Knowledge about Plastic Bag Making Machine

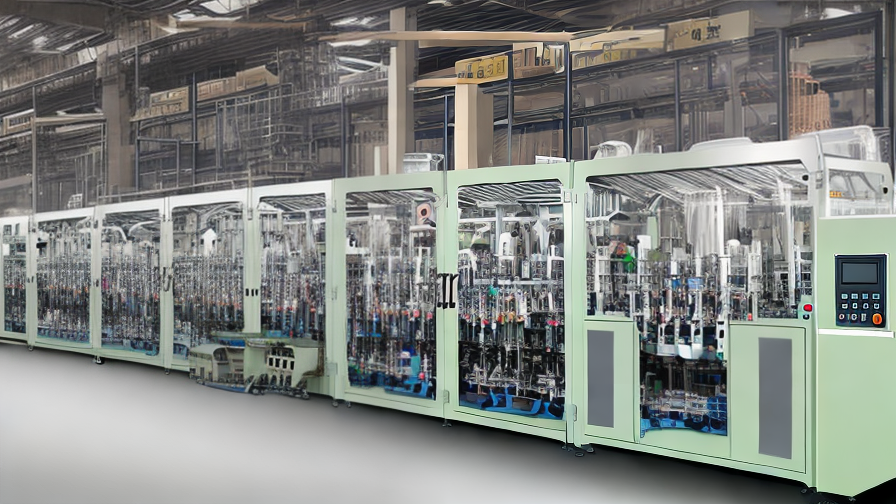

Plastic bag making machines have become an essential tool in the manufacturing sector. The increasing demand for plastic bags across the world has led to the ongoing evolution of these machines, making them more efficient and cost-effective.

The basic knowledge of a plastic bag making machine is its ability to create plastic bags from rolls of plastic material. These machines come with various sections, each of which plays a significant role in the final product outcome. The first section is the unwinding section that unrolls the plastic roll to be utilized in the process. This section also has a braking system that stops the roll from unwinding inadequately.

The second section is the sealing section. This section seals the plastic together using heat and pressure. The dimension of the seal can be adjusted depending on the required dimensions of the bags. A cutting section follows the sealing process that cuts the plastic roll sealed in the previous section into the bag’s desired length, creating a tube formation.

This tube is then put in the form, fill, and seal section that cuts the bag to the desired width, applies printing labels and fills the bags with the intended material, seals the top and finally cuts the bag into an individual unit.

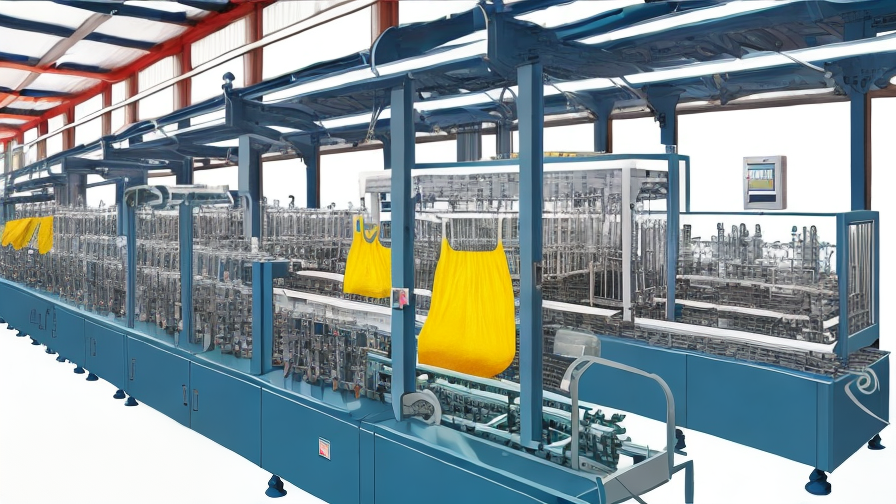

A modern plastic bag making machine has options for adding handles, providing easy carrying and reusability. These machines are versatile and allow for the production of various types of bags, ranging from shopping bags, ziplock bags, garbage bags, courier bags, and more.

