Fiber Laser Marking Machine Manufacturer

Benefits

The fiber laser marking machine offers numerous benefits to its users, including:

1. High precision and accuracy: The machine delivers high-quality, permanent markings with excellent precision and accuracy, ensuring that your products have a professional and lasting appearance.

2. Fast marking speed: The fiber laser marking machine can mark materials at a rapid pace, allowing you to increase your production efficiency and reduce downtime.

3. Low maintenance: The machine has a long service life and requires minimal maintenance, saving you time and money in the long run.

4. Environmentally friendly: The fiber laser marking machine uses no consumables and produces no harmful emissions, making it an eco-friendly choice for your business.

Features

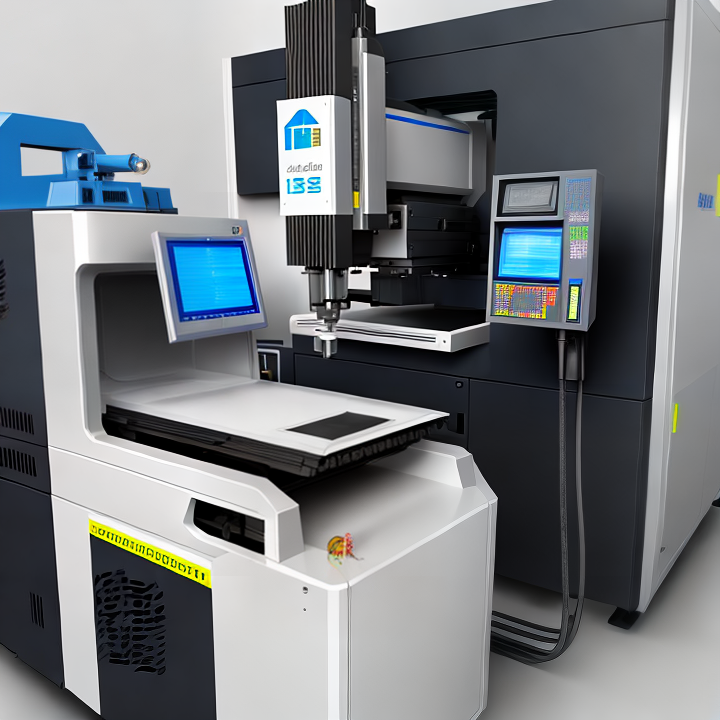

Some of the key features of the fiber laser marking machine include:

1. High-quality fiber laser source: The machine uses a high-quality fiber laser source, ensuring stable and consistent performance.

2. User-friendly software: The machine comes with easy-to-use software, allowing you to create and edit designs quickly and efficiently.

3. Wide range of materials: The fiber laser marking machine can mark a variety of materials, including metals, plastics, ceramics, and more.

4. Compact design: The machine has a compact design, making it easy to integrate into your existing production line.

Specifications

The fiber laser marking machine has the following specifications:

1. Laser power: 20W, 30W, or 50W

2. Marking area: 110mm x 110mm (customizable)

3. Marking speed: ≤7000mm/s

4. Min. line width: 0.01mm

5. Min. character size: 0.15mm

6. Cooling method: Air cooling

Applications

The fiber laser marking machine is suitable for a wide range of applications, including:

1. Electronics: Marking of PCBs, IC chips, and electronic components

2. Automotive: Marking of vehicle identification numbers (VIN), engine parts, and other components

3. Medical: Marking of surgical instruments, implants, and medical devices

4. Jewelry: Marking of logos, designs, and text on various jewelry items

5. Aerospace: Marking of aircraft components and parts

FAQ

1. What materials can the fiber laser marking machine mark?

The machine can mark a wide range of materials, including metals, plastics, ceramics, and more.

2. How long does the laser source last?

The fiber laser source has a long service life of up to 100,000 hours, ensuring minimal maintenance and downtime.

3. Is the software compatible with different file formats?

Yes, the software is compatible with various file formats, including AI, PLT, DXF, and more.

4. Can the marking area be customized?

Yes, the marking area can be customized according to your specific requirements.

5. What is the warranty period for the fiber laser marking machine?

The machine typically comes with a one-year warranty, covering any manufacturing defects or issues.

A Beginner’s Guide to fiber laser marking machine manufacturer

A fiber laser marking machine is a type of laser equipment that uses a fiber laser source to create high-quality, permanent marks on a wide range of materials, such as metal, plastic, and ceramics. Fiber laser marking machines are widely used in various industries, including automotive, aerospace, electronics, medical, and jewelry. As a beginner, it is essential to understand the basics of fiber laser marking machine manufacturers and their products.

