Introduce about pulse tig welder guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

The Pulse TIG Welder Guide is a comprehensive resource that provides valuable information about pulse TIG welding. This guide offers detailed insights into the welding process, equipment, and techniques involved in pulse TIG welding.

Quality is an essential consideration when choosing a pulse TIG welder. High-quality welders ensure efficient and precise welding while delivering consistent results. Durability, ease of use, and advanced features are factors to consider when assessing the quality of a pulse TIG welder.

Cost is an important factor to consider during the purchasing process. Pulse TIG welders range in price depending on their quality, features, and brand reputation. It is important to compare prices and features to find the best welder that suits your needs and budget.

When selecting a supplier for a pulse TIG welder, it is crucial to choose a reputable and reliable supplier. Trusted suppliers offer high-quality products, provide warranties, and offer excellent customer service. Researching supplier reviews and customer feedback can help identify reliable suppliers.

Certification is an important aspect that ensures the welder meets industry standards and specifications. Look for certification from reputable organizations such as the American Welding Society (AWS) to ensure the welder’s quality and performance.

The pulse TIG welder market offers a wide range of choices from various brands and models. It is advisable to gather information on different models, their features, and customer reviews to make an informed decision.

The guide also provides valuable tips for pulse TIG welding, such as proper technique, electrode selection, and setting parameters. These tips help improve welding efficiency, quality, and overall performance.

The guide also includes a frequently asked questions (FAQ) section, addressing common queries and concerns related to pulse TIG welding. This section provides quick answers and helpful information to assist welders in their decision-making process.

In conclusion, the Pulse TIG Welder Guide is a comprehensive resource offering valuable information on pulse TIG welding. It covers topics such as quality, cost, suppliers, certification, market trends, tips, and frequently asked questions. This guide aims to equip welders with the knowledge and guidance they need to make informed decisions when it comes to purchasing and using pulse TIG welders.

Types of pulse tig welder

There are several types of pulse TIG welders available on the market. These welders combine the benefits of traditional TIG welding with high-frequency pulsing technology, allowing for greater control and precision in the welding process. Here are three common types of pulse TIG welders:

1. Manual Pulse Welders: These welders require the operator to manually adjust the pulse parameters during the welding process. They offer the most control over the pulse settings and are ideal for experienced welders who are comfortable making adjustments on the fly. Manual pulse welders allow for customization of pulse frequency, duration, and peak current.

2. Synergic Pulse Welders: These welders feature pre-programmed pulse settings that automatically adjust based on the selected parameters. Synergic pulse welders are designed to simplify the welding process, making them suitable for beginner or less experienced welders. They offer a range of pre-set options that can be selected based on the type of material being welded.

3. Pulse-on-Pulse Welders: These welders use two pulses, also known as the base pulse and the peak pulse, to achieve enhanced control over heat input and weld penetration. The base pulse establishes an arc stable enough to prevent sticking and provides a low average current. The peak pulse, on the other hand, increases the current to create a deeper weld penetration. Pulse-on-pulse welders are commonly used for welding aluminum and other non-ferrous metals.

In addition to these types, there are also AC/DC pulse TIG welders that can switch between alternating current (AC) and direct current (DC). These welders are versatile and can be used for various types of welding applications, including both aluminum and steel.

Pulse TIG welders are highly regarded for their ability to reduce heat input, minimize distortion, and improve overall weld quality. They are commonly used in industries such as automotive, aerospace, and fabrication, where precision and control are paramount. Whether you choose a manual, synergic, or pulse-on-pulse TIG welder, each type offers its own advantages and is tailored to different skill levels and welding requirements.

Pros and Cons of Using pulse tig welder

Pulse TIG welding, also known as pulse arc welding, is a type of Tungsten Inert Gas (TIG) welding that utilizes a high-frequency pulsed current to produce a more controlled and efficient welding process. Here are some pros and cons of using a pulse TIG welder:

Pros:

1. Improved heat control: Pulse TIG welding allows better control over the heating and cooling cycles, resulting in reduced distortion and warping of the welded metal. This is especially useful when working with thin materials or heat-sensitive alloys.

2. Higher welding speeds: The pulsed current helps increase the welding speeds without compromising the quality of the weld. This is advantageous when dealing with large-scale projects or time-sensitive tasks.

3. Enhanced weld quality: The pulsed current produces a focused arc, leading to a narrower weld bead and improved precision. This makes it suitable for applications requiring high aesthetics or demanding quality standards.

4. Better penetration control: Pulse TIG welders provide the ability to adjust both the pulse frequency and width, enabling welders to fine-tune the penetration depth. This is particularly beneficial when welding various material thicknesses.

5. Reduced heat input: Pulse TIG welding results in lower overall heat input, minimizing the heat-affected zone (HAZ). This reduces the risk of weakening the surrounding base metal and helps maintain the original material properties.

Cons:

1. Skill requirements: Pulse TIG welding requires a certain level of skill and expertise to operate effectively. Proper training and experience are essential to maximize the benefits and avoid potential issues.

2. Equipment cost: Pulse TIG welding machines and accessories tend to be more expensive compared to conventional TIG welders. The initial investment might be higher, especially for small-scale welders or hobbyists.

3. Complex setup: Pulse TIG welding involves more complicated setup and parameters compared to regular TIG welding. The welder needs to understand and adjust various settings, such as pulse frequency, duty cycle, and peak/valley currents, appropriately.

4. Limited material compatibility: While pulse TIG welding is suitable for various metals, it may not be the optimal choice for all materials. Certain alloys, such as aluminum, require significant skill and adjustments for successful pulse TIG welding.

5. Increased noise levels: Pulse TIG welding produces a higher level of noise due to the rapid on/off cycles of the current. Adequate hearing protection is necessary to minimize the risk of hearing damage to the welder and nearby individuals.

In conclusion, pulse TIG welding offers significant advantages in terms of heat control, welding speed, weld quality, penetration control, and HAZ reduction. However, it requires skilled operators, has a higher equipment cost, involves complex setup, may have limited material compatibility, and produces increased noise levels. Considering these pros and cons is crucial for welders to make informed decisions when deciding whether to use a pulse TIG welder or opt for other welding techniques.

pulse tig welder Reference Specifications (varies for different product)

A pulse TIG welder is a type of welding machine that uses the Tungsten Inert Gas (TIG) welding process. It is a versatile tool used in various industries for joining metals together. Here are some reference specifications commonly found in pulse TIG welders, although they may vary depending on the specific product.

1. Power Output: Pulse TIG welders come in different power ratings, typically ranging from 150 amps to 300 amps. The power output determines the welder’s capability to handle different materials and thicknesses.

2. Pulse Frequency: Pulse TIG welders offer adjustable pulse frequencies, usually ranging from 0.5 Hz to 500 Hz. The pulse frequency control allows welders to manipulate the heat input and control the weld puddle, resulting in improved weld quality and reduced heat-affected zone.

3. Duty Cycle: The duty cycle indicates the maximum amount of time a pulse TIG welder can operate continuously at a given load before needing to cool down. For example, a 60% duty cycle at 250 amps means that the welder can be used for six minutes within a ten-minute period before requiring a break.

