Benefits of Portable Line Boring Equipment

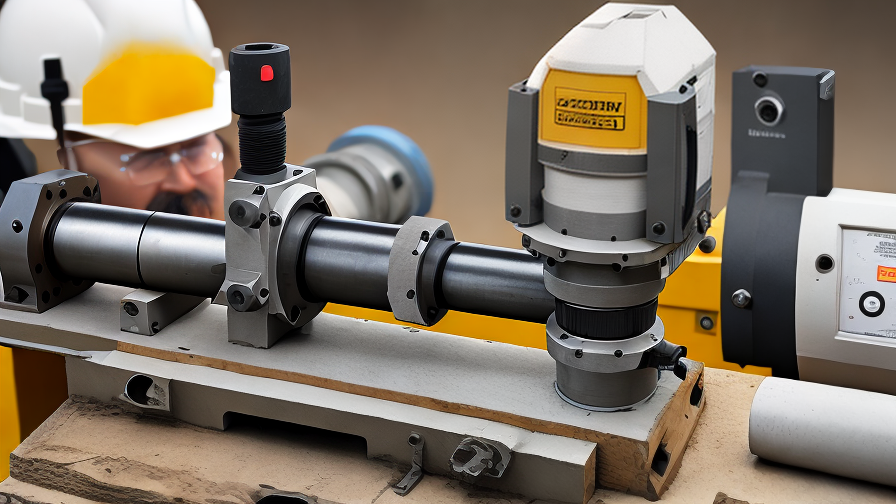

Portable line boring equipment has been in high demand for decades. The technology has been used in various industrial and construction applications. This equipment, such as the portable line boring machines or boring bars, is designed to repair or overhaul damaged bores or pinholes in equipment.

The benefits of portable line boring equipment are numerous. One of the major advantages of this equipment is that it can save a lot of time and money. Owing to its easy-to-set-up nature, it eliminates the need to dismantle the equipment or machinery to get it to a workshop for repairs. This saves hours or even days by avoiding the need to transport machinery to a repair facility, which also saves cost in transportation or downtime.

The equipment is also easy to operate and does not require any special training or expertise. This means that an individual can operate the equipment without the need to hire a specialized technician or machinist. In addition to saving costs, it offers flexibility and convenience, which makes it ideal for small-scale or remote operations.

Portable line boring equipment offers the ability to take on jobs that would have been previously unfeasible. With the ability to mount directly onto a workpiece, making bore repairs or machining operations that were once unfeasible, the equipment offers a new level of flexibility.

Another benefit of portable line boring equipment is that it can be used on various types of equipment or machinery, including large or heavy-duty industrial machinery. This makes it ideal for maintenance or repair operations in mining, construction, agriculture or oil and gas industries.

In conclusion, portable line boring equipment offers numerous benefits, including time and cost savings, flexibility and convenience, and the ability to take on new types of jobs. Portable line boring equipment such as a portable line boring machine or boring bar, is the ideal machinery for any individual or business that is looking for a reliable and versatile tool to solve their machining needs.

Features of Portable Line Boring Equipment

Portable line boring equipment has revolutionized the way we conduct line boring operations. Unlike traditional line boring machines, portable line boring equipment is easy to transport, setup, use, and is more versatile.

Here are some of the features of portable line boring equipment that make it an excellent choice for line boring operations:

1. Portability: The primary feature of portable line boring equipment is that it is easy to transport from one job site to another. The compact design allows it to fit in a truck or trailer, making it more convenient to move around.

2. Ease of setup: Setting up the equipment is also easy, and it requires no special skills or tools. The equipment can be set up and ready to use in just a few minutes.

3. Adjustable bar: Portable line boring equipment comes with an adjustable bar that can accommodate various bore sizes. This feature allows the equipment to handle different line boring applications, making it more versatile.

4. Precise and accurate: Portable line boring equipment is designed to be precise and accurate. The equipment is equipped with advanced technology that ensures accuracy, such as digital readouts and lasers.

5. Durability: The equipment is made of high-quality materials that make it durable and able to withstand harsh conditions. This feature ensures that the equipment is long-lasting, providing value for money.

