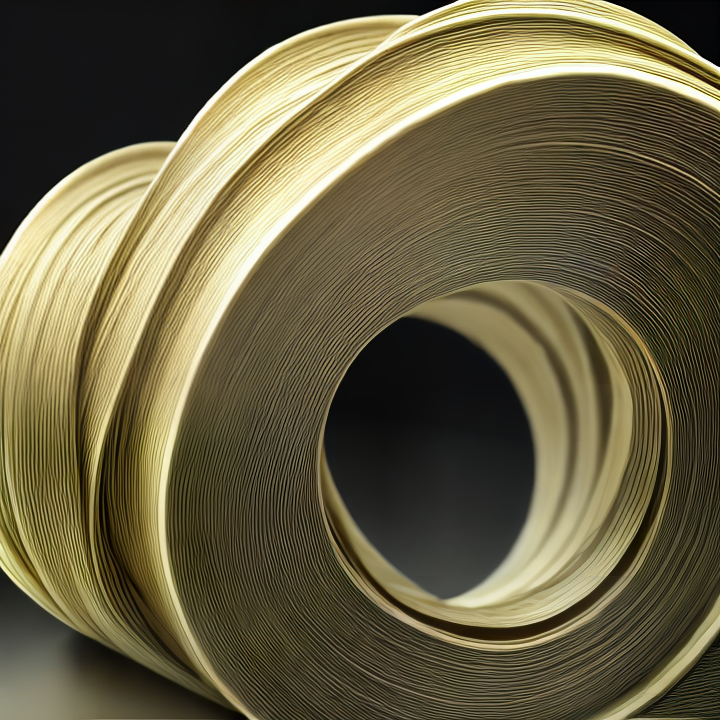

Spiral Wrapping Band Manufacturer

Benefits

The spiral wrapping band from our trusted manufacturer offers numerous benefits to users, including:

1. Organized cable management: The spiral wrapping band keeps your cables and wires neatly bundled, preventing tangling and ensuring a clutter-free environment.

2. Enhanced protection: The durable material of the spiral wrapping band provides excellent protection against abrasion, wear, and damage from external factors.

3. Easy installation: The flexible design of the spiral wrapping band allows for quick and easy installation, saving you time and effort.

4. Reusable: The spiral wrapping band can be easily removed and reused, making it an eco-friendly and cost-effective solution for cable management.

Features

Our spiral wrapping band boasts the following features:

1. High-quality material: Made from high-quality polyethylene (PE) or polyamide (PA), the spiral wrapping band is resistant to wear, tear, and chemicals.

2. Wide temperature range: The spiral wrapping band can withstand temperatures ranging from -40°C to +80°C, making it suitable for various environments.

3. Customizable: The spiral wrapping band is available in various sizes, colors, and lengths to cater to your specific requirements.

4. Flame retardant: The spiral wrapping band is flame retardant, ensuring safety in case of fire hazards.

Specifications

1. Material: Polyethylene (PE) or Polyamide (PA)

2. Temperature range: -40°C to +80°C

3. Color: Available in various colors

4. Length: Customizable

Applications

The spiral wrapping band is ideal for a wide range of applications, including:

1. Electrical wiring: Organize and protect electrical cables and wires in homes, offices, and industrial settings.

2. Automotive: Manage and protect automotive wiring harnesses and cables.

3. Telecommunications: Bundle and protect cables in telecommunication networks and data centers.

4. Marine: Secure and protect cables and wires in marine environments.

FAQ

1. Can the spiral wrapping band be cut to a specific length?

Yes, the spiral wrapping band can be easily cut to your desired length using a pair of scissors or a sharp knife.

2. Is the spiral wrapping band resistant to UV rays?

Yes, our spiral wrapping band is UV resistant, making it suitable for outdoor applications.

3. Can the spiral wrapping band be used in high-temperature environments?

Yes, the spiral wrapping band can withstand temperatures ranging from -40°C to +80°C, making it suitable for various environments.

4. Is the spiral wrapping band available in different colors?

Yes, the spiral wrapping band is available in various colors to cater to your specific requirements.

A Beginner’s Guide to spiral wrapping band manufacturer

A spiral wrapping band manufacturer is a company that specializes in producing spiral wrapping bands, which are flexible and versatile cable management solutions used to organize and protect wires, cables, and hoses in various industries and applications. These bands are made from durable materials like polyethylene or nylon and come in different sizes, colors, and lengths to cater to specific requirements. As a beginner, it is essential to understand the basics of spiral wrapping bands and the factors to consider when choosing a manufacturer.

