Knowledge about Plastic Cutting Machines

Plastic cutting machines are becoming increasingly popular in various industries as they offer the flexibility and precision required for cutting plastics into different shapes and sizes. However, to effectively utilize these machines, it is essential to have some knowledge about them.

One of the most important aspects to consider when using plastic cutting machines is the type of plastic material you intend to cut. Different types of plastic materials require different cutting techniques, which means that you need to select the right type of blade or cutting tool for the specific material you wish to cut.

Another essential aspect to consider is the thickness of the plastic material as this affects the type of machine and blade required. If the material is thin, a single-bladed machine may be enough, while thicker materials may require a double-bladed machine.

Additionally, the type of cutting method you use is also critical. For instance, laser cutting is ideal for cutting intricate shapes, while water jet cutting is excellent for cutting thick materials.

It is also essential to ensure that all safety precautions are followed when using plastic cutting machines. This means using protective gear such as gloves, eyewear, and ear protection, and ensuring that the machine is well-maintained and operated in the correct manner.

Lastly, it is also essential to consider the cost of plastic cutting machines. The cost varies depending on the type of machine, functionality, and size. It is therefore essential to do some research and select a machine that is within your budget and can effectively meet your cutting needs.

In conclusion, having knowledge about plastic cutting machines is essential for anyone interested in utilizing them in their industry. Factors such as choosing the right type of blade, considering the thickness of the material, selecting the right cutting method, following safety precautions, and considering costs should be kept in mind when dealing with plastic cutting machines.

Various Types of Plastic Cutting Machines

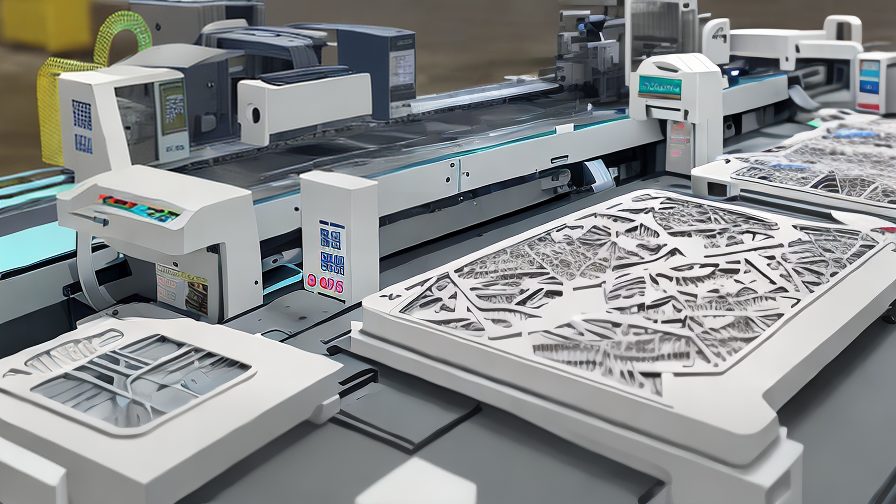

Plastic cutting machines are essential in the production of various plastic products. They are used to shape and size plastics to create precise and accurate results. Different types of plastic cutting machines are available in the market, each designed to suit specific needs and requirements.

The most popular type of plastic cutting machine is the CNC router. This machine uses computerized controls to cut the plastic into various shapes and sizes. It is suitable for cutting plastics with high precision, making it ideal for creating intricate designs.

Another type of plastic cutting machine is the laser cutter. This machine uses a high-powered laser to cut through the plastic. It is a fast and precise method of cutting, making it ideal for cutting shapes and designs with high accuracy.

A third type of plastic cutting machine is the guillotine cutter. This machine uses a blade to cut the plastic into required shapes and sizes. It is a common method used for cutting thin sheets of plastic and is effective in producing straight cuts.

The fourth type of plastic cutting machine is the hot wire cutter. It uses a heated wire to cut through the plastic, making it ideal for cutting thick plastic sheets. This machine is suitable for creating simple shapes and designs.

Lastly, water jet cutting machines are used to cut plastics using high pressure water. These machines use a precise nozzle to cut plastic with a high degree of accuracy. They are ideal for cutting thick or hard plastics that may be difficult to cut using other methods.

