Knowledge about Puller Machine

Puller machines are a type of heavy-duty equipment that is used in various industries to pull, remove or lift heavy loads. These machines have become an essential part of many industries as they can greatly increase efficiency and reduce the risk of injury to workers.

To operate a puller machine, it is important to have a good understanding of how it works, and the different types of puller machines available. There are various types of puller machines, such as hydraulic puller machines, manual puller machines, motor-driven puller machines, and more.

The hydraulic puller machine is one of the most common types, as it uses hydraulic pressure to pull heavy loads. Hydraulic puller machines are easy to operate, and they come in various sizes, making them ideal for different types of heavy-duty work.

Another important factor to consider when operating a puller machine is safety. Puller machines must be used with caution and according to the manufacturer’s instructions. Some safety tips to keep in mind include wearing protective gear, keeping a safe distance from the machine while in use, and using the proper lifting techniques.

It is also important to maintain your puller machine regularly to avoid breakdowns and ensure its longevity. Regularly inspecting and servicing the machine’s parts will help identify any potential problems early on and prevent them from getting worse.

In conclusion, having knowledge about puller machines is important in the industries that commonly use them. With proper training and safety measures, puller machines can be used to greatly improve efficiency and productivity in the workplace.

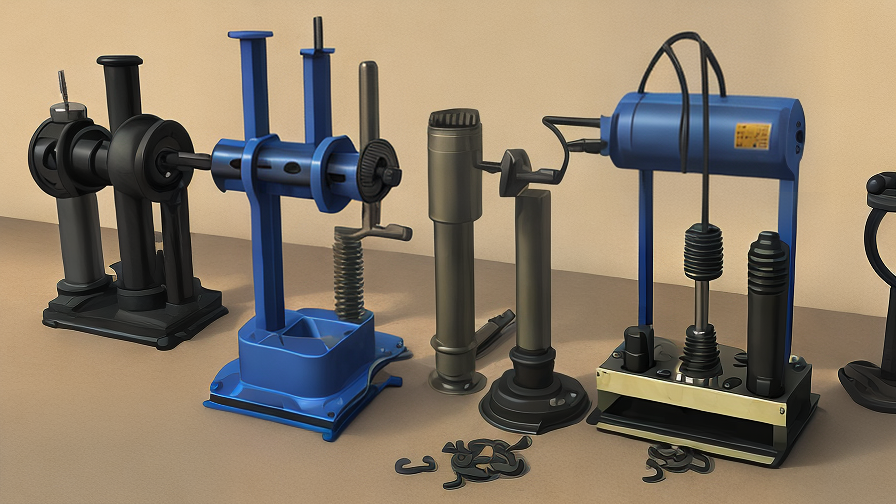

Various Types of Puller Machine

A puller machine is a device used to remove or pull objects out of tight spaces or from difficult positions. Puller machines are of various types and are used in different industries such as automotive, manufacturing, and construction.

The first type of puller machine is the gear puller. It is used to remove gears from shafts or wheels without causing any damage to the surrounding surfaces. Gear pullers come in various sizes and shapes to accommodate different types of gears.

The second type is the bearing puller. A bearing puller is used to remove bearings from various machines or equipment. The puller works by applying pressure on the bearing and pulling it out with ease.

The third type is the hydraulic puller machine. Hydraulic pullers are powerful machines that use hydraulic force to pull out objects. Hydraulic pullers are useful in removing large or heavy objects from tight spaces or difficult-to-reach angles.

The fourth type is the cable puller machine. A cable puller is used to pull cables or wires through pipes or other narrow channels without damaging them. Cable pullers often find use in the construction or electrical industries.

The fifth type is the rope puller machine. A rope puller is used to pull objects from hard-to-reach places. Rope pullers are often used in rescue operations or construction sites.

Lastly, the magnetic puller machine is used to pull out metallic objects in tight spaces or hard-to-reach angles. It uses magnetism to pull out metallic objects, making it useful in automotive, manufacturing, or construction industries.

In conclusion, puller machines are essential devices in various industries. They come in different shapes, sizes, and functionalities. Each type of puller machine is designed to cater to specific needs, making them useful and practical for the industry they are meant for.