In summary, understanding plastic bag making machines is essential for any business that involves the production of plastic bags. Advanced knowledge of these machines leads to more efficient production processes and products of higher quality. With the demand for plastic bags expected to increase, knowledge about plastic bag making machines will be essential in the years to come.

Various Types of Plastic Bag Making Machine

Plastic bags are an essential commodity in today’s world. Its extensive use coupled with its cheap production makes it a popular choice. To keep up with the demand, the plastic bag making machine industry has been thriving with several types of machines available in the market.

The T-Shirt Bag Making Machine, commonly known as the “vest bag”, is one of the most commonly used machines. It produces the classic and economical “T-shirt” bag. The machine is capable of producing 100-250 bags per minute and can handle low-density PE and HDPE plastic films.

The Roll Bag Making Machine produces bags in a roll form which is useful for automatic packaging. The bags can be perforated or plain and can have printing options. The machine has a wide range of applications such as in supermarkets and grocery stores where the bags are used for packaging vegetables, fruit, and other produce.

The Ziplock Bag Making Machine, also known as the resealable bag making machine, is used to produce bags that can be sealed after opening. It can produce bags that have two or more compartments and perforated lines for easy tear. These bags are often used in the food industry for packaging perishables like vegetables, fruits, and meat.

The Side Seal Bag Making Machine produces bags that have a sealed seam. It is much more versatile than the T-Shirt Bag Making Machine as it can produce bags that have different shapes and sizes. The bags can also have printing options, including the capability to print on both sides.

Apart from these, there are other machines available like the Four Side Seal Bag Making Machine, Vacuum Bag Making Machine, and Die Cut Handle Bag Making Machine, each designed for specific purposes.

In conclusion, the plastic bag making machine industry has come a long way from producing simple T-Shirt bags to producing bags with special features, shapes, and sizes. Understanding the different types of machines can help manufacturers make informed decisions on which machine best suits their production requirements.

FAQ sourcing Plastic Bag Making Machine manufacturer from China

If you are looking for a reliable and high-quality plastic bag making machine manufacturer from China, you might have some questions in mind. In this article, we will answer some of the frequently asked questions to help you make an informed decision.

Q: What type of plastic bag making machines do Chinese manufacturers offer?

A: Chinese manufacturers offer a wide range of plastic bag making machines, including side sealing, bottom sealing, and T-shirt bag making machines.

Q: What is the production capacity of plastic bag making machines?

A: The production capacity varies depending on the type and configuration of the machine, but most plastic bag making machines have a capacity of 60 to 300 bags per minute.

Q: What materials can be used with plastic bag making machines?

A: Plastic bag making machines can use various materials such as LDPE, HDPE, LLDPE, and biodegradable plastics.

Q: What is the cost of plastic bag making machines from China?

A: The cost of plastic bag making machines from China depends on various factors such as the type, configuration, and production capacity of the machine. However, Chinese manufacturers offer competitive prices compared to other countries.

Q: How can I ensure the quality of plastic bag making machines from China?

A: To ensure the quality of plastic bag making machines from China, you can check the manufacturer’s certifications and customer reviews. You can also request a sample machine or visit the manufacturer’s factory to inspect the quality.

Q: Can I customize plastic bag making machines to suit my requirements?

A: Yes, most Chinese manufacturers offer customizations to suit the specific requirements of customers.

In conclusion, China is a hub for plastic bag making machine manufacturers who offer a wide range of machines with various features and capacities. By asking the right questions, you can find a reliable manufacturer that meets your requirements and budget.

Applications of Plastic Bag Making Machine

Plastic bag making machine is a versatile and efficient equipment that is extensively used in the packaging industry. It is used for making plastic bags of various sizes and shapes. In this article, we will explore some of the important applications of plastic bag making machine and how it benefits the packaging industry.