In conclusion, there are several types of plastic cutting machines available in the market, each with its specific strengths and weaknesses. Choosing the right machine depends on the requirements of the task, such as the thickness and type of plastic to be cut, the precision level required, and the shape and design of the final product.

FAQ sourcing Plastic Cutting Machines manufacturer from China

If you are considering sourcing plastic cutting machines from a manufacturer in China, you may have a few questions about the process. Here are some frequently asked questions and their answers to help guide you:

Q: How do I find a reliable manufacturer of plastic cutting machines in China?

A: You can start by researching manufacturers online, reading reviews from previous customers, and asking for references. It’s important to verify their certifications and quality control procedures as well.

Q: What types of plastic cutting machines are available from Chinese manufacturers?

A: Chinese manufacturers offer a wide range of plastic cutting machines, including laser cutting machines, CNC routers, waterjet cutting machines, and more.

Q: Can I request customized plastic cutting machines from a Chinese manufacturer?

A: Yes, most Chinese manufacturers are willing to produce customized machines according to your specifications.

Q: How much does a plastic cutting machine cost from a Chinese manufacturer?

A: The cost of a plastic cutting machine varies depending on the type of machine, its features, and other factors. It’s best to obtain quotes from multiple manufacturers to compare prices.

Q: How long does it take to receive a plastic cutting machine from a Chinese manufacturer?

A: The lead time for production and delivery of a plastic cutting machine can range from several weeks to several months, depending on the manufacturer and the complexity of the machine.

Q: Are there any risks associated with sourcing plastic cutting machines from China?

A: Yes, there are always risks involved when doing business with overseas manufacturers. However, you can minimize these risks by conducting thorough research, communicating clearly with the manufacturer, and using safe payment methods.

By understanding the process of sourcing plastic cutting machines from Chinese manufacturers and asking the right questions, you can find a reliable supplier and acquire the machines you need to enhance your business operations.

Applications of Plastic Cutting Machines

Plastic cutting machines have become an important tool in the plastic industry due to their versatility in cutting various types of plastics. These machines are used to cut plastics of different sizes and thicknesses with high precision, speed and accuracy. Here are some of the applications of plastic cutting machines:

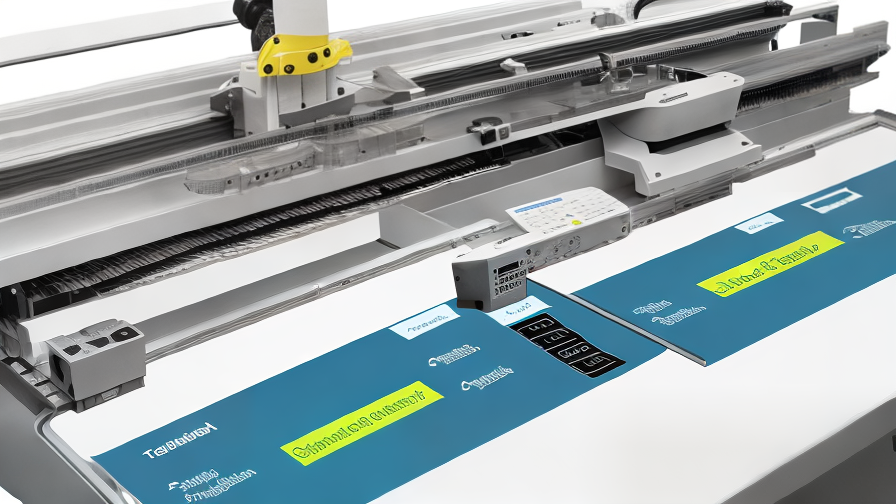

1. Packaging – plastic cutting machines are widely used in the packaging industry to cut and shape plastic materials of different shapes and sizes. The machines can make custom cuts that meet the specific needs of packaging products.

2. Signage – In the advertising industry, plastic cutting machines are used to create a variety of signs with high precision and accuracy. The machines can cut several types of plastics including acrylic, PVC, polycarbonate, and others.

3. Automotive industry – cutting machines are essential in the automotive industry. They are used to cut plastic parts for vehicle manufacturing, such as dashboards, door panels, and instrument panels.

4. Aerospace industry – plastic cutting machines are also used in the aerospace industry where they are used to cut and shape various plastic materials for aircraft components.

