Knowledge about Rapier Loom

Rapier looms are one of the most commonly used textile machines in the world. They are known for their accuracy in producing high-quality textiles, and have played a significant role in the history of the textile industry.

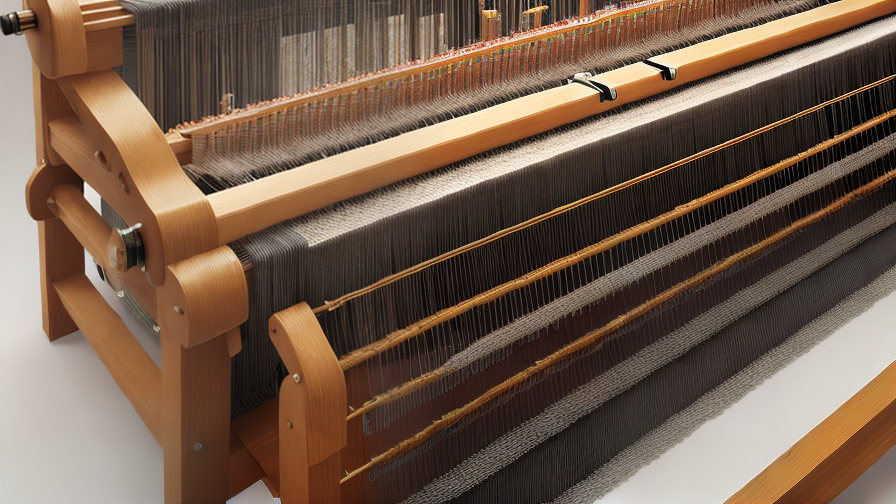

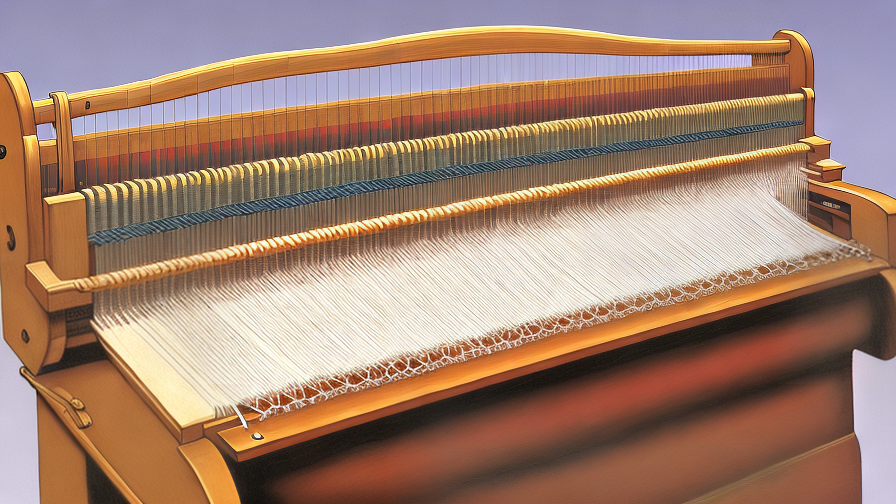

The design of a typical rapier loom consists of a reed that controls the number of threads and the direction of the weft. The weft is passed through the warp using a rapier, or a rod, which pulls the weft thread from one side of the fabric to the other. Unlike other types of looms, such as a shuttle loom or a projectile loom, rapier looms do not require the bobbin to be thrown back and forth from one side to the other.

One of the key benefits of using a rapier loom is the level of precision it offers. Due to the use of rapiers, rapier looms are able to achieve higher levels of accuracy compared to other types of looms. This makes them particularly well-suited for the production of specialized textiles such as technical fabrics, high-end fashion fabrics, and home decor fabrics.

Rapier looms are also known for their versatility. They can be used to produce a wide range of fabrics, including jacquard fabrics and double cloth fabrics. The flexibility of the loom enables it to handle various types of threads and yarns, including cotton, polyester, and silk.

In conclusion, rapier looms are an essential component of the textile industry. Their precision and versatility have made them a popular choice for textile manufacturers looking to produce high-quality fabrics. As technology evolves, rapier looms are also being developed to be more efficient, making them an even more valuable tool in the hands of textile manufacturers.