FAQ sourcing Puller Machine manufacturer from China

FAQ sourcing Puller Machine manufacturer from China with multiple answers

When it comes to sourcing Puller Machine manufacturer from China, there are several questions that buyers often ask. Here are some of the most commonly asked questions and their answers.

Q: How can I find a reliable Puller Machine manufacturer in China?

A: You can begin your search by looking for suppliers on popular B2B platforms like Alibaba, Made-in-China, or Global Sources. Check the supplier’s background information, such as their experience, factory size, production capacity, and certifications. You may also request samples, and conduct a factory audit before placing an order. It is also best to work with a reputable sourcing agent who can help you find reliable suppliers.

Q: What is the MOQ for Puller Machine in China?

A: The MOQ or minimum order quantity depends on the supplier. Some manufacturers require a minimum order of 1-5 pieces, while some require a larger quantity. This is typically negotiable, but the more units you purchase, the lower the cost per unit.

Q: Can I request customization for my Puller Machine order?

A: Yes, but it depends on the supplier’s manufacturing capabilities. Not all suppliers provide custom services. If they do, you may request changes in the machine’s design, capacity, or other features. However, note that customization may add extra cost and time to the manufacturing process.

Q: What is the lead time for Puller Machine orders from China?

A: Lead time varies by the supplier’s production capacity, order quantity, and customization requests. On average, it takes around 15-30 days from manufacturing to shipping. However, it may take longer depending on your specifications, shipping method, and customs clearance procedures.

Q: What are the payment terms for Puller Machine orders from China?

A: Payment terms may vary by the supplier’s preference and negotiation. Common payment methods include T/T (telegraphic transfer), L/C (letter of credit), and

Applications of Puller Machine

A puller machine is a versatile piece of equipment that can be used in a variety of applications. Whether in a manufacturing plant or a repair shop, puller machines are essential for removing damaged or stubborn components. These machines work by applying force to pull objects apart or push them into place. Here are some common applications of puller machines:

1. Automotive repair: Puller machines are commonly used in automotive repair shops for removing gears, bearings, and other tools that are stuck on the shaft. It can also be used to separate the transmission from the engine block.

2. Manufacturing: Puller machines are widely used in manufacturing plants for removing metal parts from molds. These machines can also be used to press-fit bearings, seals, and bushings in place on various machine tools.

3. Construction: In the construction industry, Puller machines are used for removing nails, bolts, and other fixtures from wood, concrete, or other materials. They can also be used to remove roofing panels or other metal components.

4. Maintenance and repair: Puller machines can be an essential tool for maintenance and repair. They can be used to replace ball bearings, shafts, and other damaged components in industrial machinery or engines.

5. Power transmission: Puller machines can be used in power transmission applications for removing pulleys, flywheels, and other equipment from the shaft. This can be useful in repairing or replacing these parts, without damaging the fittings.

In conclusion, puller machines are versatile tools that can be used in a wide array of applications across a diverse range of industries. From automotive repair to manufacturing and construction, these machines are essential for removing stubborn components and providing precise force applications. With such a wide range of capabilities, a puller machine is an excellent investment for any manufacturing plant, repair shop or other industry that requires a reliable, durable and high-performing tool.

Manufactured Products made of Puller Machine

Puller machines are highly versatile devices that are used to create a range of manufactured products. These machines operate by pulling materials through a set of rollers, thereby creating a smooth and uniform product. The resulting product can be used for a variety of purposes, including packaging, construction, and manufacturing.

One of the most common applications of puller machines is in the creation of plastic products. Plastic materials are fed through the machine and pulled through the rollers to create a consistent and uniform texture. This texture can be further manipulated to create a variety of shapes and products, such as pipes, tubes, and sheets.

Another use for puller machines is in the production of paper products. The machines are used to create a uniform texture on the paper, which can then be cut, folded, and manipulated to create a range of products, such as envelopes, stationery, and packaging materials.

In addition to plastic and paper products, puller machines can also be used to create metal products. The machines are used to pull the metal through a set of rollers, which creates a uniform texture that can be shaped and manipulated to create a variety of products, such as wire, rods, and metal sheets.