Food Packaging:

One of the most common uses of plastic bags is in the food packaging industry. Plastic bags that are made with food-grade materials help preserve the freshness, taste, and quality of the food. A plastic bag making machine is specially designed to produce high-quality food-grade plastic bags that can be used for packaging various food items such as grains, cereals, snacks, and other food products.

Medical Industry:

The medical industry also extensively uses plastic bags that are sterile and hygienic. These bags are used to store and transport medical equipment, instruments, and other essentials. Plastic bag making machine that uses medical-grade materials is used to make these bags, which are essential in ensuring the safety and well-being of patients.

Retail Industry:

Plastic bags are also widely used in the retail industry for packaging various products. The plastic bags come in different shapes, sizes, and colors and can be customized to suit a particular need. A plastic bag making machine is used to produce quality plastic shopping bags that can be used in supermarkets, clothing stores, and other retail outlets.

Agriculture Industry:

Plastic bags are also frequently used in the agriculture industry. The bags are used to store crops, seeds, fertilizers, and other agricultural produce. The bags help to protect the produce from moisture, insects, and other environmental factors. A plastic bag making machine produces high-quality bags that can withstand harsh weather conditions and protect the agricultural produce.

In conclusion, the plastic bag making machine has many applications in different industries. It is an essential equipment for the packaging industry and plays a crucial role in providing high-quality packaging materials. The machine’s versatility and efficiency make it a valuable investment for businesses that require high-quality plastic bags

Manufactured Products made of Plastic Bag Making Machine

A plastic bag making machine is a specialized tool that is used to produce various types of plastic bags for industrial, commercial, and domestic applications. The machine uses a wide range of materials such as HDPE, LDPE, and LLDPE to produce plastic bags of different thicknesses, sizes, and shapes.

Manufactured products made of plastic bag making machine come in different categories, including grocery bags, merchandise bags, trash bags, and even medical waste bags. These products have become popular due to their convenience, affordability, and durability.

Grocery bags made by plastic bag making machines are the most commonly used products. They are lightweight and are ideal for carrying groceries from the store to your home. They are also relatively cheap, and some retailers even offer discounts when you bring in your reusable bag.

Merchandise bags are another common product made from plastic bag making machines. They are typically used in retail shops to pack customer purchases, and they often feature a company’s logo or name. These bags are lightweight and cost-effective, making them a preferred choice for businesses.

Trash bags are another popular product made from the plastic bag making machine. These bags come in different sizes, strengths, and colors to fit different types of garbage cans. They are essential in households, hospitals, and industries for waste collection and disposal.

Medical waste bags are heavy-duty bags used to dispose of medical waste. They are designed to prevent the spread of infection and are used in hospitals, dental practices, labs, and other healthcare facilities. The bags are made of durable materials capable of carrying hazardous materials and sharp objects, and they often conform to health and safety regulations.

In conclusion, a plastic bag making machine is an essential tool in the manufacturing industry. Its versatility in producing different types of plastic bags has made it possible to come up with cost-effective products that are both durable and convenient. From grocery bags to medical waste bags, the plastic bag making machine has revolutionized the way products are made, and it continues to be an essential

The Evolution history of Plastic Bag Making Machine

The history of plastic bag making machines dates back to the early 1900s when people began to recognize the need for faster and more efficient ways to produce bags. Early machines were simple, manually operated units that could produce only a limited number of bags at a time.

As technology advanced, so did the machines. In the 1960s, the first fully automated plastic bag making machines were developed. These machines used a continuous feed of plastic film to produce bags at a high rate of speed, drastically increasing productivity.

In the 1970s, machines capable of creating different bag shapes and sizes were introduced. This allowed manufacturers to produce bags for a wider range of uses, from grocery shopping to industrial packaging.

The 1980s saw a focus on energy efficiency and sustainability, with the development of machines designed to use less electricity and produce fewer emissions. Additionally, machines capable of producing biodegradable bags were introduced, providing a more eco-friendly option for consumers.

The 1990s brought about advancements in computer technology, allowing for more precise control over the bag making process. This resulted in more consistent and high-quality bags.