4. AC/DC Functionality: Some pulse TIG welders offer both AC and DC output modes. AC mode is primarily used for welding aluminum, while DC mode is suitable for welding stainless steel, copper, and other metals.

5. Waveform Control: Pulse TIG welders often come with waveform control features, allowing welders to adjust the shape of the welding current waveform. This feature provides precise control over the heat input, arc stability, and penetration depth.

6. Pre and Post Gas Flow: Pulse TIG welders generally offer adjustable pre and post-gas flow timers, enabling welders to set appropriate shielding gas flow rates before and after the welding process to protect the weld from contamination.

7. Digital Controls: Many pulse TIG welders feature digital control interfaces, enabling operators to easily adjust parameters such as amperage, pulse frequency, and gas flow. Digital controls provide accuracy and repeatability in weld settings.

8. Portable Design: Some pulse TIG welders are designed to be lightweight and portable for easy transportation to various job sites. Features like carry handles and compact dimensions make them suitable for on-site welding applications.

These are just a few reference specifications commonly associated with pulse TIG welders. It’s important to consult the specific product’s documentation for accurate and detailed information as each welder may have different features and capabilities.

Applications of pulse tig welder

Pulse TIG welders are versatile welding machines that offer several applications in various industries. They are designed to provide precise control over the heat input, making them suitable for welding both thin and thick materials. Some of the common applications of pulse TIG welders include:

1. Automotive Industry: Pulse TIG welders are widely used in the automotive industry for fabricating components and bodywork. They can be used to join different types of metals, such as steel, aluminum, and stainless steel, with high precision and quality. The pulse feature allows for better control of heat input, reducing the risk of warping and distortion.

2. Aerospace Industry: Pulse TIG welding is extensively used in the aerospace industry for joining lightweight materials like aluminum and titanium. The ability to control the heat input with precision helps in ensuring the strength and integrity of the welds while minimizing the risk of deformation. Pulse TIG welders also produce cleaner and aesthetically pleasing welds, making them suitable for visible joints in aircraft components.

3. Pipe Welding: Pulse TIG welders are commonly used for pipe welding applications, including gas and oil pipelines, plumbing, and HVAC installations. They offer excellent control over the welding process, enabling operators to achieve consistent and high-quality welds on a variety of pipe materials, such as carbon steel, stainless steel, and copper.

4. Fabrication and Sheet Metal Work: Pulse TIG welders are ideal for fabricating intricate structures and welding thin sheet metal. The pulse function allows for precise control of the heat input, reducing the chances of burn-through and distortion while achieving strong and aesthetically pleasing welds. They are widely used for manufacturing cabinets, enclosures, electrical panels, and similar components.

5. Food and Beverage Industry: Pulse TIG welding finds application in the food and beverage industry for fabricating stainless steel equipment like tanks, vessels, and piping systems. The precise control over the weld puddle and reduced heat input minimize the risk of contaminating the welded joints, ensuring high sanitation standards.

In conclusion, pulse TIG welders offer a wide range of applications across industries, including automotive, aerospace, pipe welding, fabrication, and the food and beverage industry. Their ability to provide precise heat control, produce clean and aesthetically pleasing welds, and accommodate various materials and thicknesses makes them an excellent choice for professional welders.

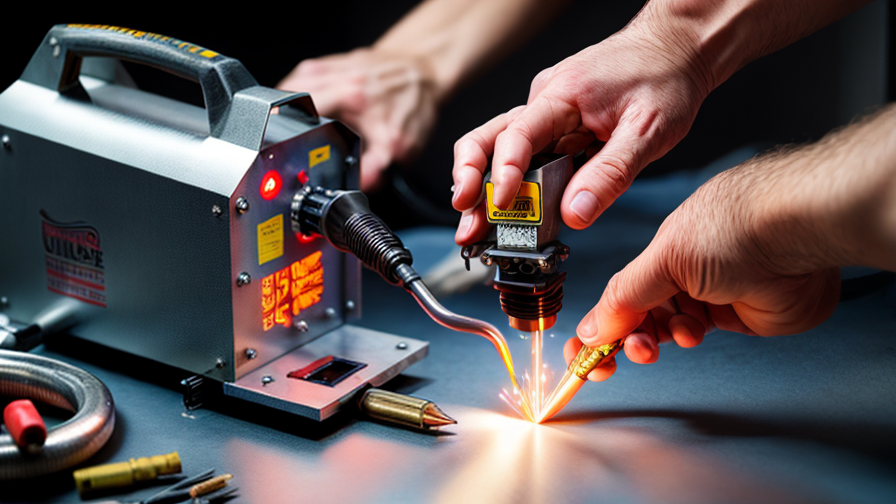

The Work Process and how to use pulse tig welder

The work process of TIG (Tungsten Inert Gas) welding involves using a pulse TIG welder, which is a type of welding machine that generates an electric arc between a non-consumable tungsten electrode and the workpiece. This process is commonly used in industries like automotive, aerospace, and fabrication, as it allows for precise and high-quality welds.

To use a pulse TIG welder, follow these steps:

1. Prepare the workspace: Clear the area of any flammable materials and ensure proper ventilation. Put on personal protective equipment like welding gloves, helmet, and clothing.

2. Set up the machine: Connect the welding machine to a power source and adjust the relevant settings, including amperage, pulse frequency, pulse width, and gas flow rate. Refer to the user manual for specific instructions based on the type and model of welder.

3. Prepare the workpiece: Clean the area to be welded using a wire brush or grinder to remove any dirt, rust, or paint. Make sure the workpiece is securely positioned and clamped to prevent movement during welding.

4. Install the tungsten electrode: Select an appropriate tungsten electrode based on the type of material being welded. Grind the tip of the electrode to a point using a bench grinder. Insert the electrode into the TIG torch and tighten it securely.

5. Set the shielding gas: Connect the gas supply (argon or a mixture of argon and helium) to the welder. Adjust the gas flow rate to ensure a stable shield around the weld area.

6. Start welding: Position the TIG torch above the workpiece, ensuring a suitable distance between the tungsten electrode and the workpiece. Use the foot pedal or control panel to initiate the welding process and control the heat output.

7. Use pulse settings: Depending on your specific requirements, adjust the pulse frequency and width to control the heat input and penetration. Pulsing the current allows for better control and reduces heat stress on the workpiece.

8. Welding technique: Move the torch along the joint using a steady and consistent motion. Maintain a slight backward tilt of the torch to direct the heat towards the weld puddle. Add filler metal if necessary.

9. Finish and inspect the weld: Once the welding is complete, release the foot pedal or close the welding current. Allow the weld to cool down before inspecting it for quality. Look for uniformity, lack of porosity, and proper penetration.

10. Post-welding clean-up: Remove any spatter, slag, or residue using a wire brush or appropriate cleaning tools. Clean the TIG torch and store it properly for future use.

By following these steps and practicing proper welding techniques, you can effectively use a pulse TIG welder to create strong and high-quality welds on various materials.

Quality Testing Methods for pulse tig welder and how to control the quality

There are several quality testing methods that can be used to evaluate the performance and reliability of a pulse TIG (Tungsten Inert Gas) welder. These methods aim to ensure that the welder meets all required standards and specifications.