6. Safety: Portable line boring equipment is designed with safety in mind. The equipment comes with safety features such as emergency stops and safety guards that protect the operator from accidents.

7. High performance: Portable line boring equipment is designed to deliver high performance. The equipment is powerful and can handle heavy-duty boring jobs with ease.

In conclusion, portable line boring equipment is an excellent choice for line boring operations. It is portable, easy to set up, precise, durable, safe, and delivers high performance. These features make the equipment an essential tool for any line boring operation.

Various Types of Portable Line Boring Equipment

Portable line boring equipment is essential for repairing large equipment and machinery that cannot be repaired on-site. Line boring is a technique used to enlarge or repair existing holes within equipment, using a portable boring machine. There are various types of portable line boring equipment suitable for different applications, and in this article, we will be discussing a few.

Firstly, the standard portable line boring equipment consists of a boring bar, which can be extended to the required length, and a cutterhead that can be changed according to the size of the hole. This type of equipment is typically used for repairing smaller equipment, such as engines and hydraulic cylinders.

Secondly, hydraulic line boring equipment is used for larger, heavier equipment that requires more power. The hydraulic line boring machine is powered by an external hydraulic power pack, which is connected to the machine’s motor. This type of equipment is essential for repairing large earth-moving equipment such as cranes, excavators, and bulldozers.

Thirdly, mini-line boring equipment is designed for narrow, confined spaces that standard-sized machines cannot access. This type of equipment is often used in shipbuilding, mining, and oil rigging industries.

Lastly, automated line boring equipment is used for high-precision line boring projects that require consistent results. The automated line boring machine is equipped with a digital control system that ensures a high level of accuracy and repeatability, making it an essential tool for large-scale projects.

In conclusion, portable line boring equipment is a vital tool for repairing heavy equipment and machinery that cannot be moved to a repair shop. There are various types of portable line boring equipment suitable for different applications, including standard, hydraulic, mini, and automated line boring machines. Each type of equipment has its own unique features, making it suitable for specific projects.

Applications of Portable Line Boring Equipment

Portable line boring equipment is a versatile tool that has a wide range of applications in various industries. These machines are designed to bore, ream, or drill precise holes in materials including iron, steel, and other metals. They are ideal for on-site repairs, maintenance, and fabrication projects. Here are some of the most common applications of portable line boring equipment.

1. Repairing Heavy Equipment

Portable line boring equipment is used to repair heavy equipment such as cranes, excavators, and bulldozers. These machines often experience wear and tear on their components, resulting in damage or misalignment. With portable line boring equipment, it is possible to repair these components on-site, saving time and money.

2. Reconstruction of Marine Components

Marine vessels require regular maintenance to keep them in good working condition. Portable line boring equipment is used to repair and reconstruct marine components such as propeller shafts, rudder bearings, and stern tube bearings. The equipment can handle both cylindrical and spherical bores, making it a versatile choice for marine applications.

3. Industrial Construction

Portable line boring equipment is used in industrial construction projects to create high-quality and accurate holes in large components, including piping and tanks. These machines can be used to drill holes of various diameters and depths, making them an essential tool for safe and effective industrial construction.

4. Repairing Engines and Compressors

For engines and compressors, the right alignment of the components is crucial for their optimum performance. Portable line boring equipment is an ideal choice for aligning the components of engines and compressors. The equipment can also be used for boring or reaming holes, making it an indispensable tool for engine and compressor repair.

5. Rebuilding Hydraulic Cylinders

Portable line boring equipment is commonly used to rebuild hydraulic cylinders. It can bore out the old cylinder to accept a new sleeve, which is then honed to the specified size. This process produces a new, precise hole, which ensures the functionality and prolongs the lifespan of the cylinder.

In conclusion, portable line boring equipment is a valuable tool for many applications, whether in heavy equipment repair, industrial construction, or marine vessel maintenance. Its versatility and precision make it an essential piece of equipment for many industries.