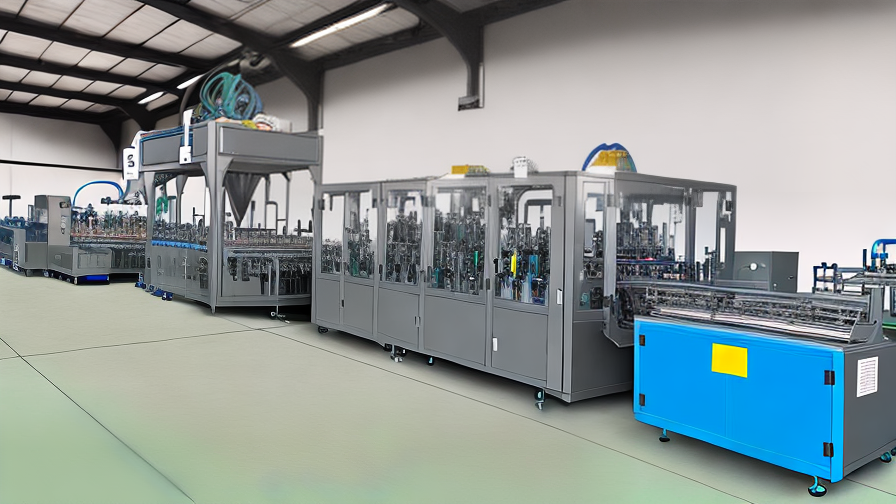

Today, plastic bag making machines continue to evolve. Modern machines are highly automated, incorporating sophisticated computer controls and advanced materials to produce a wide variety of high-quality bags quickly and efficiently.

As the world becomes increasingly concerned with environmental sustainability, the plastic bag making industry has responded with innovations in biodegradable and reusable bags, as well as improved energy efficiency in manufacturing processes. With continued innovation and improvements, it is likely that the evolution of plastic bag making machines will continue long into the future.

The Process of Plastic Bag Making Machine

The plastic bag making machine is a sophisticated apparatus that manufactures plastic bags from raw materials. The process of making these bags typically involves several stages, starting with the feeding of raw materials into the machine.

The first stage in the process is the feeding of the raw material into the machine. This can be done manually or through the use of automated systems. The raw materials may include plastic pellets, resins, or other forms of polymer-based materials.

Once the raw materials are fed into the machine, the next stage involves heating and melting them to form a molten mass. This process is usually achieved through the use of a heating element that is located within the machine. The molten mass is then extruded out of the machine through a die, which shapes the material into the desired form and size.

After the plastic bag has been formed, it is then cooled down to harden and solidify it. This is done to prevent unwanted wrinkles or deformities in the final product. The bags are then trimmed to the desired shape and size and are packed for distribution.

The process of making plastic bags using the plastic bag making machine can be performed at a high rate of speed, which makes it ideal for mass production purposes. The machines are easy to operate and require minimal maintenance.

Today, plastic bags have become ubiquitous in our daily lives, with nearly every industry relying on them for storage, transportation, and packaging purposes. The use of plastic bags has become a matter of concern due to their environmental impact, and this has led to a growing demand for eco-friendly alternatives.

In summary, the process of making plastic bags using the plastic bag making machine involves feeding raw materials into the machine, heating and melting them, extruding the molten mass through a die, cooling and solidifying the bags, and trimming them to the desired size and shape. The plastic bags made through this process have a variety of uses and applications, making them a crucial part of modern-day life.

Benefits Advantages of Utilizing Plastic Bag Making Machine

Plastic bags are a common household item that is used almost daily, from carrying groceries to storing small items. Plastic bag making machines are innovative machines that produce bags of different sizes and shapes to meet various needs. If you’re in the plastic bag manufacturing business, here are several benefits and advantages that come with utilizing a plastic bag making machine.