One commonly used method is visual inspection, where a trained technician visually examines the welds for any visible defects such as cracks, undercutting, or porosity. This inspection helps to identify any immediate issues or abnormalities that may affect the quality of the weld.

Another important testing method is non-destructive testing (NDT). This includes techniques like ultrasonic testing, radiographic testing, and liquid penetrant testing. Ultrasonic testing uses sound waves to detect internal defects in the weld, whereas radiographic testing uses X-rays to capture images of the weld and identify any discontinuities. Liquid penetrant testing involves applying a dye to the weld surface and then examining it under ultraviolet light to reveal any cracks or flaws.

In addition to these testing methods, it is crucial to control the quality of pulse TIG welding by implementing certain measures. One key aspect is to ensure proper calibration and maintenance of the welding equipment. Regular inspections and calibrations of the power source, torch, and shielding gas system help to maintain consistent and reliable performance.

Moreover, it is important to select the appropriate welding parameters such as pulse frequency, pulse width, and pulse current to achieve the desired weld quality. These parameters can significantly affect the weld penetration, fusion, and appearance. It is recommended to conduct procedure qualification tests to determine the optimal welding parameters before starting production.

Lastly, proper training and qualification of welders are essential to control the quality of pulse TIG welds. Adequate training ensures that welders understand the welding procedures, techniques, and safety requirements. Certification and periodic requalification of welders help to maintain the required skill level and ensure the consistency of the welding process.

In conclusion, quality testing methods such as visual inspection and non-destructive testing, along with proper equipment calibration, selection of welding parameters, and trained welders can effectively control the quality of pulse TIG welds. These measures ensure that the welder produces consistent, reliable, and defect-free welds, meeting the required standards and specifications.

pulse tig welder Sample Policy and Post-Purchase Considerations for pulse tig welder from China

Sample Policy:

1. Quality Assurance: The pulse TIG welder should meet the required international quality standards and certifications. The supplier must provide a warranty period and agree to replace or repair any defects found within this period.

2. Technical Support: The supplier should offer technical support, including online assistance or a helpline, to help resolve any technical issues that may arise during the operation of the pulse TIG welder.

3. Spare Parts Availability: The supplier should ensure the availability of spare parts for the pulse TIG welder, either by providing them directly or by giving access to a reliable source for spare parts, to avoid downtime in case of component failures.

4. Packaging and Shipping: The supplier should ensure the safe and secure packaging of the pulse TIG welder to minimize the risk of damage during transit. They should also arrange for appropriate shipping methods and provide relevant tracking information.

Post-Purchase Considerations:

1. Installation and Training: Ensure that proper installation and setup guidelines are provided by the supplier. Request training sessions or online tutorials to familiarize with the pulse TIG welder’s operation, features, and maintenance requirements.

2. Testing and Calibration: After receiving the welder, perform initial testing and calibration to ensure accurate performance. Seek assistance from the supplier if any issues are observed during this process.

3. Safety Measures: Implement necessary safety precautions and ensure that all operators are adequately trained to use the pulse TIG welder safely. Provide protective gear, such as welding helmets, gloves, and safety glasses, to minimize the risk of accidents.

4. Regular Maintenance: Follow the maintenance schedule recommended by the supplier to prolong the life and ensure reliable performance of the pulse TIG welder. Regularly inspect and clean the welder, check for any loose connections, and replace worn-out parts as required.

5. Feedback and Reviews: Share your experience with the supplier and provide feedback on the performance and reliability of the pulse TIG welder. Consider leaving reviews on relevant platforms to assist other potential buyers in their decision-making process.

By following these sample policies and post-purchase considerations, you can ensure a smooth purchasing process and maintain the optimal performance of your pulse TIG welder from China.

Sourcing pulse tig welder from China: Opportunities, Risks, and Key Players

Sourcing pulse TIG welders from China presents both opportunities and risks for businesses. China is known for its manufacturing capabilities, and the country produces a wide range of welding equipment, including pulse TIG welders, at competitive prices. This presents an opportunity for businesses to acquire cost-effective welding machines to meet their production needs.

One of the key advantages of sourcing pulse TIG welders from China is the availability of a large number of suppliers and manufacturers. This allows businesses to have more options and opportunities to find the right product at the right price. Additionally, Chinese manufacturers often offer customization options, allowing businesses to tailor the welders to their specific requirements.

However, sourcing from China also involves certain risks. Quality control can be a concern, as the standards and regulations may not be as stringent as in some other countries. It is crucial for businesses to carefully screen potential suppliers and manufacturers before placing orders. Conducting thorough due diligence, such as inspecting samples, checking certifications, and reading customer reviews, can help mitigate this risk.

Another risk associated with sourcing from China is intellectual property infringement. The country has had a reputation for counterfeiting and piracy issues. To protect their intellectual property, businesses should choose reputable suppliers and consider using legal contracts and agreements.

When sourcing pulse TIG welders from China, there are several key players to consider. Some of the well-known Chinese manufacturers in this field include Huayilong Electric, Riland Electric, and JASIC Technology. These companies have established themselves in the market and offer a wide range of pulse TIG welders with different specifications and features.

In conclusion, sourcing pulse TIG welders from China can provide opportunities for businesses to acquire cost-effective and customizable products. However, it is essential to carefully evaluate potential suppliers, consider quality control measures, and protect intellectual property rights to minimize risks. Key players in the market include Huayilong Electric, Riland Electric, and JASIC Technology.

How to find and select reliable pulse tig welder manufacturers in China,use google search manufacturers and suppliers

When searching for reliable pulse TIG welder manufacturers in China, using Google search can be an effective tool. Here are some steps to follow:

1. Start by entering relevant keywords such as “pulse TIG welder manufacturers China” or “reliable TIG welder suppliers in China” into the Google search bar.

2. Browse through the search results and visit the websites of various manufacturers and suppliers that appear on the first few pages. These companies usually have better visibility and credibility.

3. Look for manufacturers with extensive experience in producing pulse TIG welders. Assess their expertise and specialization in this particular type of welder.

4. Check for certifications and quality management systems such as ISO 9001, which indicate that the manufacturer follows stringent quality control processes.

5. Look for manufacturers that have a professional and informative website. A well-designed website with detailed product descriptions, specifications, and contact information signifies a reputable company.

6. Read customer reviews and testimonials on the manufacturer’s website or other reputable platforms. This can provide insights into the quality of their products and services.

7. Contact the shortlisted manufacturers and inquire about their product range, customization options, lead time, and pricing. A reliable manufacturer should promptly respond to your queries and provide comprehensive information.

8. Request product samples or ask for references from other customers who have purchased their pulse TIG welders. This can help you assess the quality firsthand.

9. Finally, consider the manufacturer’s location, proximity to shipping ports, and their ability to handle international shipping and logistics.

As you conduct your search, be cautious of potential scams or fraudulent manufacturers. Look for red flags such as insufficient contact information, unrealistic pricing, and poor website design. Taking these precautions will help you select reliable pulse TIG welder manufacturers in China.

How to check pulse tig welder manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To check the reliability of a pulse TIG welder manufacturer’s website, you can follow these steps:

1. Use Google Chrome: Start by accessing the manufacturer’s website using the Google Chrome browser. Google Chrome is known for its compatibility with various web applications and provides a stable browsing experience.