1. Fiber laser source: The core component of a fiber laser marking machine is the fiber laser source, which generates the laser beam. The most common type of fiber laser source is the ytterbium-doped fiber laser, known for its high efficiency, excellent beam quality, and long service life.

2. Manufacturers: There are numerous fiber laser marking machine manufacturers worldwide, offering a wide range of products with varying features and capabilities. Some well-known manufacturers include IPG Photonics, SPI Lasers, Trumpf, Rofin, and Han’s Laser. It is essential to research and compare different manufacturers to find the best fit for your specific needs and budget.

3. Features and specifications: When choosing a fiber laser marking machine, consider factors such as the laser power, marking speed, marking area, and software compatibility. Higher laser power allows for faster marking speeds and deeper engraving, while a larger marking area enables marking on larger workpieces. Additionally, ensure that the machine’s software is user-friendly and compatible with your existing systems.

4. After-sales support: A reliable manufacturer should provide comprehensive after-sales support, including technical assistance, training, and maintenance services. This ensures that you can maximize the performance and lifespan of your fiber laser marking machine.

5. Price: Fiber laser marking machines can vary significantly in price, depending on the manufacturer, features, and specifications. It is crucial to balance your budget with the machine’s capabilities to ensure that you invest in a machine that meets your requirements.

In conclusion, understanding the basics of fiber laser marking machine manufacturers is crucial for beginners looking to invest in this technology. By considering factors such as the manufacturer’s reputation, product features, after-sales support, and price, you can make an informed decision and select the best fiber laser marking machine for your needs.

How to Select a Reliable fiber laser marking machine manufacturer

Selecting a reliable fiber laser marking machine manufacturer is crucial to ensure the quality and efficiency of your marking operations. Here are some key factors to consider when choosing a manufacturer:

1. Experience and Reputation: Look for a manufacturer with a proven track record and a strong reputation in the industry. Check their years of experience in producing fiber laser marking machines and read customer reviews and testimonials to gauge their credibility.

2. Quality and Performance: The quality and performance of the machine are essential factors to consider. Research the materials and components used by the manufacturer in their machines. High-quality components will result in better performance and durability. Also, inquire about the machine’s marking speed, accuracy, and overall efficiency.

3. Technical Support and Customer Service: A reliable manufacturer should provide excellent customer service and technical support. Check if they offer installation, training, and maintenance services. Additionally, ensure they have a responsive support team that can address any issues or concerns promptly.

4. Certifications and Compliance: Verify if the manufacturer complies with industry standards and holds relevant certifications, such as ISO, CE, or FDA. This ensures that their products meet quality and safety requirements.

5. Customization and Scalability: Choose a manufacturer that offers customizable solutions to cater to your specific marking needs. They should be able to provide machines with different power levels, marking areas, and other features to suit your requirements.

6. Warranty and After-sales Service: A reliable manufacturer should offer a warranty on their machines, ensuring that any defects or issues are addressed promptly. Check the warranty period and the terms and conditions to ensure you are adequately covered.

7. Price and Value for Money: Compare the prices of different manufacturers and evaluate the features and benefits of their machines. Choose a manufacturer that offers a competitive price without compromising on quality and performance.

In conclusion, selecting a reliable fiber laser marking machine manufacturer involves researching their experience, reputation, product quality, customer service, certifications, customization options, warranty, and pricing. By considering these factors, you can make an informed decision and invest in a machine that meets your marking needs and delivers value for money.

Comparing fiber laser marking machine manufacturer and Suppliers: Which is Better?

When it comes to choosing between fiber laser marking machine manufacturers and suppliers, it is essential to consider various factors to determine which option is better for your specific needs. Here are some key aspects to consider when making your decision:

1. Quality and Reliability: The quality and reliability of the fiber laser marking machines are crucial for ensuring efficient and accurate marking. Manufacturers typically have more control over the production process and can ensure higher quality standards. Suppliers, on the other hand, may source their machines from multiple manufacturers, which could lead to variations in quality.

2. Customization and Flexibility: Manufacturers may offer more customization options for their machines, as they have direct control over the production process. This allows you to tailor the machine to your specific requirements. Suppliers, however, may have limited customization options, as they source their machines from various manufacturers.

3. Price: Suppliers often have lower prices due to their ability to source machines from multiple manufacturers, allowing them to offer competitive pricing. Manufacturers, on the other hand, may have higher prices due to their focus on quality and customization.

4. After-sales Support and Service: Manufacturers typically provide better after-sales support and service, as they have a deeper understanding of their machines and can offer more comprehensive assistance. Suppliers may have limited knowledge of the machines they sell, which could affect the level of support they can provide.

5. Lead Time: Manufacturers may have longer lead times due to their focus on customization and quality control. Suppliers, on the other hand, may have shorter lead times as they source machines from multiple manufacturers.

