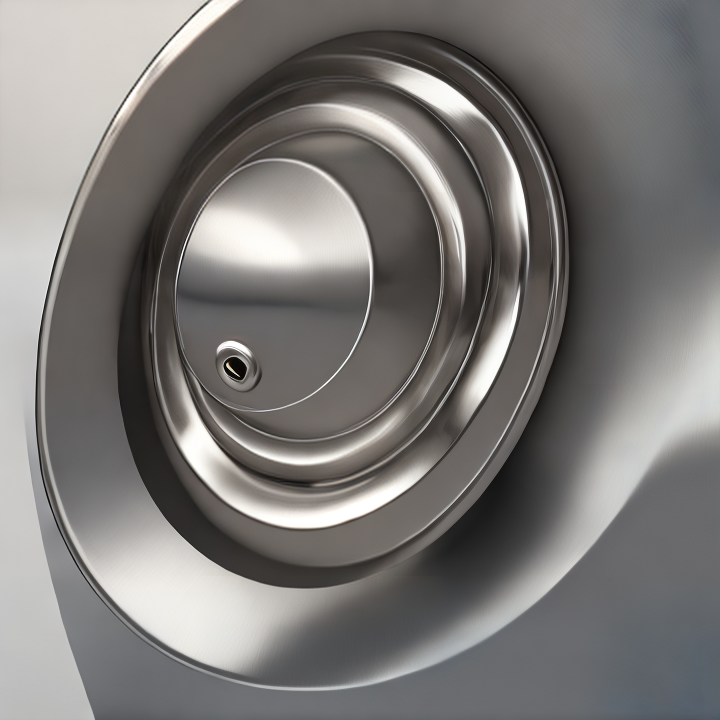

Linished Stainless Steel

Product Description: Linished Stainless Steel is a specially treated steel material that offers a flawless, smooth finish that is ideal for a wide range of applications. The linishing process involves grinding and polishing the surface of stainless steel to create a uniform, consistent finish that looks great and is incredibly durable.

Benefits: Linished stainless steel is incredibly strong and durable, making it a great choice for a wide range of applications. It is resistant to corrosion, heat and wear, making it ideal for use in harsh environments. It is also easy to clean and maintain, which makes it the perfect material for applications where hygiene is important.

Features: Linished Stainless Steel has a beautifully smooth finish that is achieved through the linishing process. This creates a uniform and consistent look, making it perfect for use in interior and exterior design, decorative fixtures, and tools. Linished stainless steel is also scratch and stain-resistant, making it ideal for use in high traffic areas where wear and tear is common.

Specifications: Linished Stainless Steel is available in various grades and finishes to suit your specific needs. The thickness and width of the material can be customized to meet your requirements. Our linished stainless steel is manufactured to the highest quality standards, ensuring that it meets all industry standards.

Applications: Linished Stainless Steel is used in a wide range of applications, including architecture and interior design, automotive parts, food processing equipment, and medical equipment. It is also used in marine environments where saltwater exposure can cause corrosion. Linished Stainless Steel is often used in high traffic areas where durability is important such as commercial kitchens, hospitals, and public spaces.

FAQ:

Q: What is Linished Stainless Steel?

A: Linished Stainless Steel is a specially treated steel material that offers a flawless, smooth finish that is ideal for a wide range of applications.

Q: What are the benefits of using Linished Stainless Steel?

A: Linished stainless steel is incredibly strong and durable, making it a great choice for a wide range of applications. It is resistant to corrosion, heat, and wear, making it ideal for use in harsh environments.

Q: What applications is Linished Stainless Steel used for?

A: Linished Stainless Steel is used in a wide range of applications, including architecture and interior design, automotive parts, food processing equipment, and medical equipment. It is also used in marine environments where saltwater exposure can cause corrosion.

Q: Can you customize the thickness and width of the material?

A: Yes, the thickness and width of the material can be customized to meet your requirements.

Q: Is Linished Stainless Steel easy to maintain?

A: Yes, Linished Stainless Steel is incredibly easy to clean and maintain, making it the perfect material for applications where hygiene is important.

