearbox is shipped to the customer.

Throughout the production process, the manufacturer must conduct strict quality control measures to ensure that the final product meets the required specifications and standards. This includes inspections at each stage of production and rigorous testing before the gearbox is shipped to the customer.

In conclusion, the process of planetary gearbox manufacturer is a complex and intricate one that requires careful attention to detail and high precision. By following these steps, manufacturers can produce reliable, durable, and high-performance gearboxes that meet the needs of their customers.

How to use Planetary Gearbox Manufacturer

A planetary gearbox, also known as an epicyclic gearbox, is a complex mechanical system that can be a challenge for those who have never used one before. However, with the right knowledge and guidance, it’s straightforward to use. Here’s a brief guide on how to use a planetary gearbox manufacturer:

Step 1: Determine your torque and speed requirements. Before selecting a gearbox, it’s essential to define the torque and speed levels you require. This will depend on the application, so make sure to consult engineering specifications before proceeding.

Step 2: Choose the right type of gearbox. Planetary gearboxes come in various types, including inline, parallel shaft, and right-angle designs, among others. Consider the space constraints, mounting requirements, and shaft orientation when choosing the appropriate gearbox.

Step 3: Connect the gearbox to your motor. Once you’ve selected the gearbox, connect it to your motor by aligning the shafts and using appropriate couplings. Make sure to follow the manufacturer’s installation guidelines for a precise fit.

Step 4: Adjust the gearbox’s gearing ratio. Planetary gearboxes consist of multiple gears with varying tooth sizes, which means you can adjust the gearing ratio to modify speed and torque output. Adjust the ratio using the gearbox’s input and output shafts to match your application’s requirements.

Step 5: Test the gearbox. Once you’ve made all the necessary adjustments, test the gearbox to ensure optimal performance. Check the gear and motor temperatures, noise levels, and vibration frequencies to ensure the system is functioning correctly.

In conclusion, using a planetary gearbox manufacturer requires precise calculations, careful selection of the gearbox type, and accurate installation. Follow these steps, and you’ll be on your way to a well-functioning mechanical system.

Selecting the Ideal Manufacturer Planetary Gearbox Manufacturer

When it comes to selecting an ideal Planetary Gearbox Manufacturer, it is crucial to keep certain factors in mind. Planetary gearboxes are used in various industries for a variety of applications, and selecting the right manufacturer is essential to ensure that the gearbox is reliable and effective.

The first factor to consider when selecting a manufacturer is their experience in producing planetary gearboxes. It is important to choose a manufacturer who has a proven track record of producing high-quality gearboxes, which can be done by researching their reputation and customer reviews.

Another crucial factor is the customization options available. The manufacturer should be able to provide customized gearboxes to suit individual requirements. This can range from gear ratio and torque requirements to special coatings or materials.

Quality is another important factor to consider. The manufacturer should have a robust quality control process in place to ensure that each gearbox is thoroughly tested and meets the necessary standards before being shipped out to the customer.

Cost is also a consideration, but it shouldn’t be the only factor. It is best to choose a manufacturer who offers competitive prices while also providing high-quality gearboxes and excellent customer service.

Finally, a manufacturer who provides after-sales service and support is crucial. This can include technical support, maintenance, and repairs. It is important to choose a manufacturer who can provide prompt and efficient assistance in the event of any issues or problems with the gearbox.

In conclusion, selecting the ideal planetary gearbox manufacturer requires careful consideration of factors such as experience, customization options, quality, cost, and after-sales service and support. By choosing a manufacturer who excels in all these areas, you can ensure that your gearbox is reliable, efficient, and tailored to your unique needs.

list FAQ with answer about Planetary Gearbox Manufacturer

Planetary gearbox is one of the most efficient types of gearboxes that is commonly used in various industrial applications. However, when it comes to choosing the right planetary gearbox manufacturer, customers often have a lot of questions, which we aim to answer in this article.

Q: What is a planetary gearbox and how does it work?