In conclusion, the better option between fiber laser marking machine manufacturers and suppliers depends on your specific needs and priorities. If quality, customization, and after-sales support are your top concerns, a manufacturer may be the better choice. However, if price and lead time are more important to you, a supplier could be the more suitable option. Ultimately, it is essential to carefully evaluate your requirements and research potential manufacturers and suppliers to make an informed decision.

The Manufacturing Process of fiber laser marking machine manufacturer

The manufacturing process of a fiber laser marking machine involves several key steps, ensuring the production of a high-quality and efficient machine for various marking applications. Fiber laser marking machines are widely used in industries such as automotive, aerospace, electronics, and medical devices for marking, engraving, and etching on different materials like metal, plastic, and ceramics.

1. Design and Development: The process begins with the design and development of the machine, where engineers create a blueprint of the machine’s structure, components, and specifications. This includes the selection of the appropriate laser source, scanning system, control software, and other essential components.

2. Laser Source Production: The core component of the machine, the fiber laser source, is manufactured by doping a glass fiber with rare-earth elements like ytterbium, erbium, or thulium. The doped fiber is then placed between two mirrors, forming a resonator. When the fiber is pumped with energy from a diode laser, it emits a highly focused laser beam.

3. Fabrication of Mechanical Components: The mechanical components of the machine, such as the frame, marking head, and focusing lens, are fabricated using high-precision CNC machines. These components are made from materials like aluminum, stainless steel, and brass to ensure durability and stability during operation.

4. Assembly and Integration: Once all the components are manufactured, they are assembled and integrated to form the complete fiber laser marking machine. This includes mounting the laser source, scanning system, and control electronics onto the machine frame, as well as connecting the necessary cables and power supply.

5. Software Development: The control software for the machine is developed to provide an easy-to-use interface for users to create and edit marking designs, control the laser parameters, and monitor the machine’s performance.

6. Testing and Quality Control: After assembly, the fiber laser marking machine undergoes rigorous testing to ensure its performance, accuracy, and safety. This includes testing the laser output power, marking speed, and overall system stability.

7. Packaging and Shipping: Once the machine passes all quality control checks, it is carefully packaged and shipped to customers worldwide.

In conclusion, the manufacturing process of a fiber laser marking machine involves a combination of precise engineering, high-quality components, and strict quality control measures to produce a reliable and efficient marking solution for various industries.

Custom Manufacturing Options for fiber laser marking machine manufacturer

Fiber laser marking machines are widely used in various industries for marking, engraving, and cutting purposes. As a fiber laser marking machine manufacturer, there are several custom manufacturing options available to cater to the diverse needs of clients. These options allow businesses to choose the most suitable machine for their specific requirements, ensuring efficiency and productivity.

1. Power Options: Fiber laser marking machines come with different power options, ranging from 20W to 100W or more. Depending on the material and depth of marking required, clients can choose the appropriate power option for their needs.

2. Working Area: The working area of the fiber laser marking machine can be customized according to the size of the materials being marked. This ensures that the machine can accommodate various sizes of materials, from small components to large industrial parts.

3. Software Integration: Custom software integration allows clients to use their preferred software for designing and controlling the marking process. This ensures seamless integration with existing systems and processes, reducing the learning curve for operators.

4. Automation: Fiber laser marking machines can be integrated with automated systems, such as conveyors or robotic arms, to streamline the marking process and increase productivity. This is particularly useful for high-volume production environments.

5. Accessories: Additional accessories, such as rotary devices, can be added to the fiber laser marking machine to enable marking on curved surfaces or cylindrical objects. This expands the range of materials and products that can be marked using the machine.

6. Custom Enclosures: Enclosures can be customized to meet specific safety and environmental requirements, such as noise reduction, dust protection, or temperature control. This ensures that the fiber laser marking machine operates safely and efficiently in various working environments.

7. Training and Support: Customized training and support packages can be provided to ensure that operators are well-equipped to use the fiber laser marking machine effectively. This includes on-site training, remote support, and access to online resources.

In conclusion, custom manufacturing options for fiber laser marking machine manufacturers allow clients to tailor the machines to their specific needs, ensuring optimal performance and productivity. By offering a range of power options, working areas, software integration, automation, accessories, enclosures, and training and support, manufacturers can cater to the diverse requirements of various industries and applications.

Quality Control in fiber laser marking machine manufacturer

Quality control is a crucial aspect in the manufacturing process of fiber laser marking machines. It ensures that the final product meets the required standards and specifications, providing customers with reliable and efficient equipment. Manufacturers must implement strict quality control measures at every stage of production to guarantee the performance, durability, and safety of their fiber laser marking machines.