2. Install SEOquake: SEOquake is a popular browser extension that provides valuable SEO metrics for websites. Install the SEOquake extension on your Google Chrome browser.

3. Search for the Manufacturer’s Website: Use a search engine like Google to find the official website of the pulse TIG welder manufacturer. Enter relevant search terms such as “pulse TIG welder manufacturer” or the specific brand name.

4. Check organic ranking: Once you land on the manufacturer’s website, open SEOquake by clicking on the extension icon in your browser. This tool provides you with an overview of various SEO metrics for the website you are browsing.

5. Look for “Google Index” data: In the SEOquake overview, locate the “Google Index” section. Check if the website is indexed by Google. If the website is not indexed, it may indicate a lack of credibility or other issues.

6. Check “Alexa Rank” and “Google PageRank”: SEOquake also provides the “Alexa Rank” and “Google PageRank” of the website. The Alexa Rank indicates the popularity of the website based on traffic, while the Google PageRank reflects its authority in search engine rankings. Higher ranks generally indicate a more reliable website.

7. Look for “SEM Rush Rank”: SEM Rush Rank is another useful metric provided by SEOquake. It gives an estimate of the website’s ranking in the top 10 million websites worldwide. If the manufacturer’s website has a high SEM Rush Rank, it suggests a reliable source.

8. Assess overall user experience: While SEO metrics can provide some insights, it’s important to thoroughly explore the website. Look for customer reviews, product information, contact details, and other relevant information. A reputable manufacturer will have a user-friendly and informative website.

Remember, relying solely on SEO metrics does not guarantee the reliability of a manufacturer’s website. It is advisable to consider additional factors such as customer feedback, product quality, and certifications before making a decision.

Top 10 pulse tig welder manufacturers in China with each 160 words introduce products,then use markdown create table compare

**1. Huaheng Welding Co., Ltd.**

Huaheng Welding Co., Ltd. is one of the premier pulse TIG welder manufacturers in China. This company primarily focuses on the development and production of advanced welding machines. Their pulse TIG welders are equipped with state-of-the-art technology that ensures precise welding performance. These machines boast features like pulse frequency control, digital display, and IGBT inverter technology, making them suitable for a wide range of applications. Additionally, Huaheng Welding Co., Ltd. offers excellent after-sales support and a comprehensive warranty for their products.

**2. Jasic Technology Co., Ltd.**

Jasic Technology Co., Ltd. is a leading player in the pulse TIG welder market in China. They have a wide range of pulse TIG welders that cater to different welding requirements. These welders are known for their high efficiency, stable welding performance, and durability. Jasic Technology Co., Ltd. integrates advanced technology like IGBT modules and PWM control to ensure precise and reliable welding results. Their pulse TIG welders are widely used in industries such as construction, automotive, and metal fabrication.

**3. Riland Industry Co., Ltd.**

Riland Industry Co., Ltd. is another prominent manufacturer of pulse TIG welders in China. They offer a comprehensive range of welders with various power capacities to suit different welding applications. Riland’s pulse TIG welders are known for their excellent arc ignition, stable arc control, and low spatter generation. These machines also feature advanced thermal protection systems and high-frequency arc-starting performance. With a focus on product quality, Riland Industry Co., Ltd. ensures that their pulse TIG welders comply with international standards.

**4. Shenzhen GSDO Technology Co., Ltd.**

Shenzhen GSDO Technology Co., Ltd. is a reliable manufacturer of pulse TIG welders known for their innovative designs and advanced features. Their pulse TIG welders integrate features like adjustable pulse current and frequency, digital displays, and precise control interfaces. These welders are designed to provide efficient welding with minimal power consumption and ensure stable performance even in challenging conditions. Shenzhen GSDO Technology Co., Ltd. focuses on customer satisfaction by delivering high-quality products and excellent after-sales service.

| Manufacturer | Notable Products |

|—————————|——————————————–|

| Huaheng Welding Co., Ltd. | – Pulse TIG Welder A |

| | – Pulse TIG Welder B |

| Jasic Technology Co., Ltd. | – Pulse TIG Welder X |

| | – Pulse TIG Welder Y |

| Riland Industry Co., Ltd. | – Pulse TIG Welder P |

| | – Pulse TIG Welder Q |

| Shenzhen GSDO Tech Co., Ltd| – Pulse TIG Welder M |

| | – Pulse TIG Welder N |

**5. Shenzhen Arcsonic Welding Equipment Co., Ltd.**

Shenzhen Arcsonic Welding Equipment Co., Ltd. specializes in the production of pulse TIG welders that deliver exceptional performance and long-lasting durability. Their welders feature innovative designs with advanced control systems, ensuring efficient and precise welding results. Shenzhen Arcsonic Welding Equipment Co., Ltd. offers a wide range of pulse TIG welders, catering to the diverse needs of different industries.

**6. Ningbo S.D.M. Welder’s Company Ltd.**

Ningbo S.D.M. Welder’s Company Ltd. is a renowned manufacturer of pulse TIG welders with a strong focus on product quality and customer satisfaction. Their pulse TIG welders are designed to provide stable arc control, high welding efficiency, and exceptional performance. Ningbo S.D.M. Welder’s Company Ltd. offers a comprehensive range of pulse TIG welders suitable for various applications in industries such as aerospace, automotive, and shipbuilding.

**7. Beijing Ron-En Machinery & Integration Co., Ltd.**

Beijing Ron-En Machinery & Integration Co., Ltd. is a leading manufacturer of pulse TIG welders known for their technological advancements and reliable performance. They offer a wide range of welders that are highly efficient, easy to operate, and ensure precise welding results. Beijing Ron-En Machinery & Integration Co., Ltd.’s pulse TIG welders find application in industries such as power generation, petrochemical, and nuclear energy.

**8. Taizhou Retop Mechanical & Electrical Co., Ltd.**

Taizhou Retop Mechanical & Electrical Co., Ltd. is a prominent manufacturer of pulse TIG welders that are built with exceptional quality and efficiency in mind. Their welders boast features like adjustable pulse current and frequency, digital displays, and advanced control systems. Taizhou Retop Mechanical & Electrical Co., Ltd. ensures that their pulse TIG welders are rigorously tested and adhere to international standards.

**9. Hangzhou Color Powder Coating Equipment Co., Ltd.**

Hangzhou Color Powder Coating Equipment Co., Ltd. is a trusted manufacturer of pulse TIG welders renowned for their reliability and performance. Their pulse TIG welders are designed to deliver efficient and accurate welding results, making them suitable for a wide range of applications. Hangzhou Color Powder Coating Equipment Co., Ltd. focuses on continuous product improvement and innovation to meet the evolving needs of their customers.

**10. Shanghai Boson Machinery Co., Ltd.**

Shanghai Boson Machinery Co., Ltd. is a reliable manufacturer of pulse TIG welders known for their quality and performance. Their welders feature advanced technology, including IGBT-based inverters and precise control interfaces. Shanghai Boson Machinery Co., Ltd. offers a wide range of pulse TIG welders that provide excellent welding performance with ease of operation.