1. Functionality: Spiral wrapping bands are designed to bundle and protect cables, wires, and hoses from abrasion, tangling, and damage. They are widely used in industries such as electronics, automotive, machinery, and telecommunications. The bands can be easily applied and removed, making them a convenient and reusable cable management solution.

2. Material: The most common materials used for spiral wrapping bands are polyethylene (PE) and nylon (PA). PE bands are lightweight, flexible, and resistant to chemicals and UV radiation, making them suitable for outdoor applications. Nylon bands offer higher tensile strength, temperature resistance, and durability, making them ideal for heavy-duty applications.

3. Size and Color: Spiral wrapping bands come in various sizes, ranging from small bands for delicate wires to large bands for heavy-duty cables and hoses. They are also available in different colors, allowing for easy identification and organization of cables.

4. Customization: Some manufacturers offer customized spiral wrapping bands, such as specific lengths, colors, or materials, to meet unique customer requirements.

5. Quality and Certification: It is crucial to choose a manufacturer that adheres to strict quality control standards and holds relevant certifications, such as ISO or RoHS compliance, ensuring that the products are safe, reliable, and environmentally friendly.

6. Pricing and Availability: Compare prices and availability of spiral wrapping bands from different manufacturers to find the best value for your needs.

In conclusion, understanding the basics of spiral wrapping bands and considering factors such as functionality, material, size, customization, quality, and pricing will help you choose the right manufacturer for your cable management needs.

How to Select a Reliable spiral wrapping band manufacturer

Selecting a reliable spiral wrapping band manufacturer is crucial for ensuring the quality and durability of the product. Here are some steps to help you choose the right manufacturer:

1. Research: Start by conducting thorough research on various spiral wrapping band manufacturers. Look for companies with a strong reputation in the market and a history of producing high-quality products. You can search online, read reviews, and ask for recommendations from industry peers.

2. Product Range: Choose a manufacturer that offers a wide range of spiral wrapping bands in different sizes, materials, and colors. This will ensure that you can find the perfect product for your specific application.

3. Quality Assurance: A reliable manufacturer should have strict quality control measures in place to ensure the production of high-quality spiral wrapping bands. Look for certifications such as ISO 9001, which indicates that the company follows internationally recognized quality management standards.

4. Customization Options: A good manufacturer should be able to customize their products according to your specific requirements. This includes custom sizes, colors, and materials. Make sure the manufacturer is willing to work with you to create a product that meets your needs.

5. Technical Support: Choose a manufacturer that offers excellent technical support. They should be able to provide you with detailed product information, installation guides, and troubleshooting assistance if needed.

6. Customer Service: A reliable manufacturer should have a dedicated customer service team that is knowledgeable, responsive, and helpful. Make sure they can be easily reached through phone, email, or live chat.

7. Pricing: Compare the prices of different manufacturers to ensure you are getting a competitive rate. However, do not compromise on quality for the sake of a lower price.

8. Lead Time: Check the manufacturer’s lead time for production and delivery. A reliable manufacturer should be able to meet your deadlines and deliver the products on time.

9. Samples: Request samples from the manufacturer to evaluate the quality of their spiral wrapping bands. This will give you a better idea of what to expect from the final product.

10. Warranty: A reliable manufacturer should offer a warranty on their products, which shows confidence in the quality and durability of their spiral wrapping bands.

By considering these factors, you can select a reliable spiral wrapping band manufacturer that will provide you with high-quality products and excellent customer service.

Comparing spiral wrapping band manufacturer and Suppliers: Which is Better?

When comparing spiral wrapping band manufacturers and suppliers, it is essential to consider various factors to determine which option is better for your specific needs. Both manufacturers and suppliers play a crucial role in the supply chain, but they serve different purposes and have their own advantages and disadvantages.

Manufacturers are the companies that produce the spiral wrapping bands. They have complete control over the production process, from raw materials to the finished product. This allows them to ensure high-quality standards and customize the product according to specific requirements. Additionally, manufacturers can offer competitive prices as they eliminate the need for a middleman.

On the other hand, suppliers are the companies that source and distribute the spiral wrapping bands from manufacturers to end-users. They have a wide range of products from different manufacturers, which allows them to offer a diverse selection to their customers. Suppliers also have established relationships with manufacturers, which can lead to better pricing and availability. Furthermore, suppliers often provide additional services such as customer support, technical assistance, and logistics management.

So, which is better? The answer depends on your specific needs and priorities. If you require a customized product with strict quality control, working directly with a manufacturer may be the better option. This will allow you to have more control over the production process and potentially lower costs.