List Technical Parameters of “linished stainless steel”

Linished stainless steel is a smooth, polished finish that has been achieved through a mechanical process. This finish is commonly used in applications where a matte or brushed finish is unsuitable, and where a more polished aesthetic is desired. There are several technical parameters that are associated with this finish, and these include:

1. Surface roughness: The surface roughness of linished stainless steel is typically measured in micrometers (μm). The roughness of the finish will depend on the type of equipment and technique used during the linishing process. Typically, the roughness range for linished stainless steel is between 0.5 – 3 μm.

2. Surface finish: The surface finish of linished stainless steel is typically smooth and highly polished, which gives it a reflective appearance. This finish is achieved through a multi-stage mechanical process that uses abrasives to create a uniform surface texture.

3. Material thickness: Linished stainless steel can be produced in a range of thicknesses, depending on the application and the requirements of the project. Thicker materials may require a longer linishing process to achieve the desired finish.

4. Material grade: Linished stainless steel can be produced using a range of stainless steel grades, including austenitic, ferritic, and martensitic stainless steel. The grade of stainless steel selected will depend on the application and the specific properties required.

5. Tolerance: The tolerance of linished stainless steel will depend on the thickness of the material, the grade of stainless steel used, and the specific requirements of the project. Typically, the tolerance range for linished stainless steel is between +/- 0.2mm.

In conclusion, linished stainless steel is a popular finish that is used in a range of applications where a smooth, polished surface is desired. This finish is achieved through a mechanical process that creates a uniform surface texture, and can be produced using a range of stainless steel grades and thicknesses. The technical parameters associated with linished stainless steel include surface roughness, surface finish, material thickness, material grade, and tolerance.

List Product features of “linished stainless steel”

Linished stainless steel is a popular material for various products in different industries due to its many features. Some of the main features of linished stainless steel include:

1. Corrosion Resistance: One of the most important features of linished stainless steel is its high resistance to corrosion. This material is durable and able to withstand harsh environments, making it ideal for outdoor products such as railings, bridges, and other infrastructure.

2. Easy to Clean: Another great feature of linished stainless steel is that it is easy to clean. It does not require special cleaning agents or materials, and can be cleaned with a simple soap and water solution. This makes it ideal for use in areas where cleanliness is important, such as in food processing plants.

3. Aesthetically Pleasing: Linsihed stainless steel has a clean, modern look that is aesthetically pleasing. It is often used in architectural designs, home decor, and industrial design to create a sleek and polished look.

4. High Strength: Linsihed stainless steel has a high strength to weight ratio, meaning it is strong and durable while still being lightweight. It can be used for products that require both strength and ease of use.

5. Heat Resistant: Linsihed stainless steel is also heat resistant, making it ideal for use in high-temperature environments, such as in the automotive and aerospace industries.

6. Versatile: Linsihed stainless steel is highly versatile and can be used for a wide range of products, from kitchen equipment to medical instruments.

7. Low Maintenance: Linsihed stainless steel requires very little maintenance, making it cost-effective for businesses that use it in large quantities.

In summary, linished stainless steel is a versatile and durable material that offers many benefits, including high strength, corrosion resistance, ease of cleaning, and a modern aesthetic. Its many features make it a popular choice for various products across different industries.

List Application of “linished stainless steel”

Linished stainless steel, also known as brushed stainless steel, is a popular choice for many applications due to its aesthetic appeal and durability. Here are some of the various applications of linished stainless steel:

1. Architecture: Linished stainless steel is a common choice for exterior and interior architectural elements, such as facades, cladding, ventilation covers, handrails, and pillars. The brushed finish allows for a sleek look, and the material’s corrosion-resistant properties make it ideal for harsh environments.

2. Kitchen appliances: Stainless steel is a popular material for kitchen appliances because of its durability and easy-to-clean surface. Linished stainless steel is commonly used for appliances such as refrigerators, dishwashers, cooktops, and range hoods.

3. Automotive industry: Due to its corrosion resistance and durability, linished stainless steel is used to manufacture automotive parts such as bumpers, exhaust pipes, and trim pieces.