Various Types of Rapier Loom

Rapier looms are one of the types of shuttle-less looms widely used in the textile industry. They are used to weave a variety of fabrics such as cotton, wool, silk, and polyester, among others. The uniqueness of the rapier loom is its flexible rapier or rigid rapier. The machine brings the weft yarns through the warp yarns to create the fabric. The movements of the yarns are controlled by rapier, which is the main component of the machine. There are various types of rapier looms based on their construction, application, and features.

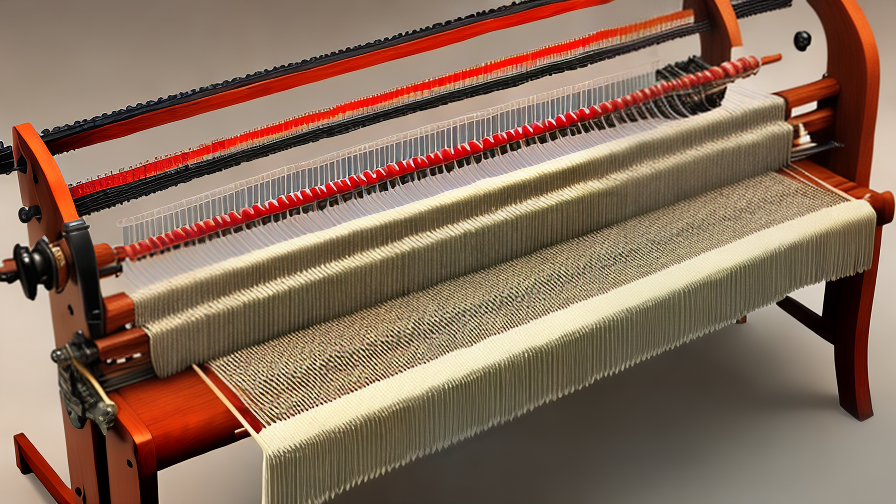

The first type of rapier loom is the flexible rapier loom that utilizes a thin and flexible rapier to carry the weft yarn through the warp yarns. The machine is used to weave light to medium weight fabrics, and the fabrics are characterized by their excellent quality and sharp selvedges.

The second type of rapier loom is the rigid rapier loom that uses a rigid rapier to carry the weft yarn across the warp yarns. The rigid rapier loom is used to weave heavier fabrics such as denim and towels. The machine can withstand high tension and pressure and its rugged construction ensures its durability.

The third type of rapier loom is the positive rapier loom that utilizes a positive weft insertion mechanism. The machine uses compressed air or hydraulic pressure to throw the weft yarn into the warp yarns. The positive rapier loom is used to weave technical fabrics such as airbags and filter fabrics.

The fourth type of rapier loom is the negative rapier loom that uses a negative weft insertion mechanism. The machine uses grippers to pull the weft yarn through the warp yarns. The negative rapier loom is used to weave heavy and coarse fabrics.

The fifth type of rapier loom is the double rapier loom that uses two rapiers to insert the weft yarn across

FAQ sourcing Rapier Loom manufacturer from China

Rapier looms have become increasingly popular in the textile industry for their efficient and high-speed weaving capabilities. If you’re considering sourcing a Rapier Loom manufacturer from China, you likely have questions about the process. Here are some frequently asked questions and multiple answers to help guide you.

Q: What is a Rapier Loom?

A: A Rapier Loom is a type of weaving machine that uses a rapier to carry the weft yarn across the warp yarn during the weaving process.

Q: Why would I source a Rapier Loom from China?

A: China has become a major player in the textile industry and is home to many reputable Rapier Loom manufacturers who offer high-quality machines at a competitive price.

Q: What should I consider when choosing a Rapier Loom manufacturer in China?

A: Look for a manufacturer with a good reputation, experience in producing Rapier Looms, and who offers after-sales support.

Q: How do I determine what type of Rapier Loom to source from China?

A: Consider your production needs, the type of fabric you will be weaving, and the level of automation needed. Discuss your requirements with the manufacturer to determine which loom will best fit your needs.

Q: How long does it take to receive a Rapier Loom from a manufacturer in China?

A: Delivery time can vary depending on the manufacturer and your location. It’s recommended to discuss delivery times with the manufacturer before making a purchase.

Q: What are the payment terms for purchasing a Rapier Loom from a China-based manufacturer?