5. Medical applications – plastic cutting machines are widely used in the manufacturing of medical devices such as catheters, surgical implements, and prosthetics. They can also be used to cut medical-grade plastics that are used in medical packaging.

6. Electronic industries – plastic cutting machines are used to cut various plastics, including materials used in electronics. They can be used to make casings and housings for electronic devices such as cell phones and laptops.

In conclusion, plastic cutting machines have numerous applications in different industries due to their efficiency and precision. They help to provide the necessary precision and accuracy required in cutting different plastics for various applications.

Manufactured Products made of Plastic Cutting Machines

Plastic cutting machines are widely used in the manufacturing industry for their ability to create high-quality, precise pieces for various end products. These devices are commonly used for fabrication, sign-making, advertising, and many other purposes.

In the manufacturing industry, plastic cutting machines are used to create a wide range of products, including polycarbonate sheets, acrylic signs, and polyurethane parts. The precision of these machines allows manufacturers to produce high-quality plastic products with exceptional accuracy.

One of the most popular applications for plastic cutting machines is in the creation of acrylic signs. By using these machines, manufacturers can create signs that are transparent, colored, and etched. With this technology, the possibilities are endless. Whether you need a custom sign for your business or a unique design for your home, plastic cutting machines can help you achieve your vision.

Another popular application for plastic cutting machines is in the creation of polycarbonate sheets. These sheets are widely used in construction, transportation, and other industries due to their strength, durability, and resistance to impact. By using plastic cutting machines, manufacturers can create polycarbonate sheets that are precise, strong, and long-lasting.

Polyurethane parts are another product that can be produced with plastic cutting machines. These machines are commonly used to create parts for machinery, cars, and other applications. Polyurethane is a versatile material that is known for its toughness, flexibility, and strength. By using plastic cutting machines to create custom parts, manufacturers can create products that meet their specific needs and requirements.

In conclusion, plastic cutting machines are essential tools in the manufacturing industry, as they allow manufacturers to create high-quality, precision plastic products for a wide range of applications. From signs and sheets to parts and products, plastic cutting machines are an indispensable part of the manufacturing process.

The Evolution history of Plastic Cutting Machines

Plastic cutting machines have come a long way since their inception. The earliest version of these machines was a simple metal blade attached to a wooden handle that required a considerable amount of skill to operate. Later versions of plastic cutting machines were electric-powered, but did not have any special features.

Over time, these machines evolved to accommodate the increasing demand for more complex cutting tasks. In the 1950s, the first computer-controlled cutting machines were introduced. These machines had the ability to produce intricate designs and shapes at a high speed.

In the 1960s, the first CNC plastic cutting machines were introduced. These machines had the ability to cut materials with precision and accuracy that was unachievable with manual machines. The technology continued to evolve, with the introduction of more powerful computer software and cutting technologies.

In the 1990s, the concept of waterjet cutting was introduced. This technology has revolutionized the industry rapidly. It utilizes the power of high-pressure water jets mixed with tiny abrasive particles that can cut through materials with unprecedented precision, speed, and accuracy. Laser cutting technology was introduced around the same time as well. This technology uses a precisely targeted beam of light that can cut through materials quickly and accurately.

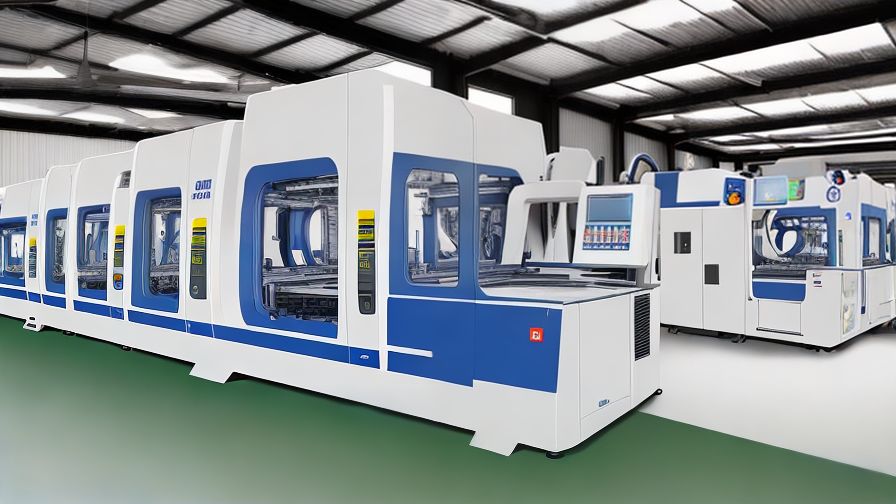

Today, plastic cutting machines are a staple in many industries. From factory floors to workshops, they play an indispensable role in ensuring that materials are cut to precise dimensions quickly and safely. The demand for these machines continues to grow, and this is driving rapid innovation in the industry.