In conclusion, these top 10 pulse TIG welder manufacturers in China, including Huaheng Welding Co., Ltd., Jasic Technology Co., Ltd., and Riland Industry Co., Ltd., are known for their high-quality products, advanced features, and commitment to customer satisfaction. Each manufacturer offers a range of pulse TIG welders suitable for various industrial applications, ensuring optimal welding results.

Background Research for pulse tig welder manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to pulse TIG welder manufacturers in China, there are several notable companies worth considering. Utilizing sources such as qcc.com, archive.org, and importyeti.com, we can gather some background information on these manufacturers.

One notable manufacturer is Shenzhen Greatec Technology Co., Ltd., specializing in the research and development, production, and sales of welding machines. They offer a range of products, including pulse TIG welders, welding robots, and plasma cutting machines. With a strong emphasis on quality and innovation, Greatec has become a trusted supplier to both domestic and international markets.

Another reputable company is Shenzhen TieXi Electric Machinery Co., Ltd., which has a focus on developing and manufacturing welding equipment. Their product range includes pulse TIG welding machines, inverter welders, and plasma cutting machines. TieXi Electric Machinery has gained recognition for their commitment to technological advancement and stringent quality control measures.

One more manufacturer to consider is JASIC Technology Limited, a leading welding equipment supplier based in Guangzhou. They have a comprehensive product portfolio that includes pulse TIG welders, MIG/MAG welders, plasma cutters, and more. JASIC is known for its state-of-the-art manufacturing facilities and internationally recognized certifications, ensuring the reliability and performance of their products.

These three manufacturers exemplify the quality and expertise found in Chinese pulse TIG welder manufacturing. However, it is essential to conduct further research and due diligence before making any business decisions. Platforms such as qcc.com, archive.org, and importyeti.com can provide valuable insights into the history, reputation, and market presence of these manufacturers, helping potential buyers make informed choices.

Leveraging Trade Shows and Expos for pulse tig welder Sourcing in China

Trade shows and expos are excellent platforms for sourcing products, including pulse TIG welders, in China. These events provide opportunities for businesses to discover new suppliers, network with industry professionals, and learn about the latest trends and technologies.

Attending trade shows and expos focused on welding and manufacturing, such as the China International Welding Expo or the Canton Fair, allows buyers to directly connect with numerous Chinese suppliers under one roof. These events showcase a wide range of pulse TIG welders, providing buyers with the chance to assess product quality, compare prices, and negotiate favorable deals.

One major advantage of attending these events is the ability to interact face-to-face with suppliers. This direct communication helps establish a rapport, build trust, and ensure clear understanding of product specifications and requirements. Additionally, buyers can witness live product demonstrations and evaluate welder performance first-hand, helping them make informed decisions.

Trade shows and expos also provide a platform to gauge industry trends. Exhibitors at these events often showcase the latest innovations, improvements, and technological advancements in pulse TIG welders. This allows buyers to stay updated with the newest features, efficiency enhancements, and safety measures, ultimately ensuring they source the most advanced products from China.

Apart from sourcing, trade shows and expos offer valuable networking opportunities. Numerous industry professionals, welding experts, and potential business partners attend these events. Engaging in discussions with them can provide insights into the best suppliers, market demands, and emerging opportunities in the field. These connections can prove invaluable for sourcing products in China and building long-term business relationships.

To maximize the benefits of trade shows and expos for pulse TIG welder sourcing, it is crucial to thoroughly research and plan in advance. Identifying relevant events, reviewing exhibitor lists, and preparing a checklist of requirements enables buyers to make the most of their time and efforts. Attending seminars, workshops, and networking events during these expos also adds value by increasing knowledge and expanding professional networks.

In conclusion, trade shows and expos provide an ideal platform for sourcing pulse TIG welders in China. These events offer direct access to multiple suppliers, enable face-to-face interactions, showcase the latest trends and technologies, and facilitate networking opportunities. By leveraging these platforms, buyers can effectively source high-quality pulse TIG welders while staying informed about industry developments.

The Role of Agents and Sourcing Companies in Facilitating pulse tig welder Purchases from China

Agents and sourcing companies play a crucial role in facilitating pulse TIG welder purchases from China. These intermediaries act as a bridge between overseas buyers and Chinese manufacturers, ensuring a smooth and successful procurement process.

Firstly, agents and sourcing companies have in-depth market knowledge and expertise in the pulse TIG welder industry. They are familiar with the Chinese market, local manufacturers, and production capabilities. This knowledge helps them identify reliable and reputable suppliers that meet the specific requirements and quality standards of the buyers. Agents can also provide valuable insights on pricing trends, industry regulations, and emerging technologies, enabling buyers to make informed decisions.

Secondly, agents and sourcing companies have established relationships with a network of manufacturers in China. These connections allow them to quickly identify suitable suppliers and obtain competitive prices. Agents can negotiate on behalf of the buyers to ensure favorable terms, such as product customization, pricing discounts, and flexible payment options. By leveraging their relationships, agents and sourcing companies can help buyers save time and effort in searching for the right pulse TIG welder supplier.

Additionally, agents and sourcing companies assist buyers in the pre-production phase. They can arrange factory visits, conduct quality inspections, and ensure that the manufacturing process adheres to the buyer’s specifications. This proactive involvement helps prevent potential issues and ensures that the final product meets the desired standards.

Furthermore, agents and sourcing companies facilitate communication and bridge the language barrier between buyers and suppliers. They act as intermediaries, translating technical specifications, negotiating terms, and ensuring effective communication throughout the purchasing process. This reduces miscommunication and enhances collaboration between the parties.

Overall, agents and sourcing companies serve as valuable resources for overseas buyers looking to purchase pulse TIG welders from China. Their market expertise, supplier network, negotiation skills, quality control, and communication capabilities streamline the procurement process, mitigating risks and ensuring a successful transaction.

Price Cost Research for pulse tig welder manufacturers Companies in China, use temu.com and 1688.com

When it comes to pulse TIG welder manufacturers in China, two prominent online platforms that can be utilized for price cost research are temu.com and 1688.com.

temu.com is a comprehensive B2B platform that offers numerous products, including pulse TIG welders, from various manufacturers in China. This platform provides detailed product information, company profiles, and customer reviews, enabling users to assess the credibility and quality of different manufacturers. temu.com also provides a convenient price comparison feature, allowing users to compare prices and make informed decisions.

1688.com, owned by Alibaba Group, is one of the largest online marketplaces in China. It offers a vast array of products from various manufacturers and suppliers. Users can find a wide variety of pulse TIG welders at different price points on this platform. Additionally, 1688.com allows users to contact manufacturers directly to negotiate prices or inquire about specific product details.

To conduct price cost research using these platforms, users can start by searching for “pulse TIG welders” on each platform. Both temu.com and 1688.com provide filtering options that allow users to refine their search results according to specific criteria such as price range, brand, and certification.

Once a list of potential manufacturers is generated, users can further examine each manufacturer’s profile and product details to ensure they meet their requirements. It is advisable to consider factors such as the manufacturer’s reputation, production capacity, and product quality. Users can also take into account customer feedback and ratings to gain insights into the overall satisfaction level of previous buyers.

Finally, users can compare prices among different manufacturers and request quotations directly through the platforms or by contacting the manufacturers themselves. Negotiating prices directly might provide an opportunity for further cost reduction.