The Process of Portable Line Boring Equipment

Portable line boring equipment is a versatile machine which is widely used for the repair and maintenance of heavy-duty equipment in diverse industries. From paper mills to mining operations, from agriculture to construction, a portable line boring equipment can work into a wide range of projects that require in-place machining. But how does it work?

The process of portable line boring equipment is relatively easy to understand. At its core, the machine consists of a boring bar which is mounted on the workpiece using bolts and clamps. Once the boring bar is secured, it’s time to set the right speed and feed rate. The speed determines how fast the bar rotates while the feed rate controls how fast the cutting tool moves along the workpiece. Both values are adjusted according to the type of material, diameter, and length of the bore.

Next, the operator sets the cutting tool. Different types of cutting tools are used depending on the application, such as carbide, diamond or high-speed steel. The chosen tool is aligned to the desired angle, cutting depth, and diameter to create the perfect bore. Since the machine is portable, it can be operated in the field, saving time and money that would be spent in transporting the equipment to a workshop.

In conclusion, portable line boring equipment has revolutionized the way industries approach machinery repair and maintenance. With its compact size, high accuracy, and efficiency, a portable line boring equipment can tackle a wide range of projects, from simple repairs to extensive customized machining. By following the process outlined in this article, operators can take effective advantage of the portable line boring equipment to reduce downtime, increase equipment lifespan, and improve productivity.

How to use Portable Line Boring Equipment

Portable line boring equipment is a crucial tool used in the repair of heavy equipment such as engines, pumps, turbines, and ship propellers. They are designed for in-situ machining where the equipment does not need to be moved. Here’s how to use portable line boring equipment.

First, you need to anchor the equipment to avoid movement that can affect the accuracy of the bore. You can use clamps or bolts to stabilize the machine. Make sure there is a good grip on the equipment as this will prevent accidents.

Next, you need to select the appropriate boring bar for the job. The boring bar is the tool that cuts into the material being machined. The right size will depend on the diameter of the hole you want to make. The boring bar should be adjusted to the correct length depending on the length of the hole you need to make.

The boring bar should be inserted into the machine and locked securely. The cutting head should be adjusted to the correct angle to ensure that it cuts the material correctly. This will depend on the material being machined.

Once the cutting head is set, the machine should be turned on, and the cutting head should be lowered to the material to which it will be performing the task. The machine should be operated slowly, and then the operator should monitor the process to ensure that the machine is running properly.

Portable line boring equipment is an efficient tool for repairing heavy equipment. It is easy to use and can be employed in a variety of applications. By following the steps above, you can get the job done safely and effectively.

Selecting the Ideal Manufacturer Portable Line Boring Equipment

When it comes to portable line boring equipment, there are plenty of options available in the market. However, it is essential to choose the ideal manufacturer to ensure durability and reliability in the long run.

One of the first things to consider when selecting a manufacturer is their experience in the industry. Look for manufacturers who have been in the line boring business for several years and have a proven track record of producing high-quality equipment.

Another critical factor to consider is the equipment’s performance specifications. Check if the equipment is powerful enough to handle the clients’ needs and able to handle different types of materials. Look for manufacturers who offer customizable solutions to meet the specific requirements of your projects.

The manufacturer’s customer service is also a crucial consideration. Choose a manufacturer who provides excellent after-sales support, including technical support and maintenance services. Ask for references from the manufacturer and speak to previous clients to get an idea of their experience with the manufacturer and their support services.

Another vital consideration when selecting a manufacturer is the equipment’s overall cost. While it may be tempting to choose the cheapest option, investing in high-quality equipment may save you more money in the long run. Look for manufacturers who offer competitive pricing without compromising on the equipment’s quality.

In conclusion, selecting the ideal portable line boring equipment manufacturer requires careful consideration of several factors. Look for experienced manufacturers, check the equipment’s performance capabilities, ensure excellent customer service, and consider overall cost. With these considerations, you can be sure to find a reliable and durable line boring equipment that will meet your clients’ needs.

list FAQ with answer about Portable Line Boring Equipment

Portable line boring equipment is an essential tool for industries involved in field machining, repair, and reconditioning of heavy machinery. Here are some frequently asked questions and their answers about portable line boring equipment:

1. What is Portable Line Boring Equipment?

Portable line boring equipment is a set of tools used for on-site machining of large industrial equipment. The equipment allows the machinist to bore holes in equipment while it remains in place, without requiring disassembly or transportation.