1. Raw material inspection: The quality control process begins with the inspection of raw materials, such as metal sheets, laser sources, and electronic components. Suppliers must provide certification and test reports to ensure that the materials meet the required standards. Additionally, manufacturers should conduct random sampling and testing of the raw materials to verify their quality.

2. In-process inspection: During the production process, quality control teams should monitor and inspect the assembly and manufacturing of the fiber laser marking machines. This includes checking the accuracy of the laser source, the alignment of optical components, and the proper functioning of the control system. Any deviations from the set standards should be corrected immediately to prevent defects in the final product.

3. Finished product testing: Once the fiber laser marking machines are assembled, they must undergo rigorous testing to ensure their performance, accuracy, and stability. This includes testing the marking speed, precision, and repeatability of the machine, as well as verifying the compatibility of the software with various file formats and operating systems. The machines should also be tested under different environmental conditions to ensure their durability and reliability.

4. Quality documentation: Manufacturers should maintain detailed records of their quality control processes, including raw material certifications, inspection reports, and test results. This documentation helps to identify any potential issues and allows for continuous improvement in the manufacturing process.

5. Training and certification: To maintain high-quality standards, manufacturers should invest in the training and certification of their employees. This ensures that the production team is knowledgeable about the latest industry standards and best practices, enabling them to produce high-quality fiber laser marking machines consistently.

In conclusion, quality control is an essential aspect of fiber laser marking machine manufacturing. By implementing strict quality control measures at every stage of production, manufacturers can ensure that their products meet the required standards and provide customers with reliable, efficient, and durable equipment.

Import and Export Regulations for fiber laser marking machine manufacturer

Fiber laser marking machines are widely used in various industries for engraving, etching, and marking purposes. As a manufacturer of these machines, it is essential to be aware of the import and export regulations that govern the international trade of such equipment. These regulations vary from country to country and are subject to change. However, some general guidelines can be followed to ensure compliance with the relevant laws and regulations.

1. Compliance with technical standards: Fiber laser marking machines must meet the technical standards and safety requirements of the importing country. This may include certifications such as CE marking for European countries, UL listing for the United States, or other relevant standards. Manufacturers should ensure that their products comply with these standards and maintain proper documentation to prove compliance.

2. Export controls: Some countries may impose export controls on fiber laser marking machines due to their potential use in military or nuclear applications. Manufacturers should be aware of any export restrictions or licensing requirements in their home country and the destination country. This may involve obtaining an export license or submitting a declaration to the relevant authorities.

3. Customs classification: Fiber laser marking machines must be classified under the appropriate Harmonized System (HS) code for customs purposes. This code is used to determine the applicable import duties and taxes. Manufacturers should ensure that their products are correctly classified and provide accurate documentation to facilitate smooth customs clearance.

4. Import duties and taxes: Importing countries may impose duties and taxes on fiber laser marking machines, which can vary depending on the country and the specific product. Manufacturers should be aware of these costs and factor them into their pricing strategy. It is also essential to provide accurate documentation to ensure that the correct duties and taxes are applied.

5. Intellectual property rights: Manufacturers should ensure that their fiber laser marking machines do not infringe on any patents, trademarks, or other intellectual property rights in the importing country. This may involve conducting a thorough search of existing patents and trademarks and obtaining any necessary licenses or permissions.

6. Packaging and labeling: Fiber laser marking machines should be packaged and labeled according to the requirements of the importing country. This may include specific labeling requirements, such as language, warnings, or symbols, and packaging materials that meet safety and environmental standards.

In conclusion, manufacturers of fiber laser marking machines must be aware of and comply with the import and export regulations in their home country and the destination country. This involves ensuring technical compliance, obtaining necessary licenses and permissions, providing accurate documentation, and adhering to packaging and labeling requirements. By doing so, manufacturers can facilitate smooth international trade and avoid potential legal issues.

The Role of Agents and Sourcing Companies in Facilitating Purchases from fiber laser marking machine manufacturer

Agents and sourcing companies play a crucial role in facilitating purchases from fiber laser marking machine manufacturers. These intermediaries bridge the gap between buyers and manufacturers, ensuring a smooth and efficient procurement process. In this article, we will discuss the key functions of agents and sourcing companies in the purchasing process of fiber laser marking machines.

1. Identifying reliable manufacturers: Agents and sourcing companies have extensive knowledge of the market and can help buyers identify reliable and reputable fiber laser marking machine manufacturers. They conduct thorough research and background checks to ensure that the chosen manufacturer meets the buyer’s quality standards and requirements.