In conclusion, temu.com and 1688.com are reliable online platforms where users can conduct price cost research for pulse TIG welder manufacturers in China. By utilizing these platforms efficiently, users can obtain comprehensive information about manufacturers, compare prices, and negotiate deals to find the best value for their money.

Shipping Cost for pulse tig welder import from China

The shipping cost for importing a pulse TIG welder from China will depend on various factors, including the size and weight of the welder, the shipping method chosen, the destination country, and any additional services required.

There are several shipping methods available, such as express shipping, air freight, and sea freight. Express shipping is usually the fastest but also the most expensive option. Air freight is a quicker alternative to sea freight, while sea freight is the most cost-effective method for bulky or heavy items like welders.

To estimate the shipping cost, it is necessary to consider the dimensions and weight of the welder. Freight forwarders or shipping companies will provide a quote based on these details. As an example, a typical pulse TIG welder may have dimensions of approximately 24 x 12 x 18 inches and weigh around 60 pounds.

Using sea freight as an example, the approximate shipping cost from China to certain popular destinations are as follows: to the United States, it could range from $500 to $800; to Europe, it could range from $600 to $1000; and to Australia, it could range from $400 to $800. These values are just estimates and may vary depending on the specific circumstances.

It is important to note that these costs do not include any import duties, taxes, or custom fees that may apply in the destination country. Additionally, additional services like insurance, customs clearance, and delivery to the final destination may incur additional charges.

To obtain an accurate shipping cost, it is advisable to request quotes from several shipping companies or freight forwarders, providing them with detailed information about the pulse TIG welder, the desired shipping method, and the destination country. By comparing these quotes, one can select the most cost-effective shipping option.

Compare China and Other pulse tig welder Markets: Products Quality and Price,Visible and Hidden Costs

China and other pulse TIG welder markets show considerable differences in terms of product quality, pricing, and visible and hidden costs.

When it comes to product quality, the Chinese market has developed a reputation for offering a wide range of products. However, the quality can vary significantly, as there are many different manufacturers operating in China, ranging from those producing low-quality and cheap welders to those manufacturing high-quality and reliable ones. On the other hand, other pulse TIG welder markets such as Germany, the United States, and Japan are known for their premium quality products that often come with advanced features and durability. These markets tend to prioritize quality over quantity and are mostly associated with well-established and reputable brands.

Pricing is another aspect that distinguishes China from other markets. Chinese welders are often competitively priced, making them attractive to buyers who are looking for affordable options. However, these low prices can sometimes be reflective of lower quality and substandard components used in the manufacturing process. In contrast, pulse TIG welders from other markets tend to have higher price points due to the emphasis on quality, advanced features, and the reputation of the brands behind them. Buyers are expected to pay a premium for the reliability and superior performance associated with these welders.

Visible and hidden costs also differ between China and other markets. Chinese welders may have lower upfront costs, but buyers should be aware of potential hidden costs such as maintenance, repairs, and part replacement. The availability and cost of spare parts and after-sales services are often not as favorable in China compared to other markets where these services are better established. On the other hand, other markets typically have better support networks and easier access to spare parts, which can contribute to a higher initial purchase price but potentially reduce unforeseen expenses in the long run.

In conclusion, while China offers a wide range of pulse TIG welders at competitive prices, quality can vary significantly, and hidden costs can arise in terms of maintenance and repairs. Other markets such as Germany, the United States, and Japan prioritize product quality, often associated with higher prices, but tend to offer better support networks and more reliable after-sales services. Ultimately, buyers should carefully consider their priorities, weighing initial costs against long-term expenses and their preferences for brand reputation and product reliability.

Understanding Pricing and Payment Terms for pulse tig welder: A Comparative Guide to Get the Best Deal

Pulse TIG welders are advanced welding machines that offer smooth, precise, and high-quality welds. If you are in the market for a pulse TIG welder, understanding the pricing and payment terms is essential to get the best deal. In this comparative guide, we will explore the factors that affect pricing and payment options, helping you make an informed decision.

When it comes to pricing, several factors influence the cost of a pulse TIG welder. The brand, quality, power output, features, and warranty are crucial considerations. The reputation and reliability of the manufacturer can also impact the pricing. Additionally, the availability and demand for the welder may affect its cost. Generally, higher-end pulse TIG welders with advanced features and greater power output tend to be more expensive.

Payment terms vary depending on the seller or manufacturer. Many suppliers offer flexible financing options, including installment plans, leasing, or rent-to-own arrangements. These options allow you to spread out the cost of the welder over time, making it more affordable. Some companies may require a down payment upfront, while others offer no-interest financing for a specific period. It is crucial to carefully review the payment terms to ensure they align with your budget and financial goals.

To get the best deal on a pulse TIG welder, it is recommended to compare prices and payment options from multiple suppliers. Researching different brands and models can help you identify the welder that best suits your needs and budget. Additionally, consider checking for any ongoing promotions, discounts, or package deals that can provide added value. Comparing customer reviews and ratings can also give you insights into the performance and reliability of different welders and their manufacturers.

When negotiating pricing and payment terms, don’t hesitate to reach out to the supplier or manufacturer. They may be willing to offer special discounts or adjust the payment options to meet your requirements.

In conclusion, understanding the pricing factors and payment terms is crucial when purchasing a pulse TIG welder. Comparing prices, payment options, and considering factors like brand reputation and features will help you make an informed decision. Research thoroughly, negotiate when possible, and choose the best deal that suits your needs and budget.

Chinese Regulations and Industry Standards Certifications for pulse tig welder,Import Regulations and Customs for pulse tig welder from China

In China, there are several regulations and industry standards certifications that apply to pulse TIG welders. These regulations and certifications ensure the quality, safety, and compliance of these products in the Chinese market. Some of the key regulations and certifications include:

1. China Compulsory Certification (CCC): This certification is mandatory for several product categories, including electrical and electronic products. Pulse TIG welders fall under this category, and therefore manufacturers must obtain the CCC mark before selling their products in China.

2. National Standards: These are industry-specific standards developed by the relevant authorities. For pulse TIG welders, national standards related to welding equipment, electrical safety, and performance parameters are applicable. Compliance with these standards is necessary for product certification.

3. Safety Regulations: Pulse TIG welders must also comply with safety regulations to ensure that they meet the necessary safety requirements. These regulations cover aspects such as electrical safety, protection against electric shock, and functional safety.

Importing pulse TIG welders from China involves adhering to the import regulations and customs requirements of the destination country. These can vary across different countries, but some common considerations include:

1. Import Duties and Taxes: Importing any product, including pulse TIG welders, may attract import duties and taxes. Importers should research and understand the applicable rates and ensure compliance with customs authorities.

2. Import Documentation: Importers need to provide the necessary documentation to clear customs. This typically includes invoices, packing lists, bill of lading/airway bill, import licenses (if required), and any other relevant certificates or permits.

3. Product Compliance: Importers should ensure that the pulse TIG welders they import from China meet the specific regulations and standards of their country. This may include obtaining the necessary certifications or conformity assessment documentation.

4. Customs Clearance: Importers need to go through the customs clearance process, which includes submitting the required documentation, paying any applicable duties and taxes, and complying with customs regulations.