However, if you prioritize a diverse product selection, convenience, and additional services, working with a supplier may be more suitable. Suppliers can offer a wide range of products from different manufacturers, making it easier for you to find the perfect spiral wrapping band for your needs. Additionally, suppliers can provide valuable support and assistance throughout the purchasing process.

In conclusion, both spiral wrapping band manufacturers and suppliers have their own advantages and disadvantages. The better option depends on your specific requirements, such as customization, quality control, product diversity, and additional services. By carefully considering these factors, you can make an informed decision and choose the best partner for your spiral wrapping band needs.

The Manufacturing Process of spiral wrapping band manufacturer

The manufacturing process of a spiral wrapping band involves several steps, including material selection, extrusion, cooling, cutting, and packaging. The process begins with the selection of the appropriate raw materials, typically polyethylene (PE) or polypropylene (PP), which offer excellent flexibility, durability, and chemical resistance.

1. Material selection: The raw materials are chosen based on the desired properties of the final product, such as flexibility, strength, and resistance to chemicals and UV radiation. PE and PP are commonly used due to their excellent performance and cost-effectiveness.

2. Extrusion: The raw materials are fed into an extruder, which melts and mixes them to form a homogeneous mixture. The extruder consists of a heated barrel with a rotating screw that pushes the molten material through a die, shaping it into a continuous profile with a specific cross-sectional shape. In the case of spiral wrapping bands, the die is designed to create a flat, thin strip with a tapered edge.

3. Cooling: The extruded profile exits the die and enters a cooling system, typically a water bath or air-cooling unit, which solidifies the material and maintains its shape. The cooling process is crucial for ensuring the dimensional stability and quality of the final product.

4. Cutting: Once the profile has cooled and solidified, it is cut into the desired length using a cutting machine. The cutting process can be automated or manual, depending on the production volume and specific requirements of the manufacturer.

5. Spiral winding: The flat strip is then wound into a spiral shape using a winding machine, which wraps the material around a rotating mandrel or core. The tapered edge of the strip allows it to overlap and interlock with the adjacent layer, forming a secure and flexible wrapping band.

6. Packaging: The finished spiral wrapping bands are inspected for quality and packaged for shipment to customers. The packaging process may involve coiling the bands into rolls, bundling them with straps or shrink wrap, or placing them in boxes or bags, depending on the customer’s requirements.

In summary, the manufacturing process of spiral wrapping bands involves material selection, extrusion, cooling, cutting, spiral winding, and packaging. The use of high-quality raw materials and advanced extrusion technology ensures the production of durable and flexible wrapping bands suitable for various applications.

Custom Manufacturing Options for spiral wrapping band manufacturer

Custom manufacturing options for spiral wrapping band manufacturers provide clients with tailored solutions to meet their specific requirements. These options enable manufacturers to produce spiral wrapping bands in various sizes, materials, colors, and other specifications to suit the needs of different industries and applications. Some of the key custom manufacturing options available for spiral wrapping band manufacturers include:

1. Material Selection: Spiral wrapping bands can be made from various materials, such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), or nylon (PA). Clients can choose the material that best suits their application requirements, such as temperature resistance, chemical resistance, and flexibility.

2. Size Customization: Manufacturers can produce spiral wrapping bands in different sizes, including diameter, width, and thickness, to accommodate various cable and wire bundles. This allows clients to select the most suitable size for their specific needs.

3. Color Options: Spiral wrapping bands can be manufactured in a wide range of colors, allowing clients to choose a color that matches their branding or helps with identification and organization. Custom colors can also be produced upon request.

4. UV Resistance: For outdoor applications, manufacturers can offer UV-resistant spiral wrapping bands that can withstand exposure to sunlight and prevent degradation over time.

5. Flame Retardancy: In industries where fire safety is a concern, manufacturers can produce flame-retardant spiral wrapping bands that comply with relevant safety standards.

6. Printing and Labeling: Custom printing and labeling options can be provided to help clients with identification, branding, or other specific requirements. This can include company logos, part numbers, or other relevant information.

7. Packaging Options: Manufacturers can offer various packaging options, such as bulk packaging, individual packaging, or custom packaging, to meet the client’s needs and preferences.

8. Certifications and Compliance: Custom manufacturing options can also include meeting specific industry certifications and compliance requirements, such as RoHS, REACH, or UL standards.

By offering these custom manufacturing options, spiral wrapping band manufacturers can cater to the diverse needs of their clients and provide tailored solutions for different industries and applications. This not only ensures customer satisfaction but also helps manufacturers stand out in the competitive market.