1. Cost-effective: One of the significant advantages of plastic bag making machines is the cost-effectiveness they offer. These machines can produce a considerable number of bags at a lower cost than manual production. With this, you can get more bags for less expense, which ultimately translates to more profits.

2. Improved Efficiency: Plastic bag making machines are designed to streamline the bag manufacturing process, reducing the labor required. This process is faster and more efficient than manual production, as it can create multiple bags at once in a matter of seconds.

3. Customization: With a plastic bag making machine, you have the flexibility to customize bags according to your clients’ preference. You can adjust the machine to create bags of different colors, shapes, and sizes, making it easy to accommodate your customers’ demands.

4. Versatility: A plastic bag making machine can be used to produce bags for various purposes. This versatility means plastic bag manufacturers can expand their business by venturing into new markets like medical, industrial, and agriculture sectors.

5. Better Quality Bags: The use of a plastic bag making machine ensures that the produced bags are of consistent quality. The bags are stronger, more durable, and resistant to wear and tear. This improved quality also means that customers can reuse the bags, reducing the amount of waste produced.

In conclusion, utilizing a plastic bag making machine in your business comes with numerous benefits, including cost-effectiveness, improved efficiency, customization, versatility, and better quality bags. It’s worth investing in this innovative machine to enjoy all these advantages and grow your business.

Disadvantages Plastic Bag Making Machine

Plastic bag-making machines have revolutionized the way plastic bags are manufactured. They have certainly made the process easier, faster, and more efficient, but as with all technologies, they come with several disadvantages.

Firstly, these machines emit harmful gases that are harmful to the environment. These gases contribute to air pollution, which is a significant issue in today’s world. Moreover, plastic bags require heavy amounts of petroleum and natural gases for their manufacturing, making it a significant contributor to greenhouse gas emissions that cause global warming.

Secondly, plastic bags produced by these machines are not biodegradable. They take hundreds of years to decompose, and often end up in landfills or oceans, endangering marine life and polluting the environment. Furthermore, they can take up valuable space and lead to soil contamination.

Thirdly, the use of plastic bags has been detrimental to marine ecosystems, as they pose a significant threat to marine life. Animals, such as turtles and seagulls, mistake plastic bags for food, and will often ingest the plastic of which they are made – this leads to serious harm or death. Moreover, plastic bags in the ocean could also lead to the entanglement of marine life.

Lastly, plastic bags made by these machines may not be suitable for carrying heavy items, and if they are forced to bear more weight than their capacity, they may break, causing inconvenience and harm to the user.

In summary, while plastic bag-making machines have their advantages, notably in streamlining the manufacturing process, their environment and social impact are too profound to be ignored. Plastic bags are a source of pollution, endangerment and hurt to the environment and animals alike. Thus, a need to reduce the use of plastic bags and promote the importance of eco-friendly alternatives that would reduce the environmental effects caused by such machines.

Selecting the Ideal Manufacturer Plastic Bag Making Machine

Selecting the ideal manufacturer of plastic bag making machines is an important decision that requires careful consideration. The market is flooded with numerous manufacturers claiming to have the best plastic bag making machines, but not all can deliver as promised.

To start with, it’s important to consider the reputation of the manufacturer. A good manufacturer should have a solid reputation in the industry, and this can be confirmed by reading reviews and testimonials from other customers. A reputable manufacturer will also have a proven track record of delivering high-quality machines that meet the needs of their clients.

Another important factor to consider is the quality of the materials used in making the machine. A high-quality machine should be built with durable and long-lasting materials that can withstand the high demands of the plastic bag production process. This minimizes the risk of frequent breakdowns and repairs, thus increasing efficiency and productivity.

Additionally, it’s important to consider the features and capabilities of the machine. A good manufacturer should offer a range of plastic bag making machines that can handle different capacities and types of bags. The machine should also have modern features such as computerized controls, automatic temperature and speed adjustments, and safety sensors to ensure optimal performance.

The cost of the plastic bag making machine is also an important consideration. While it’s important to look for a machine that fits within your budget, it’s equally important to ensure that the machine you select provides high-level functionality and performance. A cheap machine may end up costing you more in the long run due to frequent repairs and replacement costs.