2. What are the components of Portable Line Boring Equipment?

Typical components of Portable Line Boring Equipment are boring bars, bore welders, drive units, power packs or hydraulic pumps, and a set of accessories.

3. What industries use Portable Line Boring Equipment?

Portable line boring equipment is used in a wide range of industries, including mining, power generation, construction, maritime, and others. It is beneficial in any industry that requires on-site bore repairs, modification or welding.

4. How do I charge Portable Line Boring Equipment?

Portable line boring equipment is usually powered by hydraulic or electric power packs and may also require a generator or compressor if the power source is not available on the site. The power packs can be charged by connecting to a power source like a standard wall socket, generator, or using batteries.

5. How do I maintain Portable Line Boring Equipment?

Regular maintenance is essential for the proper functioning of portable line boring equipment. It includes wiping the components clean, checking for damaged or worn parts, lubricating any moving parts, and storing the equipment in a dry area.

6. What are the benefits of using Portable Line Boring Equipment?

Portable line boring equipment allows on-site repairs, reduces the downtime of the machinery, and saves transport costs, making it a cost-effective solution. Moreover, it provides precise and accurate results, which result in safer and more reliable equipment.

In conclusion, if you work in any industry that requires on-site bore repairs, modification, or welding, portable line boring equipment is an essential tool to have. By understanding the basic components, functions, and best practices of this equipment, you can ensure smooth and efficient operations.

Things to Consider When Purchasing Portable Line Boring Equipment

Portable line boring equipment is used to repair or replace worn or damaged parts in machinery like excavators, bulldozers, and other heavy equipment. When purchasing portable line boring equipment, there are several factors you need to consider so that you can get the best equipment for your needs.

First and foremost, it’s important to consider the size and weight of the equipment. The portable line boring equipment should be small, lightweight, and easy to transport, especially if you’re planning to use it in different locations. You also need to consider the line boring tool size and the range of workpiece diameter it can handle, as it will determine the versatility of the machine.

Secondly, consider the power source of the portable line boring equipment. Are you going to use an electric or hydraulic power source? Hydraulic line boring machines are usually more powerful, but they require a separate hydraulic power unit, which may not be practical in some situations.

Thirdly, it’s important to consider the quality of the bearings, drive gears, and other essential components. Look for portable line boring equipment with high-quality components that will last long, even under intense use. This will save you money in the long run since you won’t have to replace your machine frequently.

Fourthly, consider the price of the portable line boring machine. Most portable line boring equipment is expensive, but you can find some affordable options on the market. It’s important to strike a balance between the price and the quality of the machine. In other words, look for a machine that is reasonably priced without compromising on its quality and performance.

Lastly, consider the warranty period of the portable line boring equipment. A good warranty period assures you that the manufacturer stands behind the product and is confident in its quality. Look for portable line boring machines that come with a decent warranty period.

In conclusion, purchasing portable line boring equipment requires careful consideration of the size, weight, power source, quality of components, price, and warranty period. By considering these factors, you can make a well-informed purchase and get equipment that will serve you well for many years.

Properties of Portable Line Boring Equipment

Portable line boring equipment is used to bore holes in metal, such as engines, gearboxes, and other metal components. This equipment is used mainly in industries where high precision is needed. The portable line boring equipment has several key properties that make it an essential tool in various industrial sectors.

One of the main properties of portable line boring equipment is its portability. This equipment is designed to be carried from one location to another, making it ideal for on-site repairs. The portability aspect of line boring equipment makes it easy to move around the job site, saving time and effort in the process.

Another property of portable line boring equipment is its precision. This equipment is designed to make highly accurate cuts, which is critical for industries such as aerospace and automotive that require high precision. The equipment is equipped with high-quality components, including precision cutters and measuring tools, to ensure that the cuts are made accurately.