A: A planetary gearbox is a type of gearbox that works on the principle of planetary motion. It consists of a central gear or sun gear, a ring gear, and one or more planet gears. The sun gear rotates around the ring gear, while the planet gears rotate around the sun gear, resulting in high torque output.

Q: What industries typically use planetary gearboxes?

A: Planetary gearboxes are commonly used in industries such as robotics, automotive, aerospace, defense, material handling, and construction.

Q: What factors should be considered when selecting a planetary gearbox manufacturer?

A: Factors such as the manufacturer’s experience, quality certification, customization options, price competitiveness, customer support, and after-sales service should be considered when selecting a planetary gearbox manufacturer.

Q: What types of planetary gearboxes are available?

A: Planetary gearboxes are available in various types such as spur gear planetary gearbox, helical gear planetary gearbox, bevel gear planetary gearbox, worm gear planetary gearbox, and hybrid planetary gearbox.

Q: What are the advantages of using a planetary gearbox?

A: Planetary gearboxes possess several advantages such as high torque density, high efficiency, compact size, low noise, and minimum maintenance.

Q: Can planetary gearboxes be customized?

A: Yes, planetary gearboxes can be customized according to the application requirements, such as size, ratio, input/output mechanism, and material.

Q: What is the lead time for manufacturing a planetary gearbox?

A: The lead time for manufacturing a planetary gearbox can vary depending on the complexity and customization of the gearbox. However, it typically takes 4-12 weeks for standard planetary gearboxes.

Planetary gearbox manufacturers play a crucial role in the industrial supply chain. By addressing these frequently asked questions and concerns, customers can make informed decisions regarding their gearbox needs.

Things to Consider When Purchasing Planetary Gearbox Manufacturer

When it comes to purchasing a planetary gearbox, there are several things you need to consider to ensure that you get the right product. Planetary gearboxes are vital components in many manufacturing processes, so it’s essential to choose a reliable and reputable manufacturer. Here are some things to consider when purchasing a planetary gearbox manufacturer.

Quality: The first and foremost thing to consider is the quality of the manufacturer’s products. You need to ensure that the planetary gearbox you’re buying is made of high-quality materials and meets industry standards. You can check the manufacturer’s credentials, read reviews from previous customers, and look at their product warranty to gauge their product’s quality.

Price: Planetary gearboxes can be expensive, so you need to consider the cost when choosing a manufacturer. You can compare prices from different manufacturers and choose the one that provides products within your budget. However, make sure that you don’t compromise on quality when choosing a cheap product.

Experience: The level of experience a planetary gearbox manufacturer has is also a crucial factor to consider. You can find out how long they have been in business and what type of customers they have worked for. An experienced manufacturer is more likely to produce high-quality gearboxes and provide better customer service.

Customization: If you need customized planetary gearboxes, you need to find a manufacturer that can provide them. You should consider a manufacturer that offers a variety of customization options, including ratio, size, and torque. Customized gearboxes can be tailored to meet specific requirements in your manufacturing process.

Customer service: Good customer service is critical when purchasing a planetary gearbox manufacturer. You need to ensure that the manufacturer you choose has a good reputation for providing excellent customer service. You want to make sure that they can answer your questions and provide assistance when you need it.

In conclusion, when choosing a planetary gearbox manufacturer, you need to consider the quality of products, price, the level of experience, customization options, and customer service. By considering these factors, you can select the best manufacturer for your needs and ensure that you get a reliable and high-quality planetary gearbox.

Properties of Planetary Gearbox Manufacturer

Planetary gearbox manufacturers create a unique type of gearbox that works with multiple gears rotating around a central sun gear. This type of gearbox has a unique set of properties that make it useful in a variety of industrial settings.

One of the main properties of planetary gearboxes is their high torque capacity. Due to the way the gears are arranged, they can transfer a large amount of torque without taking up much space, making them ideal for applications where space is limited. Planetary gearboxes are often used in robotics, aerospace, and industrial automation because of their compact size and high power density.

