Types and Applications of rare earth permanent magnets

Rare earth permanent magnets are a class of permanent magnets made from alloys of rare earth elements. They are widely used in various applications due to their exceptional magnetic properties, such as high remanence, coercivity, and energy product. Some of the types and applications of rare earth permanent magnets are outlined below.

1. NdFeB magnets: NdFeB magnets are made from a combination of neodymium, iron, and boron. They are the strongest permanent magnets available and are used in a variety of applications, including hard disk drives, wind turbines, and electric motors.

2. SmCo magnets: SmCo magnets are made from a combination of samarium and cobalt. They have excellent magnetic properties at high temperatures and are used in applications such as aerospace, military, and medical devices.

3. Alnico magnets: Alnico magnets are made from a combination of aluminum, nickel, and cobalt. They are the oldest type of rare earth permanent magnets and have been used for over 80 years in applications such as sensors, speakers, and guitar pickups.

4. Ferrite magnets: Ferrite magnets, also known as ceramic magnets, are made from a combination of iron oxide and barium or strontium carbonate. They have relatively low magnetic properties but are inexpensive and widely used in applications such as loudspeakers, motors, and transformers.

In summary, rare earth permanent magnets have become an essential component in various applications, including renewable energy, transportation, and healthcare. Their exceptional magnetic properties make them ideal for industries that require high energy density, strength, and durability. Each type of rare earth permanent magnet has its unique properties and applications, allowing them to serve specific purposes that other materials cannot.

Benefits and Feature of Utilizing rare earth permanent magnets

Rare earth permanent magnets are made of highly magnetized materials, such as samarium-cobalt and neodymium-iron-boron, and they provide several benefits and features that make them highly useful in a variety of industrial applications.

One of the key benefits of rare earth permanent magnets is their high magnetic strength, which makes them more powerful than traditional magnets. They have a high magnetic energy product and are able to create magnetic fields that are several times stronger than their non-rare earth counterparts.

Another key benefit of rare earth permanent magnets is their excellent temperature stability. They maintain their magnetic strength even when exposed to high temperatures, making them ideal for use in high-temperature industrial applications such as motors and generators.

Rare earth permanent magnets are also highly resistant to corrosion, which makes them ideal for use in environments where exposure to moisture and harsh chemicals is common. They have a long lifespan and can withstand high levels of stress and shock.

Some of the key features of rare earth permanent magnets include their small size and high magnetic energy density, which make them ideal for use in compact devices. They are also highly responsive, which makes them ideal for use in applications where fast switching speeds are required.

Overall, the benefits and features of rare earth permanent magnets make them highly useful in a wide range of industrial applications, from automotive and aerospace to medical equipment and consumer electronics. Their high magnetic strength, temperature stability, and corrosion resistance make them an excellent choice for applications where reliability and performance are key.

The Process of rare earth permanent magnets

Rare earth permanent magnets are made up of rare earth metals combined with other metallic elements such as cobalt or iron. The process of making rare earth magnets involves several steps.

The first step is the production of rare earth metals such as neodymium, samarium, and dysprosium through a process called solvent extraction. In this process, rare earth ore undergoes chemical processing to isolate rare earth metal oxides. These oxides are then transformed into pure metals using a reduction process.

The second step involves the production of rare earth alloys. These alloys are made by melting pure rare earth metals with other metallic elements like cobalt, iron, or nickel in a furnace. The resulting mixture is then cooled to form a solid metal alloy.

The third step involves the preparation of the rare earth permanent magnet powder. The alloy produced in the second step is crushed into a fine powder. This powder is then mixed with a binder, typically a plastic material, and then pressed into the desired shape.

The fourth step is the sintering of the magnet. The pressed powder is heated in a furnace at high temperatures to bond the particles together. This process allows the magnets to become dense and strong.

The fifth and final step is the magnetization of the rare earth permanent magnet. This process involves exposing the magnet to a strong magnetic field to align the magnetic domains in the material, resulting in a permanent magnet with a strong magnetic field.

In summary, the process of making rare earth permanent magnets involves the production of rare earth metals, the production of rare earth alloys, the preparation of the magnet powder, the sintering of the magnet, and finally, the magnetization of the magnet.

How to use rare earth permanent magnets

Rare earth permanent magnets are a type of magnet that has extremely strong magnetic properties. They are versatile and can be used in a variety of applications, including:

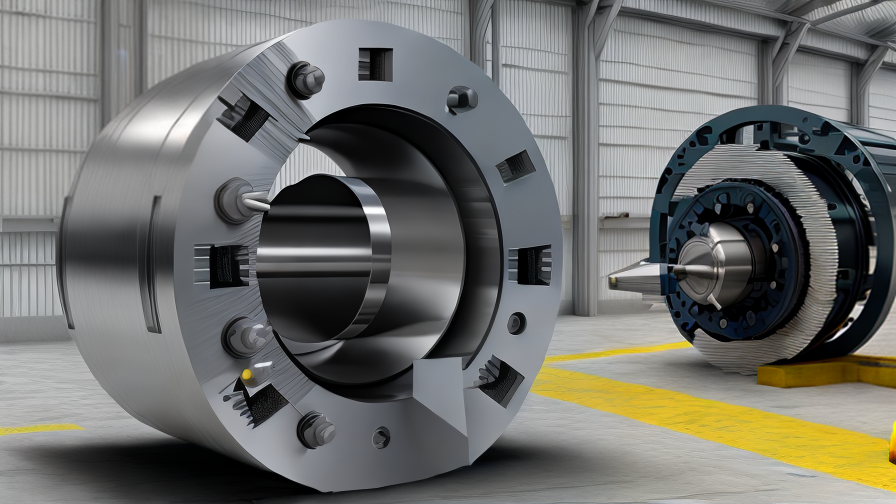

1. Electric Motors: Rare earth magnets are widely used in electric motors as they offer high magnetic strength and efficiency. These motors are particularly suited to high-performance applications like electric vehicles and industrial machinery.