Overall, puller machines are critical tools in the manufacturing process, as they provide a consistent and uniform texture to a range of materials. These machines are used in a variety of industries, including plastics, paper, and metal manufacturing, and are essential for creating high-quality products that meet the needs of consumers around the world.

The Evolution history of Puller Machine

The history of puller machines dates back to the ancient times when ropes and pulleys were used as the simplest forms. The use of pullers was a game-changer for the industry and people’s daily lives. With the start of the industrial revolution, machines started evolving with various purposes, from lifting heavyweight goods to reducing human labour.

The earliest forms of puller machines were steam-powered winches used for mining and pulling out the earth. After this, the technology started developing gradually, with the advent of diesel and electric engines. In the early 20th century, the pinch-bar puller was introduced, which was a manual puller with heavy-duty construction that could easily lift small loads.

The hydraulic puller was invented in the 1940s and revolutionized the way we look at pullers. It works by using hydraulic pressure, which is created by the operator, to lift heavy objects. Another major advancement in the industry came in the 1960s when cable pullers were introduced. From here on, the concept of hydraulic pullers underwent massive development, and now there are different types of hydraulic puller machines available in the market.

One of the most significant modern-day advancements in the puller machine industry is in the design and safety standards. More features and safety measures are being included to make the equipment user-friendly and reduce accidents. Today, puller machines are an essential tool for construction, aerospace, automotive, and entertainment industries.

In conclusion, the history of puller machines has seen many advancements and has become an integral part of various industries. With more technological advancements, the puller machine industry is expected to continue evolving and become even more intuitive and safe.