Another property of planetary gearboxes is their efficiency. The multiple gears in the gearbox allow for power to be transferred over a larger area, reducing stresses on individual gears and improving overall efficiency. This makes planetary gearboxes ideal for applications where energy efficiency is important, such as in electric vehicles.

Planetary gearboxes also have excellent speed reduction capabilities. The arrangement of the gears allows for multiple speed reductions to be achieved in a single gearbox, making them useful in applications such as conveyor systems or machinery that requires multiple speed settings.

Finally, planetary gearboxes are highly adaptable. They can be customized for specific applications by changing the number and size of the gears, or by adjusting the gear ratios. This versatility makes planetary gearboxes suitable for a wide range of industries and applications.

In conclusion, planetary gearbox manufacturers produce gearboxes with unique properties that make them ideal for a range of industrial applications. Their ability to transmit high torque in a compact space, high efficiency, speed reduction capabilities, and adaptability make them a valuable tool in industries that require precise and powerful machinery.

Technical Parameters Terms for Planetary Gearbox Manufacturer

A planetary gearbox is a mechanism that is used to transmit power between two or more components in a system. The gearbox consists of a set of gears that rotate around an axis in a planetary motion. A planetary gearbox manufacturer must have a good understanding of the technical parameters that are required to design, develop and manufacture efficient planetary gearboxes.

Technical parameters refer to the design criteria that must be achieved by a planetary gearbox manufacturer. These include torque rating, gear ratio, input speed, output speed, gear quality, and service life. Torque rating refers to the maximum amount of power that can be transmitted through the gearbox. Gear ratio refers to the ratio between the number of teeth on the input and output gears. Input speed refers to the speed at which the gearbox receives power, while output speed refers to the speed at which the gearbox transmits power.

Gear quality is essential in ensuring efficient power transmission through the gearbox. It is measured by the accuracy of the gear teeth, which should be free from any imperfections that may cause wear and tear or reduce the performance of the gearbox.

Another important technical parameter is the service life of the gearbox. The service life refers to the total number of operational hours that the gearbox can deliver without developing any faults or requiring maintenance. The service life can be increased by using high-quality components in the gearbox, such as bearings, seals, and lubricants that reduce wear and tear.

In conclusion, the technical parameters of a planetary gearbox are crucial in ensuring that the gearbox can deliver optimal performance and reliability. A planetary gearbox manufacturer must prioritize the design and development of their gearboxes to achieve these technical parameters in order to meet the needs of their customers. Therefore, investing in research and development, advanced manufacturing technologies, and quality control systems are essential to produce high-quality planetary gearboxes that meet or exceed the technical parameter requirements.

Planetary Gearbox Manufacturer Price

When it comes to planetary gearboxes, there are a number of factors that can influence the price of these components. Some of the key factors that can impact the cost of a planetary gearbox include the manufacturer, the materials used in the construction of the gearboxes, and the overall design and engineering of the component.

One of the biggest factors that can impact the price of a planetary gearbox is the manufacturer. Different manufacturers will have different levels of experience, expertise, and resources, all of which can influence the final cost of the product. Some manufacturers may specialize in producing high-end, precision gearboxes, while others may focus on more affordable, mass-produced components.

In addition to the manufacturer, the materials used in the construction of planetary gearboxes can also have a significant impact on the final price. High-quality, durable materials like steel and aluminum can increase the cost of a gearbox, while cheaper materials like plastic or lower-quality metals may bring costs down.

Another key factor that can influence the price of a planetary gearbox is the overall design and engineering of the component. More complex, intricate gearboxes with a higher degree of precision and durability will likely command a higher price than simpler, more basic gearboxes. Additionally, gearboxes that are designed for use in high-stress, demanding environments may have a higher price tag due to the unique requirements associated with their use.

Ultimately, the cost of a planetary gearbox will depend on a variety of factors, including the manufacturer, materials, and design. By shopping around and comparing prices from different manufacturers, buyers can find the best combination of quality and value for their specific needs. With the right gearbox in place, businesses and individuals can enjoy the benefits of improved performance, efficiency, and reliability across a wide range of applications.