4. Medical equipment: Stainless steel is a common material for medical equipment due to its ability to maintain a sterile surface with regular cleaning. Linished stainless steel is often used for medical equipment such as surgical instruments and hospital trolleys.

5. Pharmaceuticals: Linished stainless steel is also used in the pharmaceutical industry for the manufacturing of cleanrooms, equipment, and cabinets. The material’s corrosion resistance, easy-to-clean surface, and durability make it ideal for this industry.

6. Marine industry: Due to its corrosion resistance, linished stainless steel is commonly used in the construction of boats, ships, and other marine vessels. Additionally, it is used for marine equipment such as bulkheads, hatch covers, and handrails.

Overall, linished stainless steel is a versatile material that can be used for various applications due to its aesthetic appeal, durability, and corrosion resistance.

List Various Types of “linished stainless steel”

Linished stainless steel is a highly versatile material that has many applications across a wide range of industries. This material can be used to create a variety of different products, each with its unique properties and characteristics. Below are some of the most common types of linished stainless steel and their uses:

1. Standard linished stainless steel – This type of linished stainless steel is the most commonly used and is ideal for a variety of different applications. It is available in a range of thicknesses and is often used for cladding, furniture, and architectural installations.

2. Mirror polished linished stainless steel – This type of linished stainless steel is highly polished to create a mirror-like finish. It is often used in architectural applications where the appearance of a surface is important, such as in building facades or high-end interiors.

3. Satin polished linished stainless steel – This type of linished stainless steel has a low sheen and is often used in applications where a reflective finish is not desirable. It is commonly used in kitchens, bathrooms, and other domestic environments.

4. Brushed linished stainless steel – This type of linished stainless steel has a distinct brushed finish, created by polishing the material with a wire brush. It is often used in applications where a textured surface is required, such as in handrails, guardrails, and other architectural features.

5. Bead blasted linished stainless steel – This type of linished stainless steel has a uniform, matte finish created by blasting the material with fine glass beads. It is often used in rotor blades of a centrifuge, chemical equipment, food processing machinery and more.

6. Coloured linished stainless steel – This type of linished stainless steel is available in a range of colours and finishes. The surface is treated with various pigments or dyes, which are then sealed with a protective coating to prevent fading or peeling.

In conclusion, linished stainless steel is a versatile material that can be used in many different applications, from industrial machinery to high-end interiors. Its durability, resistance to corrosion and low maintenance make it a popular choice for many designers and manufacturers.

List The Evolution history of “linished stainless steel”

Linished stainless steel is a type of steel that has a polished finish and is widely used in the construction industry. Its evolution can be traced back to the late 19th century when stainless steel was first developed by Harry Brearley in Sheffield, England. It was initially used in the manufacturing of cutlery and surgical instruments.

In the 1920s and 1930s, the use of stainless steel expanded to include architectural applications. The first linished stainless steel finish was introduced in the 1930s. It involved using abrasives to polish stainless steel sheets to create a uniform finish. This finish was popular for its durability, corrosion resistance, and aesthetic appeal.

Over the years, the process of linishing stainless steel has evolved to include the use of different types of abrasives and equipment. Modern linishing techniques involve the use of electric or pneumatic sanders, belts, and polishing wheels. These tools enable faster and more precise polishing, resulting in a smoother and shinier finish.

In recent years, linished stainless steel has become increasingly popular in the design and architecture industries. It is commonly used in kitchen and bathroom fixtures, decorative panels, handrails, and balustrades. It is also used in the automotive and aerospace industries due to its high strength and corrosion resistance.

Overall, the evolution of linished stainless steel highlights the continued innovation and improvement in the manufacturing and processing of stainless steel. Its versatility and durability make it a popular choice for a wide range of applications, and its continued evolution is sure to bring even more innovative uses and applications in the future.

