Knowledge about Pouch Sealing Machine

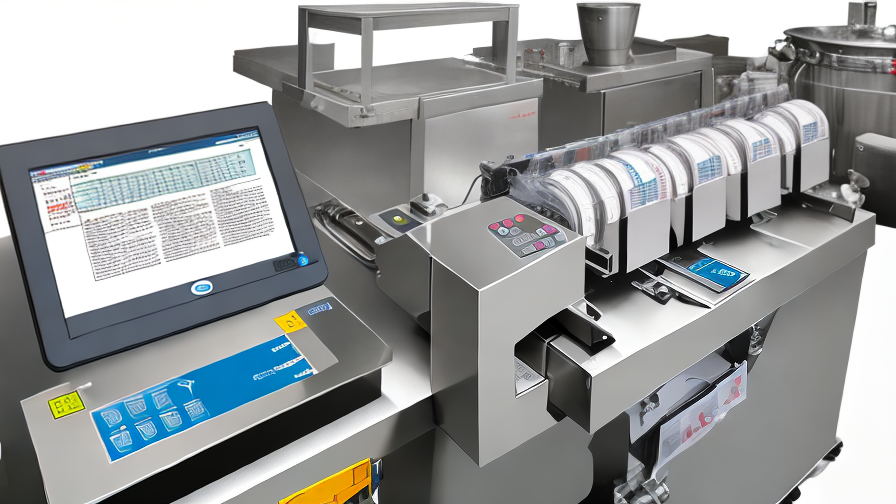

Pouch sealing machines are used to seal bags and pouches that contain a variety of products. These machines allow a company to package their product with ease and increase their productivity. Knowing the information about pouch sealing machines is crucial to making the right investment in your business.

There are different types of pouch sealing machines available, including heat sealers, impulse sealers, and vacuum sealers. The heat sealer is the most common type, using heat to melt the plastic and seal it shut. Impulse sealers use heat and pressure to seal the bag shut. Vacuum sealers must first remove the air from the bag before sealing it shut. Knowing which type of pouch sealing machine will work best for your product and business is important.

The size of the pouch sealing machine is also a factor to consider. Large machines are available for high-volume production, and smaller ones are available for producing small runs of products. Understanding your production needs and how to scale them accordingly can ensure your business operates smoothly and cost-effectively.

Different pouch sealing machines also vary in the materials they can seal. Some machines can only seal plastic, while others can seal foil or laminated bags. It is essential to know which materials you need to seal and which machine will work for your specific product packaging.

It is also important to factor in your budget when purchasing a pouch sealing machine. The price of a pouch sealing machine will depend on its features and capabilities. Investing in a high-quality machine that suits your business needs is wise, but always consider the return on investment (ROI) before making the investment.

In conclusion, a pouch sealing machine is a valuable investment for companies looking to improve their productivity by increasing production capabilities. Making an informed purchase decision by understanding the differences in types, sizes, materials, and costs can help businesses ensure they are making the most of their investment.

Various Types of Pouch Sealing Machine

Pouch sealing machines are an essential part of packaging industries. These machines are designed to heat seal various types of pouches for packing food items, pharmaceutical products, cosmetic creams, and many other products. There are different types of pouch sealing machines available in the market, and each machine has its own unique features.

One of the most popular types of pouch sealing machines is the vertical pouch sealing machine. As the name suggests, this machine seals the pouches vertically. It is ideal for packing lightweight products such as snacks and candy bags. Another type of pouch sealing machine is the horizontal pouch sealing machine, which seals pouches horizontally. This machine is widely used for packing liquids and thick products such as shampoo and detergents.

The third type of pouch sealing machine is the vacuum pouch sealing machine. This machine removes the air from the pouch, which prolongs the product’s shelf life. It is used for packaging products that need to be stored for a long time, such as frozen meats and vegetables. A fourth type of pouch sealing machine is the band sealing machine, which seals the pouches using a band. This machine is widely used in the pharmaceutical industry for sealing sachets and pouches.