In conclusion, the evolution of plastic cutting machines has seen a remarkable transformation in terms of the technology’s ability to cut materials faster and more accurately. To stay at the forefront of the industry, manufacturers must continue to innovate and adapt to changing needs and preferences.

The Process of Plastic Cutting Machines

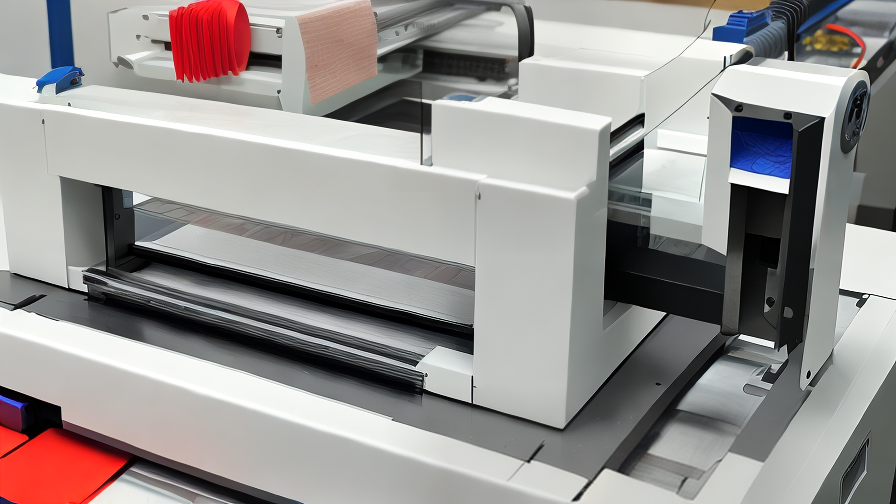

Plastic cutting machines are essential in the manufacturing and packaging industries. It helps to cut, shape and form plastic materials into various designs and sizes. The process of plastic cutting machines involves several steps.

Firstly, the machine operator will feed the plastic material into the cutting machine. The plastic is then passed through a series of sharp blades or cutting tools which cut it into different shapes and sizes. The cutting tools used in plastic cutting machines can be circular, straight or wavy blades, depending on the requirements of the design.

Secondly, the cutting tools are designed to work at high speeds, ensuring that the plastic is cut cleanly and efficiently without leaving any rough edges or burrs. This is crucial as rough edges or burrs can affect the quality of the finished product.

Thirdly, the plastic is held in place during the cutting process to ensure accuracy and consistency. This is done through the use of clamps or vacuum suction cups that hold the plastic in place while it is being cut.

Fourthly, after the plastic has been cut, it is then passed through a quality control process. This involves checking the cuts for accuracy, ensuring that there are no rough edges or burrs and that the shapes and sizes are consistent with the design specifications.

Lastly, the finished products are discharged from the plastic cutting machine. Depending on the design requirements, the plastic products may be further processed through techniques such as welding, polishing, and painting.

In summary, the process of plastic cutting machines involves feeding the plastic material, cutting it into shapes and sizes using sharp blades, holding it in place, checking for quality control and discharging the finished product. The use of plastic cutting machines has revolutionized the manufacturing industry by making it faster, more precise and cost-effective.

Benefits Advantages of Utilizing Plastic Cutting Machines

Plastic cutting machines have been designed with the primary objective of making the cutting process easier, convenient, and more efficient. These machines come in various designs, sizes, and shapes to cater to the varying needs and preferences of users. The benefits and advantages of using plastic cutting machines are numerous, making them an indispensable tool across various industries.

Firstly, plastic cutting machines ensure precision cuts. These machines offer a level of accuracy that is difficult to achieve when manually cutting plastics. The cutting process is automated, and this means that there is little to no room for human error. As a result, the finished product is almost always perfect, which is essential, especially for industries such as the medical sector, where precision is critical.