Quality Control in spiral wrapping band manufacturer

Quality control is a crucial aspect in the manufacturing process of spiral wrapping bands, as it ensures that the final product meets the required standards and specifications. It involves a series of inspections, tests, and corrective actions to identify and eliminate any defects or inconsistencies in the product. In a spiral wrapping band manufacturer, quality control is implemented through various stages of the production process to ensure that the final product is of the highest quality and fit for its intended purpose.

The first step in quality control is the inspection of raw materials. The manufacturer must ensure that the raw materials, such as plastic resins, are of high quality and meet the required specifications. This is done by conducting tests on the raw materials to check for properties such as tensile strength, elongation, and melting point. Any substandard materials are rejected and replaced with materials that meet the required standards.

During the production process, quality control measures are implemented at various stages to ensure that the spiral wrapping bands are being produced according to the set specifications. This includes monitoring the extrusion process, where the plastic resin is melted and formed into a continuous profile. Parameters such as temperature, pressure, and extrusion speed are closely monitored and adjusted as needed to maintain the desired product dimensions and properties.

Once the spiral wrapping bands are produced, they undergo a series of tests to ensure their quality and performance. These tests may include:

1. Dimensional inspection: This involves measuring the width, thickness, and diameter of the spiral wrapping bands to ensure they meet the specified dimensions.

2. Tensile strength test: This test measures the force required to break the spiral wrapping band, ensuring that it can withstand the required load without breaking.

3. Elongation test: This test measures the extent to which the spiral wrapping band can be stretched before breaking, ensuring that it has the necessary flexibility for its intended application.

4. Aging test: This test exposes the spiral wrapping bands to various environmental conditions, such as heat, humidity, and UV light, to ensure that they can withstand these conditions without degrading in quality or performance.

Any products that fail these tests are rejected and sent back for reprocessing or disposal. The manufacturer also implements corrective actions to address the root cause of the defects and prevent their recurrence.

In conclusion, quality control in a spiral wrapping band manufacturer is a continuous process that involves inspecting raw materials, monitoring the production process, and conducting various tests on the final product. By implementing these measures, the manufacturer ensures that the spiral wrapping bands meet the required standards and specifications, providing a high-quality and reliable product for their customers.

Import and Export Regulations for spiral wrapping band manufacturer

Spiral wrapping band manufacturers are subject to various import and export regulations depending on the country they operate in and the countries they trade with. These regulations are in place to ensure product safety, quality, and compliance with international trade laws. In this brief overview, we will discuss some of the key regulations that spiral wrapping band manufacturers should be aware of.

1. Product Standards and Certifications: Spiral wrapping bands must meet specific product standards and certifications in the importing country. For example, in the European Union, manufacturers must comply with the Restriction of Hazardous Substances (RoHS) directive, which restricts the use of certain hazardous materials in electrical and electronic equipment. Additionally, products may need to meet specific safety standards, such as the International Electrotechnical Commission (IEC) standards for electrical insulation materials.

2. Customs Duties and Taxes: Importing and exporting spiral wrapping bands may be subject to customs duties and taxes, depending on the country of origin and destination. Manufacturers should be aware of the applicable tariff rates and any preferential trade agreements between the countries involved in the transaction.

3. Import and Export Licenses: Some countries may require import or export licenses for spiral wrapping bands, particularly if they are considered a controlled or restricted item. Manufacturers should check with the relevant authorities in both the exporting and importing countries to determine if any licenses are required.

4. Intellectual Property Rights: Manufacturers should ensure that their products do not infringe on any intellectual property rights, such as patents, trademarks, or copyrights. This may involve conducting a thorough search of existing patents and trademarks in the countries where the products will be sold.

5. Packaging and Labeling Requirements: Spiral wrapping bands must be packaged and labeled according to the regulations of the importing country. This may include specific labeling requirements, such as displaying the country of origin, product specifications, and safety warnings.

6. Environmental Regulations: Manufacturers should be aware of any environmental regulations that may apply to their products, such as restrictions on the use of certain materials or chemicals. Compliance with these regulations is essential to avoid fines and penalties.

In conclusion, spiral wrapping band manufacturers must navigate a complex web of import and export regulations to ensure their products are compliant with international trade laws. By understanding and adhering to these regulations, manufacturers can minimize the risk of legal issues and ensure the smooth flow of goods across borders.

The Role of Agents and Sourcing Companies in Facilitating Purchases from spiral wrapping band manufacturer

Agents and sourcing companies play a crucial role in facilitating purchases from spiral wrapping band manufacturers. These intermediaries help to bridge the gap between buyers and manufacturers, ensuring a smooth and efficient procurement process. In this article, we will discuss the various ways in which agents and sourcing companies contribute to the purchasing process.