Another type of pouch sealing machine is the pneumatic pouch sealing machine. This machine is designed to seal pouches with high-speed and accuracy. It is widely used in the food industry for packing snacks, chips, and other lightweight products. The sixth type of pouch sealing machine is the hot bar sealing machine, which is ideal for packing thick products such as gels, creams, and wax.

In conclusion, various types of pouch sealing machines are available in the market, each with its own unique features. The type of pouch sealing machine that is required depends on the products being packaged, the industry, and the volume of production. It is essential to choose a machine that is suitable for the task at hand to ensure efficient productivity and cost-effectiveness.

FAQ sourcing Pouch Sealing Machine manufacturer from China

If you are looking for a reliable pouch sealing machine manufacturer from China, you might have a lot of questions in mind. In this article, we have put together some frequently asked questions to help you find the best supplier for your business.

1. How can I find a reliable pouch sealing machine manufacturer in China?

There are several ways to find a reliable manufacturer in China, including online research, asking for referrals, and attending trade shows. You should look for a company that has a good reputation, a wide range of machines, and years of experience in the industry.

2. What types of pouch sealing machines are available from Chinese manufacturers?

Chinese manufacturers offer a wide range of pouch sealing machines, including vertical form fill seal machines, horizontal form fill seal machines, and automatic pouch sealing machines. You can choose the machine that best suits your business needs.

3. What are the advantages of buying from a Chinese manufacturer?

Chinese manufacturers offer competitive prices, high-quality products, and a vast range of machines. They also have the ability to customize products according to your specific needs.

4. How do I ensure the quality of pouch sealing machines from China?

Before making a purchase, you should ask for product samples, test the machines, and check the manufacturer’s certifications and credentials. You may also want to look for reviews and feedback from other customers.

5. How do I communicate with the manufacturer and place an order?

Most Chinese manufacturers have English-speaking staff that you can contact via email or phone. You can also use online platforms such as Alibaba to find and communicate with manufacturers. When placing an order, make sure to specify your requirements and get a detailed quote, including shipping and delivery times.

In conclusion, sourcing a pouch sealing machine manufacturer from China requires some research and due diligence. However, by asking the right questions and choosing a reliable supplier, you can find the best machine for your business at a competitive price.

Applications of Pouch Sealing Machine

Pouch sealing machine is a versatile and robust machine that is widely used in various industries. One of the main applications of pouch sealing machine is in the packaging industry. This machine is utilized to seal different types of pouches such as stand-up, zipper, spout, square bottom, and quad seal pouches.

Pouch sealing machines can be used to seal pouches made of different materials such as plastic films, aluminum foil, and laminates. This makes it ideal for packaging products like snacks, pet food, spices, and liquid products. These machines can also handle different sizes of pouches, which make them suitable for different types of products.

Another application of pouch sealing machine is in the pharmaceutical industry. These machines offer a high level of sealing quality required for packaging sensitive products such as drugs, medical devices, and nutritional supplements. Pouch sealing machines used in the pharmaceutical industry are designed to meet stringent regulations such as FDA and GMP.

Pouch sealing machine can also be used in the cosmetics industry, where it is utilized to package products like lotions, creams, and shampoos. These machines are also used in the automotive industry to package chemicals, cleaners, and lubricants. Pouch sealing machines have also found use in the construction industry where they are used to package adhesives, sealants, and other construction materials.

In conclusion, the applications of pouch sealing machines are diverse, and they are not limited to the industries highlighted above. Pouch sealing machines have contributed significantly to enhancing the quality, durability, and shelf life of products. It is, therefore, crucial for different industries to invest in high-quality pouch sealing machines to enhance their packaging process and meet consumer expectations.

Manufactured Products made of Pouch Sealing Machine

A pouch sealing machine is an essential piece of equipment used in the production of manufactured products. These machines are designed to seal plastic bags or pouches filled with a range of products from food and snacks to medical supplies and cleaning products. The pouch sealing machine is a versatile tool that has found its way into various industries and is used to produce a range of manufactured products.

One of the most common manufactured products made with a pouch sealing machine is food packaging. Sealed pouches protect food products from contamination, moisture, and air, which extends their shelf life. From snacks to ready-to-eat meals, pouch sealing machines are used to produce a range of food packaging products. Similarly, medical products such as bandages, syringes, and surgical masks are often packaged in sealed pouches produced by sealing machines to ensure their sterility.