A: Payment terms can vary among manufacturers. Common options include full payment up front, a deposit with the remainder paid on delivery, or a payment plan. Discuss payment options with the manufacturer before making a purchase.

In conclusion, sourcing a Rapier Loom manufacturer from China can be a wise decision for your textile production needs. Take the time to research and communicate with potential manufacturers to ensure you choose the right

Applications of Rapier Loom

The use of rapier looms has revolutionized the textile industry, as it offers unparalleled speed, accuracy and efficiency in weaving fabrics. A rapier loom is a shuttle-less weaving machine that uses a rapier to insert the weft yarn across the warp threads of a fabric. The versatile and flexible nature of the rapier loom has enabled it to be used in a wide range of applications.

Apparel:

The textile industry uses rapier looms in the production of dress materials, shirting, trouser fabrics, knits and sportswear among others. Rapier looms have a high production capacity, and the garments produced display superior texture and color consistency. The use of rapier looms in the apparel industry helps to ensure uniformity in the final product which is important for the buyer and the manufacturer.

Home Furnishings:

Rapier looms have found extensive use in the home furnishings industry because of its versatility in weaving heavy fabrics. The loom is used in the production of bed linen, towels, upholstery, window treatments and rugs due to their high-quality texture, intricate designs and strength that meet the demand of household use.

Industrial Textiles:

Rapier looms are used in the production of technical textiles, which require functional properties such as moisture-wicking, water-repellency, and flame retardancy. Industrial textiles are used for manufacturing automotive, aviation, geotextiles, and protective clothing. Rapier looms offer a flexibility and precision that is required when producing specialized fabrics for industrial use.

Conclusion:

Rapier looms are an essential component of the textile industry that has raised the standards of fabric production. Their application in the apparel, home furnishings and industrial textiles sector is testament to its versatility and efficiency in fabricating a variety of textiles. As technology advances, it is anticipated that rapier looms will continue to evolve to meet the demands of an ever-growing textile industry.

Manufactured Products made of Rapier Loom

Rapier looms are a type of weaving machine that produces high-quality manufactured products. These machines use a rapier, which is a thin metal rod that carries the weft yarn across the width of the fabric. The rapier is guided by a computer system, which helps to ensure that the fabric is woven with great precision and accuracy.

Manufactured products made of rapier looms are commonly used in a variety of applications, including clothing, home furnishings, and industrial purposes. One of the benefits of using rapier looms is that they can produce fabrics with a wide range of textures and densities, which makes them suitable for a variety of products.

Clothing made of rapier looms are especially popular, as they are often of high quality and durable. These products can be made from a variety of materials, including cotton, linen, wool, and synthetic fibers. Clothing made from rapier looms can be found in a wide range of styles and designs, from casual wear to high-end fashion.

Home furnishings are another common use of manufactured products made of rapier looms. These products can be used for curtains, upholstery, and bedding. The high-quality fabrics produced by rapier looms are often soft, durable, and long-lasting, making them a popular choice for home décor.

Lastly, manufactured products made of rapier looms can also be used in industrial applications, such as for filters or conveyor belts. These products are often made from synthetic fibers, which are strong and durable, and can withstand harsh environments.

In conclusion, rapier looms are a valuable tool for producing high-quality manufactured products. From clothing to home furnishings to industrial applications, these machines allow for a wide range of applications, and the resulting products are often of excellent quality and durability.

The Evolution history of Rapier Loom

The rapier loom is a type of shuttleless weaving machine that first appeared in the mid-twentieth century. It is a highly mechanical and sophisticated tool for producing high-quality fabrics at a fast pace. The rapier loom’s evolution can be traced back to early weaving methods that used manual tools to produce fabrics, such as the handloom.

The earliest rapier looms featured two warp beams and a shuttle that was attached to long, flexible rods. The rods were used to pass the shuttle of the weft yarn back and forth through the shed. The rods were the “rapiers,” and the machine was called a “rapier loom.” This method was faster than most shuttleless looms that came before it because of its ability to cut down on the time required for setting up the warp and loading the shuttle.

In the 1970s, a new class of rapier looms was developed that featured a long, rigid rapier that could reach across the width of the loom. The rapier mechanization was improved whereby the weft yarn passed through guides on the rapier head. The guides were placed to allow for efficient movement and improved operability of rapier loom. This innovation enabled the weft to be passed more swiftly across the width of the loom, reducing the amount of weaving time required for each piece of fabric.