2. Magnetic Resonance Imaging (MRI) Scanners: MRI scanners use strong magnetic fields to produce images of the human body. Rare earth magnets are used to generate these magnetic fields, making MRI scanners possible.

3. Audio/Video Equipment: Rare earth magnets are used in audio and video equipment like speakers, microphones, headphones, and hard disk drives. They offer powerful magnetism, high stability, and low noise levels, making them perfect for high-fidelity audio and video systems.

4. Wind Turbines: Wind turbines require strong magnets to generate electrical power. Rare earth magnets, used in wind turbine generators, have excellent magnetic properties, reducing the size and weight of the generator.

5. Aerospace Applications: Rare earth magnets are used in aerospace applications like actuators, sensors, and fuel pumps. They offer reliability and high resistance to extreme temperature changes, making them suitable for space and aviation applications.

In summary, rare earth permanent magnets are versatile and have many practical applications. Their magnetic properties make them invaluable in various industries, including electric motors, MRI scanners, audio/video equipment, wind turbines, and aerospace applications.

rare earth permanent magnets Manufacturer,Supplier and Wholesale

We are a renowned manufacturer, supplier, and wholesaler of high-quality rare earth permanent magnets. Our magnets are made from rare earth elements, such as neodymium, samarium, and cobalt, which offer high magnetization, coercivity, and energy product. Our rare earth permanent magnets have immense industrial applications due to their superior magnetic properties.

Our manufacturing process is highly sophisticated with stringent quality control measures in place to ensure that our magnets meet international standards. We use cutting-edge technology and specialized equipment to manufacture these magnets with consistent and precise dimensions. Additionally, our rare earth permanent magnets are available in a range of shapes and sizes to cater to diverse industrial requirements.

We have a well-established supply chain network to ensure timely delivery of our products to our customers. We offer competitive prices without compromising the quality of our products. We pride ourselves on maintaining excellent customer relationships that have been built over the years by providing excellent customer service.

In conclusion, we are a reliable and one-stop-shop for rare earth permanent magnets, catering to various industries worldwide. Give us a call or drop an email to order or to learn more about our product range and services.

rare earth permanent magnets Price

Rare-earth permanent magnets are essential components in many technological devices such as electric vehicles, wind turbine generators, and computer hard drives. They are also commonly used in numerous electronic devices, including smartphones and headphones. The price of these magnets has increased significantly over the past few years, primarily due to the rising demand from various industries and the limited supply of raw materials.

China is currently the largest producer and exporter of rare-earth permanent magnets, accounting for over 80% of the global supply. However, the Chinese government has recently imposed strict regulations on their production and export, causing prices to soar.

The price of neodymium-iron-boron (NdFeB) magnets, the most commonly used type of rare-earth permanent magnet, increased by over 300% between 2016 and 2018. This increase was partly due to China’s restrictions on production and export, as well as increased demand from the electric vehicle industry, which requires large quantities of the magnets for their motors.

In 2019, the price of neodymium (Nd), one of the key raw materials used to make NdFeB magnets, also increased due to supply shortages. This further contributed to the rising prices of rare-earth permanent magnets.

Currently, the price of rare-earth permanent magnets varies depending on the size, quality, and application. However, a rough estimate would be between $40 to $80 per kilogram for NdFeB magnets.

In conclusion, the price of rare-earth permanent magnets has risen dramatically in recent years due to increasing demand and limited supply. The cost of these magnets is likely to remain high in the coming years, affecting the production and pricing of various technological devices.

FAQ sourcing rare earth permanent magnets manufacturer from China with multiple answers

Q: Where can I find a rare earth permanent magnets manufacturer in China?

A: China is the world’s largest producer of rare earth permanent magnets. There are several ways to find a reliable manufacturer. You can search online through trade websites such as Alibaba or Made-in-China. You can also attend trade shows such as the Canton Fair or the China International Industry Fair where manufacturers showcase their products. Another option is to use a sourcing agent who can help connect you with appropriate manufacturers.

Q: What should I look for in a rare earth permanent magnets manufacturer?

A: It is important to look for a manufacturer that has a reputation for producing high-quality magnets. Check for certifications such as ISO 9001 and ISO 14001 which confirms that the manufacturer follows standards for quality management and environmental management. It is also important to inquire about their production capacity to ensure that they can meet your needs in terms of volume.

Q: How can I ensure that the manufacturer is reliable?

A: Before deciding on a manufacturer, conduct due diligence by researching their reputation and reviews online. You can also request references from the manufacturer and contact existing customers to verify their satisfaction with the manufacturer’s products and services. It is also important to have a clear contract that outlines the payment terms, delivery schedule, and quality standards to ensure that both parties are on the same page.

Q: What types of rare earth permanent magnets can I source from a manufacturer in China?

A: China produces a range of rare earth permanent magnets including neodymium magnets, samarium cobalt magnets, and alnico magnets. Neodymium magnets are the most commonly used rare earth magnets and are known for their high strength and affordability. Samarium cobalt magnets are more expensive but have higher temperature limits and better corrosion resistance. Alnico magnets are composed of aluminum, nickel, and cobalt and are known for their high magnetic flux density.

Q: How long does it take to receive magnets from a manufacturer in China?

A: The delivery time will vary depending on the manufacturer’s production capacity, shipping method, and location. Typically, it takes around 2-4 weeks for production and an additional 4-8 weeks for shipping. However, this can be expedited with air freight or express shipping, although it will come at an extra cost.