Secondly, plastic cutting machines save time and increase productivity. These machines can cut through plastics much faster than manual cutting methods. This means that users can complete tasks that would have taken a considerable amount of time in a few minutes or hours, depending on the workload. This increase in productivity translates to higher yields, reduced turnaround times, and ultimately, increased profitability for businesses.

Thirdly, plastic cutting machines offer versatility. These machines have been designed to cut through a wide range of plastics, including PVC, nylon, polyethylene, and polystyrene, among others. This versatility makes them ideal for use in various industries, ranging from packaging, construction, automotive to medical and pharmaceutical.

Fourthly, plastic cutting machines are cost-effective. These machines come in various models and sizes, with each model designed to cater to different needs and budgets. Investing in a plastic cutting machine is a wise decision, given that it pays for itself in a short time through increased productivity, reduced material wastage, and labor costs.

Finally, plastic cutting machines are safe to use. Unlike manual cutting methods, these machines are equipped with safety features such as safety sensors and emergency stop buttons, which ensure that accidents are prevented. Additionally, the cutting process is automated, and this means that users can operate the

Disadvantages Plastic Cutting Machines

Plastic cutting machines are essential equipment in the plastic manufacturing industry. They are used extensively for precision cutting of plastic materials, shaping them into various forms and sizes. However, despite their usefulness, plastic cutting machines have some significant disadvantages, which can negatively affect the efficiency and effectiveness of their use.

One of the most significant disadvantages of plastic cutting machines is their high cost of maintenance. Due to their complex design and structure, maintaining these machines requires highly trained professionals and expensive spare parts. Additionally, frequent servicing and repairing can lead to significant downtime, which, in turn, negatively impacts productivity.

Also, plastic cutting machines generate a large amount of waste, which can be both hazardous and costly to dispose of properly. Plastic waste, unlike other waste materials, is not biodegradable and can take centuries to decompose. Improper disposal of plastic waste can lead to severe environmental degradation and pose a significant threat to human health.

Another significant disadvantage of plastic cutting machines is their inability to handle multiple materials. Most plastic cutting machines can only cut specific types and thickness of plastic, which limits their versatility. This limitation can also lead to the need for purchasing multiple machines to cut different types of plastics. The purchase of multiple machines increases cost and occupies valuable floor space.

Additionally, plastic cutting machines can be hazardous to operate. The machines’ sharp blades, high cutting speed, and high-pressure hydraulic systems can cause severe injuries to the operator if not handled correctly. Proper training and safety precautions are essential to mitigate the risk of accidents.

In conclusion, plastic cutting machines are essential equipment in the plastic manufacturing industry. However, the disadvantages of high maintenance costs, environmental degradation, limited versatility, and potential hazards to the operator require careful consideration before investing in them. It is essential to conduct a comprehensive cost and risk-benefit analysis when deciding whether to purchase plastic cutting machines for your plastic manufacturing enterprise.

Selecting the Ideal Manufacturer Plastic Cutting Machines

Selecting the Ideal Manufacturer Plastic Cutting Machines

When it comes to buying plastic cutting machines, selecting the ideal manufacturer is crucial. This decision can determine the quality of machines, the level of support and the durability of the equipment. In this article, we will explore what factors you need to consider when selecting a manufacturer for plastic cutting machines.

Experience

Choose a manufacturer that has been in the industry for a long time. A manufacturer with years of experience is more likely to produce high-quality plastic cutting machines with excellent performance capabilities. Additionally, if a manufacturer has been in the business for a long time, they are more likely to have good customer feedback and be a reliable supplier.

Product Quality

Do some background research on the manufacturer to understand their quality standards. It is essential to confirm that the manufacturer has quality control processes in place for the plastic cutting machines they produce. You can look for reviews or ask for references, and you can have a better idea of their product quality.

Service and Support

The best manufacturers have exceptional customer support services, including providing product with warranty periods and offering maintenance services. Many plastic cutting machines are customised to meet the needs of buyers. Find out if the manufacturer offers custom design services and if they can guide you through selecting the right cutting machine for your application.

Price

Price is always a factor to consider when buying plastic cutting machines, but compromising on quality can be expensive in the long run. Try to strike a balance between the price and the quality of the plastic cutting machines.