List The Process of “linished stainless steel”

Linished Stainless Steel is a finishing process that is commonly used in many different industries, including automotive, architecture, and food service. The process involves creating a uniform surface finish on the stainless steel by removing any surface imperfections, scratches, or marks. Here are the steps involved in the process of linishing stainless steel:

1. Surface Preparation: The first step involves preparing the surface of the stainless steel by cleaning it to remove any dirt or debris. This is essential to ensure a smooth and uniform finish.

2. Sanding: After surface preparation, the stainless steel is sanded using abrasive belts or pads of varying grits. This removes any scratches or marks on the surface, and it also creates a uniform finish.

3. Polishing: Once the stainless steel is sanded, it is then polished to remove any remaining scratches or marks. Polishing can be carried out using a polishing wheel or a polishing compound, depending on the desired finish.

4. Finishing: Finally, the stainless steel is finished by using a special linishing machine that creates a uniform grain pattern on the surface. This gives the stainless steel a consistent finish, and it also helps to hide any surface imperfections.

Overall, the process of linishing stainless steel involves several steps, and it requires skill and expertise to achieve a high-quality finish. However, the end result is a durable and attractive surface that is suitable for a wide range of applications.

How to use “linished stainless steel”

Linished stainless steel, also known as brushed stainless steel, is a popular material used in a variety of products such as appliances, furniture, and vehicles. It is known for its resistance to corrosion, durability, and aesthetic appeal. Here are some ways to use linished stainless steel:

1. Kitchen appliances: Linished stainless steel is often used for kitchen appliances such as refrigerators, ovens, and dishwashers. It is easy to clean and its brushed finish gives it a sleek and modern look.

2. Furniture: Linished stainless steel is used in furniture such as chairs, tables, and desks. Its durability and resistance to wear and tear make it an ideal material for these pieces. The brushed finish also gives a unique texture to the furniture.

3. Automotive industry: Linished stainless steel is used in the automotive industry for exterior and interior components such as body panels, trims, and dashboards. Its durability and resistance to corrosion make it a popular material for these applications.

4. Medical equipment: Linished stainless steel is also used in the medical industry for surgical instruments. Its non-reactive properties make it ideal for use in surgical equipment where it won’t interact with bodily fluids.

5. Architectural applications: Linished stainless steel is often used in architectural applications such as building facades, window frames, and handrails. The brushed finish gives a sophisticated look that is both modern and timeless.

In conclusion, linished stainless steel is a versatile material that can be used in various industries and products. Its durability, resistance to corrosion, and aesthetic appeal make it a popular choice for both functional and decorative items.

List Properties of “linished stainless steel”

Linished stainless steel is a type of finish that gives a smooth and polished appearance to stainless steel. This finish is achieved by using a fine abrasive material that is rubbed over the surface of the stainless steel, creating a uniform and consistent pattern. Linished stainless steel has several properties that make it a preferred choice for many applications.

Durability: One of the most significant properties of linished stainless steel is its durability. This material is highly resistant to corrosion and rust, making it suitable for use in harsh environments without the risk of deterioration. It can withstand exposure to chemicals, moisture, and extreme temperatures, making it an excellent choice for industrial, marine, and aerospace applications.

Hygienic: Another important property of linished stainless steel is its high level of hygiene. This material is non-porous and has a smooth surface, which makes it easy to clean and maintain. Linished stainless steel is often used in food processing plants, hospitals, and laboratories because it inhibits the growth of bacteria and other harmful microorganisms.

Aesthetics: Linished stainless steel has an attractive and modern look that makes it a popular choice for architectural and design applications. Its smooth surface creates a reflective effect that enhances the visual appeal of the material. It can be used for cladding, roofing, and interior design elements, such as elevator doors and wall panels.

Versatility: Linished stainless steel is a versatile material that can be easily fabricated to suit different requirements. It can be cut, welded, and shaped to fit specific dimensions, making it ideal for manufacturing complex components and structures. Its malleability allows it to be formed into different shapes and sizes without compromising its strength and durability.

Cost-effective: Despite its superior properties and high-quality finish, linished stainless steel is a cost-effective option compared to other high-end materials. It has a longer lifespan than most other materials, which reduces the need for frequent replacement and maintenance, resulting in lower overall costs in the long run.

