Types and Applications of polypropylene webbing

Polypropylene webbing is a versatile material that is commonly used in a wide range of applications. This type of webbing is made from polypropylene fibers that are woven together to create a strong and durable strap. Polypropylene webbing is lightweight, highly resistant to chemicals, and has excellent abrasion resistance. Its unique properties make it ideal for a variety of applications.

Some of the most common types of polypropylene webbing include flat, tubular, and patterned webbing. Each type of webbing has specific properties that make it suitable for different uses. Flat polypropylene webbing is the most basic type and is commonly used for straps and tie-downs. Tubular polypropylene webbing is used for applications that require a round shape, such as rope handles. Patterned polypropylene webbing is designed to add durability and strength to a product while also creating a decorative effect.

Polypropylene webbing has numerous applications across various industries. One key application is in the manufacturing of outdoor gear which includes straps for backpacks, tents, and sleeping bags. Other common applications include automotive seat belts, luggage straps, and pet collars. Polypropylene webbing is also used in the medical industry as bindings for orthopedic braces and supports.

In conclusion, polypropylene webbing is a versatile material that has a range of applications. Its lightweight nature, high resistance to chemicals, and excellent abrasion resistance make it a preferred choice for many industries. The different types of polypropylene webbing include flat, tubular, and patterned webbing, with each having specific properties that make it suitable for various applications. Ultimately, polypropylene webbing is an essential material for manufacturers seeking high-quality and durable straps and binding materials.

Benefits and Feature of Utilizing polypropylene webbing

Polypropylene webbing is a high-quality material that has become increasingly popular in the manufacturing and crafting industries due to its numerous benefits and features. Polypropylene webbing is a type of lightweight and durable plastic webbing that is commonly used in a variety of applications.

One of the primary benefits of utilizing polypropylene webbing is its outstanding strength-to-weight ratio. This material is exceptionally strong and durable, yet it is light enough to be used in a wide range of products without adding unnecessary weight. Furthermore, this material possesses excellent abrasion resistance, making it suitable for a wide variety of high-wear applications.

Another benefit of using polypropylene webbing is its high resistance to water, chemicals, and UV radiation. This feature makes it ideal for outdoor applications such as patio furniture cushions, boat covers, and other marine-related products.

Polypropylene webbing is also incredibly versatile, as it comes in a wide range of colors, widths, and designs. This quality makes it easy to find a webbing that matches your specific needs and makes your project stand out. It is also easy to clean and maintain, making it ideal for products that are exposed to dirt and other substances on a regular basis.

In addition to these benefits, polypropylene webbing is also incredibly affordable compared to other materials used for similar applications. This makes it a popular choice for budget-conscious individuals and businesses.

Overall, there are many benefits and features of utilizing polypropylene webbing, including its strength, durability, versatility, resistance to water/chemicals/UV radiation, and affordability. These qualities make it an ideal choice for a wide range of applications, including straps, belts, luggage, outdoor furniture, and more.

The Process of polypropylene webbing

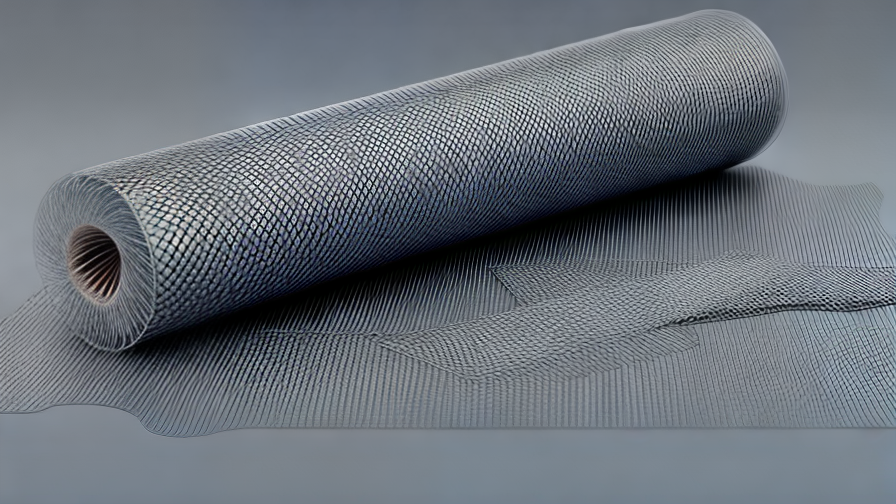

Polypropylene webbing is a popular material used for a wide range of applications from making straps for bags to dog leashes, seatbelts, and furniture webbing. The process of producing polypropylene webbing starts with the polymerization of propylene to produce polypropylene pellets. The pellets are then melted and extruded through a spinneret to form long fibers.

The fibers are then drawn or stretched to improve their strength and increase their length. This process is known as orientation and can be done in two ways, either by uniaxial or biaxial stretching. Biaxial stretching involves stretching the fibers in two directions, while uniaxial orientation involves stretching the fibers in one direction only.

After orientation, the fibers are then cooled, and the continuous filaments are then fed into a loom. The loom interlaces the fibers in a process known as weaving, which creates the intricate and durable patterns that make up polypropylene webbing. The woven webbing is then wound on spools or rolls and prepared for finishing.

The finishing process involves various operations such as dyeing, printing, or coating. For dyeing, the webbing is immersed in a dye bath where the color is absorbed by the fibers. Printing involves applying a design on the surface using screen printing or digital printing techniques. Coating involves applying a layer of resin or rubber on the surface to improve its durability and weather resistance.

In summary, the process of producing polypropylene webbing involves polymerization, extrusion, orientation, weaving, and finishing. Each step is critical in producing a high-quality, durable product that meets the diverse needs of various industries.