Another key property of portable line boring equipment is its versatility. It can be used to bore holes of different sizes and shapes, making it an ideal tool for various industrial applications. This versatility makes it an essential tool for industries such as mining, construction, and infrastructure development.

The durability of the portable line boring equipment is another important property. The equipment is made of high-quality materials that can withstand the rigors of daily use. The equipment is designed to last for a long time, reducing replacement costs for the buyer.

In addition to the above properties, portable line boring equipment is easy to use, and it requires minimal maintenance. Manufacturers provide buyers with the necessary training and support to ensure that they use the equipment correctly.

In conclusion, portable line boring equipment has several valuable properties that make it an essential tool in various industries. Despite being portable, the equipment is highly precise, versatile, and durable, making it an ideal tool for on-site repairs that require high precision. The equipment is also easy to use, and it requires minimal maintenance, reducing operational costs for buyers.

Technical Parameters Terms for Portable Line Boring Equipment

When it comes to portable line boring equipment, technical parameters are essential for proper functioning and efficient operation of the machinery. These technical parameters are a set of standards that govern the performance, capacity, and functionality of the equipment.

The first and most important parameter is the bore diameter that the equipment can handle. This parameter determines the range of hole sizes that the equipment can bore, and it’s important to ensure that the equipment can accommodate the hole sizes needed for a particular project.

Another critical technical parameter is the rotational speed of the spindle. This parameter specifies the speed at which the spindle rotates while boring, and it’s important to ensure that the equipment can handle the required rotational speed for the material being bored.

The power output of the equipment’s motor is also a critical technical parameter. This parameter indicates how much power the motor can produce, and it’s vital to ensure that the motor is powerful enough to handle the job.

The feed rate is another important technical parameter. This parameter determines how quickly the equipment can advance the cutting tool through the material being bored, and it’s vital to ensure that the feed rate is at an optimal rate, which allows for efficient operation and high-quality results.

The depth of cut is another technical parameter that correlates with the feed rate. The depth of cut determines the amount of material that the cutting tool can remove in one pass, and its vital to ensure that the depth of cut is set to a level that doesn’t strain or damage the equipment, but still removes the required amount of material.

In conclusion, technical parameters are essential aspects of portable line boring equipment as they are set to optimize the equipment’s performance, capacity and functionality. These parameters vary depending on the specifications of each machine model, and it’s, therefore, necessary to consider them before purchasing or using the equipment.

Portable Line Boring Equipment Price

Portable line boring equipment is an essential tool for repair and maintenance work in various industries. Whether it’s mining, construction or agriculture, line boring machines are used to repair worn-out bores in equipment and machinery.

One of the most common concerns among customers is the price of portable line boring equipment. The cost of this equipment varies depending on several factors such as size, make, model and additional features being offered.

Generally, most portable line boring equipment cost ranges between $3,000 and $10,000. However, more advanced models can range up to $20,000. It is important to note that the cost of this equipment should be considered a long-term investment. For businesses that require multiple repairs and maintenance work, owning a portable line boring machine can save them thousands of dollars in outsourcing expenses.

The size of the equipment is a significant factor in determining the price. Smaller and lightweight models are relatively cheaper compared to larger models. The larger machines are designed to handle the heaviest and most challenging repair work, which is why their price tends to be higher. It is essential to assess the required bore diameter and repair work to determine the appropriate size and price of the machine.

Customers can also choose between hydraulic and pneumatic line boring equipment. Pneumatic machines are typically less expensive compared to hydraulic models. However, the performance and efficiency of hydraulic equipment far outweigh the price of the pneumatic line boring equipment.

Additional features such as a digital measuring system, multiple feed rates, and variable spindle speeds also contribute to the pricing of line boring equipment. These features enhance the precision and accuracy of the machine, making it more efficient and reducing the time spent on each repair job.

In conclusion, the price of portable line boring equipment varies depending on the size, model, and additional features being offered. While the initial cost may seem high, investing in this equipment can save customers a considerable amount of money in the long run. It is important to assess the required bore diameter and repair work to ensure that the machine selected is appropriate for specific needs.