Another application of pouch sealing machines is in the production of cleaning and hygiene products. Liquid detergents, shampoos, and lotions are sealed in pouches using these machines, making them easy to use and transport. Similarly, baby wipes, sanitary products, and tissue paper are also packaged using pouch sealing machines.

Pouch sealing machines offer several advantages in the manufacturing process. These machines are automated, which means they can pack products at a faster rate than manual packing, reducing production time and costs. Additionally, pouch sealing machines ensure the product is sealed tightly and consistently, reducing the chances of leakage and contamination.

In conclusion, pouch sealing machines are a crucial tool in the production of various manufactured products. These machines have gained popularity due to the versatility they offer in packaging, from food and medical products to hygiene and cleaning products. By automating the packaging process, pouch sealing machines increase production efficiency and reduce the risk of product contamination. The popularity of pouch sealing machines is only set to grow as manufacturers seek innovative ways to package their products.

The Evolution history of Pouch Sealing Machine

Pouch sealing machines have come a long way since their inception. Initially, they were manual and required human intervention to seal the pouches. However, advancements in technology have led to the development of fully automated machines that can seal multiple pouches in a matter of seconds.

The first pouch sealing machine was invented in the early 1900s. It was a simple machine that required the operator to manually insert the pouch into the machine and rotate a handle to seal it. This machine was cumbersome and slow, but it was a significant improvement over manually sealing pouches.

In the 1950s, the first semi-automated pouch sealing machines were introduced. These machines used a foot pedal to activate the sealing process, reducing human intervention significantly. These machines were faster and more efficient than their manual counterparts, but they still required an operator to oversee the process.

The 1980s saw the introduction of fully automated pouch sealing machines. These machines are equipped with sensors and programmable logic controllers that allow them to operate independently. They can detect if a pouch is misaligned or if the sealing temperature is too high or too low, and adjust the sealing process accordingly.

As technology continues to evolve, so do pouch sealing machines. Today’s machines use advanced sealing techniques, such as ultrasonic sealing, to create a strong and secure seal. They can also be customized to seal different types of pouches, including stand-up pouches, zipper pouches, and spout pouches.

In conclusion, the evolution of pouch sealing machines has been remarkable. From simple manual machines to fully automated ones, the industry has come a long way. The future of pouch sealing machines looks promising, with continued advancements in technology expected to make them even more efficient, productive, and versatile.

The Process of Pouch Sealing Machine

A pouch sealing machine is a device used in many industries for sealing bags or pouches that contain various products such as food, medical equipment, or pharmaceutical products. The process of pouch sealing involves the use of heat, pressure, and a sealing material. Here’s a brief overview of the process:

1. Filling the pouch: Before pouch sealing, products such as food, medical equipment, or pharmaceuticals are filled into a pouch. The pouch is then placed onto the pouch sealing machine.

2. Clamping or holding the pouch: The machine’s clamping or holding mechanism ensures that the pouch stays in place. The clamp’s pressure is adjusted according to the pouch’s material, size, and type.

3. Sealing the pouch: Once the pouch is clamped, the sealing process begins. The sealing material is inserted into the machine, where the temperature and pressure parameters are set. The machines then heat the sealing material to the optimal temperature, melting it and applying pressure to the pouch.

4. Cooling: Once the pouch’s sealing is completed, the machine cools it down to solidify the seal.

5. Trimming: Some machines have built-in trimmers that cut off the excess sealing material from the pouch’s edges, giving it a neat appearance.

Pouch sealing machines come in various types, such as impulse, direct-line, and band sealing, among others. Each type has a specific sealing method that suits different pouch’s materials, sizes, and types.

In conclusion, the process of pouch sealing involves several essential steps, including filling, clamping, sealing, cooling, and trimming. The use of a sealing machine ensures consistent and reliable packing, improves production efficiency, and protects products from contamination and spillage.