2. Negotiating prices and terms: Agents and sourcing companies have strong negotiation skills and can help buyers secure the best possible prices and terms for their purchases. They leverage their industry knowledge and relationships with manufacturers to negotiate favorable deals on behalf of the buyer.

3. Quality control and inspection: Agents and sourcing companies ensure that the fiber laser marking machines meet the buyer’s specifications and quality standards. They conduct on-site inspections and supervise the production process to ensure that the machines are manufactured according to the agreed-upon standards.

4. Logistics and shipping: Agents and sourcing companies coordinate the logistics and shipping process, ensuring that the fiber laser marking machines are delivered to the buyer on time and in good condition. They handle customs clearance, documentation, and transportation, making the entire process hassle-free for the buyer.

5. After-sales support: Agents and sourcing companies provide after-sales support to buyers, addressing any issues or concerns that may arise after the purchase. They act as a liaison between the buyer and the manufacturer, ensuring that any problems are resolved quickly and efficiently.

In conclusion, agents and sourcing companies play a vital role in facilitating purchases from fiber laser marking machine manufacturers. They help buyers navigate the complex procurement process, ensuring that they receive high-quality machines at competitive prices. By leveraging their industry expertise and relationships, agents and sourcing companies provide invaluable support to buyers throughout the entire purchasing process.

Supply Chain Management for fiber laser marking machine manufacturer

Supply Chain Management (SCM) is a crucial aspect for any manufacturing company, including a fiber laser marking machine manufacturer. It involves the efficient management of all processes, from sourcing raw materials to delivering the final product to the customer. In this highly competitive market, effective SCM can lead to reduced costs, improved product quality, and increased customer satisfaction.

The first step in SCM for a fiber laser marking machine manufacturer is to identify and select reliable suppliers for raw materials, such as metals, electronic components, and fiber lasers. This involves evaluating potential suppliers based on factors like cost, quality, delivery time, and their ability to meet the manufacturer’s specific requirements. Building strong relationships with suppliers can help ensure a steady supply of high-quality materials and reduce the risk of delays or disruptions in the supply chain.

Next, the manufacturer needs to optimize its production processes to minimize waste, reduce lead times, and improve overall efficiency. This can be achieved through lean manufacturing techniques, such as just-in-time (JIT) production, which involves producing goods only when they are needed, reducing inventory costs and waste. Additionally, implementing advanced manufacturing technologies, such as automation and robotics, can further enhance productivity and reduce human error.

Quality control is another essential aspect of SCM. The manufacturer must establish strict quality control procedures to ensure that the fiber laser marking machines meet the required specifications and perform reliably. This may involve regular inspections, testing, and monitoring of production processes to identify and address any potential issues before they become significant problems.

Once the fiber laser marking machines are produced, the manufacturer must manage the logistics of delivering the products to customers. This involves coordinating with transportation providers, warehouses, and distributors to ensure timely and cost-effective delivery. The manufacturer should also establish a responsive customer service system to address any issues or concerns that may arise during the delivery process.

Lastly, effective SCM requires continuous monitoring and improvement. The manufacturer should regularly review its supply chain processes, identify areas for improvement, and implement necessary changes to stay competitive in the market. This may involve adopting new technologies, reevaluating supplier relationships, or streamlining production processes.

In conclusion, effective supply chain management is essential for a fiber laser marking machine manufacturer to remain competitive and ensure customer satisfaction. By optimizing supplier relationships, production processes, quality control, logistics, and continuous improvement, the manufacturer can reduce costs, improve product quality, and ultimately, deliver a superior product to its customers.

Negotiating with fiber laser marking machine manufacturer

Subject: Fiber Laser Marking Machine Inquiry and Negotiation

Dear [Manufacturer’s Name],

I hope this email finds you well. I am writing to inquire about your fiber laser marking machines, specifically the [model name/number]. Our company, [Your Company Name], is currently in the market for a high-quality and reliable machine to cater to our growing production needs.

After conducting thorough research, we have identified your company as a potential supplier due to your reputation for producing high-quality machines and providing excellent customer service. However, before we proceed with any potential collaboration, we would like to discuss a few points to ensure that your product meets our requirements and budget constraints.

1. Pricing: We understand that the listed price for the [model name/number] is [listed price]. However, considering our intention to establish a long-term business relationship with your company, we kindly request a more competitive price. We believe that a mutually beneficial agreement can be reached, and we are open to discussing volume discounts or other incentives that may be applicable.

2. Customization: Our production process requires specific features and capabilities that may not be available in the standard [model name/number]. We would appreciate it if you could provide information on the possibility of customizing the machine to meet our requirements, as well as any additional costs associated with such modifications.

3. Warranty and After-sales Support: We value reliable after-sales support and a comprehensive warranty for our investments. Please provide detailed information on the warranty terms and conditions for the [model name/number], as well as the availability of spare parts and technical support in our region.