How to use polypropylene webbing

Polypropylene webbing is a versatile material that is often used in various applications. It is most commonly used as a strap for bags or as a handle for equipment. It is also often used in the production of slings, belts, harnesses, and many other products.

There are four primary ways of utilizing this material, namely sewing, welding, fusing, and hot-cutting. Sewing is most utilized when attaching polypropylene webbing to another material. It can be easily sewn on a sewing machine to create straps or handles. Welding, on the other hand, is preferred when creating loops or continuous straps. Fusing works best to bond two pieces of webbing together end-to-end, while hot-cutting is used to prevent fraying when cutting the webbing.

When working with polypropylene webbing, it is essential to choose the appropriate size and strength for the intended use. The width of the webbing usually ranges from ½ inch up to 2 inches, and the strength from 200 to 600 pounds. Knowing the required strength of the webbing is crucial, as using a weaker material may lead to its breakage, particularly in heavy-duty applications like construction or towing.

Another significant advantage of polypropylene webbing is that it is water-resistant, making it ideal for use in water sports and outdoor activities. It is also easy to clean, just by using a simple cleaning solution and wiping it down.

In conclusion, polypropylene webbing is a highly versatile material that can be used in various applications. Not only is it water-resistant and easy to clean, but it is also easy to work with, offering multiple options to attach, bond, or cut the material. By choosing the appropriate strength and size, the material is suitable for many types of jobs and will provide satisfactory performance.

polypropylene webbing Manufacturer,Supplier and Wholesale

As a leading manufacturer and supplier of polypropylene webbing, we provide quality products at competitive prices. Our polypropylene webbing is made from high-quality materials and is available in different sizes, colors, and thicknesses to meet the diverse needs of our customers. We have a team of experts who use advanced technology and equipment to manufacture our products.

Our polypropylene webbing is highly durable, abrasion-resistant, and water-resistant, making it ideal for a wide range of applications. It is widely used in the manufacture of bags, backpacks, outdoor gear, and other products that require high strength and durability. Additionally, our polypropylene webbing is easy to work with and can be easily sewn or welded to create custom designs.

We offer our polypropylene webbing in custom lengths and widths, making it easy for our customers to order the exact amount they need for their projects. We also offer wholesale pricing to customers who purchase our products in large quantities. We are committed to providing our customers with high-quality products and exceptional customer service.

With our years of experience in the industry, we have established ourselves as a reliable and trusted supplier of polypropylene webbing. Our commitment to quality and customer satisfaction has enabled us to build long-lasting relationships with our customers. Whether you are a small business owner or a large corporation, we can provide you with the polypropylene webbing you need to take your products to the next level.

polypropylene webbing Price

Polypropylene webbing is a type of synthetic material used in the manufacture of belts, straps, and other applications that require a durable and strong material. It is a popular choice due to its strength, resistance to abrasion, and water-resistance. It is also very lightweight and easy to handle, making it a cost-effective choice for many applications.

There are many factors that can affect the price of polypropylene webbing. Some of these factors include the width and thickness of the webbing, the color and pattern of the webbing, and the quantity and quality of the materials used in manufacturing. Webbing that is wider and thicker is generally more expensive than thinner webbing, as it requires more raw material to produce. Likewise, webbing that is created in more complex patterns or colors may be more expensive than plain webbing.

Another important consideration when it comes to polypropylene webbing price is the quantity of materials required to manufacture. In general, purchasing larger quantities of webbing will result in a lower price per unit, as the cost of manufacturing is spread out over a larger number of units. Additionally, some manufacturers may offer discounts for bulk purchases, which can further reduce the overall cost of the webbing.

The quality of the materials used in manufacturing can also have an impact on polypropylene webbing price. Higher-quality materials will generally be more expensive than lower-quality materials, as they are more durable and have a longer lifespan. However, investing in higher-quality webbing can be a cost-effective choice in the long run, as it will require less frequent replacement and maintenance.

Overall, the cost of polypropylene webbing can vary widely depending on a number of different factors. However, by carefully considering these factors and shopping around for the best deals, it is possible to find a high-quality, cost-effective webbing solution that meets your needs.

FAQ sourcing polypropylene webbing manufacturer from China with multiple answers

1. What is Polypropylene Webbing?

Polypropylene webbing is a type of synthetic webbing that is made from polypropylene fibers. It is a popular choice for a range of applications due to its strength, durability, and resistance to water and UV rays.

2. Why source polypropylene webbing from China?

China is a leading manufacturer of polypropylene webbing, offering high-quality products at competitive prices. This makes it an ideal source for businesses and organizations looking to purchase webbing in bulk quantities.

3. What are the advantages of sourcing polypropylene webbing from a manufacturer in China?

Some of the main advantages of sourcing polypropylene webbing from a manufacturer in China include high-quality products, competitive pricing, and a wide range of options in terms of colors, widths, and lengths. Additionally, China’s efficient logistics and shipping systems ensure timely delivery of orders.

4. How can businesses ensure they are sourcing high-quality polypropylene webbing from China?

When sourcing polypropylene webbing from China, businesses should do their research and choose a reputable and experienced manufacturer with a proven track record of producing quality products. It is also important to ask for samples and conduct quality control checks before placing large orders.

5. What factors should businesses consider when selecting a polypropylene webbing manufacturer in China?

Some important factors to consider when selecting a polypropylene webbing manufacturer in China include the manufacturer’s experience and reputation, quality of products, pricing, lead times, and customer service. It is also important to ensure the manufacturer is compliant with relevant industry standards and regulations.

6. Can polypropylene webbing be customized according to specific requirements?

Yes, many polypropylene webbing manufacturers in China offer customization options such as printing, embossing, and custom colors and designs. Businesses can work with the manufacturer to create customized products that align with their specific needs and branding requirements.