Benefits Advantages of Utilizing Pouch Sealing Machine

Pouch sealing machines are widely used in various industries to seal pouches of different shapes, sizes, and materials. These machines are versatile, efficient, and cost-effective, making them an ideal choice for businesses of all sizes. Here are a few benefits and advantages of utilizing pouch sealing machines:

Firstly, pouch sealing machines are easy to operate, efficient, and require minimal maintenance. It allows business owners to produce a large number of sealed pouches quickly and effortlessly. The machines can seal a wide range of heat-sealable materials, such as polyethylene, polypropylene, laminates, and foils.

Secondly, pouch sealing machines provide a safe and secure seal that is resistant to tampering and provides protection against moisture, dirt, and other contaminants. This quality sealing ensures that the product stays fresh and intact for a longer period. Pouch sealing has become an essential packaging method for food and pharmaceutical industries because it provides a longer shelf life to their products.

Thirdly, pouch sealing machines offer a high degree of customization, allowing businesses to adjust the sealing temperatures, pressure, and sealing times to match the packaging material’s requirements. Also, there are various types of pouch sealing machines available in the market, such as semi-automatic, automatic, and manual machines that provide the flexibility to businesses to choose the machine as per their requirement.

Fourthly, pouch sealing machines are cost-effective and can pay for themselves quickly. The machines eliminate the need for labor to seal pouches manually, reducing the operating costs and increasing production rates. The machine’s efficient operation also reduces the materials used, leading to cost savings.

Fifthly, pouch sealing machines are suitable for a wide variety of industries, including food, pharmaceutical, and industrial applications. These machines are ideal for packaging liquids, powdered products, granules, and small parts, making the packaging process simple and efficient.

In conclusion, the benefits and advantages of utilizing pouch sealing machines are vast, including cost-effectiveness, versatility, safety, and customization.

Disadvantages Pouch Sealing Machine

Pouch sealing machines have become an essential requirement for various industries, from food to pharmaceutical to cosmetic products. These machines offer a range of advantages, such as cost-effectiveness, increased productivity and efficiency, and improved quality control. However, there are some disadvantages to consider with pouch sealing machines that industries must keep in mind when deciding to invest in these machines.

One significant disadvantage of pouch sealing machines is their complexity. These machines require technical expertise to operate, maintain, and troubleshoot. Industries that lack the necessary technical knowledge and expertise may need to invest in specialized training of their workforce or hiring of technical experts to handle these machines. This training or employment of experts can add an additional cost to the industry.

Another disadvantage of pouch sealing machines is their susceptibility to faults and breakdowns. These machines require continuous maintenance to prevent faults and breakdowns, which can lead to downtime, lost productivity, and increased production costs. Some components of these machines may require regular replacement, which can also add to the ongoing cost of operating these machines.

Additionally, pouch sealing machines can also impact the environment negatively. These machines emit a considerable amount of heat, which can affect the working environment, especially in warmer climates. Furthermore, these machines consume a substantial amount of energy, contributing to environmental pollution.

Finally, another disadvantage of pouch sealing machines is their limited flexibility in handling different types of materials. These machines require specific materials to operate efficiently, which can limit their versatility. Industries that require pouch sealing of various types of materials, such as thin films or aluminum foils, may need to invest in multiple machines, which can add to the initial cost.

In conclusion, pouch sealing machines have many advantages, but it is important to consider the disadvantages and be informed before investing in these machines. Industries must weigh the benefits against the cost, the required technical expertise, the potential for downtime and maintenance, the environmental impact, and their limited flexibility in handling different types of materials. By considering these factors, they can make an informed decision and choose the

Selecting the Ideal Manufacturer Pouch Sealing Machine

Pouch sealing machines are useful in a variety of industries, including food packaging, medical supplies, and electronics. With so many manufacturers and models available, selecting the ideal pouch sealing machine can be difficult. However, a few key factors can help narrow down the search.

Firstly, it’s important to consider the type of pouches being used. Some machines are better suited for specific materials, such as mylar or aluminum foil. It’s also important to ensure that the machine is compatible with the size of the pouches needed for the particular product being packaged.