In conclusion, selecting the ideal manufacturer of plastic bag making machines requires careful consideration of various factors including the reputation of the manufacturer, quality of materials used, features and capabilities of the machine, and cost. By choosing a reputable and experienced manufacturer, you can be sure to get a high-performing and durable machine that meets your needs and delivers value for your money.

Things to Consider When Purchasing Plastic Bag Making Machine

If you are planning to invest in a plastic bag making machine, there are several factors you need to consider. This is because there are different types of machines available, and each has its unique features and capabilities. Here are some things to keep in mind when purchasing a plastic bag making machine.

1. Production Capacity – You need to consider how many bags you want to produce per day. This will help you determine the type and capacity of the machine to buy.

2. Type of Bags – Plastic bag making machines can produce different types of bags such as T-Shirt bags, grocery bags, and garbage bags. You should consider the type of bag you want to produce and ensure that the machine you are buying can produce it.

3. Machine Quality – The machine’s quality is critical as it determines its durability and efficiency. You should opt for a machine that is made of high-quality materials to ensure it can withstand heavy usage and operate at optimum capacity.

4. Auto Features – You should consider buying a machine that has automatic features such as auto-tension control, auto oil lubrication, and auto temperature control. These auto features make the machine easier to use, and they increase production efficiency.

5. Power Consumption – The power consumption of the machine is an essential factor to consider as it affects your electricity bill. You should opt for a machine that has low power consumption without compromising on production capacity and quality.

6. Price – The price is yet another factor to consider when purchasing a plastic bag making machine. You should look for a machine that offers value for money and one that fits within your budget.

In conclusion, purchasing a plastic bag making machine requires careful consideration of several factors. You need to consider the production capacity, type of bags, machine quality, auto features, power consumption, and price. By keeping these factors in mind, you can select the best machine that will suit your needs and provide value for your money.

Properties of Plastic Bag Making Machine

Plastic bag making machines are highly efficient machines that are used for producing plastic bags of different sizes and shapes. These machines are popularly used in the packaging industry due to their high production capacity and low cost. Here are some properties of a plastic bag making machine that make it popular among manufacturers:

1. Versatility: A plastic bag making machine can be used to produce bags of various sizes and shapes, depending on the requirements of the manufacturer. These machines are highly flexible and can produce bags ranging from small ziplock bags to large shopping bags.

2. Speed: These machines are highly efficient and can produce large volumes of bags in a short period. This makes them ideal for large-scale production and reduces the overall production time.

3. Accuracy: These machines are designed to produce bags with consistent accuracy, ensuring that each bag is of the same size and quality. This is important in ensuring customer satisfaction, as it reduces the likelihood of defective bags.

4. Automation: Modern plastic bag making machines are highly automated and can carry out most of the production process without human intervention. This reduces the need for human labor and increases productivity.

5. User friendliness: Most modern plastic bag making machines are designed with user-friendliness in mind. They are easy to operate and require minimal maintenance. This makes them popular among manufacturers with limited technical expertise.

In conclusion, plastic bag making machines are highly efficient machines that are popularly used in the packaging industry. They are versatile, accurate, and highly automated, making them ideal for large-scale production. Their user-friendliness and low maintenance requirements make them a valuable asset for manufacturers.

How to use Plastic Bag Making Machine

A plastic bag making machine is a crucial piece of equipment that helps to streamline the production of plastic bags in various industries such as retail, food, and beverage packaging. This machine is easy to use and can produce different types of plastic bags, including shopping bags, trash bags, and food packaging bags.

Here are some steps to follow when using a plastic bag making machine:

1. Install the rolls of plastic film onto the machine. The rolls should be correctly positioned to ensure smooth and continuous production of bags.

2. Set the correct parameters on the machine. This includes setting the width and length of the bag, thickness of the plastic film, and the speed of production. You can adjust these parameters depending on the type of bag you want to produce.