Conclusion

When selecting the ideal manufacturer of plastic cutting machines, consider their product quality, years of experience in the industry, customer support, and price. Remember to get the many possible details about plastic cutting machines through the manufacturer on the products they specialize in, so you can pick the right machine, and get the most out of your investment.

Things to Consider When Purchasing Plastic Cutting Machines

Plastic cutting machines have become popular in various industries, including packaging manufacturing, automotive, and electronics. These machines come in different shapes and sizes, and they have different features. Therefore, before purchasing a plastic cutting machine, there are several factors to consider.

The first thing to consider is the type of plastic you will be cutting. Different types of plastics require different cutting techniques. Some plastic cutting machines are specifically designed for cutting thin plastic sheets, while others can cut thicker and harder plastics. Therefore, you should ensure that the machine you are purchasing can handle the type of plastic you want to cut.

Secondly, the capacity of the machine is crucial. Consider the volume of plastic you will be cutting, and choose a machine that can handle the amount. If you plan to cut a large volume of plastic, a machine with a high capacity will be ideal.

Thirdly, consider the accuracy and precision of the machine. If you need to cut intricate shapes or patterns, then precision is critical. Therefore, you should choose a machine with a high level of accuracy.

Fourthly, the cost of the machine is an important factor. You should consider your budget and choose a machine that offers value for money. However, don’t compromise on the quality of the machine because of the price.

Lastly, consider the maintenance and upkeep of the machine. Choose a machine that is easy to maintain and comes with a warranty. A machine that requires low-maintenance will save you time and money in the long run.

In conclusion, plastic cutting machines are essential equipment for industries that deal with plastic materials. Therefore, before purchasing a plastic cutting machine, consider the type of plastic you want to cut, the capacity of the machine, accuracy and precision, cost, and maintenance requirements. By considering these factors, you will be able to choose a machine that meets your needs and offers value for money.

Properties of Plastic Cutting Machines

Plastic cutting machines have become an indispensable tool for businesses involved in the manufacturing industry. These machines are used to cut various types of plastic materials with precision, which helps in the creation of quality products. Here are some of the most important properties of plastic cutting machines:

Cutting Capabilities

The cutting capabilities of these machines are undoubtedly their most important property. They can precision cut a wide range of plastic materials, including PVC, acrylic, polypropylene, and ABS efficiently. Plastic cutting machines are versatile and can be programmed to cut any shape or size accurately. They provide multiple cutting options, from straight, curved, angled, to circular cuts.

Speed and Precision

Speed and precision are essential properties of plastic cutting machines. These machines are equipped with advanced technologies, including computer numerical control (CNC) and lasers, which ensure that cuts are made with high accuracy and speed. CNC machines allow for more complex cuts and precise shapes, while laser machines ensure speed and precision, making them ideal for mass production.

Ease of Use

With the advancement of technology, plastic cutting machines have become more intuitive and easier to use than ever before. They come with user-friendly software that allows operators to program cutting patterns, change parameters, and adjust speed and power settings to suit their needs. This improved usability is critical since it reduces downtime, increases production efficiency, and cuts down on the need for highly trained operators.

Maintenance

To ensure long service life and maximum productivity, plastic cutting machines require regular maintenance. The good news is that most of these machines are designed to be easy to maintain. Components such as cutting blades, cooling systems, and belts require regular inspections and cleaning. Proper maintenance ensures that these machines continue to operate at peak efficiency, reducing the chances of breakdowns, and extending their overall service life.

In conclusion, plastic cutting machines are essential tools in today’s manufacturing industry. Their properties of cutting capabilities, speed and precision, ease of use, and maintenance make them indispensable tools for businesses looking to create quality products

How to use Plastic Cutting Machines

Plastic cutting machines are used to cut plastic materials, sheets, and objects easily and precisely using various cutting techniques such as laser cutting, waterjet cutting, and router cutting. These machines have revolutionized the plastic industry by increasing production efficiency and reducing manufacturing costs.

Here are some tips on how to use plastic cutting machines effectively:

1. Understand the Machine: Before using the machine, it is important to have a good understanding of its operating principle. Read the user manual, and learn about the various settings, speeds, and cutting techniques available.