Firstly, agents and sourcing companies have extensive knowledge of the market and industry. They are well-versed in the latest trends, technologies, and innovations in the spiral wrapping band manufacturing sector. This expertise enables them to identify the best manufacturers and suppliers for their clients, ensuring that buyers receive high-quality products at competitive prices.

Secondly, agents and sourcing companies have established relationships with manufacturers and suppliers. These connections enable them to negotiate better deals and secure favorable terms for their clients. They can also leverage their network to identify new suppliers and manufacturers, ensuring that buyers have access to a diverse range of products and services.

Thirdly, agents and sourcing companies provide logistical support throughout the purchasing process. They coordinate with manufacturers and suppliers to ensure that products are delivered on time and in good condition. This includes managing shipping, customs clearance, and other logistical challenges that may arise during the procurement process.

Fourthly, agents and sourcing companies offer quality control services. They inspect products before they are shipped to ensure that they meet the buyer’s specifications and quality standards. This helps to minimize the risk of receiving defective or substandard products, which can lead to delays and additional costs.

Lastly, agents and sourcing companies provide after-sales support. They assist buyers in resolving any issues that may arise after the products have been delivered, such as warranty claims or technical support. This ensures that buyers receive the best possible customer service and can rely on their agents and sourcing companies for ongoing support.

In conclusion, agents and sourcing companies play a vital role in facilitating purchases from spiral wrapping band manufacturers. Their expertise, connections, logistical support, quality control, and after-sales services ensure that buyers receive the best products and services at competitive prices. By partnering with a reliable agent or sourcing company, buyers can streamline their procurement process and focus on their core business operations.

Supply Chain Management for spiral wrapping band manufacturer

Supply chain management (SCM) is a crucial aspect for a spiral wrapping band manufacturer to ensure smooth operations, cost efficiency, and customer satisfaction. It involves the coordination and integration of all activities related to the procurement, production, and distribution of spiral wrapping bands.

The first step in the supply chain is the procurement of raw materials, such as plastic resins, from reliable suppliers. The manufacturer must establish strong relationships with suppliers to ensure a steady supply of high-quality materials at competitive prices. This can be achieved through long-term contracts, supplier evaluations, and regular communication.

Next, the production process involves the transformation of raw materials into finished spiral wrapping bands. The manufacturer must implement efficient production techniques, such as lean manufacturing and just-in-time inventory management, to minimize waste and reduce lead times. This includes investing in advanced machinery and equipment, as well as training employees to enhance their skills and productivity.

Quality control is another essential aspect of the production process. The manufacturer must establish strict quality standards and inspection procedures to ensure that the finished products meet customer requirements. This can be achieved through regular audits, process improvements, and employee training.

Once the spiral wrapping bands are produced, they must be stored and distributed to customers. The manufacturer should invest in an efficient warehouse management system to optimize storage space and reduce inventory holding costs. This includes implementing a first-in, first-out (FIFO) inventory management approach and using real-time data to track inventory levels.

The distribution process involves transporting the finished products to customers, either directly or through distribution channels such as wholesalers and retailers. The manufacturer must establish a reliable logistics network to ensure timely and cost-effective delivery of products. This can be achieved by partnering with reputable logistics providers, optimizing transportation routes, and using technology to track shipments.

Finally, the manufacturer must continuously monitor and evaluate the performance of its supply chain to identify areas for improvement. This includes analyzing key performance indicators (KPIs) such as lead times, inventory turnover, and customer satisfaction. By implementing a robust supply chain management strategy, a spiral wrapping band manufacturer can enhance its competitiveness, reduce costs, and improve customer satisfaction.

Negotiating with spiral wrapping band manufacturer

Subject: Partnership Inquiry for Spiral Wrapping Bands

Dear [Manufacturer’s Name],

I hope this message finds you well. My name is [Your Name] and I represent [Your Company], a leading supplier of cable management solutions. We have come across your impressive range of spiral wrapping bands and are interested in exploring a potential partnership with your esteemed organization.

Our company has a strong presence in the [Your Market] market, and we believe that your high-quality spiral wrapping bands would be an excellent addition to our product portfolio. We are confident that our extensive distribution network and marketing capabilities can help expand your brand’s reach in our region.

Before proceeding further, we would like to discuss the following key points to ensure a mutually beneficial collaboration:

1. Pricing: We request you to provide us with your best possible wholesale prices, considering the potential for high-volume orders. Additionally, we would appreciate it if you could offer flexible payment terms to accommodate our cash flow requirements.