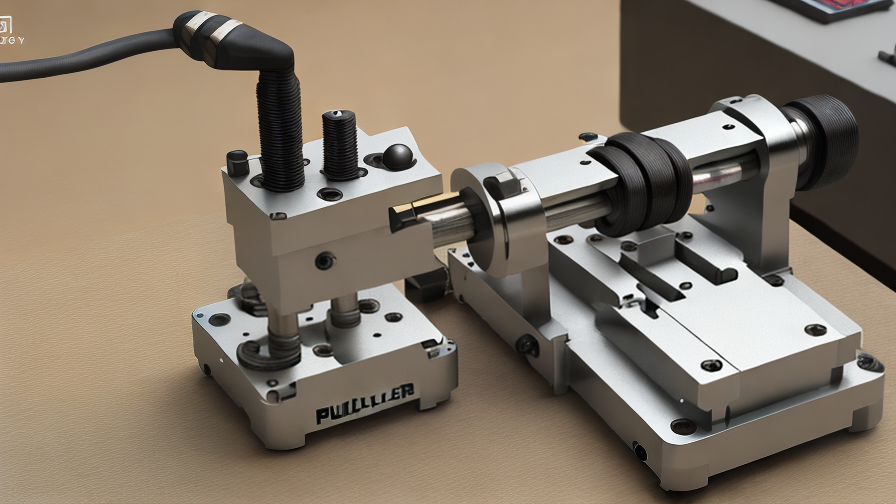

The Process of Puller Machine

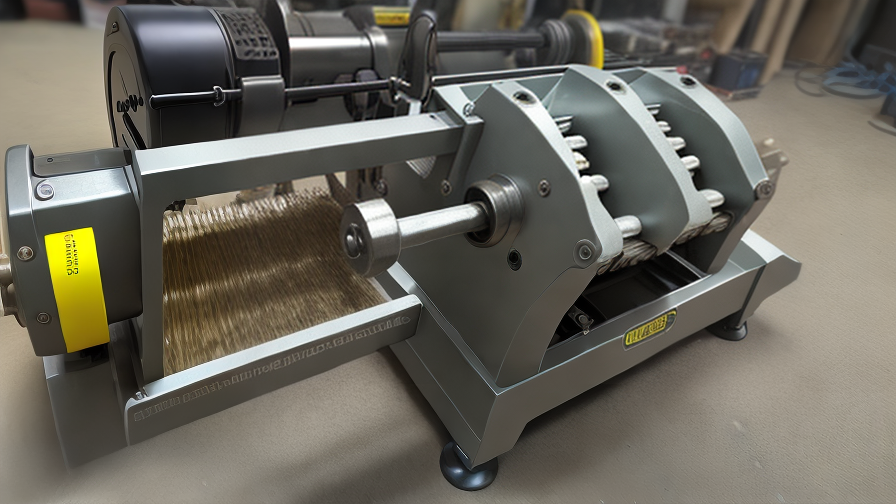

The pulling process is a crucial procedure in the manufacturing of wires and cables. The machine, called a puller machine, plays a major role in this process. It is responsible for accomplishing several crucial tasks, such as ensuring consistency in the diameter of the wire and maintaining a constant rate of speed for the wire to pull.

The pulling machine has two major components; the drive and the capstan. The drive is responsible for maintaining the right speed of the wire, while the capstan plays the role of guiding the wire out of the machine. This machine is designed to work with varying wire diameters, and it must be adjusted to accommodate each size.

To begin the process, the operator must first set the capstan to the diameter of the wire being produced. Then, the wire is fed through the machine and attached to the drive. The pulling machine will take care of the rest as it pulls the wire through the capstan at a constant rate. It is important to keep the wire lubricated to prevent it from breaking during the pulling process.

Additionally, pulling machines utilize feedback sensors to detect abnormalities in tension or speed. This system allows the operator to monitor and adjust the pulling machine to ensure it is working correctly.

In conclusion, puller machines are essential in the wire and cable manufacturing process. They play a vital role in ensuring consistency in wire diameter, regulating the speed of the wire, and monitoring the tension to prevent wire breakage. Proper maintenance of this machine will result in a reduced risk of defects and increased efficiency, resulting in significant cost savings.

Benefits Advantages of Utilizing Puller Machine

A puller machine is a tool used to remove or pull something. It is an invaluable asset to have in various industries, including automotive, construction, and manufacturing. The machine can be used to remove, repair, and replace parts of machinery, vehicles, and buildings. Below, we will discuss the benefits and advantages of utilizing a puller machine.

Time-Saving and Efficiency

One of the most significant advantages of using a puller machine is its ability to save time and make work more efficient. Traditionally, removing parts, such as bearings or gears, would require manual removal, which can be time-consuming and often dangerous for the laborer or technician involved. With a puller machine, parts can be removed quickly, safely and with minimal effort.

Reliable and Consistent Results

Using a puller machine ensures that the removal process is performed in a precise, consistent, and reliable manner. This is because the machine provides a controlled force that ensures the part is removed without causing any damage to the surrounding structure. This also ensures that the part is removed safely without any damage, reducing the possibility of the need for further repairs.

Versatility

Another advantage of using a puller machine is its flexibility and versatility. The machine can be used to remove different parts of varying sizes and shapes, such as gearwheels, bearings, pulleys, and even parts like prop shafts. This makes the machine ideal for use in different industries, including metalworking, construction, automotive, and maintenance.

Cost-Effective

Using a puller machine is also cost-effective because it can eliminate the need for outsourcing specialized labor, which can be expensive, time-consuming, and risky. By having the machine available, technicians can perform multiple removal tasks with ease, avoiding the need for specialized technicians, which can save a significant amount of money.

In conclusion, utilizing a puller machine is a wise investment as it provides numerous benefits and advantages to various industries. Whether it is used in construction projects, automotive repairs,

Disadvantages Puller Machine

Puller machines are a type of equipment that serves the purpose of pulling, tugging, or dragging heavy loads with relative ease. Despite being used in various industries such as construction, logistics, and transportation, they have their drawbacks.

Firstly, puller machines require a considerable amount of maintenance. The equipment is prone to breakdowns and wears and tears, making it crucial to regularly ensure that it is in good working condition. This maintenance can be expensive, with the need to replace parts, lubricate the equipment and fix other probable issues.

Secondly, puller machines can have a significant adverse impact on the environment. For instance, they are mostly powered by diesel or petrol engines, which contribute to environmental pollution. This pollution is harmful to the environment as it leads to global warming, acid rain, and air pollution. This puller machine’s environmental drawbacks could thus have long-term consequences.