Over time, the rapier loom increased in popularity and sophistication. Advances were made in the design and control systems of the machine, which helped to increase weaving efficiency and improve fabric quality. Today, rapier looms are widely used in the textile industry, producing high-quality fabrics at high volumes.

The evolution of the rapier loom has led to significant improvements in the textile manufacturing process. The machine’s features have increased over time, eventually making it possible to produce finer fabrics that are more intricate in design. The rapier loom is one of the most important tools in the textile industry, and its evolution has

The Process of Rapier Loom

Rapier looms are often used in textile industries for weaving fabrics. This process involves the use of a shuttle that carries the weft yarn across the warp yarns to form a fabric. There are different types of rapier looms, but the basic process remains the same.

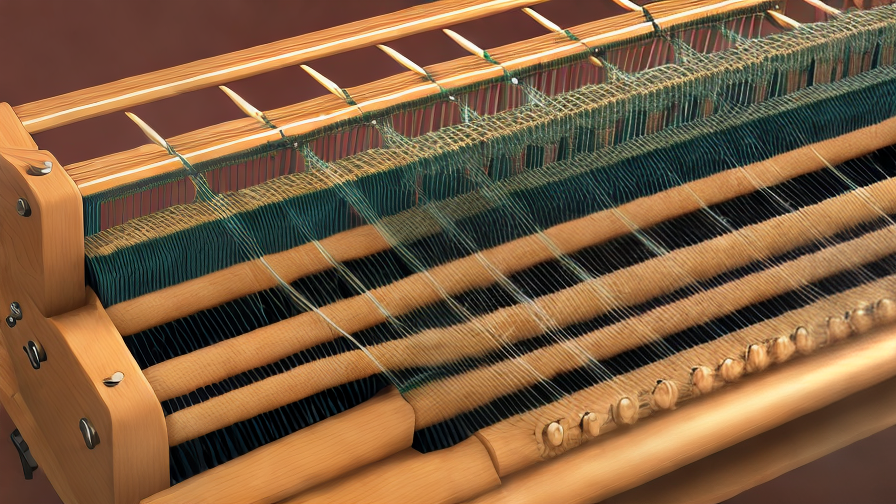

The process of rapier loom starts with the preparation of warp yarns. The warp yarns are wound onto a beam which is then placed on the loom. The warp yarns are then threaded through the heddles and reed. The heddles are used to control the warp yarns, while the reed is used to space them out.

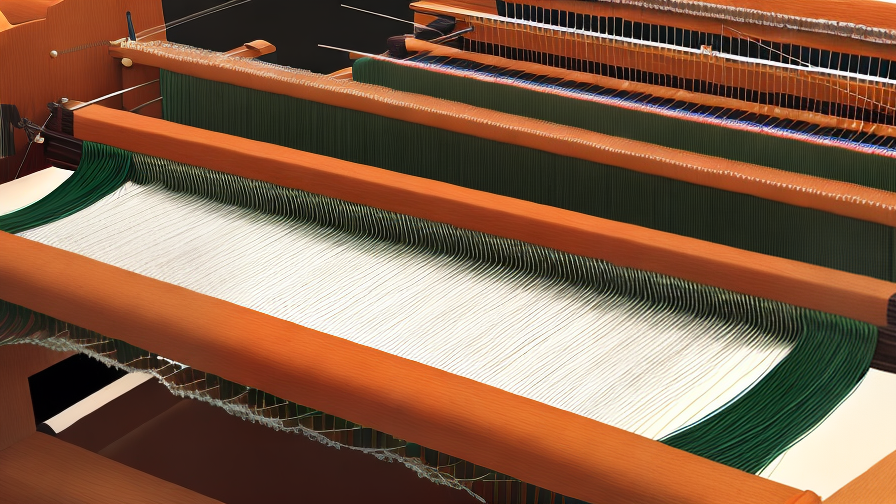

Once the warp yarns are in place, the weft yarns are loaded onto the rapier. The rapier moves the weft yarns across the warp yarns, using a flexible steel rod. The weft yarn is then beaten down by the reed to form a fabric that is tightly woven.