2. Customization: Our clients often require customized solutions to meet their specific needs. We would like to know if you can accommodate custom orders in terms of sizes, colors, and materials, and what would be the minimum order quantity for such requests.

3. Lead Time: Timely delivery is crucial for our business. Kindly share your standard lead times for both regular and custom orders, as well as any expedited shipping options you may offer.

4. Quality Assurance: We maintain high standards for our products and expect the same from our partners. Please provide details on your quality control processes and any certifications your products hold.

5. Samples: To evaluate the quality and compatibility of your spiral wrapping bands with our existing product range, we would like to request some samples. Kindly let us know the procedure for obtaining these.

We look forward to your response and the opportunity to establish a long-lasting and fruitful partnership. Should you have any questions or require further information, please do not hesitate to contact us.

Thank you for your time and consideration.

Best regards,

[Your Name] [Your Company] [Your Contact Information]Protecting Intellectual Property When Working with spiral wrapping band manufacturer

When working with a spiral wrapping band manufacturer, it is crucial to protect your intellectual property (IP) to ensure that your innovative ideas, designs, and products are not misused or copied without your consent. Here are some steps you can take to safeguard your IP:

1. Non-Disclosure Agreements (NDAs): Before sharing any sensitive information with the manufacturer, have them sign a Non-Disclosure Agreement (NDA). This legally binding document ensures that the manufacturer cannot disclose or use your confidential information for any purpose other than the agreed-upon project.

2. Intellectual Property Ownership Agreement: Draft and sign an Intellectual Property Ownership Agreement with the manufacturer, which clearly states that you own all the IP rights related to the product, including patents, trademarks, and copyrights. This agreement should also outline the consequences of any IP infringement.

3. Register Your IP: Register your patents, trademarks, and copyrights with the appropriate government agencies to establish legal ownership and protection. This will help you enforce your IP rights in case of any infringement.

4. Conduct Due Diligence: Research the manufacturer’s reputation and track record before entering into a partnership. Look for any history of IP infringement or legal disputes, and consider working with a manufacturer that has a strong commitment to IP protection.

5. Limit Access to Information: Share only the necessary information with the manufacturer and avoid providing access to your entire IP portfolio. This minimizes the risk of unauthorized use or disclosure of your IP.

6. Monitor Production: Regularly monitor the manufacturing process to ensure that the manufacturer is adhering to the agreed-upon terms and not producing unauthorized copies of your product.

7. Secure Your Supply Chain: Work closely with your manufacturer to establish a secure supply chain that prevents unauthorized access to your products and IP.

8. Legal Action: In case of any IP infringement, be prepared to take legal action against the manufacturer to protect your rights and interests.

By taking these precautions, you can minimize the risk of IP theft and ensure a successful partnership with a spiral wrapping band manufacturer while safeguarding your valuable intellectual property.

Avoiding Scams When Working with spiral wrapping band manufacturer

When working with a spiral wrapping band manufacturer, it is essential to take precautions to avoid scams and ensure a smooth business transaction. Here are some tips to help you avoid scams when working with a spiral wrapping band manufacturer:

1. Research the manufacturer: Before entering into any business relationship, it is crucial to conduct thorough research on the manufacturer. Check their website, online reviews, and any available information about their reputation in the industry. Look for any red flags, such as a history of scams or poor-quality products.

2. Verify their contact information: Make sure the manufacturer’s contact information is legitimate. Call the phone number provided and send an email to the listed address to confirm their authenticity. Be cautious if the manufacturer only provides a mobile phone number or uses a free email service like Gmail or Yahoo.

3. Request samples: Before placing a large order, ask the manufacturer to provide samples of their spiral wrapping bands. This will allow you to assess the quality of their products and ensure they meet your requirements.

4. Check for certifications: Reputable manufacturers should have relevant certifications, such as ISO or other industry-specific certifications. Request copies of these certifications and verify their authenticity.

5. Use secure payment methods: When making payments, use secure methods such as bank transfers or credit cards. Avoid using cash or untraceable payment methods like Western Union or MoneyGram, as these can be difficult to trace in case of a scam.

6. Get a written contract: Before finalizing any business transaction, ensure that you have a written contract outlining the terms and conditions of the agreement. This should include payment terms, delivery timelines, and any warranties or guarantees provided by the manufacturer.

7. Inspect the products upon delivery: Once you receive the spiral wrapping bands, inspect them carefully to ensure they meet your quality standards. If there are any issues, contact the manufacturer immediately to resolve the problem.