4. Lead Time and Shipping: Kindly provide an estimated lead time for the production and delivery of the [model name/number] to our facility, located at [Your Company Address]. Additionally, please include any shipping costs and the preferred method of shipment.

We appreciate your prompt attention to our inquiry and look forward to your response. Should you have any questions or require further clarification, please do not hesitate to contact us. We are eager to establish a fruitful partnership with your esteemed company and believe that your fiber laser marking machines will significantly enhance our production capabilities.

Thank you for your time and consideration.

Best regards,

[Your Name] [Your Title] [Your Company Name] [Your Email Address] [Your Phone Number]Protecting Intellectual Property When Working with fiber laser marking machine manufacturer

Protecting intellectual property (IP) is crucial when working with a fiber laser marking machine manufacturer, as it ensures that your unique ideas, designs, and innovations are not misused or copied by others. Here are some steps you can take to safeguard your IP:

1. Non-Disclosure Agreement (NDA): Before sharing any sensitive information with the manufacturer, sign a non-disclosure agreement (NDA) to legally bind them to maintain confidentiality. The NDA should clearly outline the information to be protected, the obligations of the manufacturer, and the consequences of any breach.

2. Intellectual Property Rights Agreement: In addition to an NDA, establish an intellectual property rights agreement that explicitly states the ownership of any IP created during the collaboration. This agreement should cover patents, copyrights, trademarks, and any other relevant IP rights.

3. Limit Information Sharing: Share only the necessary information with the manufacturer, and avoid disclosing any trade secrets or confidential data that is not directly related to the project. This minimizes the risk of unauthorized use or disclosure of your IP.

4. Conduct Due Diligence: Research the manufacturer’s reputation and track record in the industry. Look for any history of IP infringement or legal disputes, and consider working with a manufacturer that has a strong commitment to IP protection.

5. Monitor Manufacturing Process: Maintain oversight of the manufacturing process to ensure that your IP is not being misused or copied. Regularly inspect the production facilities and request updates on the progress of your project.

6. Register Your IP: Register your intellectual property rights, such as patents, trademarks, and copyrights, in the relevant jurisdictions. This provides legal protection and makes it easier to enforce your rights in case of infringement.

7. Seek Legal Advice: Consult with an IP attorney to ensure that your agreements and registrations are comprehensive and enforceable. They can also help you navigate any legal disputes that may arise during the collaboration.

By taking these precautions, you can protect your intellectual property when working with a fiber laser marking machine manufacturer and ensure that your innovations remain secure.

Avoiding Scams When Working with fiber laser marking machine manufacturer

When working with a fiber laser marking machine manufacturer, it is essential to take precautions to avoid scams and ensure a smooth business transaction. Here are some tips to help you avoid scams when dealing with manufacturers:

1. Research the manufacturer: Before engaging with a manufacturer, conduct thorough research on their background, reputation, and credibility. Look for reviews, testimonials, and case studies from previous clients. Check their website and social media presence to ensure they are a legitimate and well-established company.

2. Verify their business registration: Make sure the manufacturer is a registered business entity in their country. You can usually find this information on their website or by contacting the local business registration authority. This will help you confirm that they are a legitimate company and not a fly-by-night operation.

3. Request references: Ask the manufacturer for references from previous clients. Contact these clients to inquire about their experience working with the manufacturer, the quality of the products they received, and any issues they encountered during the process.

4. Inspect the manufacturing facility: If possible, visit the manufacturing facility in person to assess the quality of their equipment, production processes, and overall working conditions. This will give you a better understanding of their capabilities and help you determine if they are a reliable partner.

5. Obtain detailed quotes: Request detailed quotes from the manufacturer, including itemized costs for materials, labor, and shipping. This will help you compare prices and ensure there are no hidden fees or charges.

6. Use secure payment methods: Avoid making payments through unsecured channels or using unfamiliar payment methods. Stick to well-known payment platforms and consider using an escrow service to protect your funds until you receive the finished product.

7. Establish clear communication channels: Ensure that you have open and transparent communication with the manufacturer throughout the entire process. This includes discussing project specifications, timelines, and any potential issues that may arise.

8. Create a contract: Draft a comprehensive contract outlining the terms and conditions of your agreement with the manufacturer. This should include payment terms, delivery schedules, quality control measures, and any warranties or guarantees.

9. Monitor the production process: Stay involved in the production process by requesting regular updates and progress reports from the manufacturer. This will help you identify any potential issues early on and ensure that the final product meets your expectations.

10. Inspect the final product: Before accepting delivery of the finished product, conduct a thorough inspection to ensure it meets your specifications and quality standards. If any issues are identified, work with the manufacturer to resolve them before finalizing the transaction.