3. Monitor the machine as it produces the plastic bags. You need to ensure that the machine is running smoothly and that the bags are being produced correctly. This includes checking the quality of the bags and making any necessary adjustments to the machine.

4. Once the bags are produced, they need to be cut and separated. This can be done manually or automatically, depending on the type of machine you are using.

5. Collect the finished bags and package them. You need to ensure that the bags are neatly stacked and packed in a way that makes them easy to transport.

While using a plastic bag making machine may seem daunting at first, with practice, it becomes easier. It’s important to follow the manufacturer’s instructions and safety guidelines when using this machine. Proper training is also essential to make sure that you use it safely and correctly.

In conclusion, a plastic bag making machine is an essential piece of equipment for any company that produces plastic bags. By following the steps above, you can produce high-quality bags efficiently and safely.

Glossary Terminology Terms for Plastic Bag Making Machine

Plastic bag making machines are used in the manufacturing of plastic bags. The technology has evolved over the years, and now, there are many specialized terms and terminologies that are associated with these machines. It is essential to understand them to make the most out of your manufacturing process. Here is a glossary of the most common terms used in the plastic bag making industry:

1. Extruder: An extruder is a machine that produces a continuous flow of plastic sheets or film by melting, mixing, and forcing raw materials through a die.

2. Blown film extrusion: This is a technique used to create plastic bags by blowing hot air into a tubular die containing plastic resin.

3. Die: This is a metal tool with a specific shape that is used to create the desired shape of the plastic film or sheet.

4. Winding: This is the process of winding the plastic film or sheet around a core, creating a roll of plastic that can then be cut into bags.

5. Bag sealer: A machine that seals the plastic bags by applying heat and pressure to melt the edges together.

6. Bag perforator: A machine that creates small holes or perforations in the plastic bag, allowing air to escape during filling.

7. Handle maker: A machine that adds handles to the top of plastic bags for easy carrying.

8. Gusseting: A process that adds extra material to the sides of the plastic bag, creating a more spacious and robust bag.

9. Bottom sealing: A process of sealing the bottom of the plastic bag to create the bag’s final shape.

10. Printing press: A machine that prints graphics, text, or patterns onto the plastic bag to promote a brand or provide helpful information.

In conclusion, understanding the terms associated with plastic bag making machines can help you make the most out of your manufacturing process. From the extruder to the printing press, each machine plays a crucial role in creating high-quality plastic bags. With this glossary of

Plastic Bag Making Machine Price

Plastic bag making machines are widely used in the manufacture of plastic bags for various purposes such as retail, packaging, and transportation. These machines produce bags of various sizes and types, including T-shirt bags, flat bags, and garbage bags. With the increasing demand for plastic bags, the price of plastic bag making machines has become a critical factor for those interested in investing in such machinery.

The price of plastic bag making machines varies depending on the manufacturer, capacity, and type of machine. Low-capacity machines for small businesses can cost between $5,000 and $10,000, while high-capacity machines used in large-scale production can cost over $100,000. Machines that produce specific types of bags, such as garbage bags, can also cost more due to their specialized functions.

However, the price of the machine is just one factor to consider when investing in a plastic bag making machine. Other factors include the quality of the machine, the level of automation, and post-sale support. A low-cost machine may seem like a good investment, but it may have hidden costs due to poor quality or a lack of after-sales support. Investing in a high-quality machine may cost more initially, but it can save money in the long run by reducing maintenance costs, increasing production efficiency, and reducing downtime.

When purchasing a plastic bag making machine, it is essential to do thorough research and comparison of prices and specifications. It is advised to work with reputable manufacturers or suppliers who can provide the necessary support and guidance throughout the investment process.

In conclusion, the price of a plastic bag making machine is a crucial factor to consider when investing in this type of machinery. With prices ranging from $5,000 to over $100,000, it is essential to balance cost with quality, automation, and post-sale support. This will ensure that the investment is a sound one, and the plastic bag making machine will deliver the required returns on investment.