Another important consideration is output capacity. Depending on the volume of production, it may be necessary to opt for a heavy-duty machine that can handle high volumes with ease. However, it’s important to balance output capacity with other factors, including space requirements and energy consumption.

Ease of use and maintenance are also important factors to consider. Some machines may require a high level of technical expertise, while others are designed to be user-friendly. Additionally, it’s important to consider the availability and cost of replacement parts, as well as the level of training needed to perform routine maintenance.

Finally, pricing should be considered when selecting a pouch sealing machine. However, it’s important to balance the budget with the desired features and capabilities. Sometimes spending a little extra upfront can ultimately save money in the long run by avoiding costs associated with downtime, maintenance, or replacement parts.

In conclusion, selecting the ideal pouch sealing machine requires careful consideration of a variety of factors, including the type and size of the pouches being used, output capacity, ease of use and maintenance, and pricing. By taking these factors into account, it’s possible to find a pouch sealing machine that will meet the needs of any particular industry.

Things to Consider When Purchasing Pouch Sealing Machine

When it comes to purchasing a pouch sealing machine, there are several factors that you must consider before making a decision. Below, we have highlighted some important things that you should keep in mind when purchasing a pouch sealing machine:

1) Sealing capacity: It is important to understand how much sealing capacity you will require before purchasing a machine. If you need to seal a large number of pouches in a short period of time, you will need a machine with a higher sealing capacity.

2) Seal strength: The strength of the seal is an important consideration, as it must be strong enough to hold the product safely inside the pouch. You must also consider the thickness of the pouch you will be sealing, as thicker pouches require a higher seal strength.

3) Size of the machine: The size of the machine is determined by the size of the pouches you will be sealing. You must consider the width and height of the pouch so that the machine can seal them efficiently.

4) Type of sealing: There are different types of sealing methods available, such as heat sealing or impulse sealing. You must choose the type of sealing that is best suited for your product.

5) Ease of use: Choose a machine that is easy to use, with clear instructions and simple controls. This will ensure that you can operate the machine without any difficulty and save time.

6) Maintenance and durability: Choose a machine that is durable and easy to maintain. Look for machines with simple designs that are easy to clean and require minimal servicing.

In conclusion, when purchasing a pouch sealing machine, you must consider factors such as sealing capacity, seal strength, size of the machine, type of sealing, ease of use, and maintenance and durability. By considering these factors, you can choose a machine that is best suited for your needs, ensuring that you can seal your pouches safely and quickly.

Properties of Pouch Sealing Machine

Pouch sealing machines are used in various industries to seal different types of pouches such as laminated pouches, aluminum foil pouches, etc. These machines come in different sizes, shapes, and have various features, which makes them suitable for different applications. In this article, we will look at some of the key properties of pouch sealing machines.

One of the most crucial properties of pouch sealing machines is their sealing strength. The sealing strength of a machine determines its ability to seal pouches tightly and keep the contents inside the pouch safe and secure. A good pouch sealing machine should have an adjustable temperature control system, which allows it to seal different types of materials with varying thicknesses effectively.

Another important property of pouch sealing machines is their speed. These machines are designed to operate at different speeds depending on the size of the pouch and the production requirements. A high-speed sealing machine can seal hundreds of pouches in a minute, while a low-speed machine may only seal a few pouches per minute.

The sealing width of a pouch sealing machine is another important property. The sealing width determines the width of the seal that the machine can create on the pouch. A wider sealing width ensures that the seal is stronger, which reduces the likelihood of the pouch tearing or leaking.

Pouch sealing machines also come with various features such as automatic pouch detection, which detects the presence of a pouch and starts the sealing process automatically. Some machines also have adjustable sealing pressure, which allows the operator to adjust the pressure applied during the sealing process.

In conclusion, pouch sealing machines are essential in various industries, and they come with different features that make them suitable for different applications. When purchasing a pouch sealing machine, it is essential to consider factors such as sealing strength, speed, sealing width, and other features that make the machine efficient and effective.

How to use Pouch Sealing Machine

If you are in the food or packaging industry, you must be aware of the significance of pouch sealing machines. These machines are used to seal the packaging of various products, including food, cosmetics, and medical supplies, to protect them from contamination.