8. Trust your instincts: If something seems too good to be true or you feel uneasy about a particular manufacturer, trust your instincts and proceed with caution. It is better to be safe than sorry when it comes to avoiding scams.

By following these tips, you can reduce the risk of falling victim to scams when working with a spiral wrapping band manufacturer and ensure a successful business relationship.

How to use import and export data website importyeti.com to search the company and spiral wrapping band manufacturer

ImportYeti is a powerful tool that allows you to search and analyze import/export data of companies worldwide. To search for a company and a spiral wrapping band manufacturer, follow these simple steps:

1. Visit importyeti.com: Open your preferred web browser and go to https://www.importyeti.com/.

2. Use the search bar: On the homepage, you will find a search bar. Type the name of the company or the product (spiral wrapping band) you are looking for and click the search button or press Enter.

3. Filter the results: After searching, you will see a list of results related to your query. To narrow down the results, use the filters available on the left side of the page. You can filter by country, HS code (Harmonized System code), or date range. For example, if you are looking for a spiral wrapping band manufacturer in the United States, select “United States” from the “Country” filter.

4. Analyze the data: Once you have filtered the results, click on the company name or the product to view more details. You will be able to see information such as the company’s address, contact details, shipment data, and more. This will help you understand the company’s import/export activities and identify potential suppliers or buyers.

5. Export the data: If you want to save the data for further analysis or reporting, click on the “Export” button located at the top right corner of the page. You can choose to export the data in CSV or Excel format.

By following these steps, you can effectively use ImportYeti to search for a company and a spiral wrapping band manufacturer. This powerful tool provides valuable insights into the global trade activities of companies, helping you make informed decisions and identify potential business opportunities.

How to use Chinese Business Search Platform: qcc.com to check spiral wrapping band manufacturer company credit

1. Open the QCC website: Go to the QCC (企查查) website at www.qcc.com. QCC is a Chinese business search platform that provides information on Chinese companies, including their credit status, registration details, and other relevant data.

2. Language selection: The default language of the website is Chinese. If you are not familiar with Chinese, you can use the Google Chrome browser to automatically translate the page into English or your preferred language.

3. Register for an account: To access detailed information about companies, you need to register for a free account. Click on the “Register” button at the top right corner of the homepage and follow the instructions to create an account.

4. Search for the company: In the search bar on the QCC homepage, enter the name of the spiral wrapping band manufacturer you want to check. You can also use keywords related to the company’s products or services. Click the search icon or press Enter to start the search.

5. Browse search results: The search results will display a list of companies that match your search query. Look for the company you are interested in and click on its name to access its detailed information page.

6. Review company information: On the company information page, you can find various details about the company, such as its legal representative, registered capital, registration date, and business scope. This information can help you assess the company’s credibility and stability.

7. Check company credit: Scroll down the company information page to find the “Credit Information” section. Here, you can view the company’s credit rating, any legal disputes or cases, and other credit-related information. A higher credit rating indicates a lower risk of doing business with the company.

8. Verify business licenses and certifications: In the “Certification and License” section, you can check if the company has the necessary licenses and certifications to operate as a spiral wrapping band manufacturer. This includes business licenses, ISO certifications, and any industry-specific certifications.

9. Investigate company history: The “Historical Information” section provides details about the company’s past, such as changes in its legal representative, registered capital, and business scope. This information can help you understand the company’s growth and development over time.

10. Analyze company financials: If available, the “Financial Information” section provides financial data about the company, such as revenue, net profit, and total assets. This information can help you assess the company’s financial health and stability.

By following these steps, you can use the QCC platform to check the credit and background information of a spiral wrapping band manufacturer in China, helping you make informed decisions when selecting a business partner.

How to use archive.org to check spiral wrapping band manufacturer business website history

Archive.org, also known as the Wayback Machine, is a digital archive that allows users to access historical versions of websites. To check the history of a spiral wrapping band manufacturer’s business website, follow these steps:

1. Open your web browser and go to the Archive.org website at https://archive.org/.

2. In the center of the page, you will see a search bar with the text “Explore more than 591 billion web pages saved over time.” Click on the search bar and enter the URL of the spiral wrapping band manufacturer’s business website. Make sure to include the “http://” or “https://” prefix. For example, if the website is “www.examplemanufacturer.com”, enter “https://www.examplemanufacturer.com” in the search bar.

3. Press the “Enter” key on your keyboard or click the “Browse History” button to the right of the search bar. The Wayback Machine will now display a calendar view of the website’s history.