As the rapier moves back and forth, it picks up the weft yarn from one side of the loom and carries it across the warp yarns to the other side. The rapier then releases the weft yarn and returns to its starting position. The process is repeated, forming a continuous loop that creates a fabric.

Rapier looms are known for their speed and efficiency, as they can produce fabrics at high rates of speed. They are often used in textile industries for producing a wide range of fabrics, including cotton, wool, silk, and synthetic fibers.

The process of rapier loom is crucial in the textile industry, as it helps to produce high-quality fabrics that are durable and long-lasting. With advancements in technology, rapier looms have become even more efficient, making it possible to produce fabrics in large quantities.

In conclusion, the process of rapier loom is essential in the textile industry. It involves the use of a shuttle that carries the weft yarns across the warp yarns

Benefits Advantages of Utilizing Rapier Loom

Rapier loom is a type of weaving machine that uses a rapier to insert the weft yarns into the warp yarns of a fabric. It is a highly advanced type of loom that has several benefits and advantages over its counterparts.

One of the most significant benefits of utilizing rapier loom is its speed. The rapier loom can weave fabric at a high speed, making it ideal for producing large quantities of fabric in a minimal time frame. This speed can help increase the productivity of any textile manufacturing unit and enable businesses to meet the demands of their customers efficiently.

Rapier looms also offer excellent versatility in the types of fabrics that can be produced. Unlike other traditional looms, the rapier loom can produce fabrics with different yarn count, weave patterns, and fabric weights. This flexibility is vital for businesses seeking to offer a wide range of fabrics to their customers, allowing them to diversify and attract more clients.

Another essential advantage of the rapier loom is its reduced material wastage. The rapier loom utilizes a highly efficient drive system that reduces the chances of yarn breakage, thus preventing any wastage of material. This efficiency represents a significant cost-saving benefit, reducing the number of wasted raw materials and minimizing the impact on the environment.

Rapier looms are also known for their high degree of accuracy and precision. The rapier ensures that the weft yarns are precisely inserted into the warp yarns, resulting in less fabric defects and imperfections. This accuracy reduces the need for manual intervention and quality checks, further increasing the productivity of textile manufacturing units.

In conclusion, the benefits and advantages of utilizing rapier loom are undeniable. From increased productivity to a wider range of fabrics, reduced material wastage, and improved accuracy, the rapier loom represents a game-changing technological innovation in textile manufacturing. Adopting this advanced technology can help businesses increase efficiency, reduce costs, and meet the demands of their customers effectively.

Disadvantages Rapier Loom

Rapier looms are widely used in modern textile industry due to their speed and versatility. However, they also come with some disadvantages that need to be taken into account.

One of the main disadvantages of rapier looms is their high initial cost. Compared to other types of looms, such as shuttle looms or projectile looms, rapier looms are more expensive to purchase and maintain. This is because they require complex and precise mechanisms to control the movement of the rapiers, which can result in more frequent breakdowns and repairs.

Another disadvantage of rapier looms is their limited fabric width. Although modern rapier looms can weave fabrics up to 3.2 meters wide, they are not suitable for wider fabrics such as those used in home furnishings or industrial applications. This is because the length of the rapier determines the maximum fabric width that can be woven, and longer rapiers are more difficult to control and can cause fabric distortion.

Furthermore, rapier looms are louder compared to other types of looms. This is due to the noise generated by the moving rapiers and the electronic control systems that are needed to control them. This noise can be a nuisance for operators working close to the loom, and can also cause discomfort for workers in adjacent areas.

Finally, rapier looms are not suitable for all types of yarns and fabrics. They are best suited for medium-to-heavy weight fabrics, such as denim, upholstery, and technical textiles. They are less suitable for lightweight and highly elastic fabrics, which require more delicate handling.

In conclusion, while rapier looms offer many advantages, they also come with some disadvantages that must be taken into account. High initial cost, limited fabric width, noise, and limited suitability for certain yarns and fabrics are the main drawbacks of these types of looms.

Selecting the Ideal Manufacturer Rapier Loom

Selecting the ideal manufacturer rapier loom for your textile production can be a challenging process. This is because there are many manufacturers in the market today, and each of them claims to offer the best loom for your needs. However, there are specific factors that you should consider when selecting the right loom for your textile production.