Thirdly, puller machines also require qualified operators, which can be a significant disadvantage. Inexperienced individuals operating the equipment could cause accidents leading to injuries or fatalities. This can pose both legal and financial implications for the company involved.

Fourthly, puller machines have high costs, making them less accessible to small businesses. They require regular servicing and significant capital investment to purchase, making them prohibitive to startups or small businesses.

In conclusion, while puller machines can make heavy load transportation easier, they have several disadvantages. They need regular maintenance, pose environmental pollution, require experienced operators and are expensive. Therefore, when buying puller machines, it is vital to consider the costs and associated drawbacks carefully.

Selecting the Ideal Manufacturer Puller Machine

Selecting the Ideal Manufacturer Puller Machine

When it comes to manufacturing, puller machines are essential equipment that are used to extract materials or products from a production line. There are different types of puller machines available in the market to choose from, and selecting the ideal one can be overwhelming. Here are some factors to consider when selecting the ideal manufacturer puller machine.

Quality

The quality of the puller machine is an important factor to consider. You need to ensure that the machine you select is made of high-quality materials and is durable. Also, make sure that the machine is well designed and manufactured for its intended use.

Capacity

The capacity of the puller machine is also a vital factor to consider. You need a machine that can handle the required material or product size and weight. If you need to extract bulky materials, you will need a machine with a higher capacity.

Ease of Use

An ideal puller machine should be easy to operate and maintain. It should have clear instructions on how to use it, and the manufacturer should provide training and support for its use. Also, ensure that the machine is easy to clean to avoid contamination.

Cost

The cost of the puller machine is another important factor to consider. You need to ensure that the machine is within your budget, and the cost should not compromise its quality and efficiency.

Reputation of the Manufacturer

The reputation of the machine manufacturer is also a crucial factor to consider. You need to ensure that the manufacturer has a good reputation in the industry, and they have been in the industry for a long time. Also, consider getting recommendations from other manufacturers who have used their machines before.

In conclusion, selecting the ideal manufacturer puller machine requires careful consideration of the factors mentioned above. Ensure that you do your research, and choose a machine that suits your business needs and budget.

Things to Consider When Purchasing Puller Machine

When purchasing a puller machine, it is important to consider several factors to ensure that you get a machine that will meet your needs. These factors include the type of machine, the size of the machine, the cost, the durability, the ease of use, and the warranty.

The type of machine you choose will depend on the application you plan to use it for. There are different types of puller machines, including hydraulic, mechanical, and electrical pullers. Hydraulic pullers are the most commonly used and are suitable for heavy-duty applications.

The size of the machine is also an important factor to consider. You need to ensure that the machine you purchase will fit the space you have available for it. Additionally, consider the size of the components you will be working on, as this will determine the pulling capacity that you need.

Cost is another factor to consider. Puller machines can vary significantly in price, so it is important to consider your budget and weigh the cost against the functionality and reliability of the machine.

Durability is crucial as you want a machine that will last for an extended period. Check the material used to make the machine and go for heavy-duty materials as they are more durable and can withstand heavy use.

Ease of use is another important consideration. Choose a machine with easy-to-understand instructions that come with it. Also, ensure that it has user-friendly controls that are easy to operate.

Lastly, consider the warranty of the machine you plan to purchase. Warranty will give you peace of mind knowing that you can get assistance if the machine develops faults within the warranty period. Always check the duration of the warranty and the conditions that come with it.

In conclusion, purchasing a puller machine requires careful considerations as it is a significant investment. By considering the factors mentioned above, you can be confident that you will select a puller machine that will meet your needs, saving you time and money in the long run.

Properties of Puller Machine

A puller machine is a type of equipment frequently used in industries that involve heavy lifting and transportation. It is designed to pull objects or materials from one place to another through the use of cables or chains. There are several properties of a puller machine that make it a versatile and reliable tool.

Firstly, a puller machine is highly durable, which is an essential property in industrial applications. Its body is usually constructed from high-strength materials such as steel and aluminum, which give the machine the structural integrity needed for heavy-duty workloads. The machine’s durable nature ensures that it can withstand harsh environments, heavy loads, and long hours of use without breaking down, malfunctioning, or wearing out.