Conclusion:

Pulse TIG welders manufactured in China are subject to various regulations and certifications, such as the CCC mark and national standards. Importing these welders involves considering import regulations and customs requirements, including import duties, documentation, product compliance, and customs clearance procedures. Compliance with these regulations and requirements is essential to ensure smooth importation and market access for pulse TIG welders.

Sustainability and Environmental Considerations in pulse tig welder Manufacturing

In the manufacturing of pulse TIG welders, sustainability and environmental considerations play a crucial role. Various steps can be taken to ensure that the manufacturing process of these welders has minimal impact on the environment.

Firstly, a significant focus is placed on energy efficiency during the production of pulse TIG welders. Efforts are made to optimize the power consumption of the welding machines, ensuring that they operate at higher energy efficiency levels. This not only reduces the carbon footprint but also lowers utility costs and promotes sustainability.

Secondly, the choice of materials used in the manufacturing process is critical. Environmentally friendly materials, such as recycled and renewable resources, are used wherever possible. This reduces the demand for virgin materials and minimizes waste generation. Additionally, efforts are made to reduce the overall weight of the welders, which not only improves portability but also reduces the energy required for transportation and distribution.

Furthermore, waste management practices are implemented to handle the waste generated during the manufacturing process. Recycling and reusing materials, as well as proper disposal of hazardous waste, are prioritized to minimize the environmental impact. By implementing effective waste management systems, manufacturers can reduce their contribution to landfill and pollution.

In addition to the manufacturing process, sustainability considerations extend to the product’s entire lifecycle. Pulse TIG welders are designed for durability and longevity, reducing the need for frequent replacements and minimizing waste generation. Repair and maintenance services are also provided, ensuring that the welders can be used for an extended period.

Finally, sustainability practices are encouraged throughout the supply chain. Suppliers are encouraged to adopt eco-friendly manufacturing processes, use sustainable materials, and reduce waste generation. By collaborating with environmentally conscious suppliers, manufacturers can ensure that their pulse TIG welders are produced with sustainability in mind from start to finish.

In conclusion, sustainability and environmental considerations play a significant role in the manufacturing of pulse TIG welders. From energy efficiency and material selection to waste management and supply chain practices, various steps can be taken to minimize the environmental impact. By prioritizing sustainability, manufacturers can contribute to a greener future while providing high-quality welding machines to customers.

List The Evolution history of “pulse tig welder”

The pulse TIG welder, also known as pulse TIG welding or pulsed Tungsten Inert Gas welding, has seen significant technological advancements throughout its evolution. The development of pulse TIG welding aimed to enhance the control, precision, and overall performance of the traditional TIG welding method. Here is a brief overview of its evolutionary history:

1. Early Years: The concept of pulse welding can be traced back to the early 1970s when manufacturers recognized the need for improved control over weld heat input. The initial pulse TIG welders featured basic pulse current modulation systems, allowing for better control of weld bead shape and heat input.

2. Analog Pulse Welders: In the 1980s, pulse TIG welders became more sophisticated with the introduction of analog pulse welding technology. These machines offered better control over pulse parameters such as peak current, background current, and pulse duration. Analog pulse TIG welders improved welding efficiency and reduced heat distortion. Some models also featured adjustable AC balance controls for improved aluminum welding.

3. Digital Pulse Welders: With the advancements in digital technology, the pulse TIG welder saw a significant leap forward. In the 1990s, digital pulse TIG welding machines were introduced. These welders offered enhanced control, repeatability, and accuracy. Digital technology enabled precise adjustment and programming of pulse parameters, resulting in improved weld quality and ease of use.

4. Inverter Technology: In the early 2000s, pulse TIG welders started incorporating inverter technology. Inverter-based pulse TIG welders provided several advantages such as improved energy efficiency, portability, and enhanced arc stability. These machines offered a higher frequency output, allowing for finer control over the welding process.

5. Advanced Features: In recent years, pulse TIG welders have witnessed the integration of advanced features. Some modern pulse TIG welders come equipped with functions like pulse frequency adjustment, waveform modulation, and ramp-up/down controls, allowing welders to customize the welding parameters according to their specific requirements. Wireless connectivity and touch screen interfaces have also become common in some models.

Overall, the evolution of pulse TIG welders has seen a significant shift from basic pulse current modulation systems to highly advanced digital machines with precise control over welding parameters. These advancements have not only improved welding efficiency but also made the process more accessible and user-friendly.

The Evolution and Market Trends in pulse tig welder Industry

The pulse TIG welder industry has undergone significant evolution and market trends over the years. Tungsten Inert Gas (TIG) welding is a popular welding technique known for its precision and high-quality welds. Pulse TIG welding is an advanced form of TIG welding that allows welders to control the heat input and improve the overall welding process.

One of the key evolutions in the pulse TIG welder industry is the development of more sophisticated equipment. Early pulse TIG welders were large and expensive, limiting their accessibility. However, technological advancements have led to the development of smaller, portable, and more affordable pulse TIG welders. This has increased their adoption in various industries, including automotive, aerospace, and manufacturing.

Another important evolution is the integration of digital controls and automation features in pulse TIG welders. These advancements have made it easier for welders to adjust various parameters, such as pulse frequency, arc length, and travel speed, resulting in improved welding quality and efficiency. Additionally, the integration of automation features has allowed for increased productivity, as it reduces the need for manual intervention in the welding process.

In terms of market trends, there has been a growing demand for pulse TIG welders due to their ability to produce high-quality welds on a wide range of materials, including stainless steel, aluminum, and titanium. Industries such as automotive, aerospace, and electronics manufacturing have been driving this demand, as they require precise and aesthetically pleasing welds.

Furthermore, there is a growing emphasis on energy efficiency and environmental sustainability, which has influenced the market trends in the pulse TIG welder industry. Pulse TIG welding consumes less energy compared to traditional welding techniques, making it an environmentally friendly option. This has led to an increased adoption of pulse TIG welders in industries that prioritize sustainability.

In conclusion, the pulse TIG welder industry has witnessed notable evolution and market trends. Advancements in technology have resulted in more sophisticated and accessible pulse TIG welders, equipped with digital controls and automation features. The growing demand for high-quality welds and the need for energy efficiency have been influencing factors in the market, resulting in increased adoption in various industries.

Custom Private Labeling and Branding Opportunities with Chinese pulse tig welder Manufacturers

Chinese pulse TIG welder manufacturers present excellent opportunities for custom private labeling and branding. They offer a wide range of welding machines with advanced pulse TIG technology, providing superior welding performance and accuracy.

Private labeling enables businesses to develop their own brand identity and establish a unique market position. With Chinese manufacturers, companies can collaborate to create customized products that suit their specific requirements. Manufacturers can incorporate a company’s logo, design, and labeling onto the welding machines, giving businesses the advantage of presenting a consistent and professional image to their customers.

Moreover, Chinese manufacturers offer flexible options for branding opportunities. Businesses can partner with manufacturers to develop unique features, add-ons, or proprietary technologies, further distinguishing their products from competitors. This creates a competitive edge in the market and increases brand recognition and loyalty.