Here are some steps on how to use pouch sealing machines:

1. Set Up the Pouch Sealing Machine

The first step is to ensure that the pouch sealing machine is properly set up. You need to adjust the temperature and speed settings according to the type of pouch and product you are sealing.

2. Load the Pouches

You need to load the pouches into the machine. Make sure that they are loaded evenly and are not crumpled. You can place them in rows, and the machine will automatically pick them up for sealing.

3. Feed the Product

Once the pouches are loaded, you can start feeding the product into the pouches using a filler or manual hand filling. Make sure that you do not overfill the pouches to avoid any spills.

4. Seal the Pouches

Now, it’s time to seal the pouches. Once the product is loaded, the machine will automatically seal the pouches. The sealing process can be a vertical or horizontal type.

5. Store the Pouches

Once the pouches are sealed, you can remove them from the machine and store them in a safe and dry place until they are ready for distribution.

In conclusion, pouch sealing machines are essential for the packaging industry, and by properly following these steps, you can ensure that your products remain safe and protected. Remember to follow the instructions carefully and regularly maintain the machine to ensure its longevity.

Glossary Terminology Terms for Pouch Sealing Machine

If you’re new to the world of pouch sealing machines, it’s essential to have an understanding of the terminology used in the industry. Knowing the right terms and definitions can help you choose the right machine for your needs and ensure that you are using it correctly. To help you get started, we’ve put together this glossary of essential terms used in pouch sealing machines.

Sealing Temperature:

The temperature required to seal the pouch properly. It depends on the type of material used in the pouch.

Sealing Time:

The amount of time required to seal the pouch from starting heat application to peak heat.

Sealing Pressure:

The amount of pressure required to seal the pouch.

Jaw Gap:

The distance between the two jaws. It is essential to measure correctly and adjust for different pouch sizes.

Jaw Alignment:

The alignment of the jaws directly affects the quality of the seal.

Dwell Time:

The amount of time that the pouch remains stationary in the sealing area after sealing the material.

Pneumatics:

The use of compressed air for the operation of the machine.

Thermal Conductance:

The measure of a material’s ability to conduct heat.

Thermal Insulation:

The measure of a material’s ability to retain heat.

Thermocouples:

Sensors that measure temperature and provide feedback to the control system.

Control System:

The electronic system managing the operating parameters of the machine.

Impulse Sealing:

A method that uses heat to seal a pouch by applying pressure and welding it.

Hot Bar Sealing:

A method that utilizes a heated bar to seal the pouch. It’s an excellent method for applications that require more precise control of the sealing process.

In conclusion, using the correct terminology is essential when working with pouch sealing machines. It is crucial to understand these terms to operate the machine correctly and select the best machine for your production process. This glossary serves as an excellent starting point, but there are many more terms to learn. By learning them, you will be making more informed

Pouch Sealing Machine Price

A pouch sealing machine is an essential piece of equipment for any manufacturing plant that deals with packaging products. It is an automated machine that seals pouches of different sizes and materials, such as plastic, paper, and aluminum. The machine is used to package products such as food, pharmaceuticals, and chemicals, among others. When looking to purchase a pouch sealing machine, the cost is one of the primary considerations.

Pouch sealing machine prices can vary depending on the features, functionality, and brand. Basic models can cost a few hundred dollars, while more advanced models with multiple features can cost several thousand. The prices also vary depending on the type of machine, including vertical and horizontal pouch sealing machines.

When comparing prices, it is important to consider the features of the machine. Some models have advanced features such as temperature control, adjustable sealing speed, and automatic pouch feeding. These features increase the efficiency of the machine and, in the long run, can be more cost-effective.

Brand is also a significant consideration when it comes to price. Some brands are known to produce high-quality machines with advanced features, while others offer more basic models. Popular brands such as Bosch, Arpac, and Mespack are generally more expensive than smaller brands.

Buying a pouch sealing machine can be a significant investment for any business. However, choosing the right machine can increase efficiency, reduce costs and ultimately lead to increased profits. It is important to do research and compare prices of different models and brands to find the most cost-effective solution.