The first factor to consider is the type of fabric you want to produce. The loom you select should be able to produce high-quality and consistent fabrics with the desired fabric weight, width, and quality. Additionally, you should consider the speed of the loom and its flexibility in producing different fabrics.

The second factor to consider is the manufacturer’s reputation. You should choose a manufacturer that has a good history of building high-quality looms. You can look for reviews from previous customers, check out the manufacturer’s website, and ask for recommendations from industry experts to gauge the manufacturer’s reputation.

The third factor is the cost of the loom. While it is essential to choose a loom that is affordable, it is also important to ensure that you do not compromise the quality of the loom due to its cost. It is advisable to compare prices from different manufacturers and models and choose the one that offers the best value for money.

The fourth factor is the after-sales service offered by the manufacturer. The ideal manufacturer should offer technical support, maintenance services, and spare parts for the loom. This will ensure that your loom operates efficiently and effectively throughout its lifespan.

In conclusion, selecting the ideal manufacturer rapier loom for your textile production requires careful consideration of several factors. These include the type of fabric you want to produce, the manufacturer’s reputation, the cost of the loom, and after-sales service. By considering these factors, you will be able to choose a loom that will meet your textile production needs effectively.

Things to Consider When Purchasing Rapier Loom

Purchasing a rapier loom is a great investment for your weaving business. However, there are several factors to consider before making a final decision. Here are some things to consider when purchasing a rapier loom.

Firstly, the width of the loom is an important consideration. The width of the loom should match the width of the fabric you intend to weave. The larger the loom, the more fabric in terms of width you can weave.

Secondly, the speed of the loom is also important. The speed of the loom should match the production volume of your business. If your business requires high production, then a high-speed loom is recommended.

Thirdly, the shuttle of the loom is an important factor to consider. Rapier looms have three types of shuttles; rigid, flexible, and semi-flexible. The shuttle should be appropriate for the type of fabric you intend to weave. Flexible shuttles are suitable for weaving cotton, wool, and linen fabrics, while semi-flexible and rigid shuttles are appropriate for weaving heavier and thicker fabrics.

Fourthly, the shedding mechanism of the loom is another essential factor. The shedding mechanism ensures that the warp threads are lifted and lowered according to a predetermined pattern. The different types of shedding mechanisms include dobby shedding, cam shedding, and electronic shedding. The mechanism should be suitable for your weaving requirements.

Finally, it is important to consider the maintenance and repair of the loom. The loom should be durable and reliable, with easy access to spare parts and maintenance services.

To sum up, purchasing a rapier loom is an investment that requires careful consideration. The width of the loom, the speed, the shuttle, the shedding mechanism, and the maintenance and repair should be taken into account before purchasing. A well-chosen loom will improve production quality, reduce downtime, and contribute to the success of your weaving business.

Properties of Rapier Loom

A rapier loom is a type of weaving machine commonly used in the textile industry for producing fabrics like cotton, silk, and wool. This loom is automated and operates with a rapier mechanism which involves the use of rods or rapiers to insert weft or crosswise yarns into the warp, or lengthwise yarns of the loom. This type of loom has several distinct features that make it a popular choice among textile manufacturers.

First, rapier looms can produce high-quality fabrics at a fast pace. Compared to other types of looms, rapier looms are known for their speed and efficiency. With modern technology, these looms can produce fabrics at a speed of up to 600 picks per minute, making them suitable for high-volume production needs.

Second, rapier looms can produce fabrics with various designs and patterns. With rapier looms, textile manufacturers can produce fabrics with unique patterns and designs, which can be achieved by changing the warp and weft yarns, or by using dobby or jacquard shedding mechanisms. Furthermore, since these looms are automated, they can accurately reproduce designs and patterns without errors.

Third, rapier looms are easy to operate and maintain. With fewer complex parts compared to other types of looms, such as shuttle looms, rapier looms are relatively easy to operate and do not require a lot of training for operators. Additionally, maintenance and repair of these looms can be done quickly and easily, ensuring that the machine runs smoothly and efficiently.

Overall, the properties of rapier looms, including their speed, ability to produce unique designs and easy maintenance, make them a popular choice among textile manufacturers. As technology continues to advance, rapier looms will continue to be improved with features such as electronic control systems that enhance their efficiency, accuracy, and reliability.