Secondly, puller machines are designed with safety in mind. They have a range of safety features that minimize the risk of accidents, which is crucial when dealing with heavy lifting, transportation, and machinery. Some of the safety features include emergency stop buttons, safety rope systems, automatic locking mechanisms, and load limiters that prevent overloading.

Thirdly, puller machines are highly versatile as they can be used in different industrial applications. For example, they can be used in construction sites for lifting building materials, in shipyards for lifting and transporting ships, in manufacturing industries for moving heavy machinery, and in mining industries for relocating mines.

Fourthly, puller machines are easy to operate, which makes them ideal for use by different people in various industries. They usually have ergonomic controls that are easy to use and understand, making it simple for operators to maneuver the machine and perform tasks effectively.

In summary, puller machines have several properties that make them a valuable tool in industries that deal with heavy lifting and transportation. Their durability, safety features, versatility, and ease of operation make them an essential piece of equipment in any industry that involves moving heavy objects.

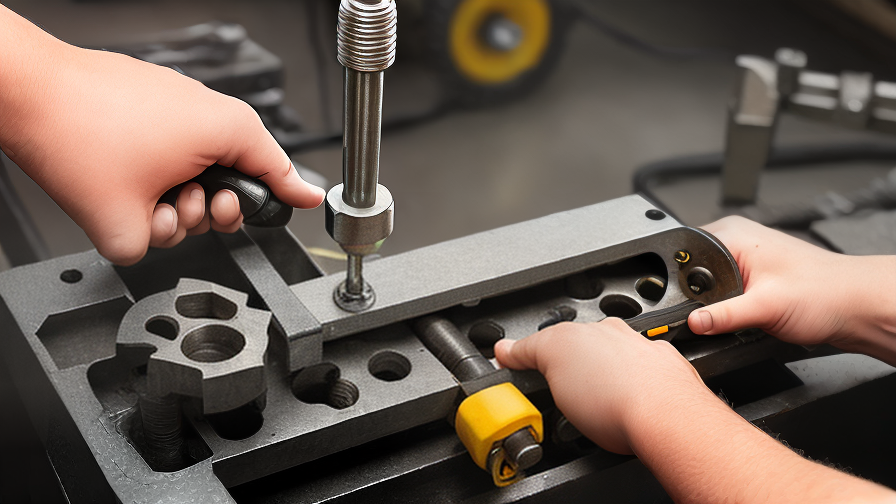

How to use Puller Machine

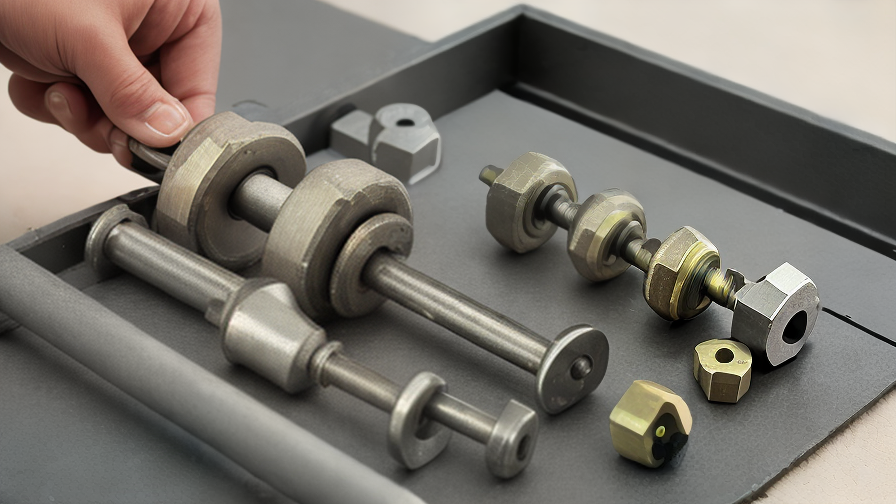

A puller machine is a tool used for removing pressed or fitted parts. It consists of a set of jaws that grip onto the part that you want to pull and a threaded rod that extends the jaws to create a pulling force. The puller machine can be used for a range of applications like removing gears, bearings or even a steering wheel. Here are some simple steps on how to use a puller machine.