2. Choose the Right Tool: Choose the tool best suited for the job based on the size, thickness, and hardness of the plastic you are cutting. For soft plastics, a laser cutter or a router cutter may be more effective; for thick and hard plastics, a waterjet cutter may be more appropriate.

3. Prepare the Material: Ensure that the plastic material is clean, dry, and free of any debris or dust before cutting. Proper preparation and positioning of the material are critical to achieving accurate and clean cuts.

4. Adjust the Settings: Depending on the type of plastic and the desired cut, adjust the cutting speed, depth, and angle settings on the machine. Ensure that the settings are appropriate before starting the cutting process.

5. Observe Safety Protocols: Always wear appropriate protective gear, including gloves, goggles, and earplugs, when operating the machine. Ensure that the machine is operated in a well-ventilated area to avoid inhaling the dust and fumes produced during the cutting process.

In conclusion, plastic cutting machines have made cutting plastic materials easier and more precise. With the above tips, you can ensure that your plastic cutting machine is used effectively, leading to increased efficiency and production cost savings.

Glossary Terminology Terms for Plastic Cutting Machines

Plastic cutting machines are essential tools in manufacturing, packaging, and other industries that deal with plastic materials. Understanding the jargon and terminology associated with these machines is vital for anyone working with plastic cutting equipment. Here are some commonly used terms:

1. Blade – the cutting component of the machine that slices through the plastic material.

2. Knife – a sharp tool used in a similar manner to blades.

3. Guillotine – a type of plastic cutting machine that uses a long blade and a flat bed to cut through larger sheets of plastic.

4. Slitter – a machine that cuts plastic sheets into narrower strips for further processing.

5. Rotary cutter – a machine that uses a rotating blade to cut through plastic materials.

6. Shear – a machine that uses two blades to cut a plastic sheet by pushing it through them.

7. Laser cutter – a type of cutting machine that uses a high-powered laser to make precise cuts through plastic materials.

8. CNC router – a machine that uses computer programs to control the cutting process.

9. Feed rollers – the set of rollers that pull the plastic material through the cutting machine.

10. Back gauge – a measuring device that sets the distance between the blade or knife and the plastic material.

11. Slitting blade – a narrow blade used in slit or cut plastic film into thinner strips.

12. Crush cut – a type of cutting method where the blade or cutter crushes the material to make a perforation.

13. Score cut – a type of cutting method where the blade makes a shallow indentation on the plastic material to facilitate the folding or bending.

14. Trimming – removing excess material surrounding the cut.

To sum up, plastic cutting machines utilize various cutting methods and terminologies. It is important to note and understand these terms to operate the equipment with safety and efficiency. So, if you’re about to work with a plastic cutting machine, make sure to familiarize yourself with these glossary terminologies to have a seamless operation.

Plastic Cutting Machines Price

Plastic Cutting Machines are becoming increasingly popular in the manufacturing industry. These machines are used to cut a wide variety of plastics to suit different manufacturing needs. With this, the demand for a machine that can accurately and precisely cut plastic has risen, making it essential for manufacturers to invest in a cutting machine that is reliable, efficient and affordable.

When looking for a plastic cutting machine, price is an important factor to consider. Plastic cutting machines come in different sizes, models, and types which contributes to the variation in the price range. Entry-level models that are more basic and designed for home use can range from $100 to $5,000, while higher-end machines used in commercial purposes cost upwards of $20,000.

Another factor affecting the price of a plastic cutting machine is the type of technology used. There are two main types of plastic cutting machines; the laser cutting machine and the mechanical cutting machine. The laser cutting machine is the more advanced type, utilizing a laser beam to cut through plastic. It is, therefore, a more expensive option and typically costs between $10,000 and $30,000. Mechanical cutting machines, however, use a mechanical cutting tool which is an option in the lower price range, costing between $1,000 and $10,000.

Additionally, brand and size of the machine have an impact on price. Branded plastic cutting machines are usually more expensive than non-branded ones, and the larger the machine, the higher the price. These machines are highly in demand in the manufacturing industry because they are more efficient and reliable. Hence, the higher cost is often regarded as an investment in a better and more efficient manufacturing process.

In conclusion, the price of a plastic cutting machine will depend on various factors such as type, technology, brand, and size. It is essential for manufacturers to consider their specific needs and select a machine that is reliable, efficient and within their budget. Investing in a good quality plastic cutting machine could lead to increased productivity and profitability in