By following these tips, you can minimize the risk of scams and ensure a successful partnership with a fiber laser marking machine manufacturer.

How to use import and export data website importyeti.com to search the company and fiber laser marking machine manufacturer

ImportYeti is a powerful tool that allows users to search and analyze import and export data of various companies. To search for a company and fiber laser marking machine manufacturer, follow these simple steps:

1. Visit importyeti.com: Open your web browser and go to the ImportYeti website at www.importyeti.com.

2. Use the search bar: On the homepage, you will find a search bar at the top. Type in the name of the company or the product (fiber laser marking machine) you are looking for and hit ‘Enter’ or click the search icon.

3. Filter the search results: After the search is complete, you will be presented with a list of companies related to your search query. You can further refine your search by using the filters available on the left side of the page. These filters include country, HS code, and date range.

4. Analyze the company data: Once you have found the company or manufacturer you are looking for, click on their name to access their import/export data. This data includes information such as the company’s trading partners, products, shipment details, and more.

5. Export the data: If you wish to save the data for further analysis or reporting, ImportYeti allows you to export the data in CSV format. Click on the ‘Export’ button located at the top right corner of the page and choose the desired format.

6. Create an account for additional features: While ImportYeti offers a wealth of information for free, creating an account provides access to additional features such as tracking specific companies, receiving email alerts, and more.

By following these steps, you can efficiently use ImportYeti to search for a company and fiber laser marking machine manufacturer. With its extensive database and user-friendly interface, ImportYeti makes it easy to analyze import and export data for various companies and products.

How to use Chinese Business Search Platform: qcc.com to check fiber laser marking machine manufacturer company credit

1. Visit the QCC website: Open your web browser and go to the QCC (企查查) website at www.qcc.com. The website is in Chinese, so you may need to use a translation tool like Google Translate to navigate the site if you are not familiar with the Chinese language.

2. Register for an account: To access the full features of the website, you need to create an account. Click on the “注册” (Register) button at the top right corner of the homepage and fill in the required information. After registering, log in to your account.

3. Search for the company: In the search bar on the homepage, type the name of the fiber laser marking machine manufacturer you want to check. You can also search using the company’s registration number or legal representative’s name. Click the search icon or press Enter to start the search.

4. Review the search results: The search results will display a list of companies matching your search query. Locate the company you are looking for and click on its name to access the company’s profile page.

5. Check the company’s credit information: On the company’s profile page, you can find various information about the company, including its registration status, legal representative, registered capital, establishment date, and more. Pay attention to the following sections to assess the company’s credit:

a. Basic Information (基本信息): Check the company’s registration status, registered capital, and establishment date to get an idea of its size and stability.

b. Credit Information (信用信息): This section includes the company’s credit rating, risk assessment, and any records of legal disputes or penalties.

c. Business Operations (经营状况): Review the company’s business scope, main products, and recent revenue to understand its market position and financial performance.

d. Shareholders and Investment (股东投资): Analyze the company’s shareholders and their investments to evaluate the company’s financial backing and stability.

e. Intellectual Property (知识产权): Check the company’s patents, trademarks, and copyrights to assess its innovation capabilities and competitiveness in the market.

6. Verify the information: To ensure the accuracy of the information you have gathered, you can cross-check it with other sources, such as the company’s official website, industry reports, or third-party credit rating agencies.

By following these steps, you can effectively use the QCC platform to check the credit of a fiber laser marking machine manufacturer in China, helping you make informed decisions when selecting a business partner.

How to use archive.org to check fiber laser marking machine manufacturer business website history

Archive.org, also known as the Wayback Machine, is a digital archive of the World Wide Web that allows users to view the history of websites. To check the history of a fiber laser marking machine manufacturer’s business website, follow these steps:

1. Visit the Wayback Machine website at https://archive.org/web/.

2. In the search bar at the top of the page, enter the URL of the manufacturer’s website. For example, if the website is “www.examplefiberlaser.com,” type this address into the search bar.

3. Press “Enter” or click the “Browse History” button to begin the search.

4. The Wayback Machine will display a calendar view of the website’s history, with blue or green circles indicating dates when the website was archived. The more circles you see, the more frequently the website was archived.

5. Click on a circle to view the website’s content on that specific date. This will open a new window or tab displaying the website as it appeared on the selected date.

6. Browse through the website’s content to gather information about the manufacturer’s history, product offerings, and any changes they have made over time. Pay attention to any updates in their product line, company news, or customer testimonials.

7. To compare different versions of the website, open multiple dates in separate tabs or windows. This will allow you to easily switch between different points in the website’s history and identify any significant changes.