First, identify the fitting or part that needs to be removed. Ensure that the puller machine has the correct size of jaws and thread for the fitting. If you are unsure, consult the user manual or a professional.

Next, mount the puller machine onto the fitting. This can be done by aligning the jaws with the fitting and tightening the threaded rod. Be sure not to overtighten the rod as this may damage the fitting or the puller machine.

Once the puller is securely mounted, apply pressure to the threaded rod using a wrench or socket wrench. Turn the wrench clockwise to extend the jaws and create a pulling force. Apply a constant force to the wrench until the fitting is removed.

As you apply the force, keep an eye on the fitting to ensure that it is coming out straight. If it is not coming out straight, release the pressure, realign the puller and try again.

After the fitting is removed, loosen the threaded rod to release the jaws. Clean and store the puller machine in a safe place.

In conclusion, a puller machine is a simple and effective tool for removing pressed or fitted parts. With the correct size of jaws and thread, and by following the simple steps outlined above, you can use a puller machine for a range of applications. Always ensure that you read the user manual or seek professional advice when unsure, and use the puller machine safely and responsibly.

Glossary Terminology Terms for Puller Machine

A puller machine is a device that is used for various automotive tasks, including removing bearings, gears, and other parts from automobiles or machineries. To better understand the functionality of a puller machine, it is essential to be acquainted with the commonly used terminology and jargon associated with it.

Below is a list of some essential glossary terminology terms for a puller machine:

1. Jaw: It is the gripping end of the puller machine that clamps onto the object, making it removable.

2. Tension bolt: It is a screw-like component that applies force to the jaws to hold the object securely.

3. Yoke: It is the frame that holds the jaws, tension bolt, and other components in place.

4. Slide hammer: A sliding weight attached to a shaft that is used to apply force to the puller surface, dislodging stuck objects.

5. Bearing splitter: A tool used to pull bearings, gears, or pulleys off a shaft without damaging them.

6. Hub puller: A specialized puller that removes hub assemblies from wheel bearings.

7. Two-jaw puller: A puller with two jaws to remove objects from tight spaces, such as brake drums.

8. Three-jaw puller: A puller with three jaws for removing objects larger than those removed by a two-jaw puller.

9. Reversible jaws: A feature that allows the jaws to be reversed for use in either inside or outside grip applications.

10. Universal joint puller: A puller that is designed to remove universal joints from driveshafts.

In conclusion, being familiar with the commonly used terminology and jargon in puller machines is imperative to quickly understand the tools’ functionality and use. The terms listed above will help you understand the different types of pullers, their applications, and how they work.

Puller Machine Price

A puller machine, also known as a cable pulling machine, is an essential tool used to move heavy loads in industries such as construction and manufacturing. These machines come in various sizes and capacities, from handheld units to large hydraulic models. The price of a puller machine varies based on its size, weight capacity, and features.

On average, a small, hand-held puller machine can cost around $30 to $100. This type of puller is suitable for small-scale jobs and has a weight capacity of up to 2 tons. The cost increases for larger machines that can handle 5 to 30 tons, ranging from $500 to $5,000.

Hydraulic puller machines are the most efficient and powerful, capable of lifting heavy loads up to 100 tons. These machines can cost anywhere from $5,000 to $30,000, depending on their capacity and features. Advanced models come with features such as remote control, wireless connectivity, and safety sensors.

It’s essential to consider various factors when purchasing a puller machine, such as the type of job being done, the weight of the load, and the machine’s specifications. Purchasing a high-quality puller machine not only ensures safety but also adds value to your investment. It would be best to choose a reputable vendor who offers warranties, training, and customer support.

In conclusion, the price of a puller machine varies depending on factors such as the size, weight capacity, and features of the machine. The cost for small, hand-held models ranges from $30 to $100, while hydraulic puller machines can cost between $5,000 to $30,000. Safety, reliability, and support are crucial considerations when purchasing a puller machine to ensure maximum return on investment.