How to use Rapier Loom

Rapier looms are a type of weaving equipment that is known for its speed and versatility. Using a Rapier loom can be a bit intimidating for beginners, but with practice and patience, anyone can learn how to use it to create beautiful fabrics.

First, before you begin weaving, it is important to prepare your warp and thread it through the loom. This involves measuring your warp threads, attaching them to the back of the loom, and threading them through the eye of the rapier. Once your warp is set up, you can begin weaving.

To start weaving, you will need to choose the correct shuttle for your project. The shuttle is the tool that carries the weft thread back and forth through the warp threads. Once you have your shuttle, you can begin weaving by passing the rapier through the shed, which is the opening between the warp threads.

Using the rapier loom involves several steps, including picking up the weft thread, passing the rapier through the shed and catching the weft thread on the other side. The rapier will then return to its original position and the process will repeat until the fabric is complete.

When using a Rapier loom, it is important to maintain an even tension on the fabric, as this will ensure that your finished product is uniform and free of any defects. To maintain even tension, be sure to adjust the warp and tension regularly.

In conclusion, using a rapier loom requires practice, patience, and attention to detail. With the right techniques and tools in hand, you can create beautiful fabrics and master the art of weaving with a Rapier loom. Happy weaving!

Glossary Terminology Terms for Rapier Loom

A rapier loom is a type of weaving machine that uses a rapier, a thin, flexible steel rod, to carry the weft yarn across the warp yarns. The loom is used to produce high-quality fabrics and is widely used in the textile industry.

To understand the functionality of a rapier loom, it is essential to be familiar with the terminology associated with this machine. Here are some of the most important glossary terminology terms for rapier loom:

1. Shedding: The process of separating and raising the warp threads to allow the weft to pass through.

2. Warp Beam: The large spool that holds the warp yarns.

3. Weft: The yarn that runs across the warp threads.

4. Rapier: A long and thin metal rod that carries the weft yarn across the warp threads.

5. Take-up Motion: A mechanism that pulls the fabric forward as it is woven.

6. Let-Off Motion: The mechanism that regulates the amount of warp yarn fed to the loom.

7. Pick: The insertion of one weft thread across the warp threads.

8. Selvage: The edge of the fabric that prevents it from unraveling.

9. Reed: A comb-like tool that keeps the warp threads spaced evenly.

10. Tensioning Devices: Various mechanisms that maintain the appropriate tension in the warp and weft yarns.

11. Woven Fabric: The final product after the process of weaving is complete.

Understanding these terminologies is important as it helps in both starting and maintaining the operations of the rapier loom. The quality of the final produce is significantly impacted by the loom model and quality, however, proficiency in using these terms will help in achieving the best possible results.

In conclusion, the glossary terminology used for a rapier loom plays a vital role in weaving high-quality fabrics. Familiarizing oneself with these terms is critical for operating the machine correctly and achieving successful outcomes

Rapier Loom Price

Rapier looms have revolutionized the textile industry by increasing production efficiency and reducing labor costs. A rapier loom is an advanced weaving machine that uses rapier technology to weave fabric. The modern rapier loom uses a rapier to carry the weft thread through the warp threads, producing a wide range of fabrics including cotton, silk, wool, and polyester.

The price of a rapier loom varies depending on its features, size, and manufacturer. The average price of a rapier loom can range from $10,000 to $100,000. The cost of a new rapier loom is significantly higher than that of a used one, but the advantage of a new loom is that it comes with a warranty and technical support.

There are several factors that affect the price of a rapier loom, including its production speed, fabric type, and weaving width. The higher the production speed, the more expensive the loom will be. Similarly, the production of delicate fabrics like silk and wool requires a specialized loom, which can add to its cost. Lastly, wider looms can produce a larger fabric width, but they are also more expensive.

In addition to the initial cost of purchasing a rapier loom, there are also ongoing maintenance costs to consider. These include costs associated with replacing parts, routine maintenance, and repairs. It is important to factor in maintenance costs when evaluating the overall cost of a rapier loom.

When purchasing a rapier loom, it is essential to do thorough research and compare features and prices from different manufacturers. Consider your production needs and budget carefully, and choose a rapier loom that meets your requirements without breaking the bank. It is also important to consider the after-sales service provided by the manufacturer, as this can impact the long-term reliability of the loom.

In conclusion, the price of a rapier loom varies depending on several factors, including its features, size, and manufacturer. While