4. The calendar view shows the years and months when the website was archived. Each year is represented by a horizontal bar with the months listed below it. The months with a blue or green circle indicate that there is at least one snapshot of the website available for that month.

5. To view a specific snapshot, click on the year you are interested in, and then click on the month with a blue or green circle. This will display a list of dates with available snapshots. The dates with a blue or green circle have a snapshot available, while the dates with a gray circle do not.

6. Click on a date with a blue or green circle to view the snapshot of the website on that date. The snapshot will open in a new browser window or tab, and you can navigate the website as it appeared on that date.

7. To compare different snapshots, open multiple snapshots in separate browser windows or tabs and switch between them to see the changes over time.

By following these steps, you can use Archive.org to check the history of a spiral wrapping band manufacturer’s business website and gain insights into their past offerings, design changes, and other relevant information.

Why contact sourcifyChina.com get free quota from reliable spiral wrapping band manufacturer?

Contacting SourcifyChina.com to get a free quota from a reliable spiral wrapping band manufacturer is a smart move for several reasons. In today’s competitive market, it is essential to find a trustworthy supplier that can provide high-quality products at reasonable prices. SourcifyChina.com is a platform that connects businesses with reliable manufacturers in China, ensuring that you get the best possible deal for your spiral wrapping band needs.

Firstly, by reaching out to SourcifyChina.com, you can save time and effort in searching for a reliable manufacturer. The platform has already done the groundwork and vetted numerous suppliers, ensuring that you only deal with credible and trustworthy manufacturers. This eliminates the risk of dealing with fraudulent suppliers or receiving substandard products.

Secondly, getting a free quota allows you to compare prices and make an informed decision. By receiving a free quota, you can assess the cost of the product and determine if it fits within your budget. This helps you make a cost-effective decision without compromising on quality.

Thirdly, SourcifyChina.com has a team of experts who can provide valuable advice and guidance throughout the process. They can help you navigate the complexities of international trade, ensuring that you understand the various regulations and requirements involved. This support can be invaluable, especially for businesses that are new to importing products from China.

Lastly, by using SourcifyChina.com, you can leverage their established relationships with manufacturers to negotiate better deals. The platform’s strong connections with suppliers can help you secure favorable terms and conditions, ensuring that you get the best possible deal for your spiral wrapping band needs.

In conclusion, contacting SourcifyChina.com to get a free quota from a reliable spiral wrapping band manufacturer is a wise decision. It saves time, reduces risks, provides expert guidance, and helps you secure the best possible deal. By leveraging the platform’s resources and expertise, you can ensure that your business receives high-quality products at competitive prices.

Related products

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Useful Links & Infomation

©2023. sourcifychina.com All Rights Reserved.

-

- Home

- Cheap Retail Shop

- Wholesale Pro

- Industries

- China Suppliers

- Our China Suppliers list

- Auto Parts Suppliers

- Packaging Solution

- Stainless Steel Suppliers

- Steel Pipe Suppliers

- Solar Inverter China

- cable manufacturing

- cnc machining China

- Apparel and Accessories

- fabric manufacturing

- Machinery

- pump China

- Screw

- wigs custom

- valves manufacturing

- hair system custom

- heated gloves wholesale

- indoor lighting fixtures

- solor panel wholesale

- snow boots factory

- Products

- Sourcing Guide

- Manufacturing

- Apparel / Fashion Accessories

- caps manufacturing

- Denim Manufacturing Company Guide: Sourcing,Types, Applications, Benefits, Process, Price

- fabric manufacturing

- face masks supplier

- hoodies manufacturer

- knitwear manufacturing

- perfume bottle custom

- Ultimate Guide about Sportswear Manufacturing: Types, Applications,Sourcing,Process and More

- T-shirt Manufacturing Companies Guide: Sourcing,Types, Applications, Benefits, Process, Price

- wigs custom

- CNC Tools Valve Pump Parts

- Machinery China Equiment Sourcing Guide

- aac block manufacturers

- acrylic cutting machine

- automatic packing machine

- Auxiliary Equipment Guide: how to Use, Sourcing, Types, Applications, Benefits, Process

- blister packing machine

- bricks manufacturing

- clay brick making machine

- feed pellet machine

- fly ash bricks machine sourcing guide

- paper bag making machine

- pellet machine

- plastic crusher machine

- pouchpacking machine

- stamping machine

- wood pellet machine

- Outdoor Sports

- Others Sourcing Guide

- Apparel / Fashion Accessories

- FAQ

- About

- Contact

- Login

- Newsletter

- [email protected] whatsapp 8615951276160

- 供应商

Login

- →

- WeChat: 8615951276160