Another advantage of sourcing from Chinese pulse TIG welder manufacturers is their ability to provide cost-effective solutions. China has a competitive advantage in terms of manufacturing capabilities, resulting in lower production costs compared to other countries. This enables businesses to maintain attractive pricing strategies when promoting their branded welding machines.

In addition to cost savings, Chinese manufacturers also offer expertise and experience in producing high-quality welding machines. They have a track record of delivering reliable and durable products, meeting international standards and certifications. This ensures that private-labeled welding machines maintain consistent quality and performance, enhancing the reputation and trustworthiness of the brand.

Overall, collaborating with Chinese pulse TIG welder manufacturers for custom private labeling and branding opportunities provides a winning combination of cost-effectiveness, quality, and flexibility. It enables businesses to create their unique brand identity while offering superior welding solutions to their customers.

Tips for Procurement and Considerations when Purchasing pulse tig welder

When purchasing a pulse TIG welder, there are several considerations that should be taken into account to ensure a successful procurement process. Here are some tips and factors to consider:

1. Welding Requirements: Assess your welding needs and determine the type and thickness of materials you will be working with. This will help you choose a pulse TIG welder that meets the necessary specifications.

2. Power and Amperage: Consider the power requirements of the welder and ensure it is compatible with your workspace and electrical supply. Also, check the amperage range of the welder to ensure it will handle your welding tasks effectively.

3. Duty Cycle: The duty cycle refers to the amount of time a welder can operate continuously before needing to cool down. Consider the duty cycle of the pulse TIG welder and choose one that can handle your workload.

4. Brand and Reputation: Research different brands and their reputation in the industry. Look for well-established brands that have a good track record for producing reliable and high-quality welding equipment.

5. Ease of Use: Consider the user-friendliness of the welder. Look for features like easy-to-understand control panels, clear and intuitive displays, and ergonomic designs that enhance comfort during operation.

6. Welding Waveforms: Different pulse TIG welders offer various waveforms, such as square wave, sine wave, or advanced forms. Choose a welder that offers the waveforms suitable for your specific welding requirements.

7. AC/DC Capability: Determine whether you need a welder that is capable of both AC and DC welding. This feature can be essential if you work with a variety of materials.

8. Price and Warranty: Compare prices from different suppliers and ensure that the welder you select offers value for the price. Additionally, check the warranty details to ensure adequate coverage for potential repairs and replacements.

9. Safety Features: Look for safety features like overload protection, thermal overload sensors, and shielding gas flow monitors to ensure a safe working environment.

10. Customer Support: Consider the availability of customer support from the manufacturer or supplier. A reliable support system can be crucial in case of any technical issues or operational queries.

To make an informed decision, consult with welding experts and read reviews from users who have experience with the specific pulse TIG welder you are considering. Taking these factors into consideration will help you choose the right pulse TIG welder that best suits your needs and ensures efficient and precise welding operations.

FAQs on Sourcing and Manufacturing pulse tig welder in China

Q: Why should I source and manufacture a pulse tig welder in China?

A: Sourcing and manufacturing a pulse tig welder in China can be advantageous for several reasons. Firstly, China is known for its competitive pricing and cost-effectiveness in the manufacturing sector. This can result in significant cost savings for businesses looking to produce pulse tig welders. Additionally, China has a vast network of suppliers and manufacturers specializing in welding equipment, ensuring a wide range of options and customization capabilities. Chinese manufacturers also offer efficient production turnaround times and scalability, allowing businesses to meet varying market demands. Lastly, China’s advanced infrastructure and technological advancements in the manufacturing industry contribute to high-quality products.

Q: How can I find a reliable supplier or manufacturer in China?

A: To find a trustworthy supplier or manufacturer in China, thorough research and due diligence are essential. One way to identify potential suppliers is by attending trade shows and exhibitions focused on welding equipment and machinery. This allows direct interaction with manufacturers and the opportunity to assess their capabilities and product quality. Online B2B (business-to-business) sourcing platforms, such as Alibaba or Global Sources, can also provide a wide range of suppliers and manufacturers with verified credentials and customer reviews. Conducting background checks, requesting product samples, and communicating extensively with potential suppliers are crucial steps in evaluating reliability.

Q: Should I consider visiting the manufacturing facility in China before finalizing an agreement?

A: Visiting the manufacturing facility in China is highly recommended, especially when considering volume production or establishing a long-term partnership. By visiting the facility in person, businesses can assess the manufacturer’s production capacity, quality control processes, and working conditions. This firsthand experience allows for better decision-making and builds trust between the buyer and the manufacturer. Furthermore, face-to-face communication enables effective negotiation and ensures that the manufacturer understands all specific requirements and expectations.

Q: Are there any potential challenges or risks in sourcing and manufacturing a pulse tig welder in China?

A: While there are numerous benefits to manufacturing in China, there are also some challenges and potential risks to consider. Quality control can be a concern, as it is crucial to select a manufacturer with a reliable quality assurance system in place. Intellectual property protection can also be a challenge, so it is advisable to work with a trusted legal advisor and ensure proper agreements and safeguards are in place. Additionally, language and cultural barriers may impact communication, leading to misunderstandings. Having a clear and detailed product specification, using technical drawings, and regular communication can help mitigate these risks.

Q: What is the typical lead time for manufacturing a pulse tig welder in China?

A: The lead time for manufacturing a pulse tig welder in China can vary depending on factors such as the complexity of the product, order quantity, and the manufacturer’s production schedule. Generally, it ranges from a few weeks to a couple of months. Close collaboration with the manufacturer, including a detailed production schedule and regular communication, can help ensure that lead times are met and potential delays are minimized.

Why contact sourcifychina.com get free quota from reliable pulse tig welder suppliers?

Sourcifychina.com offers a convenient platform for businesses seeking reliable suppliers for Pulse TIG welders in China. By contacting Sourcifychina.com, businesses can access a free quota from trusted suppliers. There are several reasons why Sourcifychina.com is able to offer this benefit to its users.

Firstly, Sourcifychina.com has established strong relationships with reputable suppliers in the welding industry. These suppliers have been thoroughly vetted to ensure reliability, quality products, and competitive pricing. By leveraging these connections, Sourcifychina.com can negotiate special arrangements with the suppliers, including the provision of free quotas for potential customers.

Secondly, Sourcifychina.com acts as a trusted intermediary between businesses and suppliers. They understand the complexities and challenges of sourcing products from abroad and aim to simplify the process. By assisting businesses through the entire procurement journey, from initial contact to final delivery, Sourcifychina.com adds value and builds trust with both parties. As a result, suppliers are more willing to offer free quotas as a way to attract potential customers using the Sourcifychina.com platform.

Moreover, by offering free quotas, suppliers have the opportunity to showcase their products and capabilities to a wider audience. This creates a win-win situation, where businesses can assess the quality of the suppliers’ offerings without incurring any costs, and suppliers can market their products to a targeted audience looking for Pulse TIG welders. If the businesses are satisfied with the supplier’s quotation, they can proceed with a purchase, generating revenue for the supplier in the long run.

In conclusion, Sourcifychina.com obtains free quotas from reliable Pulse TIG welder suppliers by leveraging their relationships, acting as a trusted intermediary, and providing a platform for mutual benefits. By doing so, they facilitate the sourcing process for businesses while enabling suppliers to showcase their products effectively.