8. Take note of any red flags, such as a sudden change in the company’s name, address, or contact information, which could indicate a change in ownership or potential issues with the manufacturer.

9. If you want to save a specific version of the website for future reference, click the “Save Page Now” button at the bottom of the page. This will create a new archive of the website’s current state, which you can access later by searching for the URL again.

By using the Wayback Machine, you can gain valuable insights into a fiber laser marking machine manufacturer’s business history and make a more informed decision when choosing a supplier for your needs.

Why contact sourcifyChina.com get free quota from reliable fiber laser marking machine manufacturer?

Contacting SourcifyChina.com to get a free quote from a reliable fiber laser marking machine manufacturer is a smart decision for several reasons.

Firstly, SourcifyChina.com is a trusted platform that specializes in connecting businesses with reliable and cost-effective manufacturers in China. By reaching out to them, you can save time and effort in searching for the right manufacturer on your own. They have a vast network of suppliers and can easily find a suitable fiber laser marking machine manufacturer that meets your requirements.

Secondly, getting a free quote allows you to compare prices and make an informed decision. This helps you to ensure that you are getting the best value for your money. By receiving a free quote, you can evaluate the cost of the fiber laser marking machine and determine if it fits within your budget. This also helps you to negotiate better deals and save on costs.

Thirdly, working with a reliable manufacturer ensures that you receive a high-quality fiber laser marking machine. SourcifyChina.com only works with reputable manufacturers who have a proven track record of delivering quality products. This means that you can trust that the fiber laser marking machine you receive will be of top-notch quality and will meet your expectations.

Moreover, partnering with a reliable manufacturer also ensures timely delivery of your fiber laser marking machine. This is crucial for businesses that need to meet tight deadlines and cannot afford delays in their production process. By working with a trusted manufacturer, you can be confident that your fiber laser marking machine will be delivered on time and in perfect condition.

Lastly, SourcifyChina.com offers excellent customer support throughout the entire process. From helping you find the right manufacturer to providing assistance with shipping and logistics, their team is there to ensure that your experience is smooth and hassle-free.

In conclusion, contacting SourcifyChina.com to get a free quote from a reliable fiber laser marking machine manufacturer is a wise decision that can save you time, money, and ensure that you receive a high-quality product. Their expertise, vast network of suppliers, and commitment to customer satisfaction make them an ideal partner for your business needs.

Related products

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

©2023. sourcifychina.com All Rights Reserved.

-

- Home

- Suppliers Search

- Cheap Retail Shop

- Wholesale Pro

- Industries

- List

- Our China Suppliers list

- Auto Parts Suppliers

- Packaging Solution

- Stainless Steel Suppliers

- Steel Pipe Suppliers

- Solar Inverter China

- cable manufacturing

- cnc machining China

- Apparel and Accessories

- fabric manufacturing

- Machinery

- pump China

- Screw

- wigs custom

- valves manufacturing

- hair system custom

- heated gloves wholesale

- indoor lighting fixtures

- solor panel wholesale

- snow boots factory

- Products

- Manufacturing

- Guide

- Thermoforming Machines

- Fasteners

- Machinery Industry

- Led Lights Companies

- Valves

- Pumps

- Custom Perfume Bottle

- Electric Scooter

- Custom Sheet Metal

- Metal Fabrication

- Wire Cable

- Furniture

- Auto Parts Industry

- Snow Boots

- Battery Welding Machines

- Top Companies

- Apparel / Fashion Accessories

- caps manufacturing

- Denim Manufacturing Company Guide: Sourcing,Types, Applications, Benefits, Process, Price

- fabric manufacturing

- face masks supplier

- hoodies manufacturer

- knitwear manufacturing

- perfume bottle custom

- Ultimate Guide about Sportswear Manufacturing: Types, Applications,Sourcing,Process and More

- T-shirt Manufacturing Companies Guide: Sourcing,Types, Applications, Benefits, Process, Price

- wigs custom

- CNC Tools Valve Pump Parts

- Machinery China Equiment Sourcing Guide

- aac block manufacturers

- acrylic cutting machine

- automatic packing machine

- Auxiliary Equipment Guide: how to Use, Sourcing, Types, Applications, Benefits, Process

- blister packing machine

- bricks manufacturing

- clay brick making machine

- feed pellet machine

- fly ash bricks machine sourcing guide

- paper bag making machine

- pellet machine

- plastic crusher machine

- pouchpacking machine

- stamping machine

- wood pellet machine

- Outdoor Sports

- Others Sourcing Guide

- FAQ

- About

- Contact

- Login

- Newsletter

- [email protected] whatsapp 8615951276160

- 供应商

Login

- →

- WeChat: 8615951276160