Overall, linished stainless steel is a durable, hygienic, aesthetically pleasing, versatile, and cost-effective material that is widely used in various industries and applications.

List “linished stainless steel” FAQ

What is Linished Stainless Steel?

Linished stainless steel is a surface finish process that gives a brushed, polished appearance to stainless steel. It is commonly used in contemporary architecture and interior design, kitchen appliances, and automotive industry.

What is the process of linishing stainless steel?

The process of linishing stainless steel involves the use of abrasive belts or discs to remove any surface defects and correct any imperfections. A series of abrasive grits is used to refine the finish, starting with a coarse grit and working down to a fine grit. The result is a brushed finish that is uniform and consistent.

What are the Benefits of Linished Stainless Steel?

The benefits of linished stainless steel include its durability, resistance to corrosion, and aesthetic appeal. The brushed finish gives a modern, sleek appearance to stainless steel, making it a popular choice for many applications.

Where is Linished Stainless Steel Used?

Linished stainless steel is used in a variety of applications including architectural cladding, kitchen appliances, automotive trim, and medical equipment. It can also be used in furniture design, such as chairs and tables, to give them a modern and contemporary look.

How to Clean and Maintain Linished Stainless Steel?

Linished stainless steel requires minimal maintenance and can be easily cleaned with soap and warm water. To remove any stubborn stains or marks, a mild abrasive cleaner can be used. It is recommended to avoid using harsh chemicals or abrasive pads that can damage the finish.

What are the Common Grades of Stainless Steel used in Linishing?

The common grades of stainless steel used in linishing include 304 and 316. These grades offer high resistance to corrosion and can withstand exposure to harsh environments.

In Conclusion

Linished stainless steel is a popular surface finish for stainless steel that offers durability, a modern appearance, and resistance to corrosion. It is commonly used in architecture, interior design, automotive industry, and kitchen appliances. Maintaining and cleaning linished stainless steel is easy, and it requires minimal maintenance.

Related products

sign letters

sign letters

sign letters

sign letters

sign letters

sign letters

sign letters

sign letters

Useful Links & Infomation

©2023. sourcifychina.com All Rights Reserved.

-

- Home

- Cheap Retail Shop

- Wholesale Pro

- Industries

- China Suppliers

- Our China Suppliers list

- Auto Parts Suppliers

- Packaging Solution

- Stainless Steel Suppliers

- Steel Pipe Suppliers

- Solar Inverter China

- cable manufacturing

- cnc machining China

- Apparel and Accessories

- fabric manufacturing

- Machinery

- pump China

- Screw

- wigs custom

- valves manufacturing

- hair system custom

- heated gloves wholesale

- indoor lighting fixtures

- solor panel wholesale

- snow boots factory

- Products

- Sourcing Guide

- Manufacturing

- Apparel / Fashion Accessories

- caps manufacturing

- Denim Manufacturing Company Guide: Sourcing,Types, Applications, Benefits, Process, Price

- fabric manufacturing

- face masks supplier

- hoodies manufacturer

- knitwear manufacturing

- perfume bottle custom

- Ultimate Guide about Sportswear Manufacturing: Types, Applications,Sourcing,Process and More

- T-shirt Manufacturing Companies Guide: Sourcing,Types, Applications, Benefits, Process, Price

- wigs custom

- CNC Tools Valve Pump Parts

- Machinery China Equiment Sourcing Guide

- aac block manufacturers

- acrylic cutting machine

- automatic packing machine

- Auxiliary Equipment Guide: how to Use, Sourcing, Types, Applications, Benefits, Process

- blister packing machine

- bricks manufacturing

- clay brick making machine

- feed pellet machine

- fly ash bricks machine sourcing guide

- paper bag making machine

- pellet machine

- plastic crusher machine

- pouchpacking machine

- stamping machine

- wood pellet machine

- Outdoor Sports

- Others Sourcing Guide

- Apparel / Fashion Accessories

- FAQ

- About

- Contact

- Login

- Newsletter

- [email protected] whatsapp 8615951276160

- 供应商

Login

- →

- WeChat: 8615951276160